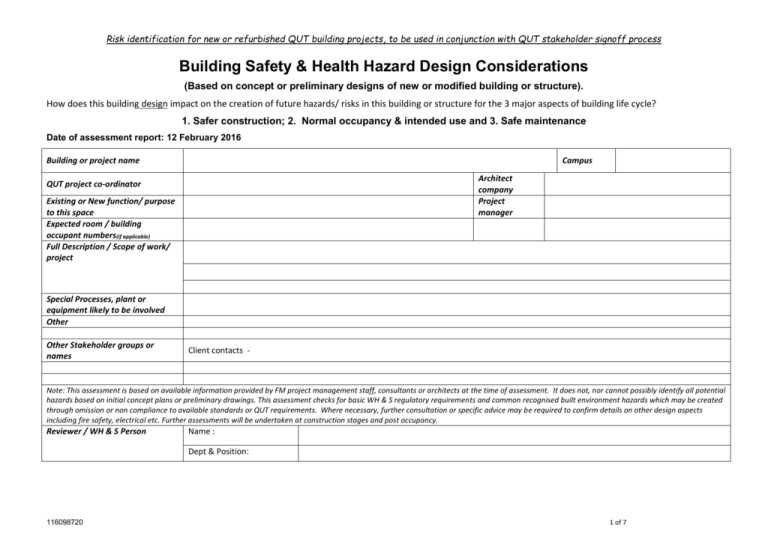

Building Safety & Health Hazard Design Considerations

advertisement

Risk identification for new or refurbished QUT building projects, to be used in conjunction with QUT stakeholder signoff process Building Safety & Health Hazard Design Considerations (Based on concept or preliminary designs of new or modified building or structure). How does this building design impact on the creation of future hazards/ risks in this building or structure for the 3 major aspects of building life cycle? 1. Safer construction; 2. Normal occupancy & intended use and 3. Safe maintenance Date of assessment report: 12 February 2016 Building or project name Campus Architect company Project manager QUT project co-ordinator Existing or New function/ purpose to this space Expected room / building occupant numbers(if applicable) Full Description / Scope of work/ project Special Processes, plant or equipment likely to be involved Other Other Stakeholder groups or names Client contacts - Note: This assessment is based on available information provided by FM project management staff, consultants or architects at the time of assessment. It does not, nor cannot possibly identify all potential hazards based on initial concept plans or preliminary drawings. This assessment checks for basic WH & S regulatory requirements and common recognised built environment hazards which may be created through omission or non compliance to available standards or QUT requirements. Where necessary, further consultation or specific advice may be required to confirm details on other design aspects including fire safety, electrical etc. Further assessments will be undertaken at construction stages and post occupancy. Reviewer / WH & S Person Name : Dept & Position: 116098720 1 of 7 Risk identification for new or refurbished QUT building projects, to be used in conjunction with QUT stakeholder signoff process 1. Foreseeable design safety hazards for Safe Construction This Design enhances: Performance considerations/ issues Details (rooms/ areas] Comments Action needed Sufficient access / space around new section or building for use of cranes, EWP’s, scaffolding etc during construction Construction workers will be protected from / proximity to HV electrical, high risk energy sources (new capital wks projects mostly) 1. Safer construction methods Traffic / pedestrian risks are minimised for planned loading & unloading for construction vehicles Neighbourhood construction considerations eg: childcare, school vicinity, site location Roof design will reduce /eliminate the risk of falls from height during construction Sufficient space is planned for access & to install / erect major fixed plant or equipment eg: fixed non maintenance structures or specialised equipment, plant rooms/ booster pumps Floor loading design has been assessed by engineer to be able to accommodate heavy equipment / plant to be installed in foreseeable future Presence of hazardous substances which impact on construction work eg: asbestos, SMF, has been checked. 116098720 2 of 7 Risk identification for new or refurbished QUT building projects, to be used in conjunction with QUT stakeholder signoff process 2. Foreseeable design safety hazards for Safe Normal Use by Occupants This Design enhances: Performance considerations/ issues Details (rooms/ areas] Comments Action needed General Access & Egress Floor surfaces – even/level with no sudden changes in levels – floor coverings non slip , suitable for levels of traffic use and suitable for type of tasks to be done Stairs – edge delineation, slip resistant (SR) stair nosing, construction / design suitable for intended use, handrails * Mandatory as per WH & S Regulation 2. Normal intended occupant use AV set up – viewing distances and angle principles are implemented to optimise experience and teaching outcomes. As per FM DSG Separation of vehicles from pedestrians when bldg in normal use (external & internal) where mobile plant eg: pallet jacks are used Amenities considerations Dining facilities are provided where type of work is hazardous and eating in work area is unsafe: As per WH & S Reg- Sched 8C, Part 3 , div 2. Drinking water availability reasonable – for nos of staff and location – As per WH & S Reg Sched 8 C Part 3 Div 5 Hand washing facility planned suitable for bldg class and staff nos. As per WH & S Reg Sched 8 C Part 3 Divis 2 , Sub div 2 Toilet requirements / location & nos are satisfactory : As per WH & S Reg Sched 8 C Part 3 Div 2 , Sub div 2 Showers are provided where work tasks pose risk if unable to shower after exposure. As per WH & S Reg Sched 8 C Part 3 Divis 6 Dressing rooms are provided if work requires persons to change – As per WH & S Reg Sched 8 C Part 3 Divis 4 116098720 3 of 7 Risk identification for new or refurbished QUT building projects, to be used in conjunction with QUT stakeholder signoff process This Design enhances: Performance considerations/ issues Details (rooms/ areas] Comments Action needed Lighting – natural or artificial is satisfactory to suit conditions, nature of work, location and times. Complies with AS 1680 (Interior lighting) or equiv to QDC provisions. See lighting plan and check with electrical projects coordinator Check that chosen wall colours adjacent to internal or other internal pedestrian areas, reflect sufficient light & luminance . Ergonomic considerations Reception counters , workstations & other joinery is designed to consider: functions/ task requirements vs standards, consultation with user group & HSAS (For workstations & reception areas, refer to specific principles on design considerations based on task requirements etc) - Working Height & widths of desktops or counters - Seating - Storage - Desk space to perform tasks Work spaces designed for likely workflow / load considerations, peak times eg: enrolment periods, high administration periods. As per WH & S Reg Sched 8F Part 1 Div5 116098720 4 of 7 Risk identification for new or refurbished QUT building projects, to be used in conjunction with QUT stakeholder signoff process This Design enhances: Performance considerations/ issues Details (rooms/ areas] Comments Action needed Shelving heights optimized to minimise risks of falls from heights during access; overreaching, manual handling processes etc when loading shelves or stacks Window positioning and solar glare/ desk / AV projection etc to computer screens/ furniture position– glare 2. Normal intended occupant use * Mandatory as per WH & S Regulations North or west facing building walls / windows – impact on heat radiation, glare into office – window treatments – internal or external Potential Airborne contaminants– short & long term ( i.e.: on initial occupation and then ongoing occupancy] * Resource areas containing MFCs or Photocopiers, printers etc are separated from workstations/ staff, and /or appropriately ventilated through mechanical AC or natural ventilation systems. – Extracted or diluted. Sched 8 E Part 2 Div 1 Low VOC wall paints and associated products area selected for internal use to minimise risk to susceptible individuals, staff or students- As per Haz Subs Regulation – as per FM Design Standards and Guidelines. Low emission carpets (recycled or low emission) selected to reduce indoor air quality impact. as per FM Design Standards and Guidelines. Selection or presence of opening windows for persons not wanting AC or in emergency or contamination event. [desirable requirement only] Additional Comments: 116098720 5 of 7 Risk identification for new or refurbished QUT building projects, to be used in conjunction with QUT stakeholder signoff process 3. Foreseeable design safety hazards for Maintenance or Service Activities This Design enhances: Performance considerations/ issues Details (rooms/areas] Comments Action needed Falls from height risks minimised Safe Access to lighting fixtures to change fittings , bulbs eg: not over stairway voids, high ceilings or roofs, balconies, roof tops etc – Can we access this safely?? Mandatory as per WH & S Regulations 3. Safe Maintenance & Service Activities Safe Access to plant rooms – locked, lighting- Who will have access? Access to roof tops – safe access to within safety zone, minimised manual handling of material, equipment tools, locked, signage How will we safely access the roof? Roof safety measures – parapets, pitch, walkways, What will help achieve safe access? Selection of appropriate roof safety systems to meet AS 1891. Fall restraint / fall arrest to match existing height safety attachment devices. Placement of plant within roof safety zones. Window cleaning methods/ access is considered Gutter cleaning methods/ access is considered Hazardous substances required for use in maintenance through design Use of hazardous substances minimised in cleaning in selection for floors and other surfaces. 116098720 6 of 7 Risk identification for new or refurbished QUT building projects, to be used in conjunction with QUT stakeholder signoff process This Design enhances: Performance considerations/ issues Details (rooms/areas] Comments Action needed Creation of new high risk maintenance areas / tasks by design Confined space creation is minimised by good design. Dirt or rubbish collection points are accessible, easy to maintain. Rubbish /waste disposal systems are considered as part of good design. nil Manual handling risks are minimised – bin styles, emptying, transport Additional comments: 116098720 7 of 7