Oil Absorbent consist of natural plant fibre, from a totally renewable

advertisement

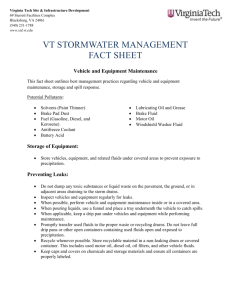

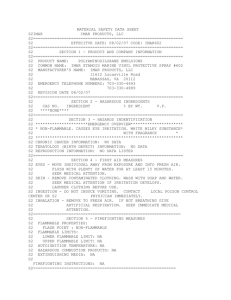

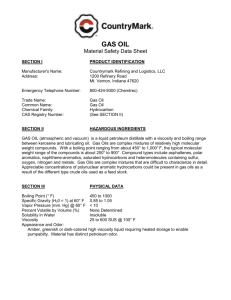

Oil Absorbent consist of natural plant fibre, from a totally renewable source, which has been chemically modified to attract oil. Introducing MultiResponse Oil Absorbent……the most cost-effective, environmentally friendly, oil spillage response product available on the planet, as those European Gulf distributors that have seen the product demonstrated will testify. Whether driven by environmental or health and safety legislation or just plain common sense every business that produces, blends or uses oil needs an effective product to deal with spillages. The market for spill response products is enormous and represents a golden opportunity for the Gulf distribution network. The Gulf MultiResponse range will be developed to provide the network with the means to take full advantage of that opportunity whilst strengthening the credibility of the Gulf brand in terms of its sensitivity to environmental issues. The first product to be launched under the MultiResponse logo is Oil Absorbent, a blend of natural plant fibres from a fully renewable source that is chemically modified to produce a high performance product that has to be seen to be believed. The natural fibre structure of the product has a unique affinity for solvents, oils and oil-based paints that delivers unequalled performance in spill containment and control. Oil is rapidly absorbed and locked into the capillary structure of the plant material, even when water is present. Once absorbed the oil cannot escape. It does not migrate even in the presence of water or under mechanical pressure. The spilled oil is totally absorbed in much less time than can be achieved with conventional absorbents. How MultiResponse Oil Absorbent compares An experiment conducted to measure the time benefit of using MultiResponse Oil Absorbent showed that it was nearly six times faster than a conventional absorbent. A spill that took 18 minutes and five applications of a "kitty litter" type product was replicated and treated. Total clean-up was achieved with one application in just three and a half minutes. After a spill area has been correctly treated with MultiResponse Oil Absorbent there is no slippery residue left behind. This significantly reduces the risk of injury to personnel. Slips, trips and falls are the most common types of accident occurring in the workplace and consequently the main source of compensation claims. How does it save money MultiResponse Oil Absorbent used in conjunction with the MultiResponse Recycling Centre can be recycled up to eight times, minimising waste product, reducing the amount of stock required and delivering massive savings in off-site waste disposal costs. The Recycling Centre is the key to major cost savings when dealing with oil spillages. It is a mobile unit that can quickly and easily be moved to the location of any spill and is equipped with everything needed to tackle the problem. With traditional absorbents all the product applied to the spill becomes, in effect, hazardous waste. With MultiResponse Absorbent the optimum amount of product is used to absorb the spill no matter how much is applied. There is no need to worry about wasted product because there won't be any! The absorbent attracts the oil which is then absorbed into the molecular structure of the plant fibre. Once absorbed, the oil is literally locked in. The spill is concentrated into solid "lumps" of material. All the absorbent that has been used is returned to the Recycling Centre. A plastic sieve in the top of the unit separates those concentrated lumps from the mass of product that has not been used to absorb the oil. The product that has not been used (and that's most of it) passes through the sieve and is ready to treat the next spill. This recycling process means that MultiResponse Oil Absorbent can be re-used up to eight times compared with the single use available from other forms of absorbent. This results in a dramatic reduction in the amount of hazardous waste produced. An experiment to compare the performance of MultiResponse Absorbent with "kitty litter" established that 1540 grams of cat litter was needed to remove 100 grams of oil. The same amount of oil was removed using just 46 grams of MultiResponse Absorbent. That's 33 times less absorbent used, 33 times less hazardous waste produced and 33 times less waste disposal cost ! How does it compare with Sand? Gulf MultiResponse Kiln Dried Sand An oil contaminated surface is quickly returned to its original condition after a single application of MultiResponse Oil Absorbent. Sand is not actually an absorbent; Particles of sand are simply coated with oil when applied to a spillage. A sand-coated surface (whether oilcontaminated or not) is actually very slippery and can contribute to slips, trips and falls. Rapid cleanup means that a work area is returned to a safe condition in minimum time. Sand requires multiple applications and meticulous recovery in order to achieve a safely usable surface. Using the MultiResponse Recycling Centre, the absorbent is filtered so that unused and part-used material is immediately available for further spill control applications. The large quantities of sand used for spill treatment are not recyclable and, due to the high bulk density of sand generate large and costly quantities of hazardous waste. MultiResponse Oil Absorbent is fast, easy, efficient, recyclable and Sand requires multiple, labourintensive applications, resulting in high Public Safety A reduction in slips, trips and falls is high on most company’s safety agendas. Speed Of Cleaning Oil spill cleanup is labour intensive: the longer the cleanup, the greater the cost. Waste Minimisation Every kilogram of a nonrecyclable cleanup of material becomes a kilogram of hazardous waste. Every kilogram of hazardous waste must be subject to costly Hazchem disposal. Overall Cost Of Cleanup The highest components in any cleanup operation are labour and waste disposal. involves minimal labour cost and minimal waste generation. labour and high waste disposal costs. What can be absorbed? It isn’t just oil that gets spilled. The MultiResponse Absorbent is ideal for spillages of any of the following: Fuels Diesel, Petrol, Aviation Fuel, Avgas, Bio Diesel, Heating Oil, Paraffin, Kerosene, Distillate, Gas Oil, Jet Fuel, Nitromethane (nitro). Oils Engine oils, Hydraulic oils, Cutting oil, Stamping oil, Pressing oil, EP Oils, Drawing oils, Broaching oils, Crude oil, Vegetable oils, Silicone Oils, Paraffin oils. Paraffinics (hydrocarbon) Regular kerosene, Odourless kerosene, Hexane, Octane, Heptane, Petrol.Diesel, Distillate, Aviation Fuel. Emulsion/semi-aqueous fluids Cutting fluids, Hydraulic fluids, Emulsion paint, Anti-Freeze, Glycols, Brake fluid. Aromatics ( Benzenoids) Benzene, Toluene, Xylenes, Aniline, Benzaldehyde, Bromobenzene, Chlorobenzenes, Nitrobenzene, Acetophenone, Benzene sulphonic acid, Anisole, Phenols. Aromatics (Non Benzenoids) Pyridine, Pyrrole, Furan,Tetrahydrofuran (THF), Pyrimidine, Thiophene Alcohols Methanol, Ethanol, Propanols, Butanols, Cyclohexanol, Octanol. Ketones Methylethyl ketone (MEK), Methylisobutyl ketone (MIBK), Acetone Miscellaneous Paints (oil based), Lactates, N-methyl-2-pyrrrolidone, Flocculant polymers, Polyacrylamides, Glycol ethers, Gamma butyrolactone, Texanol, Trichloroethane, Trichloroethylene, Acetates, Acetonitrile. Safety and Environmental Issues Summarised MultiResponse Absorbent when used correctly, leaves behind no slippery residues and can have a positive effect on slip and fall rates in industry. It is derived from renewable fibre processing residuals and can be incinerated, generating useful energy, where facilities exist, or composted using appropriate bio-augmentation techniques.