POLA_23077_sm_suppinfo

advertisement

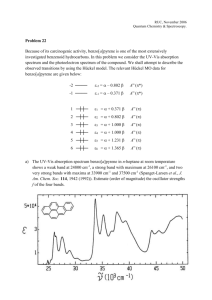

Supporting information for The Synthesis and Self-Assembly of ABA Amphiphilic Block Copolymers Containing Oligo(ethylene glycol) Methyl Ether Methacrylate in Dilute Aqueous Solutions: Aggregate Morphologies, Cloud Points and Stabilities Simon J. Holder,a Geraldine G. Durand,a Chert-Tsun Yeoh,a Elodie Illi a, , Nicholas J. Hardyb and Tim H. Richardsonb a Functional Materials Group, School of Physical Sciences, University of Kent, Canterbury, Kent. CT2 7NH. UK. b Nanomaterials Engineering Group,, The University of Sheffield, Department of Physics & Astronomy, Hicks Building, Hounsfield Road, Sheffield. S3 7RH. UK. Page 2: Determination of critical aggregation concentrations of dilute block copolymer solutions by the Pyrene 1:3 ratio method. Page 3: Figure S1. Typical determination of the CMC by the Pyrene 1:3 ratio method: CAC taken from the inflection point of a plot of the ratio I1/I3 against the log of the concentration of the block copolymer (ABA13) in solution. Page 4: Figure S2. Molecular weight distribution curves for samples during the synthesis of ABA1 illustrating evolution of molecular weight with time. Figure S3. Typical molecular weight distribution curves for ,w-dibromopolystyrene macroinitiator and resultant ABA POEGMA-PS-POEGMA block copolymer from ATRP. Page 4: Table S1. Molecular weight parameters and cloud points of the poly[oligoethylene glycol methyl ether) methacrylate] samples used in the determination of the lower critical solution temperatures. Page 5: Figure S4. A) Overlay of the particle size distributions for ABA10 over 918 hrs. B) Plot of the particle size of the first distribution of aggregates (micelles) versus the time for ABA10, ABA11 and ABA12. Page 6: Figure S5. Additional representative TEM images of various POEGMA-PSPOEGMA copolymer aggregate dispersions. Corresponding author. Tel.: +44 1227 823547 E-mail address: S.J.Holder@kent.ac.uk. 1 Determination of critical aggregation concentrations of dilute block copolymer solutions by the Pyrene 1:3 ratio method. The method involves the use of pyrene, a hydrophobic fluorescence dye, which exhibits different fluorescence characteristics depending upon the properties of the solubilising medium. The pyrene fluorescence emission spectrum consists mainly of five bands referred to as I1, I2…I5, from shorter to longer wavelength. Pyrene is sensitive to the polarity of the solubilising medium and exhibits different fluorescence behaviour in micellar and non-micellar solutions. Pyrene solubility in water is very low (solubility in water at 25°C =2x10-6) and in the presence of micelles, pyrene is preferentially solubilised into the interior of the hydrophobic regions of these aggregates. Pyrene in water has only a very small absorption at 339nm which increases substantially upon transfer to the less polar micellar domain. Kalyanasundaran and Thomas demonstrated that the characteristic dependence of the fluorescence vibrational fine structure of pyrene could be used to determine the critical micellar concentration (CMC) of surfactant solutions. This is known as the pyrene 1:3 ratio method. The vibrational fine structure changes as the transfer of pyrene from a polar environment to a non polar one allow the symmetry forbidden (0,0) band. Its change is described in terms of the ratio I1/I3, the intensities of the first and the third bands in the pyrene fluorescence spectrum, respectively. The CMC values can be obtained from the pyrene 1:3 ratio using two approaches 2, 3: from the interseption of the rapidly varying part and the nearly horizontal part at high concentration of the Pyrene 1:3 ratio plot; and from the inflection point of the Pyrene 1:3 ratio plots which is used for very low cmcs (typically below 1nM). The ratio I1/I3 (I1 at 373nm and I3 at 383nm) is dependent mainly on the polarity of the environment. Below a certain concentration (e.g. C=5.62 x 10-7 gL-1 for ABA3) the ratio I1/I3 is essentially constant and above this concentration, this intensity ratio increases with increasing log C. This change in intensity reflects the onset of micelle formation and the partitioning of the pyrene between the aqueous and micellar phases. For all samples the CAC value was taken as the center of the sigmoid, the inflection point from the plot of the I1/I3 ratio as a function of the logarithm of the copolymer concentration, e.g. Figure S1. 2 0.74 Y1=A1 0.72 0.70 I1/I3 ratio 0.68 -Log (CMC) 0.66 0.64 (Xcmc, (A1+A2)/2) 0.62 0.60 0.58 0.56 Y2=A2 0.54 -10 -8 -6 -4 -2 0 Log (C) Figure S1. Typical determination of the CMC by the Pyrene 1:3 ratio method: CAC taken from the inflection point of a plot of the ratio I1/I3 against the log of the concentration of the block copolymer (ABA13) in solution. References 1. Kalyanasundaram, K.; Thomas. J. K. J. Am. Chem. Soc. 1977, 99, 2039–2044. 2. Aguiar J.; Carpena P.; Molina-Bolivar J.A.; Carnero Ruiz C. J. Coll Inter Sci 2003, 258, 116-122. 3. Zana R.; Levy H.; Kwetkat K. Langmuir 1997, 13, 402. 3 Figure S2. Molecular weight distribution curves for samples during the synthesis of ABA1 illustrating evolution of molecular weight with time. POEGMA(56)-PS(200)-POEGMA(56) Figure S3. Typical molecular weight distribution curves for ,w-dibromopolystyrene macroinitiator and resultant ABA POEGMA-PS-POEGMA block copolymer from ATRP. 4 Table S1. Molecular weight parameters of poly[(oligoethylene glycol methyl ether) methacrylate] studied and the cloud points measured at different concentrations. POEGMA samples Mn by GPC DP by GPC Mw/Mn 1.52 Conc. Solution (wt %) 0.5 Cloud point a (oC) 63.9 ± 0.1 1 5,900 20 1 1 2 2 2 3 3 3 4 4 4 5 5 5 5,900 5,900 15,400 15,400 15,400 16,800 16,800 16,800 25,400 25,400 25,400 38,300 38,300 38,300 20 20 51 51 51 56 56 56 85 85 85 128 128 128 1.52 1.52 1.19 1.19 1.19 1.16 1.16 1.16 1.04 1.04 1.04 1.08 1.08 1.08 1 5 0.5 1 5 0.5 1 5 0.5 1 5 0.5 1 5 62.6 ± 0.1 61.7 ± 0.1 63.3 ± 0.1 62.3 ± 0.1 60.9 ± 0.1 62.9 ± 0.1 62.1 ± 0.1 60.3 ± 0.1 61.6 ± 0.1 60.9 ± 0.1 60.1 ± 0.1 61.5 ± 0.1 59.8 ± 0.1 60.0 ± 0.1 a = Average of 3 measurements; error bars represent upper and lower temperatures recorded. 5 60 Volume % 0.8 0.6 0.4 0.2 ABA10 / 26 POEGMA units ABA11 / 37 POEGMA units ABA12 / 56 POEGMA units 55 B 50 Particle Size of micelles (nm) 3hrs 24hrs 42hrs 264hrs 525hrs 918hrs A 1.0 45 40 35 30 25 20 15 10 5 0.0 0 1 10 100 Particle size (nm) 1000 -1 0 1 2 3 4 5 6 7 Log (Time) Figure S4. A) Overlay of the particle size distributions for ABA10 over 918 hrs. B) Plot of the particle size of the first distribution of aggregates (micelles) versus the time for ABA10, ABA11 and ABA12. 6 Figure S2: Additional representative TEM images of various POEGMA-PSPOEGMA copolymer aggregate aqueous dispersions. ABA1, POEGMA16-PS75-POEGMA16 ABA3, POEGMA43-PS86-POEGMA43 ABA5, POEGMA79-PS75-POEGMA79 ABA8, POEGMA16-PS204-POEGMA16 ABA11, POEGMA37-PS204-POEGMA37 ABA14, POEGMA64-PS183-POEGMA64 7 ABA15, POEGMA80-PS200-POEGMA80 Figure S3: Representative TEM images of ABA8, POEGMA16-PS204-POEGMA16 copolymer micelles prepared at different concentrations. .. ABA8, 0.01g dm-3 POEGMA16-PS204-POEGMA16 ABA8, 0.1g dmPOEGMA16-PS204-POEGMA16 8