1.INFB - HP State Electricity Board

advertisement

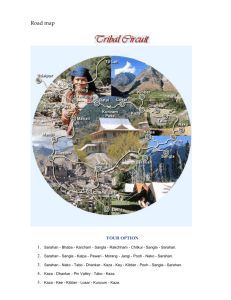

INFORMATION FOR BIDDERS 1.0 INTRODUCTION Himachal Pradesh is situated in the North-West corner of India in the lap of the Himalayan ranges. It is surrounded by Jammu and Kashmir in the North, Uttranchal/Uttar Pradesh in the South-East, Haryana in the South and Punjab in the West. The state is almost entirely mountainous with altitudes ranging from 460m to 6600 m above sea level. The normal rainfall is 181.6cm. Himachal Pradesh is drained by a number of rivers and rivulets. Five major river systems namely are the Chenab, the Ravi, the Beas, the Satluj and the Yamuna, which eminate from the western Himalayas. All the rivers are snow fed and hence perennial. The natural reservoirs and the large drops available in the river courses provide immense potential for hydel power generation at low cost. Himachal Pradesh is blessed with abundant water resources. The assessed hydroelectric potential of the country in terms of schemes considered feasible for development is about 500 billion units. Out of this potential, nearly 160 billion units i.e. 32 percent, lies in the northern region. Himachal Pradesh with its estimated power potential of more than 20,000 MW, in its five river basins, itself accounts for nearly 100 billion units. The Himachal Pradesh State Electricity Board Limited, a company, registered under companies act with its head office at Vidyut Bhawan, Shimla-171004 (hereinafter referred to as the HPSEBL/ Owner), is responsible for promoting the co-ordinated development of power potential, generation, transmission and distribution of electricity within the State in most efficient and economical manner. 2.0 PROJECT IMPLEMNTATION Himachal Pradesh State Electricity Board has undertaken the repair and renovation of electromechanical equipment of Rongtong Power House. Major cost of the works shall be financed with the 13th Financial commission Grant for strengthening of electricity infrastructure in Border blocks of HP. 2.1 PROJECT DETAILS Rongtong Power House is located in Lahul Spiti District of Himachal Pradesh. Power House is at Rangrik which is about 5 Km from Kaza Town on left bank of Rongtong Nallaha. Kalka Railway station is the nearest broad gauge railway station and is about 550 Km. from Kaza by road. Whereas Shimla is the nearest narrow gauge railway station which is about 450 Km. from Kaza by road. Kalka is connected by National Highway ( NH 22) via Shimla upto Wangtoo which is 280 Km. from Kalka. All consignments will have to be despatched to Kalka Railway station (if opted to be transported from ex-works to site through railway where un-loading facilities are available). The other option available is to transport the equipment directly from exworks to site by road transport. The Rongtong Small Hydro Project is located in hilly area of Himachal Pradesh. The catchment area of the Rongtong Nallah is 265 Sq. km. and is entirely snow-fed. The detailed discharge data of the stream are not available. Estimated design discharge is 3.42 m3/sec available for 50% of time in the year. The works of Rongtong SHP were commenced in 1976-77 and the Power House was commissioned during December, 1986. 1 3 SALIENT FEATURES : 1. i) ii) iii) iv) LOCATION State District Village Access Road v) vi) Nearest Rail Head Nearest airport 2. METEREOLOGY i) ii) Altitude Temperature 3. HYDROLOGY Himachal Pradesh Lahaul & Spiti Spiti Valley Power House about 3 km from Kaza town on left bank of Rongtong Nallaha Shimla 450 km Shimla 450 km 3600 meters above M.S.L (-) 40* C to (+) 30* C i) ii) River Catchments area above diversion Weir iii) iv) v) Mean annual rainfall in catchments 113 mm Mean annual run off 0.0975 x 10 Hect. M Design discharge 4.25 Cumecs 4. Rongtong Nallah 265 Sq. km DIVERSION AND INTAKE STRUCTURES i) Type ii) iii) iv) Length of weir No. of bays Bed level at weir site Crated weir with concrete cut off on face 10 m 14 Nos. 3688.384 m 5. WATER CONDUCTOR SYSTEM 5.1 From Rd 148 to 301 m & 340 to 938 m i) ii) iii) iv) v) vi) Type Width Total length Bed slope Height Max. Velocity 5.2 Desilting Tank at RD 301 m i) ii) iii) iv) v) vi) vii) Length Width at center Side slope Up stream transition length Down stream transition length No. of hoppers Drain pipe diameter R.C.C. Box Section 1.9 m 749.583 m 1 in 900 1.9 m 1.325 m/sec 39.9 m 4.00 m Vertical 5.0 m 2.5 m 6 Nos. 300 mm 2 viii) Height of structure 5.9 m 5.3 From RD. 1192 to 3273 m i) Type ii) iii) Width Length iv) v) Max. Velocity Fully supply depth flow 5.4 From RD 938 to 1192 m i) ii) iii) Type Length Section 6. FOREBAY/RESEVOIR i) ii) iii) iv) v) vi) vii) viii) Average length Average width Bed slope Bed level Top forebay level Full supply level Free board Storage capacity 7. PENSTOCK i) Number ii) iii) Total length Internal dia iv) v) Design discharge Liner thickness 8. POWER HOUSE i) ii) iii) iv) Size of building Installed capacity No. of Units Floor elevation 9. TURBINE i) ii) No. of turbines Type of turbine iii) Setting 4 (four) 400 HFIV-500, Francis turbine Jyoti Make. Horizontal iv) v) Turbine output Net head 750 HP 79 meters R.C. rectangular with R.C.C. Sleepers over it 1.9 m 2080.637 m Height 2.16 m Bed slope 1 in 900. 1.325 m/sec 1.41 m Tunnel 254.243 m RCC D-shaped with 2.05 m finished dia 120 m 45.00 m Horizontal bed 3676.86 m 3685.00 m 3683.5 m 1.50 m 18000 m3 One (Branching into four near PH) 502.982(inclined length) 1.2 m and 0.70 m in branching. 3.424 m3/sec 8 mm to 14 mm 37.525 x 16.75 m 2000 kW 4 of 500 kW each 3599.915 m 3 vi) vii) viii) ix) x) xi) Rated speed Runaway speed Specific speed Runner Diameter BF valve diameter Spiral inlet diameter 10. GENERATOR i) ii) No. of generator Type iii) Continuous rated output at rated power factor, rated speed and rated voltage with temperature rise within class-B limit above ambient temp. of 20 C Power Factor Frequency Speed Maximum speed (runaway speed) at which all parts are guaranteed to withstand safely Phases Voltage between phases Amperes per phase iv) v) vi) vii) viii) ix) x) 1000 rpm 1700 rpm 116.3 rpm 414 mm 500 mm 414 mm 4 (four) Salient pole type synchronous alternator horizontally mounted two bearings 625 kVA 0.8 lag 50 Hz 1000 r.p.m. 1700 r.p.m. Three 415 Volts 870 A 4 Details of existing electro-mechanical equipment : Details given hereunder are indicative only. Bidders shall visit the site before bidding and make own assessment. 4.1 Electromechanical Equipments b) Butterly Valves Butterfly valves have been provided to shut off the turbines in case of emergency viz oil pump belt breaks, pendulum belt breaks or electrical fault appears. The valve consists of body, disc, operating mechanism with weight for closure and inlet/outlet dismantling pipes. Butterfly valves of all the four machines are presently being manually opened with the help of chain-pulley blocks and kept open by chain pulley block. The closure of the valves is facilitated by counter weight provided on the valve spindle and releasing the chain pulley block. Therefore, It is not possible to shut down the turbines automatically through butterfly valves under any emergency condition. This causes over speeding of machines frequently leading to be damage of thrust pads, scratching of shafts etc. c) Turbines The turbines are horizontal shaft Francis turbine directly coupled with generators designed and supplied by M/s Jyoti. Ltd. Baroda (Gujarat). Each turbine consists of spiral casing with integral stay ring, guide apparatus with regulating mechanism, turbine shaft, runner, shaft gland seal, pedestal type thrust cum guide bearing, pedestal type 2nd guide bearing, coupling for turbine and generator, flywheel & pulley, discharge pipe and draft tube etc. 4 Spiral Casings:- Spiral casing is cast fabricated with integral stay ring. The joints of spiral casing with butterfly valve outlet pipe and draft tube bend pipe are leaking in both the running units. The outer and inner surfaces of the casing are severely corroded. Guide Apparatus:- Guide apparatus consists of turbine cover, lower ring, twelve guide vanes with upper/lower bushes, levers, lings and regulating ring. Guide vanes feather of all machines have repaired a number of times resulting in change in their original profile and other dimensions. It is observed that all the guide vanes do not close properly and opening between consecutive guide vanes are not uniform. This leads to non uniform flow of water, reduced efficiency and increased vibrations of the machines. Excessive Water Leakage:- There is substantial loss in generation due to excessive water leakages from the following components : (i) (ii) (iii) (iv) (v) Sluice valves. Butterfly valve joints Turbine gland seal and guide vane bushes Guide bearing cooling system. Joints of spiral casing with discharge pipe on draft tube side. d) Governors Hydro-mechanical type Governors manufactured by M/s Jyoti Ltd. Baroda have been provided for all the machines. These Governors comprise of belt driven oil pumps, separate belt driven pendulum for speed sensing, oil distribution valve, dashpot, built in servomotor, feed-back arrangement and hand-wheel etc. All control functions of the Governor like speed control, speed droop, gate limits etc. are done manually. These Governors do not have emergency shut-down devices to close the turbine gates. The major operational problems with regard to these governors are listed below: The pendulums of all the governors are out of service making speed indication and control impossible. Synchronizing of machines with the grid poses lot of problems as adjusting speed and load through remote control from the switch board is not possible. Also, precise control of guide vane opening directly through manual limiter is not possible due to sluggish operation. The machines have the tendency to over-speed due to failure of these governors to act when there is sudden load throw-off. These Governors have not been designed to take care of emergency shut-down. The frequent belt slippages impair the operations. e) Lubricating System f) The belt driven lubricating oil system for turbine guide and thrust bearing is presently in working order but it may be worn out and obsolete. Due to increased thrust and inadequate/improper lubrication, thrust cum guide bearing gets damaged more frequently necessitating repairs at short intervals. Bearing Cooling Water System Fine silt accompanying water get deposited over the inner lining of cooling water pipes. The chocking of cooling pipes in this fashion results in temperature rise of 5 bearings beyond permissible limits and the machines have to put under forced shutdown. Similar situation also arises in extreme winter due to icing of water in cooling pipes. There have also been instance of damage to thrust/journal bearing pads due to these reasons. During winter, only one machine is operative due to low discharge and other machines have to be kept idle. While idling, the cooling pipes of these machines sometimes burst due to temperature differential. Extensive damage was caused to machine No. IV due to icing of water in turbine casing while not in operation. The turbine casing was uprooted from the foundation due to shearing of foundation bolts. In view of urgency of maintaining the power supply of the area and difficulties in obtaining spares due to inaccessibility of the site particularly during winter, machine No. IV has been cannibalized to keep the other units running. 4.2 Electrical Equipments a) Generators & Static Excitation System Generators:- Four numbers salient pole horizontal type synchronous generators of M/s Jyoti Ltd. Vadodara make have been installed. The rating of each generator is 625 kVA, 415 V, 50 Hz, 0.8 pf lag, 1000 rpm. Two nos. roller type grease lubricated bearings are provided in the generator end shields. There is no provision of temperature measurement of bearing metal. The sleeves have been repaired a number of times through local contractors. Three generators are in good condition but one generator has shown open field winding. It may require re-winding whereas other generators require normal servicing. Static Excitation System: The panels are designed and manufactured by M/s Jyoti Ltd. Vadodara. Each unit is provided with its excitation panel. It consists of a full wave bridge converter for supplying DC voltage to the field of the generator. The converter voltage can be varied by controlling the firing angle of thrusters. Any change in alternator output voltage, due to load variation is sensed, rectified and compared with a fixed reference voltage. The error, thus, obtained adjusts the firing angle of constant output voltage. Field flushing of generator is done through a 24 V DC Battery. Though the control system of the static excitation units was duplicated to provide redundancy and reliability, but at present only one mode and that too in case of unit I & II is in working order. Moreover there is no manual channel to control the voltage. The major defects are in the electronic cards. It is however not possible to procure the requisite spares for these panels as these panels as these are no longer being manufactured by the original equipment manufacturer. Neutral Grounding Panel: One neutral grounding panel with four compartments one for each unit has been provided. b) Control And Protection Panels. i) Unit Control Panels- 4 nos. Unit control, metering, protection and annunciation panels are of obsolete design. Large number of components in these panels have developed defects and their spares are no longer available. LT breakers of generator and transformer are of obsolete design, their main contacts have worn out due to wear & tear and spares are not available. ii) Transformer Control & Protection Panels- 2 nos. These panels too are of obsolete design. Most of the components have developed defects making the panels unreliable and their spares are no longer available. 6 iii) Feeder Control Panels- 5 nos consisting of Incoming Feeder Outgoing Feeder Outgoing Feeder Outgoing Feeder Spare - 1 1 for Kaza 1 for Lossar 1 for Taba 1 MOCBs of feeder panels are of obsolete design, their main contacts have worn out due to wear & tear and their spares are not available. Protection relays and meters too are of obsolete design and not reliable. iv) Synchronizing Panel Has never been used as power house runs in isolation to cater the power requirement of Spiti Valley. c) Unit Transformers:- There are two indoor transformers of 415V/22 kV, 1250 kVA rating. The transformers are in good condition. d) Electrical Auxiliaries LT AC Supply Board:- For 415 VAC supply to auxiliaries, separate panel has been provided. The components in this panel are very old design and not reliable. Station DC Battery System:- Battery bank consists of 24 V, 400 A-H. lead-acid batteries. The float charger of battery charger is not in working order and at present DC supply in the Power House is being maintained only through the boost charger. Boost Charger, Float charger, Switch gear panel, DC distribution panel: These are full size panels and too bulky for such small application. e) Switchyard Equipments There are presently Four feeders in switch yard – one each for Kaza, Tago and Kossar The Power House operates in isolation to cater the power requirement of Spiti Valley only. Its synchronization with the Grid has not been possible as the nearest control point fork the Grid supply is located more than 180 kms away. Elevation of pressure transmitter: 3600.646 MSL 5.0 CLIMATE/WEATHER The project work area (including civil works) lies around 3600m. MSL. The temperature in the valley varies from -40 degrees C to +30 degrees C. 5.1 CLIMATIC CONDITIONS 6.0 The temperature, conditions at site are given above. Equipment to be designed & supplied shall be suitable for satisfactory working under these conditions. SEISMOLOGY The area is in the Himalayan region and lies between isoseismal VII & VIII to mm scale which gives a ground acceleration equivalent to 98 to 100 cm/sec2. The table below indicates earthquake with epicentre located in proximity to project site. 7 Sr.No. Year and date Epicentres Location Richter Magnitude 1. 1905 April 4 320-150N 760-150E 8 0 0 0 0 2. 1945 June 22 32 -45 N 76 -30 E 7 3. 1947 July 10 330-00 N 770-80 E 6 4. 1955 April 14 320-440N 760-60 E 5 5. 1958 June 11 320-450N 760-00E 5 6. 1962 June 17 330-180 N 760-120 E 6 Since the area lies in high seismic zone, a suitable seismic co-efficient shall be provided while designing the structures/ foundations. 7.0 LABOUR AVAILABILITY Sufficient skilled/unskilled labour may not be available locally. As such, most of the skilled/unskilled labour may have to be brought from outside. However, the contractor shall make maximum efforts to explore the availability of local labour of various categories and employ them to the extent possible. Liaisoning and good relation with locals is very essential. 8.0 TEMPORARY/TRANSIT ACCOMMODATION There is acute shortage of accommodation nearby the power house site. HPSEB has developed some accommodation for its own employees. Contractor has to make his own arrangement for the temporary/transit accommodation. 9.0 ELECTRIC POWER Power at 415 V shall be provided to the contractor free of cost in the power house building. HPSEB does not undertake to meet with the demand of contractor nor to guarantee uninterrupted and quality power supply as the area is fed through 22 kV feeders from Nathpa sub station which is about 200 Km from Kaza. Due to long length of 220 Km voltage in the area has very poor regulation as such machinery viz. Drilling machines, welding sets etc. may not work on grid supply. The contractor shall make his own arrangement for generating sufficient standby power (diesel generator set) to carry on the works during such or any other shut-off or interruption of power. HPSEB Ltd. shall not entertain any claim of the contractor on account of any damage or loss that may be caused to his plant, equipment and machinery and works as a result of any shut down break down or voltage fluctuations in the power supply. He is expected to have necessary protection to his electrical equipment and sufficient standby arrangement. 10.0 CONTROL POINT HPSEB/ Owner shall provide suitable benchmarks at the location of works with elevation, horizontal and vertical co-ordinates throughout the project site. The reference points shall be clearly identified at the ground and properly protected by 8 the contractor against any damage. The contractor shall be responsible to ensure that these reference points are not interfered with during the course of work and shall report any suspected damage to the Engineer-in-Charge, who will then check the accuracy and make any necessary adjustment at the contractor's expenses. 11.0 MATERIAL AND WORKSHOP FACILITIES All the material required for the main works and auxiliary works including consumables, steel etc. shall have to be arranged by the contractor. No material shall be issued by HPSEBL/Owner. Nearest workshop facilities for carrying out minor machinery jobs etc. will be available at Rampur/Shimla. For major works, facilities will be available at Chandigarh, Ludhiana and Batala. 12.0 LAND FOR INFRASTRUCTURE & STORAGE The contractor shall make his own arrangement for construction of quarters and other structures including proper facilities required for work at his own cost. Land for this purpose, as per availability, shall be provided by HPSEBL/ Owner on rent basis at power house site or any other place within 25 Kms. from the project site. In case of non-availability of land with HPSEBL, contractor has also to make his own arrangement to obtain the necessary land for his township, infrastructures, auxiliary works etc. on lease from the locals. 13.0 LABOUR LICENCE The contractor shall be required to obtain labour license for deployment of labour from competent authorities mentioned below: Labour Officer Rekong Peo, Distt. Kinnaur (H.P.) The contractor shall strictly adhere to the labour laws and minimum wage act prevailing in the State of Himachal Pradesh. 14.0 MEDICAL FACILITIES The contractor shall provide necessary medical facilities at the project site at his own expenses for his workers. 15.0 WATER SUPPLY Main source of water at project site are the adjoining Nallahs. Water for construction and potable water of suitable quality shall have to be arranged by the contractor at his own cost. These Nallahs near the project site can be tapped for potable water after seeking permission from Irrigation & Public Health department of the State Government/Local panchayat. 16.0 MAINTENANCE OF ACCESS ROADS DURING CONSTRUCTION OF THE PROJECT 9 The maintenance of National High way (NH-22) from Kalka to Wangtoo bridge and from Sumdoh to Rongtong, the project site is being done by Himachal Public Works Department and from Wangtoo to Sumdoh by Border Road Organisation. The hill roads during monsoons and winters are prone to damages and may get blocked due to landslide etc. In general, Himachal Pradesh Public Works Department and Border Road Organisation promptly clears such roadblocks and damages. The bidder shall, however, take into account/ consideration of all such events and no time extension shall be allowed except when the road is blocked continuously for more than 10 days at a stretch and the contractor conclusively establishes that this blockage of more than 10 days has affected movement of his material/ equipment leading to disruption of his work schedule. 10