18th European Symposium on Computer Aided Process Engineering – ESCAPE 18

Bertrand Braunschweig and Xavier Joulia (Editors)

© 2008 Elsevier B.V./Ltd. All rights reserved.

Supply Chain Design Considering Plants

Performance

Gabriela Corsano* and Jorge M. Montagna

INGAR- Instituto de Desarrollo y Diseño - Avellaneda 3657- (3000) Santa FeArgentina

Abstract

Most of the Supply Chain (SC) design models have focused on the integration problem,

where links among nodes have to be determined in order to allow an efficient operation

of the whole system. In this level, all the problem elements are modeled like black

boxes, and the optimal solution determines the nodes allocation and their capacity, and

the connections among nodes. In this work, a MILP model is proposed where decisions

about plant design are simultaneously taken with operational and planning variables.

The model considers unit duplication and the allocation of storage of discrete sizes. The

solved examples show the impact of plant design in the overall SC operation.

Keywords: supply chain design, multiproduct batch plant, MILP.

1. Introduction

A supply chain (SC) is a network of facilities (e.g. plants, warehouses, customers) that

perform a set of operations ranging from the acquisition of raw materials to the

distribution of finished goods to customers. The design of the SC involves making

several decisions like number, size and location of plants, products to be produced in

each plant, allocation of suppliers to plants and plants to distribution centers, etc.

Most of the design models have focused on the SC integration (Tsiakis et al., 2001, Ryu

and Pistikopoulos, 2005), where links among nodes have to be determined in order to

allow an efficient operation of the whole system. In this level, all the problem elements

are modeled like black boxes, with a maximum capacity, and the optimal solution

determines the nodes allocation and their capacity, and the connections among them.

Recently, Guillén et al. (2006) have addressed the SC design problem under demand

uncertainty through a multistage stochastic formulation, using a decomposition

technique that combines genetic algorithms and mathematical programming tools. Shah

(2005) has described the state of the art in SC modeling. remarking that there are not

published works dealing with the connection between process design and SC operation.

In this work, a mixed-integer linear programming (MILP) model is proposed for the

optimization of a SC where decisions about plant design are simultaneously taken with

operational and planning variables. The model considers unit duplication in phase and

out of phase and the allocation of intermediate storage of discrete sizes. Several

examples are solved to show the impact of plant design in the overall SC operation.

2. Problem Description

Four echelons in the SC are considered in this formulation: the raw material sites, the

manufacturing plants, the warehouses and customer zones. At each raw material site s (s

=1,…, Ns), one or more types of raw materials r (r = 1, …, Nr) are available to be

delivered to plants l (l = 1, …, Nl), that operate during the time horizon Hl. Each

2

G. Corsano and J. M. Montagna

multiproduct batch plant has stages j (j = 1, …, N jl ) for producing i products (i = 1, …,

Np). Parallel units duplication in phase and out of phase are allowed as well as the

allocation of intermediate storage between two batch stages. The warehouses m (m = 1,

…, Nm) have different stock capacity and the product demand of the customer zones k,

Dik, are known for k = 1, …, Nk. Moreover, the following data is assumed to be known:

(i)

the set of raw materials and their availability at each raw material site

(ii) the set of available discrete sizes for units in the batch plants

(iii) the cost parameters associated to: plants and warehouses installation, investment

and production, transportation, raw material and maintenance.

The problem is to determine:

(a) the allocation of each plant and each warehouse

(b) production of each product in each plant

(c) the structure of the plant considering parallel units duplications and allocation

of storage tanks, and unit sizes

(d) the SC structure: flows among SC nodes.

in order to minimize the total annual cost given by fixed cost, investment cost,

production cost, stock and maintenance cost, and transportation cost.

3. Model Formulation

The problem involves optimizing the SC performance simultaneously with the plant

design in order to minimize the total cost. Following, the basic constraints are posed.

3.1. SC Network Constraints

These constraints are mass balances between the different nodes in the SC. Q represent

total amounts, for example Qsril are the kg of r from s to l to produce i, fr the raw

material conversion factor, and zil is a binary variable equal to 1 if product i is produced

in plant l, and zero otherwise:

Ns

Q

s 1

sril

frilr Qil

r , i,l

zil QilLO Qil zil QilUP

Q

sril

i,l

Q

r , s, and

Qil

i,l

UP

rs

(1)

(2)

Qsril zil Q

UP

rs

r , s, i, l

(3)

i ,l

Nm

Q

m 1

ilm

(4)

Let ym be the binary variable equal to 1 if the warehouse m is installed, zero otherwise,

and Qmmax the capacity of warehouse m.

Q

ilm

Q

Qmmax ym and

imk

i ,l

Nl

Q

l 1

Qmmax ym

m

(5)

i,k

Nk

ilm

Qimk

Nm

i,m

(6)

k 1

Dik Qimk

i,k

(7)

m 1

3.2. Design Equations

Let SVjl={VFjl1, VFjl2, …, VFjlP} be the set of available discrete sizes for stage j of plant

l. p = 1,…, P represents the index for the different unit sizes. If the plant is not installed,

then all the unit sizes of that plant have to be zero. Let exl be the binary variable that

Supply chain design considering plants performance

3

takes value 1 if plant l is installed, and zero otherwise, and vjlp is a binary variable equal

to 1 if unit j of plant l has size p. Then, the size for unit j of plant l, Vjl, is given by:

P

V jl v jlpVFjlp

j , l

(8)

p 1

pSV jl

v jlp exl j , l

and zil exl

i, l

(9)

The sizing equations that relate the unit size with the batch size (Bijl) are:

Sijl Bijl

V jl

i, j , l

NPjl

Qil Nbil Bijl

i , j , l

(10)

(11)

NPjl represents the number of in phase units for stage j in plant l, Nbil the number of

batches of product i in plant l, and Sijl the size factor. In order to avoid no linear

constraints, the binary variable xxjld is defined and it takes value 1 if stage j of plant l has

d units in phase, and zero otherwise, so

NPjl

NPjlUP

d xx

d 1

NPjlUP

and

jld

xx

d 1

jld

exl

j, l

(12)

Then, replacing Eq. (11) in Eq. (10)

Sijl Qil

Nbijl

i, j, l

V jl NPjl

And substituting Eq.(13) for Eq. (8) and Eq. (12)

Sijl Qil

Nbijl

eijlpd

d , p VFjlp d

(13)

(14)

Q if vilp and xx jld are equal to 1

With eijlpd il

0 otherwise

UP

i, j, l, p

eijlpd Qil vilp

(15)

(16)

d

e

QilUP xx jld

ijlpd

i, j, l, d

(17)

p

P

Qil eijlp

i, l

(18)

p 1

3.3. Timing Constraints

Let tijl be the processing time for product i in stage j of plant l, TLil the cycle time of

product i in plant l, and NTjl the number of out of phase units for stage j of plant l. Then

Til ≥ Nbijl TLil, represents the total time for producing i in plant l, so that Til H l . The

i

cycle time is defined by

NT jlUP

tijl

TLil Nbijl x jln Nbijl i, j, l ,

n 1 n

NT jl

NT jlUP

nx

n 1

jln

j, l

(19)

NT jlUP

with

x

n 1

jln

exl

(20)

4

G. Corsano and J. M. Montagna

Where xjln is equal to 1 if n out of phase units are used in stage j of plant l, and zero

otherwise. In order to avoid no linear constraints, a new variable is defined as wijln =

Nbil xjln, and replaced in (20).

3.4. Intermediate Storage Constraints

According to Voudouris and Grossmann (1993) the upper bound for the storage vessels

can be defined by

VT jl 2 STijl Bijl s jl

i , j 1, 2, , N j 1, l

(21)

VT jl 2 STijl Bi , j 1,l s jl

i, j 1, 2,

, N j 1, l

(22)

STijl represents the size factor for storage tanks and sjl is a binary variable equal to 1 if a

tank is allocated after batch stage j, and zero otherwise.

Let STFjl VTFj1l ,VTFj 2l ,...,VTFjG jl l be the set of available discrete sizes for the tank

allocated after stage j. Let stjgl be the binary variable that takes value 1 if a tank of size g

is allocated. VTFj1l is equal to zero to represent the no tank allocation. Using Eq.(11) in

(21) and (22) the storage constraints are:

STijl Qil

(23)

Nbijl 2

st jgl i, j 1, 2,..., N j 1, l

g 1 VTFjgl

STijl Qil

(24)

Nbi , j 1,l 2

st jgl i, j 1, 2,..., N j 1, l

g 1 VTFjgl

(25)

st jgl exl j 1, 2, , N j 1, l

g

Using the continuous variable fijgl=Qil stjgl, constraints (23) and (24) become linear and:

(26)

fijgl QilUP st jgl

i, g, j 1, 2,..., N j 1, l

Qil fijgl

i, j 1, 2,

, N j 1, l

(27)

g

The bounds for number of batches can be stated by

1

Nbijl 1 st jgl Nbijl Nbi , j 1,l Nbijl 1 st jgl Nbijl i, j 1,2, , N j 1, l (28)

g 1

g 1

Where is a constant value corresponding to the maximum ratio allowed between

consecutive batch sizes. The nonlinearity in these equations is eliminated with the

definition of a new variable ijgl such that

ijgl NbijlUP st jgl

and Nbijl ijgl

i, j 1,..., N j -1 , l

(29)

g

3.5. Objective Function

The objective function is the minimization of the total annual cost given by fixed cost

(plant and warehouse installation), investment cost (batch units and storage vessels),

production cost (raw material consumption and operating cost), stock and maintenance

costs, and transportation cost (between the SC nodes).

4. Example

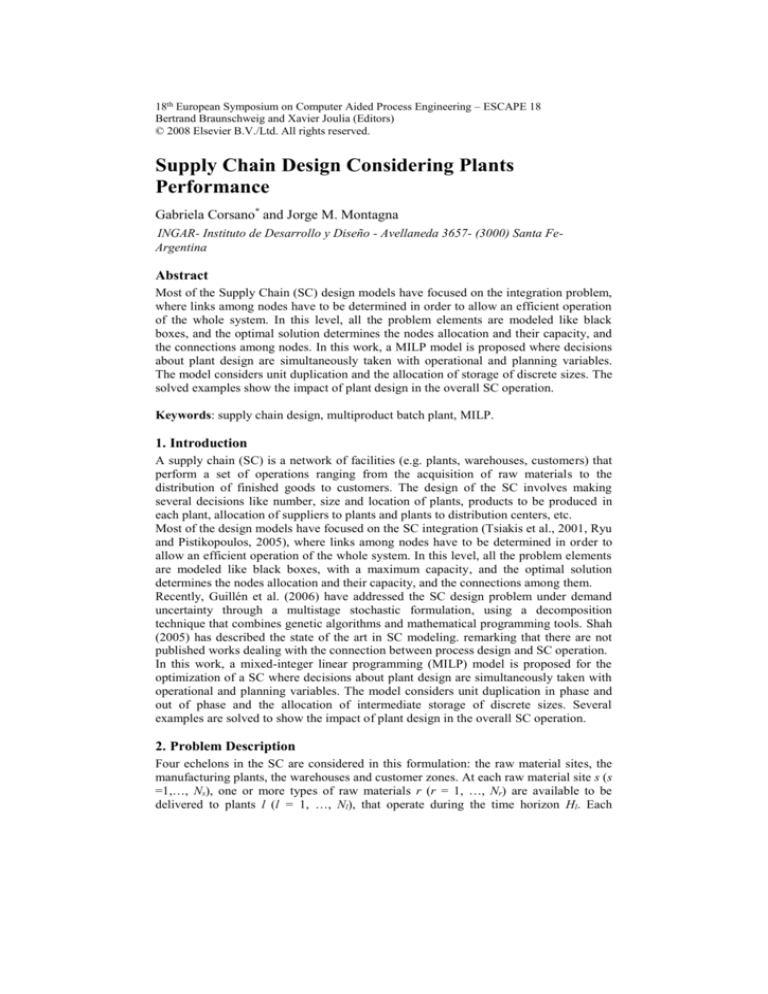

The example considers a SC that consists of 2 sites with 3 different raw materials, 3

possible plants with 3 stages for producing 3 products, 3 possible warehouses and 3

customer zones. Tables 1-3 show the most relevant model parameters. A set of 5

discrete sizes is provided for process units and 4 discrete sizes for storage tanks. Table 4

Supply chain design considering plants performance

5

shows these sizes and their costs. The problem was solved with GAMS via CPLEX

solver with a 0% optimality gap.

Table 1. Model parameters for the example

Product (for

all plants)

fril

R1

i1

i2

i3

0.8

0.7

0.6

R2

R3

0.85

0.7

0.65

0.7

0.7

0.65

tijl (h)

J1

14

12

16

Table 2. Product demands (x103 kg)

Product

i1

i2

i3

k1

150

130

150

k2

200

220

250

J2

5

6

8

Sijl

J1

J3

7

4

5

J2

0.9

0.6

0.7

J3

0.6

0.5

0.5

0.4

0.4

0.4

Table 3. Raw material availability (x103 kg)

k3

115

130

150

Sites

R1

R2

R3

S1

S2

3,200

3,500

3,000

3,200

1,950

1,800

Table 4. Discrete sizes and costs of units and storage tanks

Cost jlV jl jl

Discrete units sizes (l)

Stages

J1

J2

J3

J1

J2

P1

P2

300

500

300

500

300

500

Storage Tanks

G1

G2

0

1500

0

1500

P3

P4

750

750

750

1000

1000

1000

G3

5000

5000

G4

10000

10000

P5

(x 103)

1200

1200

1200

L1

6

8

7

0.5

0.5

L2

9

6

10

L3

5

7

7

0.6

0.6

0.7

0.6

0.6

The optimal solution consists in only one plant that produces the 3 products. The plant

and the unit sizes are shown in Fig. 1 as well the number of batches (Nbi) and the total

production (Qi). A storage tank is allocated between stages 2 and 3, that is not used by

product 1. All the consumed raw materials arrive from site 1 and two warehouses are

installed. In the first row of Table 5 the investment and operative costs of this optimal

solution (S1) are given. In Table 6 the optimal network distribution is showed.

The same model without consider unit duplications and storage tank allocation is solved

in order to compare the significance of plant design in the overall SC problem

optimization. The optimal solution for this model consists in two plants: Plant 1

produces 392,920 kg of product 2 and 480,570 kg of product 3 with unit sizes of 1200,

1000 and 750 for stages 1, 2 and 3 respectively, and Plant 3 produces 465,000 kg of

product 1, 87080 kg of product 2, and 69430 kg of product 3 with unit sizes equal to

1000, 750 and 500 for stages 1, 2 and 3 respectively. In Table 5 the economical results

are shown (S2). The total annual cost is equal to $1406300 representing 28.6% bigger

that the optimal solution considering plant design.

5. Conclusions

This work has proposed a MILP model for the optimal production and distribution SC

problem taking into account plant design in the overall model. Unit duplication in phase

6

G. Corsano and J. M. Montagna

and out of phase as well as the allocation of intermediate storage tank where considered,

using discrete unit and tanks sizes in order to avoid nonlinearities.

The model was applied to a SC with four echelons and compared with a model where

plant configuration is not taken account. The importance of considering plant

configuration has been highlighted by using an example in which considerable savings

on the overall annual costs have been achieved, given not only by the investment costs

but also by the SC design.

Acknowledgment

The authors are grateful for financial support from CONICET and ANPCyT.

References

G. Guillén, F.D. Mele, A. Espuña, L. Puigjaner, 2006, Addressing the design of chemical supply

chains under demand uncertainty, Ind. Eng. Chem. Res., 45, 7566-7581.

J. Ryu, E. Pistikopoulos, 2005, Design and operation of enterprise-wide process network using

operation policies, Ind. Eng. Chem. Res., 44, 2174-2182.

N. Shah, 2005, Process industry supply chains: Advances and challenges, Comp. and Chem.

Engn., 29, 1225-1235.

P. Tsiakis, N. Shah, C.C. Pantelides, 2001, Design of multi-echelon supply chain networks under

demand uncertainty, Ind. Eng. Chem. Res., 40, 3585-3604.

V.T. Voudouris and I.E. Grossmann, 1993, Optimal synthesis of multiproduct batch plants with

cyclic scheduling and inventory considerations, Ind. Eng. Chem. Res., 32, 1962-1980.

Table 5. Investment and operative annual costs ($)

S1

S2

Plant

Investment

519,820

795,859

Tanks

Production

18,643

-

116,200

131,150

Raw

material

84,182

100,200

Warehouse

Transport

Total

109,450

109,450

245,500

269,670

1,093,795

1,406,329

Table 6. SC optimal design and product distribution for solution S1 (x10 3 kg)

From sites to Plant 1

Products

R1

R2

R3

From Plant 1 to

warehouses

M1

M3

i1

i2

i3

372

336

330

395

336

357

325

336

357

465

0

400

0

480

150

From warehouses to customers

K1

K2

K3

M1:150

M3:130

M1:150

M1:200

M3:220

M1:250

M1:115

M3:130

M3:150

V=1200 l

V=1000 l

V=500 l

V=1200 l

V=5000 l

Nb1 = 372

Nb2 = 240

Nb3 = 357

Nb1 = 372

Nb2 = 240

Nb3 = 357

Nb1 = 372

Nb2 = 384

Nb3 = 440

Figure 1. Plant design and production planning

Q1 = 465,000 kg

Q2 = 480,000 kg

Q3 = 550,000 kg