Macro2012_Abstact TEOS_v2

advertisement

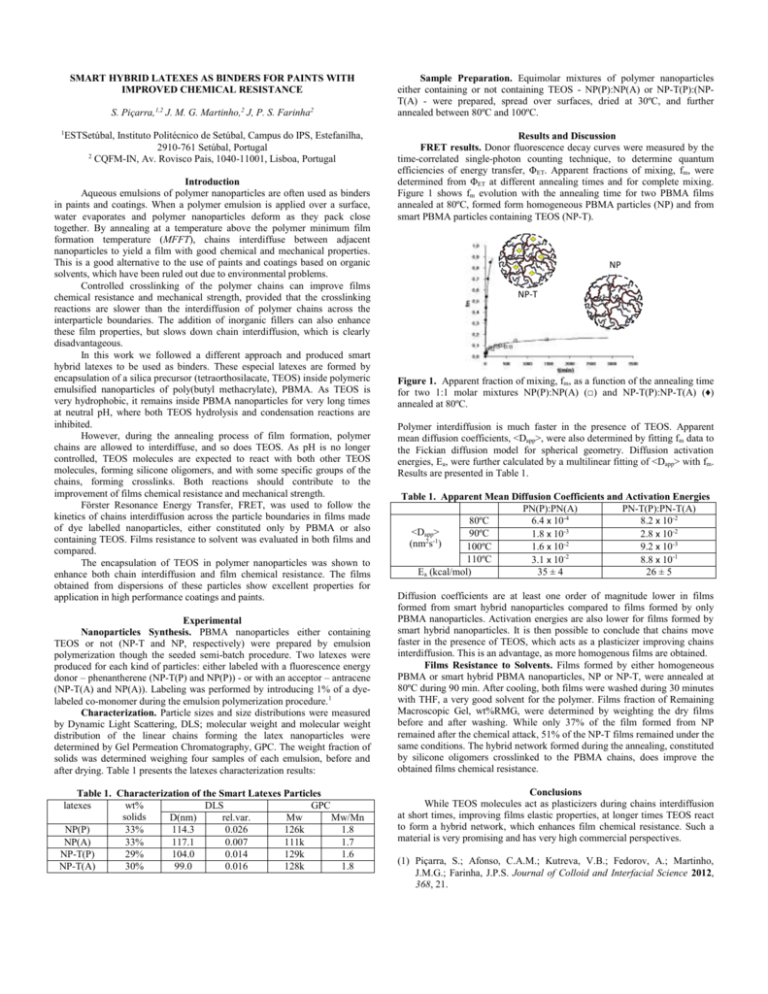

SMART HYBRID LATEXES AS BINDERS FOR PAINTS WITH IMPROVED CHEMICAL RESISTANCE S. Piçarra,1,2 J. M. G. Martinho,2 J, P. S. Farinha2 1 ESTSetúbal, Instituto Politécnico de Setúbal, Campus do IPS, Estefanilha, 2910-761 Setúbal, Portugal 2 CQFM-IN, Av. Rovisco Pais, 1040-11001, Lisboa, Portugal Introduction Aqueous emulsions of polymer nanoparticles are often used as binders in paints and coatings. When a polymer emulsion is applied over a surface, water evaporates and polymer nanoparticles deform as they pack close together. By annealing at a temperature above the polymer minimum film formation temperature (MFFT), chains interdiffuse between adjacent nanoparticles to yield a film with good chemical and mechanical properties. This is a good alternative to the use of paints and coatings based on organic solvents, which have been ruled out due to environmental problems. Controlled crosslinking of the polymer chains can improve films chemical resistance and mechanical strength, provided that the crosslinking reactions are slower than the interdiffusion of polymer chains across the interparticle boundaries. The addition of inorganic fillers can also enhance these film properties, but slows down chain interdiffusion, which is clearly disadvantageous. In this work we followed a different approach and produced smart hybrid latexes to be used as binders. These especial latexes are formed by encapsulation of a silica precursor (tetraorthosilacate, TEOS) inside polymeric emulsified nanoparticles of poly(butyl methacrylate), PBMA. As TEOS is very hydrophobic, it remains inside PBMA nanoparticles for very long times at neutral pH, where both TEOS hydrolysis and condensation reactions are inhibited. However, during the annealing process of film formation, polymer chains are allowed to interdiffuse, and so does TEOS. As pH is no longer controlled, TEOS molecules are expected to react with both other TEOS molecules, forming silicone oligomers, and with some specific groups of the chains, forming crosslinks. Both reactions should contribute to the improvement of films chemical resistance and mechanical strength. Förster Resonance Energy Transfer, FRET, was used to follow the kinetics of chains interdiffusion across the particle boundaries in films made of dye labelled nanoparticles, either constituted only by PBMA or also containing TEOS. Films resistance to solvent was evaluated in both films and compared. The encapsulation of TEOS in polymer nanoparticles was shown to enhance both chain interdiffusion and film chemical resistance. The films obtained from dispersions of these particles show excellent properties for application in high performance coatings and paints. Experimental Nanoparticles Synthesis. PBMA nanoparticles either containing TEOS or not (NP-T and NP, respectively) were prepared by emulsion polymerization though the seeded semi-batch procedure. Two latexes were produced for each kind of particles: either labeled with a fluorescence energy donor – phenantherene (NP-T(P) and NP(P)) - or with an acceptor – antracene (NP-T(A) and NP(A)). Labeling was performed by introducing 1% of a dyelabeled co-monomer during the emulsion polymerization procedure.1 Characterization. Particle sizes and size distributions were measured by Dynamic Light Scattering, DLS; molecular weight and molecular weight distribution of the linear chains forming the latex nanoparticles were determined by Gel Permeation Chromatography, GPC. The weight fraction of solids was determined weighing four samples of each emulsion, before and after drying. Table 1 presents the latexes characterization results: Table 1. Characterization of the Smart Latexes Particles latexes wt% DLS GPC solids D(nm) rel.var. Mw Mw/Mn NP(P) 33% 114.3 0.026 126k 1.8 NP(A) 33% 117.1 0.007 111k 1.7 NP-T(P) 29% 104.0 0.014 129k 1.6 NP-T(A) 30% 99.0 0.016 128k 1.8 Sample Preparation. Equimolar mixtures of polymer nanoparticles either containing or not containing TEOS - NP(P):NP(A) or NP-T(P):(NPT(A) - were prepared, spread over surfaces, dried at 30ºC, and further annealed between 80ºC and 100ºC. Results and Discussion FRET results. Donor fluorescence decay curves were measured by the time-correlated single-photon counting technique, to determine quantum efficiencies of energy transfer, ΦET. Apparent fractions of mixing, fm, were determined from ΦET at different annealing times and for complete mixing. Figure 1 shows fm evolution with the annealing time for two PBMA films annealed at 80ºC, formed form homogeneous PBMA particles (NP) and from smart PBMA particles containing TEOS (NP-T). NP NP-T Figure 1. Apparent fraction of mixing, fm, as a function of the annealing time for two 1:1 molar mixtures NP(P):NP(A) (□) and NP-T(P):NP-T(A) (♦) annealed at 80ºC. Polymer interdiffusion is much faster in the presence of TEOS. Apparent mean diffusion coefficients, <Dapp>, were also determined by fitting fm data to the Fickian diffusion model for spherical geometry. Diffusion activation energies, Ea, were further calculated by a multilinear fitting of <Dapp> with fm. Results are presented in Table 1. Table 1. Apparent Mean Diffusion Coefficients and Activation Energies PN(P):PN(A) PN-T(P):PN-T(A) 80ºC 6.4 x 10-4 8.2 x 10-2 -3 <Dapp> 90ºC 1.8 x 10 2.8 x 10-2 (nm2s-1) 100ºC 1.6 x 10-2 9.2 x 10-3 -2 110ºC 3.1 x 10 8.8 x 10-1 Ea (kcal/mol) 35 ± 4 26 ± 5 Diffusion coefficients are at least one order of magnitude lower in films formed from smart hybrid nanoparticles compared to films formed by only PBMA nanoparticles. Activation energies are also lower for films formed by smart hybrid nanoparticles. It is then possible to conclude that chains move faster in the presence of TEOS, which acts as a plasticizer improving chains interdiffusion. This is an advantage, as more homogenous films are obtained. Films Resistance to Solvents. Films formed by either homogeneous PBMA or smart hybrid PBMA nanoparticles, NP or NP-T, were annealed at 80ºC during 90 min. After cooling, both films were washed during 30 minutes with THF, a very good solvent for the polymer. Films fraction of Remaining Macroscopic Gel, wt%RMG, were determined by weighting the dry films before and after washing. While only 37% of the film formed from NP remained after the chemical attack, 51% of the NP-T films remained under the same conditions. The hybrid network formed during the annealing, constituted by silicone oligomers crosslinked to the PBMA chains, does improve the obtained films chemical resistance. Conclusions While TEOS molecules act as plasticizers during chains interdiffusion at short times, improving films elastic properties, at longer times TEOS react to form a hybrid network, which enhances film chemical resistance. Such a material is very promising and has very high commercial perspectives. (1) Piçarra, S.; Afonso, C.A.M.; Kutreva, V.B.; Fedorov, A.; Martinho, J.M.G.; Farinha, J.P.S. Journal of Colloid and Interfacial Science 2012, 368, 21.