Date/s

advertisement

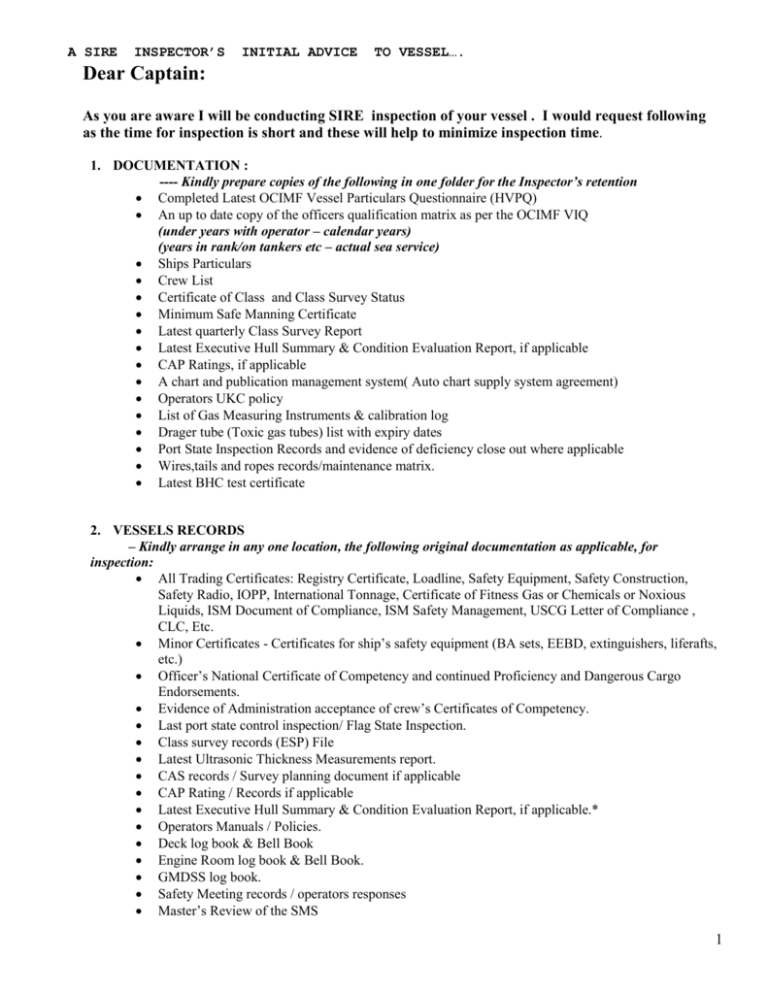

A SIRE INSPECTOR’S INITIAL ADVICE TO VESSEL…. Dear Captain: As you are aware I will be conducting SIRE inspection of your vessel . I would request following as the time for inspection is short and these will help to minimize inspection time. 1. DOCUMENTATION : ---- Kindly prepare copies of the following in one folder for the Inspector’s retention Completed Latest OCIMF Vessel Particulars Questionnaire (HVPQ) An up to date copy of the officers qualification matrix as per the OCIMF VIQ (under years with operator – calendar years) (years in rank/on tankers etc – actual sea service) Ships Particulars Crew List Certificate of Class and Class Survey Status Minimum Safe Manning Certificate Latest quarterly Class Survey Report Latest Executive Hull Summary & Condition Evaluation Report, if applicable CAP Ratings, if applicable A chart and publication management system( Auto chart supply system agreement) Operators UKC policy List of Gas Measuring Instruments & calibration log Drager tube (Toxic gas tubes) list with expiry dates Port State Inspection Records and evidence of deficiency close out where applicable Wires,tails and ropes records/maintenance matrix. Latest BHC test certificate 2. VESSELS RECORDS – Kindly arrange in any one location, the following original documentation as applicable, for inspection: All Trading Certificates: Registry Certificate, Loadline, Safety Equipment, Safety Construction, Safety Radio, IOPP, International Tonnage, Certificate of Fitness Gas or Chemicals or Noxious Liquids, ISM Document of Compliance, ISM Safety Management, USCG Letter of Compliance , CLC, Etc. Minor Certificates - Certificates for ship’s safety equipment (BA sets, EEBD, extinguishers, liferafts, etc.) Officer’s National Certificate of Competency and continued Proficiency and Dangerous Cargo Endorsements. Evidence of Administration acceptance of crew’s Certificates of Competency. Last port state control inspection/ Flag State Inspection. Class survey records (ESP) File Latest Ultrasonic Thickness Measurements report. CAS records / Survey planning document if applicable CAP Rating / Records if applicable Latest Executive Hull Summary & Condition Evaluation Report, if applicable.* Operators Manuals / Policies. Deck log book & Bell Book Engine Room log book & Bell Book. GMDSS log book. Safety Meeting records / operators responses Master’s Review of the SMS 1 SQMS Audit reports / corrective action & close out evidence. Near Miss reports, accident investigation reports etc. Hot Work / Enclosed Space Entry / Working Aloft Permits etc Officers and Ratings record of rest hours. Cargo Tank / Ballast tank / void space gas test records Records of Rest periods / working hours. Drug and Alcohol Policy and records of unannounced testing by Shore / Ship. Emergency Towing Appliances certificate / manual. Approved Manuals – Stability, Damage Stability, IGS, COW, SBT, CBT, ODME. Approved SOPEP and OPA 90 Manuals. SOLAS Training Manual / Fire Training Manual / Fire Safety Operational Booklet Class Approved Procedures and Arrangements Manual for Chemical and Gas carriers.( if applicable) Lifting gear register / Cargo Gear Register / Lifting appliances test / inspection records (including E/R lifting devices) Loading computer test records / Class approval PMS records including class approval certificate. Mooring equipment certificates (ropes, wires, shackles, bow stoppers, brake test, mooring tails) / Mooring equipment inspection records Test Certificates and Records of Mooring Wires and Ropes, Mooring Winch brakes, BHC test, Cargo Hoses, Bow Chain Stoppers etc LSA / FFA Maintenance records Drill records Lifeboat “on-load” release mechanism test / Brake test record / Inspection records Garbage Record Book and Garbage Management Plan. Ballast Water Management Plan and records of exchanges carried out. Tank Cleaning Records Stainless Steel Cargo Tank Maintenance Records (if applicable) Cargo Hose Certificates (if applicable) Fuel Oil analysis reports. Lube Oil / Hydraulic Oil analysis reports Engine Room equipment test and inspection records. Deck / Cargo Equipment test and inspection records. LIST OF DATES – Kindly fill in the dates as applicable in the sheet below : ITEM Date/s Date Operator assumed responsibility of vessel : IMO number of the management company: Date of Operators last visit : Date of last internal audit : Number of NC’s : Date NC’s closed out : Date of last external audit : Number of NC’s : Date NC’s closed out : Date of expiry of the certificate of class : Date of last dry dock (from – to ) Date of departure from the last class accredited dry dock : 2 Date of last class annual survey : Date of last class intermediate survey : Date of last inspection of Cargo Tanks : Frequency : Ballast Tanks : Frequency : Date of last shore based D & A test : Frequency : Date of last shipboard alcohol test : Frequency : Date the magnetic compass was adjusted : Date of the deviation card : Date of expiry of : Hand flare signal : Rocket Parachute signal : Man overboard marker : Smoke signal : Line throwing apparatus : Last service dates of FFA / LSA appliances by shore representatives. SCBA : EEBD : ELSA : Lifeboat Air bottles : SCBA Compressor Air Quality Check : Portable Fire Extinguishers : Fixed CO2 System : Fixed Halon System: Fixed DCP System : Foam Sample Analysis : EPIRB : Gyro Service : Date of expiry of the EPIRB battery : Annual Press Test (as applicable) Date of expiry of the SART battery : Date the VDR / S-VDR was last serviced : Last abandon ship drill : Date when the last time Port lifeboat lowered / maneuvered in the water : Date when the Last time Starboard lifeboat lowered / maneuvered in the water : Date of Last time Rescue boat lowered / maneuvered in the water : Date of Last Boat / Davit service by authorized / approved service company : Date of last davit winch brake test : Date when lifeboat falls were turned end to end : Date when liferafts were last serviced : Date of expiry of the HRU’s : 3 Last Man Over Board Drill : Last Line Throwing Apparatus (LTA) Familiarization / Drill : Last Emergency Towing Arrangement (ETA) Familiarization / Drill : Last fire drills: Last SOPEP drill: Last emergency steering drill: Last emergency procedures drill : Type of drill : Frequency of shore lab test of bunker fuel oil: Last test of bunker fuel: Frequency of shore lab test of L/O: Last done: Frequency of shore lab test of hydraulic oil: Last done: Last pressure test of cargo pipelines : est pressure : Frequency : Last pressure test of the cargo steam heating sytem: Test Pressure: Frequency: Last pressure test of bunker pipelines : Test pressure : Frequency : Last cargo hose test and test pressure: Test pressure : Frequency : Last COW line pressure test : Test pressure : Frequency : Last Port State Control Inspection : Port : Observations / Deficiencies : Date Observations / Deficiencies cleared out: Last NTM received on board and date: Voyage charts & Publications corrected till : All other charts & publications corrected till : Date when the pumproom gas detection system was last calibrated : Frequency : Pre-Set Level of LEL% & H2S (as applicable) Date when the pumproom bilge high level alarm was last tested : Frequency : Date when the Forepeak store (Bosun Store)bilge high level alarm (if fitted) was last tested : Frequency: 4 Date when the pumproom fire dampers were last tested : Frequency : Date then the pumproom flooding dampers were last tested : Frequency : Date cargo sea chest valve testing arrangement was last tested : Pressure : Frequency : Date ballast lines (if passing through cargo tanks) were last tested: Pressure: Frequency: Date of testing of the detection system fitted to monitor noncargo spaces : Frequency : Date non-cargo spaces were last monitored : Frequency : Date portable gas instruments were last calibrated by shore : Frequency : Date portable gas instruments were last calibrated by ship : Frequency : Date of test of P/V v/v’s : Frequency : Does v/l have a testing kit on board : Date of last inspection / cleaning of P/V v/v’s : Date all flame screens were last inspected : Date the loading computer was last tested (on board) : Frequency : P&I club full name: SOPEP/SMPEP Approval : Issue date: Damage Stability shore assistance: VRP Approval (if applicable) : COW Manual Approval Date : ODME Manual Approval Date : Trim & Stability Manual Approval Date : P & A Manual Approval Date : Operation Manual (if applicable) Date : Loading Manual (if separate from the Trim & Stability Manual) Date : Damage Stability Manual Approval Date : Vapor Emission Control System Manual Approval Date : VOC management plan: Ballast water management plan approval date: Last ballast water exchange date and method: Inert Gas System Manual approval Date : 5 Last safety committee meeting : Frequency : Operators Comments Received : Date of last Incident report : Date of last Accident report : Date of last near miss report : Master’s Review of The SMS : Frequency : Last ODME test : Frequency : Date mooring winches last tested (BHC / BRL) : Frequency : Date of last IG check valve overhaul : Frequency : Date fixed fire detection system was last tested (alarm): Frequency : Date the accommodation & vent fan trips were last tested : Frequency : Date the engine room & vent fan trips were last tested : Frequency : Date of last Emergency generator test : Frequency : Date of last Emergency generator on-load test : Frequency : Date engineers call alarm was tested : Frequency : Date of last Engine local maneuvering station test : Frequency : Last bunkering date: Last bunker sample analysis: Lubricant oil sample analysis frequency: Last done: NB : Do ensure that records are available to quantify the above dates. Please note that the above list is not comprehensive and I may require other information as the inspection progresses if I feel it necessary. 3. Equipment Testing : During the course of the inspection, I will be testing various equipment, provided that this testing does not interfere with the vessel’s routine operation and does not contravene any terminal regulations. 6