ovens of incineration

OVENS OF INCINERATION

GENERALITIES

The ovens EMISON for incineration combine the contrasted quality of all our products, endorsed for more than 45 years of service, with the last advances in microelectronic and isolation, applied specifically to incineration ovens, getting the exceptional results that they have taken us to be leaders in the field of the incineration.

The series FCG has been studied specifically to incinerate residuals such as slaughterhouses reamains, animals, wood, papers, garbage, RSU from 500 Kg/h, without problems of scents neither smoke, completing the effective legislation, and without necessity of having qualified personnel.

CONSTRUCTION

The oven is built outwardly of brickwork or concrete according to the plans that we facilitate.

The combustion chamber is built by refractory concretes of high mechanical resistance to guarantee a long life. The isolation is carried out by mineral and ceramic fibres of low thermal mass and great heating power, carefully placed in strata to reduce the lost of heat. The grill is mobile, built in refractory steel, and the produced ashes fall on an ashtray for its automatic extraction.

The heating can be carried out by G. L. P, natural gas, biogas, gas oil or other fuels. The control of the temperature of the chamber is assured by one or more electronic regulators with digital visualization.

OPERATION he principle of operation of these ovens is based on the pirolytic decomposition, the organic matter that disappears in form of non pollutants gases. The operation is continue with successive loads. We can also settle systems for continuous loads.

The material to burn is loaded in manually in the oven maintained to the appropriate temperature by the operation of the burner and the action of the pyrometer control that is responsible of regulating the calories contributed to the oven in function of the necessities.

When making the pneumatic opening of the chamber, the material to destroy can be introduced into the oven, and a servo motor begins a cycle of contribution of secondary air through an electro fan. The perfect combustion that is carried out in an atmosphere highly oxygenated by the contribution of air and at an adequate temperature to minimize the production of smoke what avoids the formation of scents. An oxygen analyser in the chimney adjusts the excess of air to the applications.

Some interior agitators and the action of the mobile grill allow to obtain a correct contact between the material and the air in order to eliminate un-burnt compounds.

Once initiated the combustion, an automatism impedes the opening of the door and, consequently, a second load before it has concluded the combustion of the first one.

SYSTEM OF PURIFICATION

The gases and smoke produced in the combustion of the residuals can be recycled for the use of the residual heat.

They are treated by the addition of appropriate products and refrigerated to diminish their temperature to about 200ºC. The flying ashes are eliminated by cyclones and filters. The standard system of purification is included with the basic equipment in the suitable price.

All our teams have been designed for the rigorous execution of the derived norms of the

LLEI 11/2000, of November 13, controller of the incineration of residuals in the

Autonomous Community of Catalunya, published in the Official Diari of the Generalitat of Catalunya. Núm. 3269 the 20.11.2000, the DECRET 323/1994, of November 4, r which the facilities of incineration of residuals are regulated and l their emissions to the atmosphere are limited, as well as the DIRECTIVE one 2000/76/CE OF THE

EUROPEAN PARLIAMENT AND OF THE ADVICE of December of 2000, 4 published in the Official Newspaper of the European Communities 28.12.2000, relative to the incineration of residuals. Periodically they are upgraded to complete the norms that are incorporated to the Catalan, Spanish or European legislation, like it has happened with the last Spanish normative the Real Ordinance 653/2003 on incineration.

Also they can be supplemented to fulfill those of other countries.

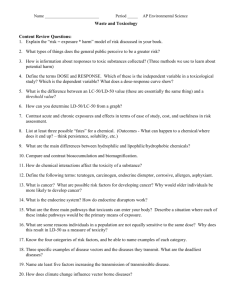

CHARACTERISTIC OVENS SERIES FCG

MODEL CHAMBER MAXIMUM POWER PRICE *

FCG - 1000

FCG - 1500

FCG - 2000

FCG - 2500

FCG - 3000

FCG - 3500

FCG - 4000

FCG - 4500

FCG - 5000

FCG - 5500

FCG - 6000

FCG - 6500 m 3

24

27

30

33

36

39

6

9

12

15

18

21

Calories

1.500.000

2.000.000

2.500.000

3.000.000

3.500.000

3.750.000

4.000.000

4.500.000

5.000.000

5.500.000

6.000.000

6.500.000

Euros

149.970

183.805

208.860

254.320

312.200

337.125

372.340

403.875

428.625

450.000

465.750

487.125

FCG - 7000

FCG - 7500

42

45

7.000.000

7.500.000

506.300

525.100

The number of the model indicates the maximum capacity of residuals incineration in

Kg/h. The power is the maxim that provides the burner. The production of smoke is considered the maximum.

* The price refers to the oven equipped with post combustion chamber, exit chimney (a meter) and gasoil burners. Consult us for other fuels, purifications of smoke, use of the generated heat, or inertization of ash.

The smoke generated in the incineration should be purified in function of their impact on the environment. The bad scents that can emanate the smoke are usually destroyed at the thermal level reached in the combustion chamber. The main generated pollutants are

CO2, CO, SO2 and ClH.

The hydrochloric acid has special interest, coming from the combustion of PVC as well as of the reaction of the ClNa coming from domiciliary residuals. The control of emissions of this gas, starting from a certain percentage of PVC, demands the purification of the gases.

In the particles of the smoke they are contained heavy metals, in dependent concentrations of the composition of the garbages. Their presence demands, therefore, an elimination of particles of the exit smoke.

The directive 89/369 of the EEC impose some conditions for the incineration of residuals: regarding on the design conditions, the permanency of the combustion gases with a minimum content of O2 of 6% is demanded to be of a minimum of 2 seconds at

850ºC.

Also in the combustion gases the concentration of CO won't exceed the 100 mg/m3 and the organic compounds in the gases the 20 mg/m3.