Use of an Optically Active Coating System will ensure that the

advertisement

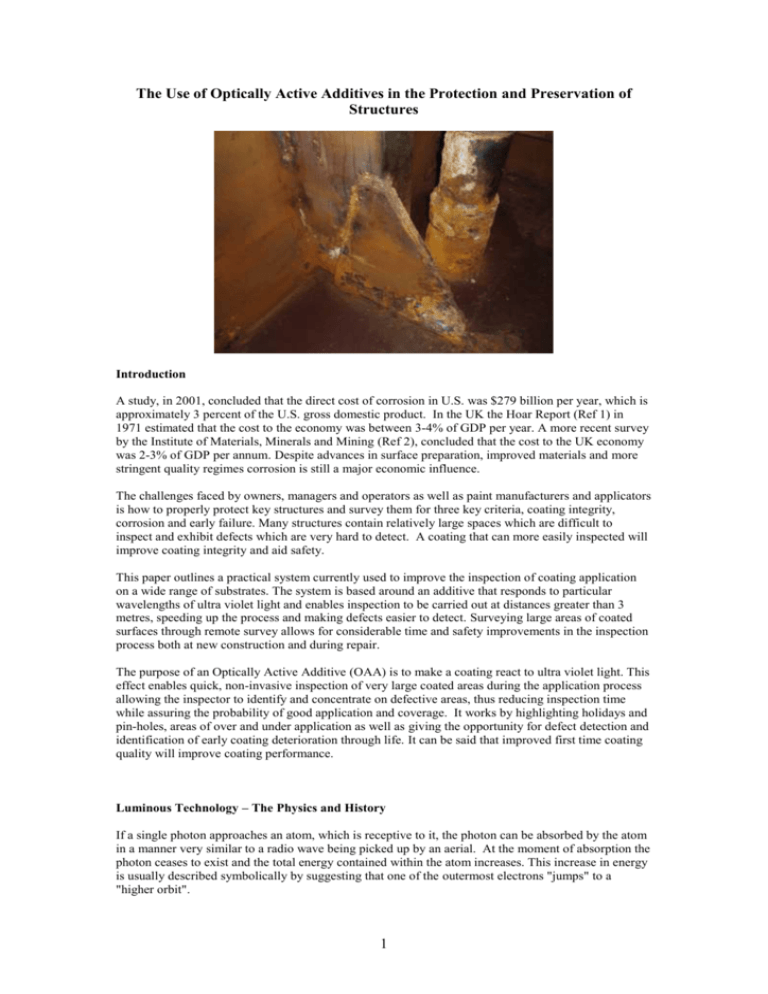

The Use of Optically Active Additives in the Protection and Preservation of Structures Introduction A study, in 2001, concluded that the direct cost of corrosion in U.S. was $279 billion per year, which is approximately 3 percent of the U.S. gross domestic product. In the UK the Hoar Report (Ref 1) in 1971 estimated that the cost to the economy was between 3-4% of GDP per year. A more recent survey by the Institute of Materials, Minerals and Mining (Ref 2), concluded that the cost to the UK economy was 2-3% of GDP per annum. Despite advances in surface preparation, improved materials and more stringent quality regimes corrosion is still a major economic influence. The challenges faced by owners, managers and operators as well as paint manufacturers and applicators is how to properly protect key structures and survey them for three key criteria, coating integrity, corrosion and early failure. Many structures contain relatively large spaces which are difficult to inspect and exhibit defects which are very hard to detect. A coating that can more easily inspected will improve coating integrity and aid safety. This paper outlines a practical system currently used to improve the inspection of coating application on a wide range of substrates. The system is based around an additive that responds to particular wavelengths of ultra violet light and enables inspection to be carried out at distances greater than 3 metres, speeding up the process and making defects easier to detect. Surveying large areas of coated surfaces through remote survey allows for considerable time and safety improvements in the inspection process both at new construction and during repair. The purpose of an Optically Active Additive (OAA) is to make a coating react to ultra violet light. This effect enables quick, non-invasive inspection of very large coated areas during the application process allowing the inspector to identify and concentrate on defective areas, thus reducing inspection time while assuring the probability of good application and coverage. It works by highlighting holidays and pin-holes, areas of over and under application as well as giving the opportunity for defect detection and identification of early coating deterioration through life. It can be said that improved first time coating quality will improve coating performance. Luminous Technology – The Physics and History If a single photon approaches an atom, which is receptive to it, the photon can be absorbed by the atom in a manner very similar to a radio wave being picked up by an aerial. At the moment of absorption the photon ceases to exist and the total energy contained within the atom increases. This increase in energy is usually described symbolically by suggesting that one of the outermost electrons "jumps" to a "higher orbit". 1 This new configuration the atom finds itself in is unstable and the tendency is for the electron to fall back to its lower orbit or energy level, emitting a new photon as it goes. The entire process may have taken no more than 1 x 10-9 seconds. The result is the same as with reflective colour but because of the process of absorption and emission the substance emits a glow.According to Planck (Ref 3), the energy of each photon is given by multiplying its frequency in cycles per second) by a constant (Planck's constant, 6.62617 x 10-27 erg seconds). It follows that the wavelength of a photon emitted from a luminescent system is directly related to the difference between the energy of the two levels involved. In terms of wavelength this relationship is an inverse one so that if an emitted photon is to be of short wavelength (high energy) the gap to be jumped by the electron must be a large one. The numerical relationship between these two aspects is the inverse of Planck's constant. Chemical engineers are able to devise molecules with these energy levels in mind, so as to adjust the wavelength of the emitted photons to produce a specific colour. In 1609, Brand discovered a substance, which glowed in air and called it phosphorous. This gave rise to the term phosphorescence. Scientific investigation of inorganic phosphors only began in the 19 th Century. Work was carried out by Becquerel, Lenard, Stokes and Verneuil amongst others. Verneuil, in 1887, identified the contribution which heavy-metal impurities had in the luminescence of inorganic materials (Ref 4). There are a variety of types of luminescence, the significant one for coating purposes is Photoluminescence. This process can be divided into 2 main categories: Fluorescence - where the interval between absorption and emission is short say less than one ten thousandth of a second (i.e. there is no appreciable afterglow). Luminescence - where the interval between absorption and emission is long (potentially days) and there is an appreciable afterglow. Both processes are used in Optically Active Coating Systems (OACS) and can be formulated to give specific responses to UV Light. Therefore a range of Optically Active Coatings can be developed to almost any colour requirements. Under Ambient Light Under UV Light Inorganic vs Organic OAA’s There a two common types of Optically Active Additives available commercially, inorganic and organic. 2 Inorganic OAA’s exhibit large particle size: 5 – 10um (no mobility), are light stable, can have a choice of colours, are useful in a wide range of coating systems, and are more expensive. Organic OAA’s exhibit low addition level, are soluble in solvents and organic liquids (mobile), are blue under UV (same colour as lint, oil, grease etc), can fade quickly, have limited use in a range of coating systems and are less expensive. They are also indistinguishable from old coat-tar epoxy type coatings still seen on some structures and vessels. Figure 1 shows two coatings each containing OAA, inorganic on the right and organic on the left. Each is illuminated by Ultra Violet light. Figure 2 shows each coating after being overcoated by a top coat also illuminated by Ultra Violet light. Figure 3 shows each coating after 25 minutes. The organic OAA can be seen migrating through the top coat when viewed under Ultra Violet light. The effect can be seen within a very short period of time (minutes) or can take a longer time to develop (weeks) as with solvent-free systems 3 Solvent-free coatings to MIL-PRF-23236C (Ref 5)with no OAA (centre on metal panel), with inorganic OAA (left on panel) and organic OAA (right on panel) were cured for 28 days then overcoated with another similar solvent-free coating but with no OAA. After a further 28 days the organic OAA (right on panel) had migrated through into the second coat. The effect is more clearly seen in the following image. It is obvious that the use of organic OAA’s can, in some instances, show false indications of low film build. Similarly, the effect shown when oil, grease and other contaminants react with UV can give false indications. 4 Both inorganic and organic types react to UV light in the same way. They convert the wavelength of the UV which is then reflected in the visible range. Organic OAA’s tend to convert into the blue visible area of wavelength, inorganic OAA’s can convert into a range of colours. As blue is the natural emission colour for a wide range of materials - grease, oil, fibres etc – there can be a tendency for the detection of false positives if organic OAA’s are used. It is best to use a non-natural emission colour such as yellow/green. This effect is possible using inorganic types. Excitation and Emission Wavelengths of Typical OAA Traditional Coating and Inspection Techniques At present a typical specification for coating would be as follows: 2 coats of 125 m Dry Film Thickness (DFT) of an epoxy based anti-corrosive, the system being of the “hard” type. In addition 2 stripe-coats of paint can be applied on edges. These edges are normally required to be rounded using mechanical means during construction. Single coat systems with very high dry film thickness are also available. The inspection regime adopted is as follows: - Inspection of surface cleanliness and degreasing before commencement of surface preparation. - Inspection post surface preparation to ensure correct surface cleanliness has been achieved. - Inspection of WFT during application - Inspection of DFT of the first coat of the system application - Inspection of stripe coating - Inspection of final coat and acceptance. This process is therefore labour and time intensive. Inspection is carried out by visual means, wet and dry film thickness measurement, and by low voltage wet sponge testing. The drying time between coats dictates throughput and surface inspection can take up to 15% of the total coating time. Even with this level of inspection failure is still commonplace from factors such as: - Poor coating specification 5 - Poor surface preparation Over application Under application Exceeding the coating envelope The inspection process is reliant on the need for close contact of the structure, making 100% inspection difficult if not impossible to achieve. A technique has been developed that enables better, faster, easier and a more thorough inspection of the coating. The technique is based on the use of Optically Active Additives (OAA’s) in paints that react to UV light and enable coating defects to be identified at a distance and hence improve the quality of the inspection process while offering reduced inspection time. The Coating Manufacturing Process An Optically Active Additive (OAA) is added to existing and established coatings, as manufactured by the major paint companies, at a low level (1%) which has no appreciable effect on the coating performance. The OAA is incorporated by the paint manufacturer during the paint manufacturing process. Testing to date by all the major manufactures indicates that there is no degradation in coating performance. The addition of an OAA is similar in effect to that of a coloured pigment addition. The Coating and Inspection Method The surface to be coated is cleaned and inspected in the normal manner. The first coat containing the optically active additive is applied using a UV light to monitor application when wet. As the technique is optical wet inspections are possible. Missed areas can be ‘repaired’ at this stage. Once dry, the first coat is inspected using the same UV light. The procedure of inspection should follow normal inspection procedures carried out by an inspector. However, as the light will detect defects such as pinholes at a distance of up to 3m, large areas can be scanned quickly, without the need for close access. This considerably reduces inspection time. The benefits increase as the inspector become familiar with the system and becomes more confident with the results from the system. Any areas of under application are readily identified and remedial work carried out as appropriate. The second coat containing no optically active additive is applied and the inspection process repeated. At the inspection of the first coat, areas of under thickness or defects will show up as “black” spots or areas of decreased glow under the UV light. Areas of high film build are brighter than areas of low film build. At the inspection of the second coat areas that are holidays will show the original first coat as bright areas or pin-holes through the second coat. Over and under application of the second coat are also detectable under UV. Through life of the system, coating degradation can be easily and quickly monitored and captured digitally to record the system performance allowing for easier repair. General The use of the OAA in a coating gives an indication of DFT. It will highlight to an inspector areas of low and high DFT, making them much easier to spot from a distance. Under the UV lamp, most defect areas should be visible at a distance of at least 3 metres depending on ambient lighting conditions. In general a smooth uniform surface of equal luminous intensity (glow) should be achieved and is a sign of a good application. A non-uniform (patchy) appearance indicates a variety of possible defects normally varying film build. The use of the OAA does not eliminate the need for normal inspection processes but serves to readily identify areas of poor application thus enabling a faster inspection process. OAA and the IMO The recent International Maritime Organization resolution (Ref 6) is a performance standard for protective coatings for dedicated Seawater Ballast Tanks (SWBT) and is designed to control the quality of ballast tank coatings including: Surface preparation 6 Ventilation Coating quality Coating application Inspection Preparation of Coating Technical File The regulation specifically states that while coating sea water ballast tanks: “Any defective areas, e.g., pin-holes, bubbles, voids, etc., shall be marked up and appropriate repairs effected. All such repairs shall be re-checked and documented.” While the resolution defines how to check and where to check dry film thickness (dft), there is no definition for determining the presence of pin-holes, holidays, etc. Current practice would be to use low voltage wet sponge testing techniques. However, at a rate of 10 m2 per minute as defined by NACE Standard RP0188-99 (Ref 7), it is not practicable to use this method when examining the SWBT’s of a VLCC with total surface areas in excess of 300,000 square meters. It goes without saying then that if the coating is not well applied or well inspected at the new build stage the coating system will fail prematurely. To re-coat this 300,000 m2 area, with a normal repair shipyard output capacity of 1,000 m2 per day means 300 days of work. The cost including off-hire loss could be in the range of $28 million ($13 million for coating, and $15 million in off-hire) (Ref 8). The much more accurate and faster inspection rate available using OAA technology makes accurate inspection of this area of coating a practical and economic possibility (Ref 9). Typical Defects Found using OAA Grey First Coat showing through Poorly Applied Second Coat 7 Poorly Coalesced Second Coat Microcracking Wrinkling (First Coat not Fully dry) Benefits In practical use it has been shown that this system offers the following benefits: 8 Improved accuracy of inspection Reduced inspection time during application (up to 50% time savings) Improved application resulting in a reduction in rework Reduction in the amount of paint used leading to lower VOC emissions Ease of recording defects for future comparison or remote off-site assessment Potential to improve the quality of the workmanship and hence future first time quality of the application Detection of coating removal Ease of inspection of the coating by unskilled personnel Ease of determining early signs of coating failure during coating life Conclusions Use of an Optically Active Coating System will ensure that the application process both at new construction and during repair is carried out defect free with full coverage of all areas. As the coating system is defect free the overall quality of the system will be improved and will ensure a longer period of maintenance free service. If at first application there are no defects re-work will be kept to a minimum. This will reduce re-work time and reduce paint usage. The reduction in paint usage will reduce VOC emission from the site. Easier and improved inspection will allow for identification of defects and repair to the coating system at an early stage preventing more expensive repair as the damage increases through time. The use of Optically Active Additives is now well established and SSPC have recently issued a Technology Up-date highlighting the technique (Ref 10). References: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Report by CC Technologies Laboratories, Inc. to Federal Highway Administration (FHWA), Office of Infrastructure Research and Development, Report FHWA-RD-01-156, September 2001 Institute of Materials, Minerals and Mining, London, SW1Y 5DB, UK Resnik and Halliday, Physics, Toppan Company, Japan. Newton Harvet. A History of Luminescence (until 1900), Academic press New York 1996. Department of Defense Single Stocking Point for Specifications and Standards (DoDSSP), Standardization Document Order Desk, 700 Robbins Avenue, Bldg. 4D, Philadelphia, PA 19111-5094 IMO Resolution MSC.215(82) adopted 08-12-2006 www.imo.org NACE Standard RP0188-99, Houston, NACE International Johnny Elliasson, Stolt-Nielsen Transportation Group B.V., Dragos Rauto, Intertanko Buckhurst and Bowry – “An Optically Active Coating System for Coating Ballast Tanks.” Presentations: The Paint and Coating Expo 2005, Paper T-44 (SSPC, Pittsburgh 2005) Technology Up-date 11 – Inspection of Fluorescent Coating Systems(SSPC, Pittsburgh 2006 9