Mandatory Experiment 7.6

advertisement

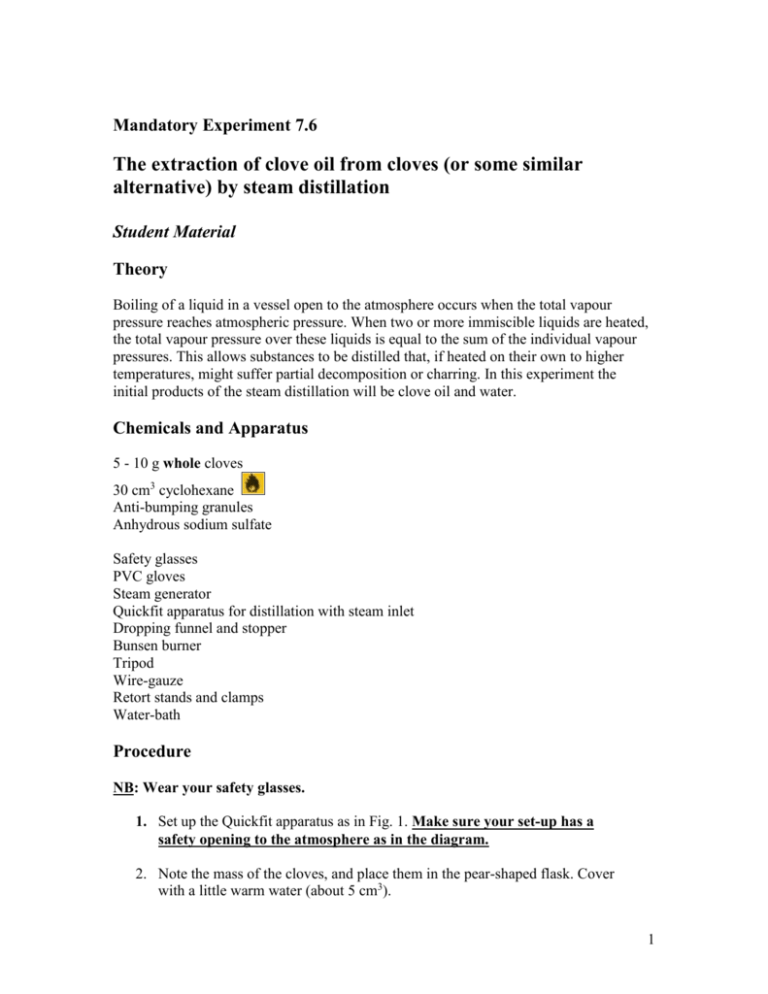

Mandatory Experiment 7.6 The extraction of clove oil from cloves (or some similar alternative) by steam distillation Student Material Theory Boiling of a liquid in a vessel open to the atmosphere occurs when the total vapour pressure reaches atmospheric pressure. When two or more immiscible liquids are heated, the total vapour pressure over these liquids is equal to the sum of the individual vapour pressures. This allows substances to be distilled that, if heated on their own to higher temperatures, might suffer partial decomposition or charring. In this experiment the initial products of the steam distillation will be clove oil and water. Chemicals and Apparatus 5 - 10 g whole cloves 30 cm3 cyclohexane Anti-bumping granules Anhydrous sodium sulfate Safety glasses PVC gloves Steam generator Quickfit apparatus for distillation with steam inlet Dropping funnel and stopper Bunsen burner Tripod Wire-gauze Retort stands and clamps Water-bath Procedure NB: Wear your safety glasses. 1. Set up the Quickfit apparatus as in Fig. 1. Make sure your set-up has a safety opening to the atmosphere as in the diagram. 2. Note the mass of the cloves, and place them in the pear-shaped flask. Cover with a little warm water (about 5 cm3). 1 Fig.1 3. Place an adequate supply of water in the steam generator, connect it to the rest of the apparatus and set it to boil. If Quickfit apparatus is used for steam generation make sure that you use anti-bumping granules in the steam generator. 2 4. If the level of the boiling water in the steam generator falls too low, the system will not work smoothly. Remove the heat, carefully loosen the safety valve, and top up the steam generator with hot water. Reconnect everything and resume heating. 5. Collect the distillate. It should have a pale milky appearance. Using the dropping funnel as a receiver at this point will facilitate the next stage of the separation. 6. After 20 to 30 minutes disconnect the steam generator to avoid the possibility of suck-back problems and turn off the heat under it. You will have probably collected between 40 and 50 cm3 of distillate. Note the smell of the distillate. Questions relating to the experiment (1) Explain why the clove oil could not be distilled directly from the cloves. (2) Explain the principles by which steam distillation works. (3) Suggest a reason why the clove oil is much more soluble in non-polar solvents (than in water). 3 Teacher Material Cloves are the dried buds of a tree that is cultivated primarily in Zanzibar and Madagascar. The tree produces abundant clusters of small red flower buds that are gathered before opening and are dried to produce the dark-brown, nail-shaped spice clove. Whole and ground cloves are popular food seasonings and account for the use of half the world production of cloves. The other half is ground and used in the manufacture of a type of cigarette popular in Indonesia. Almost 20 percent of the clove's weight is essential oil, obtained by distillation and used in perfumes, blends of spices, medicines, and sweets. Clove oil is a powerful antiseptic, and is also used as a local anaesthetic for toothache. A 100 cm3 flask should be used for holding the cloves as it eliminates the need for a water trap between the steam generator and the flask with the cloves. Using a larger flask allows for it to be filled up to some extent with water - without having to dismantle the apparatus and empty out excess water. After steam starts to come over from the steam generator, the Bunsen burner can be moved over occasionally to heat the flask containing the cloves. If this is not done, the flask should be insulated (e.g. with aluminium foil) to prevent an undue amount of water condensing in the flask. The setting up of the apparatus for this experiment will take the students quite some time as it is quite difficult to align all the connections properly, The Quickfit steam generator flask (150 cm3) should contain about 100 cm3 of water to start with. If during the experiment, the level of water drops too low, the steam distillation will not work smoothly. If this happens, add some hot water to the steam distillation flask from a kettle of boiling water. The bottom of the safety tube should be well below the water surface in the steam generator, but not touching the bottom of the flask. The use of Bibby clips to hold the parts of the assembled Quickfit apparatus together is recommended. It is advisable to have a supply of boiling water available at the start of the experiment. This may make it possible for students to complete the experiment within a double period. 4 In the diagram of the steam distillation apparatus, the separating funnel shown is only necessary if the optional extension work is to be done. Otherwise a beaker or conical flask is more convenient for collecting the distillate. It is inadvisable to use powdered cloves. If they are used, the steam inlet may become blocked. Alternatives to the quickfit steam generator include a 1 litre copper steam generator with a built in water gauge, and a large Pyrex conical flask. A glass steam generator is preferable, as it allows students to see what is happening in the generator. Students are expected to know how a pure clove oil could be isolated by solvent extraction (see extension work). A small scale or semi-micro method is available for those schools in possession of BASF mini-labs or similar equipment. Increased safety and reduced waste and shorter time required for the practical are three of the advantages of this alternative method. Extension Work Separation of clove oil from water The procedure is as follows: 1. Disconnect the dropping funnel from the rest of the apparatus. 2. Add about 8 cm3 of cyclohexane to the distillate in the dropping funnel. 3. Stopper the dropping funnel and shake the mixture. Release any pressure build-up carefully after each shake by inverting the dropping funnel while holding the stopper and slowly opening and shutting the tap. 4. Run the lower aqueous layer off. Collect the top layer - this contains the clove oil and the cyclohexane. 5 5. Dry the organic layer by shaking with anhydrous sodium sulfate in a conical flask. If possible, allow to stand overnight, before removing the solid by filtration or decanting. 6. Separate the more volatile cyclohexane from the clove oil by placing the mixture in a small beaker (whose mass is known) on a water-bath in a fume cupboard. The cyclohexane evaporates, leaving the clove oil behind. (Note that if the cyclohexane is to be distilled off it will boil at 81 0C.) Prepare the students for a very low yield of clove oil. 7. Note the smell of the clove oil. Do not allow the clove oil to come in contact with your skin. 6 Alternatives to cloves as a starting material for this experiment include the skin of an orange, lemon or grapefruit. Something slightly more adventurous would be (a) the resin extruded by conifer trees or (b) the dried fermented seed pods of the vanilla orchid. Preparation of reagents None required for this experiment. Quantities needed per working group Whole cloves 5 to 10g Cyclohexane 10 cm3 Safety considerations Safety glasses must be worn. The use of heat-resistant gloves is recommended . Hair should be tied back if necessary. Steam can cause serious burns. Make sure that each experimental set-up is firmly clamped with the two safety openings in place. The first safety valve is in the Quickfit steam generator. The second safety valve is part of the delivery tube attached to the end of the Liebig condenser. Suck-back might happen if the heat is removed from the steam-generator. Make sure the students disconnect the apparatus before turning off the heat. Chemical hazard notes One of the major components of clove oil is eugenol, an aromatic compound that can burn skin. Gloves should be worn when handling the product of the experiment. Cyclohexane is volatile and flammable. Sodium sulfate is an irritant to eyes. 7 Disposal of wastes Any residual cyclohexane may be allowed to evaporate in a fume cupboard. Solid residues can be washed with water and bagged for landfill waste. Suggested answers to student questions (1) Explain why the clove oil could not be distilled directly from the cloves. Clove oil contains component molecules whose boiling points are quite high. Heating them to their boiling point would be destructive. (2) Explain the principles by which steam distillation works. Some organic compounds are immiscible with water. Usually these compounds have a low vapour pressure. After mixing them with water, however, the mixture will distil when the sum of the two vapour pressures reaches atmospheric pressure. It follows, then, that this must happen below the boiling point of water. This process is known as steam distillation. (3) Suggest a reason why the clove oil is much more soluble in non-polar solvents (than in water). The component molecules found in clove oil are often relatively non-polar and will therefore be more soluble in the non-polar solvent than in water. 8