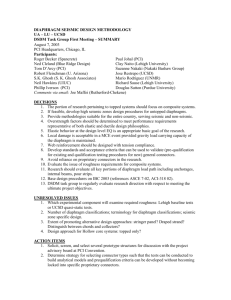

DIAPHRAGM SEISMIC DESIGN METHODOLOGY

DIAPHRAGM SEISMIC DESIGN METHODOLOGY

UA – LU – UCSD

DSDM Task Group Research Meeting #3 – SUMMARY

February 23, 2004

UCSD, La Jolla, CA

Participants:

Roger Becker (Spancrete)

Ned Cleland (Blue Ridge Design)

Tom D’Arcy (PCI)

Robert Fleischman (U. Arizona)

S.K. Ghosh (S. K. Ghosh Associates)

Doug Mooradian (Executive Director, PCMAC)

Clay Naito (Lehigh University)

Suzanne Nakaki (Nakaki Bashaw Group)

Jose Restrepo (UCSD)

Neil Hawkins (UIUC)

Richard Sause (Lehigh University)

Matt Schoettler (UCSD, Grad. Student)

Douglas Sutton (Purdue University) Liling Cao (LU, Grad. Student)

Jason Krohn (Technical Director, PCI) Ge Wan (UA, Grad. Student)

Harry Gleich ( Vice President, Metromont)

DECISIONS

1.

Use existing Prototype Structures except #5. Add 8-story office building.

UNRESOLVED ISSUES

2.

Which experimental component will examine required roughness: Lehigh baseline tests or UCSD quasi-static tests.

ACTION ITEMS

1.

UA team to distribute spreadsheet template for design forces (HG, SN to email GW their template). – Each group to provide summary of design for their prototype structure (TD,

HG, HW, SN)

2.

Add the following to the prototype structure list. a.

NH to send example structure from NEHRP 2000 b.

NC to provide example from draft of PCI industry handbook (DONE) c.

NC to add 8-story structure from examples (Send also to SN) d.

Consider hybrid structures for the future

3.

TD to look over current list of secondary diaphragm details. Indicate “best representative” one or two connections – distribute to other DSDM members- send UA the final version (with whatever design info exists if any)

4.

SK to identify two locations for each of moderate and high seismic zones – one median location and one extreme location so that DSDM can create 2003 NEHRP designs and for

UCSD can develop representative and most demanding ground motion records. Choose single soil type. Send to UA for general distribution (but particularly for UCSD and SN).

5.

Suzy – wait for seismic zones from SK, then design high seismic versions of PS#1: parking structure “A” – cast in place shear walls; parking structure “B” – horizontal lite walls. Provide details: Design composite and noncomposite (to compare). Include topped rebar details. Also create high seismic design for NC 8 story office building.

6.

Roger Becker to get together with T. D’Arcy to determine best avenue to produce four designs (high and moderate seismic designs for a topped and untopped HC system) from

(or similar to) the prototype

7.

R. Becker to provide CJN conditions for the bond stress

8.

CJN to provide test matrix

NEXT UPDATE MEETING: PCI Committee Days (Sunday Morning April 25 th ?) Chicago

NEXT FULL MEETING: Napa Valley after PCI TAC Meeting (June 8 th ? PJ to organize)

DIAPHRAGM SEISMIC DESIGN METHODOLOGY

UA – LU – UCSD

DSDM Task Group Research Meeting #3 – MINUTES

Decide upon 3 or 4 connectors to test o Test configurations

Topped

Untopped

Examine connection clamping effect on the diaphragm (Analytically) o Vary connector spacing o Vary bar diameter

No lack of communication in respect of what’s expected of the research team.

Coordinate Clay and Robert’s DSDM Feedback Requests.

Next meeting o Committee days in Chicago, IL (April) o Board meeting in Napa, CA (June)

Prototype structures o Do we need to include an office building?

If a parking structure has the highest diaphragm demands, why look at anything else? o Other structures to investigate or consider

Hotel/apartment buildings represent typical hollow core use

Schools represent a significant portion of precast funding

Class C site (school) to be provided by Harry in the next month

Follow up to ensure details arrive o Shall we give up PS#5 (the curved one)?

Design location (seismicity) o Choose two locations (Does the Research Team or DSDM group decide?)

Memphis (poor choice for high seismicity because of the small population affected)

Charleston

Seattle

San Francisco

Northridge = possible moderate-high location o Choose soil type

Secondary Details o Assess the secondary details in terms of:

Rigid case

Flexible case

Best guess o Create a commentary to go with the details that have extreme results o Describe connection and assign a

factor to it (i.e. “if ___ connects to

___ then a

factor of ___ should be used.”) o Look up metal deck and wood deck diaphragm design process

Details/Design of hollow core elements for high and moderate seismicity to be provided by Harry and ____(?)

Bob Sexmith at Univ. of British Columbia has done tests on flange connectors

Roughness of diaphragms o References

Harry’s test

Swedent specs.

References from Rodger o Testing

Cyclic loading required on smooth finish surface to pass ACI-318

Chapter 21

How will the anchorage be done?

Test smooth finish

Test larger or smaller samples? (problems with both)

Cyclic test

Boundary conditions:

How are we trying to apply the results of these tests?

Rodger to provide this (remind him)

UCSD Shaking Table Test o Aspect ratio less than 3.0 could be used o Sectional geometry is needed o DSDM decisions to make

Design procedure (Big Decision to make)

Capacity based

Code based

Design for code standards and highlight inadequacies of code force demands, BUT ensure that the result is a code effect not a PCI result.

Openings

Spandrels o Ground motions to be decided after locations are decided by DSDM group

Design Examples o NEHRP 2000, Example Structures o Industry Handbook, Diaphragm Design Example o Wood and metal deck diaphragm design process o IBC2003 o ASCE 7-02 o In IBC2005, diaphragm force is going down.

Should spandrel be modeled as a diaphragm member? o DT/SP is a significant connection to take impact load.

Lateral SYS o Global behavior o Strength o Stiffness o Overstrength o Postyielding behavior

Precast systems with hybrid lateral system.

Pour strip is used in high seismic zones instead of dry chord.

Two types of DT to IT connection: o Welded connection for low seismic structures o Pour strip with bars

Chord steel: #5~#7

Chord connector: o One embedded plate is vertical and the other is tilted so that there is always a flat interface.

wwf: o Smooth, 80ksi o 6x6 W2.9xW2.9 typical o Parallel and perpendicular spacing differs in order to follow ACI 10” spacing requirement o Smaller size, lower ductility o Typical in use

(Harry) 16x8 W2.1xW4.4

(N.Cleland) 15x6 W2.9xW2.9

(?) 16x8 W3xW6

#4 bars are used in topping for high seismic zones w/o mechanical connectors. o Detail to be provided by N.S. in her topped structure designs.

Hairpin o Cheap o Not used in 4” pretopped DTs o For untopped, only used in roof, t=2 in.

Coverplate Connector

Better shear ductility

Better shear resistance, preferred if fitted

N.C. –DT to ramp wall: plate pulls out due to secondary force; angle on the one side as bracing, stiffer