Paper

advertisement

The application of CAE in superalloy fields at HTMRI CISRI

Feng Di Z.Long J.Hu J.Wu

High temperature materials Research Institute

Central Iron and Steel Research Institute. Beijing 100081. China

Abstract

The computer aided engineering (CAE) is impacting on traditional industry.

Superalloys being used as high temperature structural materials of aeroengine are

facing the competition of composites. In consideration of performance and cost

benefits, the superalloy research and development are being sought through use of

CAE to advance its affordability. In this paper, some efforts of using CAE to improve

the cast and wrought superalloy affordability are introduced.

Introduction

Superalloy is one branch of traditional metallurgy industry. The evolution of the gas turbine

engine depended on superalloy being developed in the past century. Although in the end of 20

century, composites and intermetallics for high temperature structural using have been developed

rapidly, the key and main parts of jet engines will be still made of superalloys owing to the factor

of cost and reliability. The demands of engine designer on the materials as key components are

high performance, reliability and low cost. The affordability of superalloys is becoming

increasingly important. In order to meet these challenge, computer aided engineering (CAE) is

being sought to advance the performance of materials, reduce defects rates, manufacture cost and

cycle time, and extend service life at HTMRI.

Computer Aided Engineering in Superalloy Investment Casting

Superalloy Investment Castings are high performers in today’s jet engine world and are the

backbone of the aircraft engine industry.

Requirements for Superalloy castings in jet engine:

Light weight, high reliability, high quality

---- Thin section, integrated, and complicated structure

---- High dimension precision, low or no allowance

The shortcomings of conventional investment casting process

Lack of effective information exchange between designer and manufacturer.

Very difficulty to design and manufacture the tooling for complicated

casting.

Long lead time, high cost

Especially high expense for design modifying

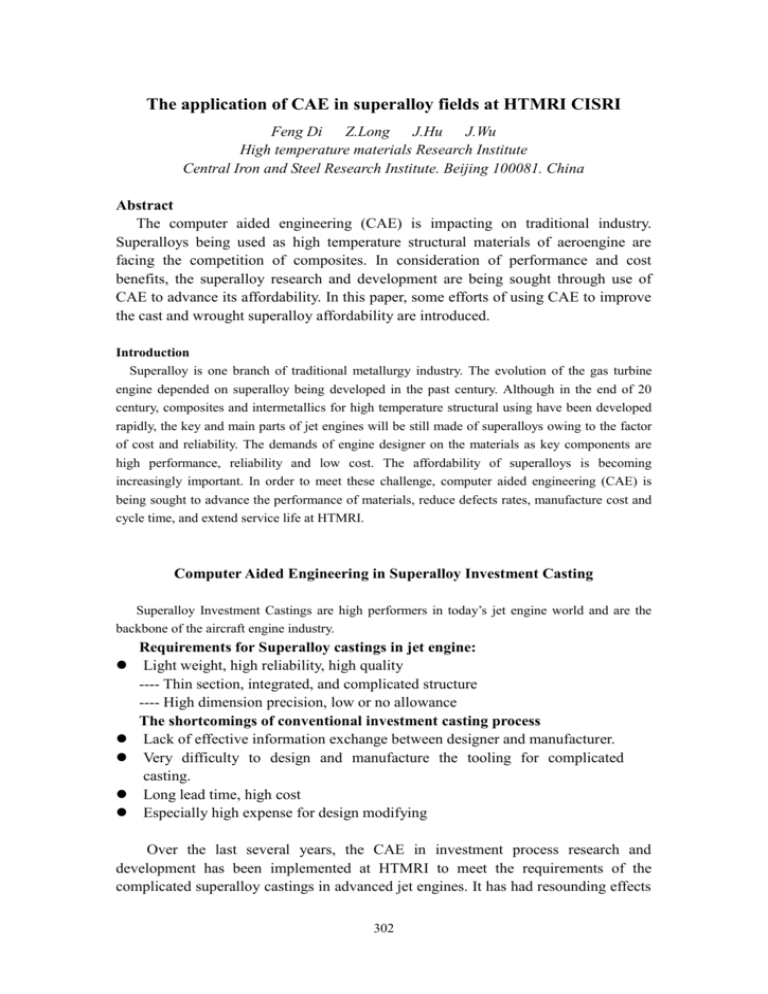

Over the last several years, the CAE in investment process research and

development has been implemented at HTMRI to meet the requirements of the

complicated superalloy castings in advanced jet engines. It has had resounding effects

302

on key aspects of producing a complicated casting.

The flowchart of complicated casting development is follows and an example

of CA Invest casting is presented in Fig.1:

Casting 3D solid modeling

Pouring system Design

Process and Parameters

Modification

STL file

Rapid Prototy ping

Wax pattern

NDT

Shell making

Casting process,solidification

and cooling simulation

thermal stress analysis,

macroporosity and defects

Predication

(1) 3-D solid modeling

Fig 1

RP mold

Pouring

(2) wax pattern

Products

HIP

Casting

(3) pouring assemble

(4) casting

An example of CA investment casting

At first, the teamwork of “design-material-process” has been realized through

using CAE in conventional investment cast process. The engine designer, materials

researcher and castings engineer are working together, to discuss and solve the

demands from designer, the performance of materials and the process of casting

through electronic data. The 3-D computer aided design software are used. The

transfer of the data into real components is being achieved through electronic data. A

rapid prototyping pattern is used directly as investment pattern in shell making for

complicated castings. It is very simple to change design pattern produced from

electronic data, but much more difficult to modify hard tooling. The lead-time is

shortened significantly, and the cost is reduced.

The traditional investment casting process is not suitable to the new demand of

aeroengine complicated castings.

Computer aided engineering has had a significant impact on superalloy

investment casting. The impact not only reduced lead time and cost, but also

promoted a new teamwork mode and created an opportunity for engine designer to

303

design more complicated casting that never be imagined.

The Hot Deformation Modeling of As-Cast Highly Strengthened Superalloys

The ingot conversion process is a key processing step in forging process

especially for large diameter superalloy ingot and the highly strengthened superalloys

such as GH742, Udimet 720 etc. which are widely used in new generation jet and land

base power engines.

Highly strengthened superalloys have less hot workability caused by high level

of alloying elements and

’ precipitating phase which induce the element

segregation and metallurgy defects. Additionally, the hot workability is very sensitive

to hot deformation parameters. In conventional manufacturing routes, numerous trial

and error steps must be taken to achieve the suitable processing parameters.

Therefore, it is very useful to develop an effective model to predict deformation

behaviors.

Alloy GH742 is used as sample to study the hot workability of highly

strengthened superalloys. First, the material database was set up using compression

tests with deformation temperature from 1050 to1125℃, engineering strain from 0.1

to 0.7; and the true strain rates of 0.1, 0.01 and 0.001S-1. The microstructure of

deformed samples was examined by optical and electrical microscope.

Empirical metallurgical equations were developed to describe the relationship

between flow stress deformation ductility, dynamic recrystallization(DRX) and

deformation parameters. The equations should not only describe the experimental

results very well, but also reflect the phenomena occurring during hot deformation.

.

These equations and simulated results are as follows

(1) The peak flow stress vs. parameters

Fig.2 gives the experimental relationship of peak flow stress with deformation

temperature and true strain rate. The following is the simulated equation.

Q

A n exp

RT

where A is a constant, n is a parameter related to the true strain rate, Q is the

deformation activation energy and R is the gas constant.

The above equation shows that ln

and ln ,lnQ and lnT have a linear

relationship as same as the experimental results of Fig.2. Therefore, the parameter n,

Q and A can be obtained from Fig. 2. N=0.159 Q=2177564.11 A=1.824. Fig.3

shows the simulated results, it predicts the experimental results very well.

304

6.2

6.2

6.0

5.8

5.6

ln(¦Ò)

5.4

C

1060

C

1080

5.8

C

1100

5.4

5.2

1120

C

5.0

4.8

1140

C

5.6

ln(¦Ò)

6.0

5.2

4.4

4.4

4.2

4.2

-3.45

-2.30

1s

0.00

4.0

0.00070

4.0

-4.60

-1

4.8

4.6

-5.75

-1

s

0.01

5.0

4.6

-6.90

-1

s

0.1

-1.15

0.00072

ln(¦Å)

0.00074

0.00076

1/T (1/C)

Fig. 2 The relationship of peak flow stress with deformation temperature and true strain rate.

300

250

200

150

300

250

200

150

100

1E-3

1060

50

1080

1100

Te m

per

1120

atu

)

0.01

re (

1140

¡æ

)

ra

0.1

u

Tr

t

eS

in

Ra

te

1060

/s

(1

1080

0.01

1100

T em

pera

1120

ture

(¡æ

1140

0.1

)

ue

ra

St

in

Ra

te

100

1E-3

50

/s)

(1

True stress (MPa)

350

Pa)

400

350

True Stress (M

450

400

Tr

(a) experimental results

(b) calculated results

Fig 3. The experimental and calculated peak flow stress

(2) Hot defamation ductility vs. parameters

Simulated equation:

T1 T

δ A( )

1

exp

f ( )

1

T T2

1

exp

f ( )

2

The effects of true strain rate on the ductility are reflected in parameters A,f1, and

f2. The equations obtained by statistical fit are as follows:

A( ) 133.83 1179.14 exp( / 0.0113)

f 1 ( ) 150.16 38.55 exp( / 0.0169)

f 2 ( ) 86.29 180.43 exp( / 0.0181)

Fig.4 shows the calculated and experimental hot deformation ductility. It is seen

that the model predicted the hot deformation ductility very well.

305

60

60

50

50

Ductility (%)

30

20

40

30

1180

1160

1140

1120

1E-3

True

(C

)

Te

m

pe

ra

tu

re

(C

0

1E-3

1100

0.01

Stra

in Ra

te (1

/s)

1080

0.1

1180

1160

1140

1120

20

)

10

True

1060

1100

0.01

Stra

in Ra

te (1

/s)

Te

m

pe

ra

tu

re

Ductility (%)

40

1080

0.1

1060

(a) experimental results

(b) caculated results

Fig.4 The experimental and calculated hot deformation ductility

(3) Percent dynamic recystallization (DRX) vs. parameters

Simulated equation:

DRX 50 31.831 a tan( p1 ( 50 ))

where P1 is the slope rate that describes the gradient of cures and ε50 is the critical

strain which indicates 50% DRX occurred during hot deformation.

The equations obtained by statistical fit of experimental data.

P1 = 27.60691-0.05203×T+2.46E5×T2

2

50 = 6291.5-10.46586×T+0.00436×T

Fig.5 presents the calculated and experimental percent dynamic recrystallization,

it shows the equations describe the relationship between percent DRX and

deformation parameters very well.

100

100

80

20

10

1180

1200

0

re

(%

tu

40

ra

10

20

30

Eng.

Stra

in (%

)

)

æ)

1160

in

20

1140

.S

1120

ture

(¡

1200

1175

1150

1125

1100

1075

1050

(¡æ

00

En

g

0

1060

1080

1100

60

50

40

30

50

pe

20

Tem

pera

40

)

40

60

60

Te

m

DRX £¨%£©

60

tra

DRX £¨%£©

80

(a) experimental results

(b)calculated results

Fig.5 The experimental and calculated percent DRX

Constitutive Equation Model of Superalloy Inconel 718 for High Speed

Counter-blow Hammer Forging

306

Inconel 718 has been most widely used as turbine discs because of its good

performance and low cost. However, it is difficult to control microstructure of forging

during deformation processing because of complicated phase composition.

In the past decade, some numerical models were set up to predict the

microstructure evolution during deformation. Most of them were based on isothermal

constant speed pancake forging process.

For economical view, high-speed counter-blow hammer forging is widely

adopted because of very efficiency. Therefore, our work focuses on the simulation of

high-speed multi-pass deformation process, the investigation of the deformation

behavior influenced by hot deformation parameters, and development of the

constitutive equation reflecting the flow rule of high-speed counter-blow hammer

forging process.

Experiment Method

Counter-blow hammer forging process is different to isothermal pancake forging

process, more than 30 deformation passes should be needed to get finished forging.

Within the interval time, static recovery and recrystallization will be occurred. Since

more than 70% strain should be completed in initial several passes, the 3-passes and 5

passes deformation schedule have been adopted to simulate the practice deformation

history. The distribution of engineering strain for 3 passed and 5 passes is 0.4+0.2+0.1

(0.7 in total) and 0.25+0.15+0.15+0.1+0.05 (0.7 in total) respectively. The compress

testing was carried out with High Speed Testing Machine. The testing parameters

were adopted as follows.

Deformation temp.: 960o C – 1040o C with an interval of

200

o

C.

Strain rate:10/s.

Interval times:5 second

Heating hold time: 30 min.

Simplification of the stress-strain Curve

3-passes and 5-passes true stress-true strain curves, which reflects the

thermo-mechanical history of compression specimen, are shown in Fig.6. These

curves are difficult to express in mathematics. In consideration of the same interval

time between two passes, the effect of interval time on the flow stress is constant.

Hence, the effect can be synthesized as one constant state variable. Fig.6 shows there

are work hardening and recrystallized softening in the recorded stress-strain curve as a

whole, which is similar with the stress-strain curve of conventional isothermal

constant speed forging process. Therefore, the multi-pass stress-strain curve can be

simplified and quantified as the only single pass forging process as showed in Fig.7. It

is easy to describe the stress-strain curve mathematically.

307

800

800

700

700

960¡æ

600

600

500

1040¡æ

True stress, MPa

True stress, MPa

980¡æ

400

300

200

1000¡æ

1020¡æ

1040¡æ

400

300

200

100

0

0.0

960¡æ

1000¡æ

500

100

0.2

0.4

0.6

0.8

1.0

0

0.0

1.2

0.2

0.4

Truestrain

0.6

0.8

1.0

1.2

Ture strain

Fig.6 True stress-true strain curve

700

Experimental data

Simplification curve

Ture stress, MPa

600

500

400

300

200

100

0

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

True strain

Fig.7 Simplification figure of multi-pass deformation true stress-strain curve (n=5)

Constitutive Equation

The relationship between the flow stress and the strain can be outlined by

following formula.

=A× n×exp(f( ))

where n is work hardening rate, A is a constant.

The relationship between the flow stress and deformation temperature can be

described as follows:

T = B0+ B1×exp[(B2-T0)/B3]

where T is deformation temperature, Bo,B1,B2 and B3 are constants.

Flow stress is the function of strain and deformation temperature, at the constant

strain rate with 10/s. The synthesized constitutive equation is as follows.

308

=A×

n×exp(f( ))×{B0+ B1×exp[(B2-T0)/B3]}

The simulation curves, which are calculated from constitutive equation, are

consistent with experiment value in Fig.8. The simplified schedule of high-speed

counter-blow hammer forging process of superalloy In718 is reasonable and feasible.

The microstructure model have been developed as follows:

D = Dmin×Fmin+ Dman×Fman

D = Co×exp(ε)×exp[C2/(Z+C3)×t×(C4+C5×t + C6×t2)]

D — the average grain size without holding process

Dmin — the recrystallization grain size

Fmin — the recrystallization fraction

Dman — the unrecrystallization grain size

Fman — the unrecrystallization fraction

D — the increment of the grain size owing to the hold process after

deformation

C0, C2, C3, C5 and C6 are constants.

800

700

True strain, MPa

600

500

400

300

960¡æ

980¡æ

1000¡æ

1020¡æ

1040¡æ

200

100

0

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

Engineering strain

Fig.8 Simulation results of stress-strain curve (n=5)

Fig.9 gives the typical examples of simulation results of the grain field of final

forged disc, it shows the calculated microstructure by numerical model is similar to

the actual experimental results of disc.

309

Fig.9 Simulation results of the grain field of final forged disc

Above mentioned are several examples of CAE application in superalloy casting and

deforming processes. The influence of computer modeling to simulate casting and deforming

processes is revolutionizing process development in the superalloy field. It will help improve

affordability of superalloy in the competitive market.

References

1. J.M.Zhang, L.Z.Ma, “Superalloy 718,625,706 and various Derivatives” Edited

by E.A.Loria. The Minerals, Metals and Materials Society 1997, P183-192.

2. Z.Long, J.Zhang, “Advanced Technologies for Superalloy Affordability” Edited

by K.M.Chang, S.K.Srivastava,2000. P187-196.

3. David Furrer and Hans Fecht, Ni-Based Superalloys for Turbine Discs, JOM,

January 1999,PP14-18

4. M.J.Goulette, The Future Costs Less-High Temperature Materials From an

Aeroengine Perspective, Superalloys 1996, eds., R.D.Kissinger et al.

(Warendale:TMS 1996) , PP3-6

5. D.Lasalmonie, et al., A Computer assisted Design and Modeling Tool For

Superalloy Powder Precision Modeling, Superalloys 1996, (Warendale:TMS

1996) PP737-743

6. .M. Zhang, Z.Y.Gao, J.Y.Zhuang, Q.Deng, and P.Janschek, J. Mater. Processing

Technol., 1997, vol.70, pp252-257

7. Z. Long, J.Zhuang, B.Deng, P.Lin, Z.Zong, The Hot Deforamtion Modeling of

As-Cast High-Strengthened superalloys, Advanced Technologies for Superalloy

Affordability, eds. K-M Chang, S.K.Srivastava, D.U.Furrer and K.R.Bain,

(Nashville, March TMS,1997) PP187-196.

8. Z. Long, J.Zhuang, B.Deng, P.Lin, Z.Zong, Advanced Technologies for

Superalloy Affordability, eds. K-M Chang, S.K.Srivastava, D.U.Furrer and

K.R.Bain, (Nashville, March TMS,1997) PP287-297.

9. F. Hediger and N. Hofmann. Proc.of the 5th Intern. Conference in Modeling of

Casting, Welding and advanced Solidification Processes, Davos, Switzerland,

sept. 16-21, 1990, eds, M.Rappaz et al., Warendale:TMS 1991, p.611-619.

310