46_SWP_QPCR_SP - Faculty of Medicine

advertisement

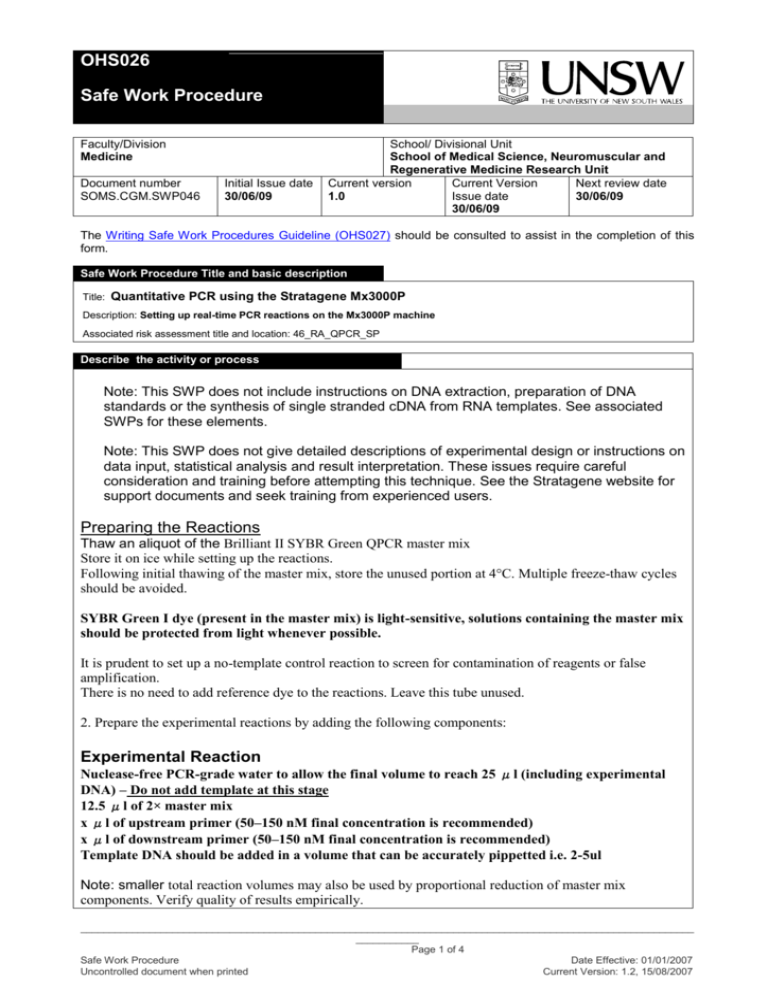

OHS026 Safe Work Procedure Faculty/Division Medicine Document number SOMS.CGM.SWP046 Initial Issue date 30/06/09 School/ Divisional Unit School of Medical Science, Neuromuscular and Regenerative Medicine Research Unit Current version Current Version Next review date 1.0 30/06/09 Issue date 30/06/09 The Writing Safe Work Procedures Guideline (OHS027) should be consulted to assist in the completion of this form. Safe Work Procedure Title and basic description Title: Quantitative PCR using the Stratagene Mx3000P Description: Setting up real-time PCR reactions on the Mx3000P machine Associated risk assessment title and location: 46_RA_QPCR_SP Describe the activity or process Note: This SWP does not include instructions on DNA extraction, preparation of DNA standards or the synthesis of single stranded cDNA from RNA templates. See associated SWPs for these elements. Note: This SWP does not give detailed descriptions of experimental design or instructions on data input, statistical analysis and result interpretation. These issues require careful consideration and training before attempting this technique. See the Stratagene website for support documents and seek training from experienced users. Preparing the Reactions Thaw an aliquot of the Brilliant II SYBR Green QPCR master mix Store it on ice while setting up the reactions. Following initial thawing of the master mix, store the unused portion at 4°C. Multiple freeze-thaw cycles should be avoided. SYBR Green I dye (present in the master mix) is light-sensitive, solutions containing the master mix should be protected from light whenever possible. It is prudent to set up a no-template control reaction to screen for contamination of reagents or false amplification. There is no need to add reference dye to the reactions. Leave this tube unused. 2. Prepare the experimental reactions by adding the following components: Experimental Reaction Nuclease-free PCR-grade water to allow the final volume to reach 25 μl (including experimental DNA) – Do not add template at this stage 12.5 μl of 2× master mix x μl of upstream primer (50–150 nM final concentration is recommended) x μl of downstream primer (50–150 nM final concentration is recommended) Template DNA should be added in a volume that can be accurately pippetted i.e. 2-5ul Note: smaller total reaction volumes may also be used by proportional reduction of master mix components. Verify quality of results empirically. ___________________________________________________________________________________________________________ ___________ Page 1 of 4 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 3. Gently mix the reaction mix without creating bubbles (do not vortex). Dispense into plate wells 4. Add x μl of experimental template gDNA, cDNA, or plasmid DNA to each experimental reaction. PCR Cycling Programs 7. Place the reactions in the instrument and run the appropriate PCR program below. This amplification protocol is recommended initially, but optimization may be necessary for some primer/template systems. Note For short targets (<300 bp), a 2-step PCR protocol may be considered. PCR Program for Amplification of Short Targets (50–400 bp) Cycles 1 Duration of cycle 10 minutes Temperature 95°C 40 30 seconds 1.0 minute a 95°C 55–60°Cb 1.0 minutesa 72°C Set the temperature cycler to detect and report fluorescence during both the annealing step and the extension step of each cycle. b Choose an appropriate annealing temperature for the primer set used. a PCR Program for Amplification of Long Targets (400–900 bp) Cycles 1 Duration of cycle 10 minutes Temperature 95°C 40 30 seconds 1.0 minute a 95°C 55–60°Cb 1.5 minutesa 72°C 3.0 minutes 72°C 1 Set the temperature cycler to detect and report fluorescence during both the annealing step and the extension step of each cycle. b Choose an appropriate annealing temperature for the primer set used. a Performing Real-Time PCR Detection 1) Check to verify that the power status indicator (the lower LED on the front of the instrument) is lit and the Ready status indicator (the upper LED) is continuously lit (glowing green). A blinking Ready status indicator indicates an experiment is already in process; if the Ready status indicator is off, the instrument is not available or ready to run an experiment. 2) Ensure the reaction mix in each well of your reaction plate is free of any bubbles and positioned at the bottom of the well. If not, centrifuge the plate at ~1000 g for 45 seconds. 3) Open the door located on the front of the instrument by sliding it all the way to the top. To expose the thermal block, pull forward on the hot-top handle and lift the hot-top up and away from the thermal block. Place your plate in the plate holder with the last row (row H) facing front. Well A1 should be positioned at the top-left corner of the thermal block. Make sure the plate is properly aligned in the holder. Close the hot-top assembly by pressing down the hot-top and pushing the handle back into its original place. Slide down the door to close. 4) Open the Stratagene MxPro QPCR Software. Click cancel when the New Experiment Options dialog box appears. 5) Select File � Open. Load the RT2Profiler™ PCR Array Template file. This will load the previously saved setup to the new plate document. Save the new document under a new filename. 6) Click Start Run to begin the PCR run. Wait for about 30 seconds for the initial priming. The estimated run time will then appear on the screen. ___________________________________________________________________________________________________________ ___________ Page 2 of 4 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 List all resources required including plant, chemicals, personal protective clothing and equipment, etc Equipment Mx3000P Instrument and computer Microcentrifuge 96 well PCR reaction plate Reagents 2X Brilliant II SYBR Green QPCR master mix Oligonucleotides Forward and Reverse (10uM) Nuclease-free water Template DNA (genomic, cDNA or recombinant) List potential hazards and risk controls including specific precautions required 1.Stratagene Mx3000P machine and computer Electrical appliance – electrocution hazard 2.Refrigerated microcentrifuge Electrical appliance – electrocution hazard Spinning rotor- physical injury hazard List emergency shutdown instructions For electrical appliances, the emergency cutoff switch (red button) is located on the wall near the entrance to the lab. List clean up and waste disposal requirements All solution s should be disposed of in chemical waste containers. Contaminated solid waste should be disposed of through the biological and chemical waste stream. List legislation, standards and codes of practice used in the development of the SWP NSW OHS Act 2000 NSW OHS Regulation 2001 Code of Practice for the Labelling of Workplace Substances AS/NZS 2243.2:2006. Safety in laboratories. Part 2: Chemical aspects AS/NZS 2243.3-2002. Safety in laboratories. Part 3: Microbiological aspects and containment facilities. AS/NZS 2243.4: 1998 Safety in Laboratories Part 4; Ionising Radiations AS/NZS 2243.6-1990. Safety in laboratories. Part 6: Mechanical Aspects. AS/NZS 2243.7-1991. Safety in laboratories. Part 7: Electrical Aspects. AS/NZS 2161.1:2000 Occupational Protective Gloves – Selection, Use and Maintenance AS/NZS 1336:1997 Recommended Practices for Occupational Eye Protection UNSW Hazardous Waste Disposal Procedure Supervisory approval, training, and review Supervisor: Edna Hardeman Signature: Plant custodian: S.Palmer Signature List competency required – qualifications, certificates, licencing, training - eg course or instruction: Training as per Training Needs Analysis, Induction to lab including Mx3000P induction training, Training in this SWP. ___________________________________________________________________________________________________________ ___________ Page 3 of 4 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 ___________________________________________________________________________________________________________ ___________ Page 4 of 4 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007