PREPARATION AND CHARACTERIZATION OF POYACRYLAMIDE

advertisement

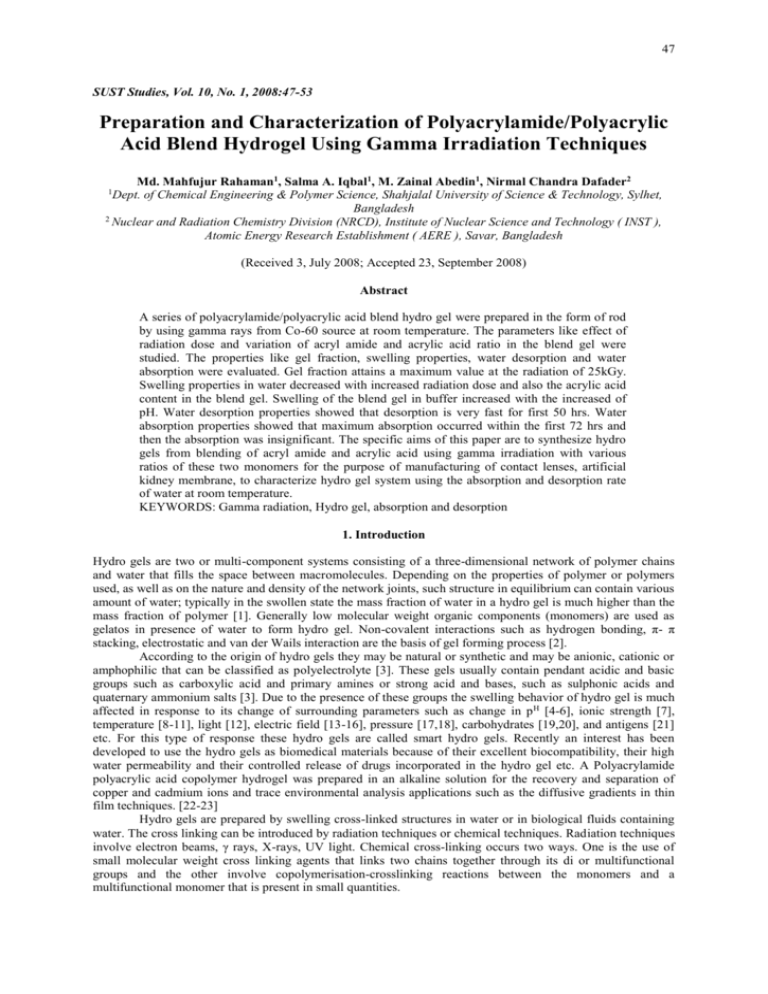

47 SUST Studies, Vol. 10, No. 1, 2008:47-53 Preparation and Characterization of Polyacrylamide/Polyacrylic Acid Blend Hydrogel Using Gamma Irradiation Techniques Md. Mahfujur Rahaman1, Salma A. Iqbal1, M. Zainal Abedin1, Nirmal Chandra Dafader2 Dept. of Chemical Engineering & Polymer Science, Shahjalal University of Science & Technology, Sylhet, Bangladesh 2 Nuclear and Radiation Chemistry Division (NRCD), Institute of Nuclear Science and Technology ( INST ), Atomic Energy Research Establishment ( AERE ), Savar, Bangladesh 1 (Received 3, July 2008; Accepted 23, September 2008) Abstract A series of polyacrylamide/polyacrylic acid blend hydro gel were prepared in the form of rod by using gamma rays from Co-60 source at room temperature. The parameters like effect of radiation dose and variation of acryl amide and acrylic acid ratio in the blend gel were studied. The properties like gel fraction, swelling properties, water desorption and water absorption were evaluated. Gel fraction attains a maximum value at the radiation of 25kGy. Swelling properties in water decreased with increased radiation dose and also the acrylic acid content in the blend gel. Swelling of the blend gel in buffer increased with the increased of pH. Water desorption properties showed that desorption is very fast for first 50 hrs. Water absorption properties showed that maximum absorption occurred within the first 72 hrs and then the absorption was insignificant. The specific aims of this paper are to synthesize hydro gels from blending of acryl amide and acrylic acid using gamma irradiation with various ratios of these two monomers for the purpose of manufacturing of contact lenses, artificial kidney membrane, to characterize hydro gel system using the absorption and desorption rate of water at room temperature. KEYWORDS: Gamma radiation, Hydro gel, absorption and desorption 1. Introduction Hydro gels are two or multi-component systems consisting of a three-dimensional network of polymer chains and water that fills the space between macromolecules. Depending on the properties of polymer or polymers used, as well as on the nature and density of the network joints, such structure in equilibrium can contain various amount of water; typically in the swollen state the mass fraction of water in a hydro gel is much higher than the mass fraction of polymer [1]. Generally low molecular weight organic components (monomers) are used as gelatos in presence of water to form hydro gel. Non-covalent interactions such as hydrogen bonding, π- π stacking, electrostatic and van der Wails interaction are the basis of gel forming process [2]. According to the origin of hydro gels they may be natural or synthetic and may be anionic, cationic or amphophilic that can be classified as polyelectrolyte [3]. These gels usually contain pendant acidic and basic groups such as carboxylic acid and primary amines or strong acid and bases, such as sulphonic acids and quaternary ammonium salts [3]. Due to the presence of these groups the swelling behavior of hydro gel is much affected in response to its change of surrounding parameters such as change in p H [4-6], ionic strength [7], temperature [8-11], light [12], electric field [13-16], pressure [17,18], carbohydrates [19,20], and antigens [21] etc. For this type of response these hydro gels are called smart hydro gels. Recently an interest has been developed to use the hydro gels as biomedical materials because of their excellent biocompatibility, their high water permeability and their controlled release of drugs incorporated in the hydro gel etc. A Polyacrylamide polyacrylic acid copolymer hydrogel was prepared in an alkaline solution for the recovery and separation of copper and cadmium ions and trace environmental analysis applications such as the diffusive gradients in thin film techniques. [22-23] Hydro gels are prepared by swelling cross-linked structures in water or in biological fluids containing water. The cross linking can be introduced by radiation techniques or chemical techniques. Radiation techniques involve electron beams, γ rays, X-rays, UV light. Chemical cross-linking occurs two ways. One is the use of small molecular weight cross linking agents that links two chains together through its di or multifunctional groups and the other involve copolymerisation-crosslinking reactions between the monomers and a multifunctional monomer that is present in small quantities. 48 Md. Mahfujur Rahaman, Salma A. Iqbal Dr. M. Zainal Abedin and Dr. Nirmal Chandra Dafader Radiation cross linking involves the use of gamma rays, electron beams (EB) or X-rays. For irradiation technologies, the main irradiating sources include gamma rays from radioactive isotopes such as cobalt 60, electron beams from electron accelerators, and X-rays converted from electron beam. This process involves subjecting of the polymers to the irradiation which produces free radicals thus initiate the cross linking. The chemical process involves the use of an initiator along with cross linking agent such as Azo-bisdiphenyl methane, Benzoyl peroxide, Cumyl peroxide etc. Among the two method of hydro gel preparation stated above, the irradiation process is most convenient to use rather than chemical method as it allows simultaneous sterilization and cross linking, minimum level of toxic residual monomers; easy control of physical properties, relatively low running cost etc. The present study was focused on to prepare poly acryl amide/poly acrylic acid blend hydro gel from acryl amide and acrylic acid monomer and evaluate their physical properties. These two monomers were selected due to their wide use in gel production for wound dressing and controlled release of drugs. As little work is done on the blend gel of poly acryl amide/poly acrylic acid, to evaluate the effect of radiation dose and the ratio of acryl amide and acrylic acid on the properties of the blend gel, different experiments were carried out. 2. Materials and Methods Materials: Acrylic acid was purchased from Fluke, Switzerland and Acryl amide was purchased from Aldrich Chemi. Both monomers were used as received. The buffer tablets were purchased from BDH Laboratory Supplies, England. The NaCl used was purchased from Fluke, Switzerland. All the chemicals were used in their state of purchasing. Preparation of blend hydro gel: The blend hydro gel was made by solution polymerization method using gamma irradiation. Three sample of blend acryl amide/acrylic acid were prepared in distilled water as 1:1, 1.5:1 and 1:1.5 weight ratios. For gel formation all the three samples were irradiated at doses of 10, 15, 20, 25, 30, 35kGy (kilo gray) from a Co-60 gamma source at room temperature and kept 24 hr for completion of the reaction. Then various physical properties were evaluated for each sample. Measurement of gel content: About 0.4 to 0.6 gm of all irradiated samples were first air dried for about 10-12 hr and then in an oven till to have a constant weight (Wic). Then the samples were subjected to 24 hr extraction in 40-500C in distilled water. The extracted samples were then oven dried at 60 0C till constant weight (Wac). The gel content was determined gravimetrically as follows: Gel content (%) = (Wic / Wac) × 100 Determination of swelling ratio in distilled water: At first about 0.4-0.6 gm of irradiated samples were oven dried. Then the sols were extracted by swelling the samples in distilled water at room temperature for 24 hr. The sample was again oven dried at 60 0C to constant weight (W1) and then dipped in distilled water for 24 hr at room temperature. Time to time, the samples were unwrapped from the water; surface water was removed gently by tissue paper and weighted (W2). The swelling ratio then calculated as: W2 - W1 weight of swelled sample Swelling ratio = = weight of dry sample W1 Determination of swelling ratio in NaCl solution: About 0.4-0.6 gm irradiated samples were at first oven dried and then the sols were extracted by swelling the samples in distilled water at room temperature for 24 hr. The samples were again oven dried to constant weight (W1) and dipped in NaCl solutions of different concentrations for 24 hr at room temperature. Time to time, the samples were unwrapped from NaCl solutions and the swelled samples were weighted (W 2) after removing adhering water. The swelling ratio was calculated as: W2 - W1 Swelling ratio in NaCl solution = W1 Determination of swelling ratio in buffer solution of various pH: 0.4-0.6 gm of all the irradiated samples were oven dried followed by sol extraction in distilled water at room temperature for 24 hr were carried out. Then the samples were again oven dried to constant weight (W 1) and dipped in buffer solution of pH 4, 7, 9 for 24 hr at room temperature. The swelled samples were weighted (W2) after removing adhering water. The swelling was calculated as: Preparation and Characterization of Polyacrylamide/Polyacrylic Acid Blend Hydrogel Using Gamma Irradiation Techniques Swelling ratio in buffer = 49 W2 - W1 W1 Determination of water absorption: 0.4-0.6 gm of all the irradiated samples dried to constant weight was immersed in distilled water at room temperature for 24 hr. Then the sample was again oven dried to constant weight and dipped in distilled water. At first day weight of the sample were taken at 2 hr interval, 3 hr interval at the second day and 6 hr interval up to 4th day. The water absorptions were calculated as: Weight of sample at time t - Initial dry weight of sample Water absorption (%) = 100 Intial dry weight of sample Determination of water desorption: The samples were kept at room temperature and weighted at different time intervals the longest being 102 hr. The experiment was repeated for the hydrogel prepared from different concentration of acryl amide/acrylic acid. Temperature and average humidity of the experimental environment were 30-33 0C and 6971% respectively. The percentage of water desorption was calculated as follows: Weight loss of hydrogelsample at time t 100 Water desorption (%) = Intial weight of sample 3. Results and Discussions Gel fraction of the sample increase with the increase of radiation dose. As the radiation dose passing through a monomer system increase, the concentration of the free radicals in the monomer system increases. As we know, the free radicals are responsible for cross-linking so with the increase of radiation dose the cross linking among monomers increases resulting an increase in gel fraction. Swelling ratio in distilled water shows a decrease pattern with the increase of radiation dose. With the increase of radiation dose cross linking among monomers increases leaving lower pore space for water to penetrate, which reduces the swelling ratio of blend hydrogel. Variable swelling ratio is observed for different ratios of acryl amide and acrylic acid in the poly acryl amide/poly acrylic acid blend hydrogel prepared at the same irradiation dose. Figure-1 shows the effect of radiation dose and the ratio of acryl amide and acrylic acid on the gel fraction of poly acryl amide/poly acrylic acid blend hydrogel. It is found that gel fraction increases with increased radiation dose and attains maximum at the radiation dose of 25kGy and stay unchanged afterwards. Figure-2, it is found that swelling ratio decreases with increased radiation dose. The decreasing trend of radiation dose is fast up to 20kGy. After this radiation dose, it becomes slow. Moreover, swelling ratio is higher with higher content of acryl amide. Figure-3 shows the response of poly acryl amide/poly acrylic acid blend hydrogel to the ionic strength of a solution. This figure describes the response of blend gel prepared from 1.0:1.0 ratios of acryl amide and acrylic acid at different radiation dose. It is found that the swelling ratio in NaCl solution is lower than that of distilled water and swelling ratio decreases with the increase of ionic strength of the solution. Figure-4 describes the response in swelling to the ionic strength of solution of the three poly acryl amide/poly acrylic acid blend hydrogel sample prepared from 1.0:1.0, 1.5:1.0 and 1.0:1.5 ratios of acryl amide and acrylic acid at 25kGy. From figure it is found that the swelling ratio decreases with the increase of ionic strength of the solution (i.e. increase of concentration of NaCl in solution) and also with the increase of acrylic acid ratio in the blend hydrogel. Figure-5 represents the effect of radiation dose and pH on the swelling ratio of poly acryl amide/poly acrylic acid blend hydrogel prepared from 1.0:1.0 acryl amide and acrylic acid solution. It is found that swelling ratio decreases with increased radiation dose. It is also found that swelling ratio increases with increase in pH. Figure-6 represents the effect of pH and acryl amide and acrylic acid ratio on the swelling ratio of poly acryl amide/poly acrylic acid blend hydrogel prepared at 25kGy. It is found that swelling ratio increases with the increase of pH of buffer solution and also with the increase of acryl amide ratio in the poly acryl amide/poly acrylic acid blend hydrogel. Figure-7 presents the effect of radiation dose on the water absorption of poly acryl amide/poly acrylic acid blend hydrogel prepared from 1:1 ratio of acryl amide and acrylic acid solution. From the figure it is found that the maximum absorption of water occurs within 72 hr and become insignificant afterwards. It is also found that with the increase of radiation dose, the percent of water absorption decreases. Figure-8 presents the absorption of water of poly acryl amide/poly acrylic acid blend hydrogel affected by the ratio of acryl amide in the blend hydrogel prepared from blend solution of acryl amide and acrylic acid at 25kGy. It is found that the absorption of water of the blend gel increases with the increase of acryl amide or acrylic acid ratio in the blend gel. It is also found that maximum absorption occurs within 72 hr of dipping in water. Then the absorption of water is in insignificant. Figure-9 views the effect of radiation dose on the water desorption rate of poly acryl amide/poly acrylic acid blend hydrogel prepared from 1.0:1.0 ratio of acryl amide and acrylic acid solution. It is found that 50 Md. Mahfujur Rahaman, Salma A. Iqbal Dr. M. Zainal Abedin and Dr. Nirmal Chandra Dafader the desorption rate of water increases with the increase of radiation dose. It is also found that maximum desorption occurs within 52 hr (except sample of 10 and 15kGy) and then the desorption attains a plateau value. Figure-10 presents the effect of acryl amide and acrylic acid content on the desorption of poly acryl amide/poly acrylic acid blend hydrogel prepared from different ratios of acryl amide and acrylic acid at 25kGy. The poly acryl amide/poly acrylic acid blend hydrogel show a decreasing trend of swelling with the increase of ionic strength of the solution. This happens due to shielding of the ions on the polymer backbone. With the increase of ionic strength of solution, the counter ions concentration increases. The counter ions present shields the ionic moieties of polymer backbone. Thus a decreased swelling is observed. At low ionic strength solution, due to the lacking of counter ions, less shielding occurs resulting greater swelling. The swelling response to buffer medium of different pH shows that lower swelling occurs for blend gel sample containing higher ratio of acrylic acid in solution of acryl amide and acrylic acid during -irradiation. This is due to the ionization state of the acrylic acid moieties on the polymer backbone. At low pH, the acrylic acid is prorogated and little or no charged structure exists. Thus the polymer shows lower swelling at lower pH. For the same time interval higher absorption observed for lower radiation dosed sample due to the lower cross-linking of monomers. Desorption rate is faster for the sample irradiated at higher dose. Desorption is characterized by the removal of water from the hydrogel surface. As for the sample irradiated at higher dose contains less water so desorption is faster for them. 4. Conclusion Polyacrylamide/polyacrylic acid blend hydro gels were prepared from different ratios of acryl amide and acrylic acid solution using gamma irradiation at different dose. It was found that the maximum gel fraction attained at 25kGy. The increase of acrylic acid ratio in the blend gel decreased the gel fraction and vice versa. The swelling in NaCl solution showed that swelling ratio decreased with the increased concentration of NaCl solution and also with the increased radiation dose. Swelling in buffer solution of different pH showed that swelling ratio decreased with decreased pH of buffer solution and with increased ratio of acrylic acid in the blend gel. Both absorption and desorption of water attained maximum value within 72 hr of experiment. The above mentioned properties provide extensive tools for the development of more biocompatible biometrics; which can be used to formulate rate controlled formulations by simply changing the process parameters. Such a blend hydro gel could be of great utility for some other pharmaceuticals. References [1] Rosiak, J. M. and Ulanski, P., “Synthesis of hydro gels by irradiations of polymers in aqueous solution,” Radiation phy. & Chem., 55, 139-151(1999). Elsevier Science Ltd. [2] Friggeri, A., Feringa B. L. and Esch, J., “Entrapment and release of quinoline derivatives using a hydrogel of low molecular weight gelatos,” J. Appl.Control.Rel., 97, 241-248(2004). [3] Kentoglu, O., Sen, M., CayKare T. and Guven, O., “Synthesis and application of N-vinyl 2-pyrrolidone based hydro gels containing mono, di and tri-portico acid moieties,” Turkey. [4] Tanaka T., Tanaka D., Sun, S. T., Nishio I., Swislow G. and Shah, A., Phys. Rev. Lett, 45, 1636(1980). [5] Chu Y. Chu, Varanasi P. P., McGlade M. J. and Varanasi S., “pH-induced swelling kinetics of polyelectrolyte hydro gels,” J. Appl. Polym. Sci, 58, 2161(1995). [6] Firestone B. A. and Siegel R. A., J. Biomat. Sci. Polymer ed. 5, 433(1994). [7] Miyata T., Asami N. and Uragami T., “Electrically credible polymer gel for controlled release of drugs,” Nature, 399, 766(1999). [8] Feil H., Bae Y. H., Feijan J. and Kim S. W., “Molecular separation by thermo sensitive hydrogel membranes,” J. Membrane Sci., 64, 283(1991). [9] Yoshida R., Uchida K., Kaneko Y., Sakai K., Kikuchi A., Sakurai Y. and Okano T., “Comb-type grafted hydrogel with rapid deswelling response to temperature change,” Nature, 374, 240(1995). [10] Hoffman A. S., “Applications of thermally reversible polymers and hydro gels in therapeutics and diagnostics,” J. Control. Rel., 6, 297(1987). [11] Hirokawa Y. and Tanaka T., J.Chem.Phy, 81, 6479(1984). [12] Mamada A., Tanaka T., D. Kungwatchakun and M. Irie, Macromolecules, 23, 1517(1990). [13] Osada Y., Okuzaki H. and Hori H., “A polymer gel with electrically driven motility,” Nature, 355, 242(1992). [14] Shiga T., Hirose Y., Okada A. and Kurauchi T., “Electric field-associated deformation of polyelectrolyte gel near a phase transition point,” J. Appl. Polym. Sci., 46, 635(1992). [15] Frank S. and LauterbuP. C., “Voltage sensitive magnetic gels as magnetic resonance monitoring agents,” Nature, 363, 334(1993). Preparation and Characterization of Polyacrylamide/Polyacrylic Acid Blend Hydrogel Using Gamma Irradiation Techniques 51 [16] Kwon I. C., Bae Y. H. and Kim S. W., “Electrically credible polymer gel for controlled release of drugs,” Nature, 354, 291(1991). [17] Lee K. K., Cussler E. L., Marchetti M. and McHugh M. A., Chem. Eng. Sci., 45, 766(1990). [18] Zhong X. , Wang Y. X. and Wang S. C., Chem. Eng. Sci., 51, 3235(1996). [19] Watanabe M., Akahoshi T., Tabata Y. and Nakayama D., J. Am. Chem. Soc., 120, 5577(1998). [20] Obaidat A. A. and Park K., Biomaterials, 18, 801(1997). [21] Miyata T., Asami N. and Uragami T., “Electrically credible polymer gel for controlled release of drugs,” Nature, 399, 766(1999). [22] Zaho,W.li. H., Teasdale P.R. John R., Zhang S. “Synthesis and Characterisation of PolyacrylamidePolyacrylic acid copolymer hydrogel for environmental analysis of copper and cadmium ion.” Journal of reactive and functional polymer Volume 52, Issue-1 July-2002, pp31-41, Elsevier publisher ltd. [23] Zaho,W.li. H., Teasdale P.R. John R, “Preparation and characterization of a poly (acrylamidoglycolic acid co-acrylamide) hydrogel for selective binding of copper ion and application to diffusive gradients in thin film measurements.” Polymer, Volume 52, Issue-1 July-2002, pp31-41, Elsevier publisher ltd. [24] Rahman, M. “Preparation and Characterization of Plyacrylamide/Polyacrylic acid blend Hydrogel using gamma irradiation Techniques” Bsc. Engineering Thesis, Shahjalal University of Science and Technology, Sylhet, Bangladesh. [25] Alam, M.M., Mina, M.F., Akhtar, F., “Swelling and Hydration properties of Acrylamide Hydrogel in Distilled water “Polymer-Plastic Technology and Engineering Volume 42, Issue 2, January-2003, Pg-533542. [26] Alam, M.M., Mina, M.F., Akhtar, F, Dafadar, N.C., Mustafa, A.I., “Studies of γ ray Induced Plymerization of Aqueous Acryl amide” Polymer-Plastic Technology and Engineering Volume 42, Issue 2, January-2003, Pg-285-296. Figures 100 200 Swelling ratio Gel fraction [%] 95 90 85 1.0:1.0 ( Acrylamide:Acrylic acid) 1.5:1.0 ( Acrylamide:Acrylic acid) 1.0:1.5 ( Acrylamide:Acrylic acid) 1.5:1.0 ( Acrylamide:Acrylic acid) 1.0:1.5 ( Acrylamide:Acrylic acid) 1.0:1.0 ( Acrylamide:Acrylic acid) 150 100 50 0 5 80 5 10 15 20 25 30 35 Dose [kGy] Fig. 1. Effect of radiation dose on gel fraction of polyacrylamide/ polyacrylic acid blend hydrogel prepared from aqueous solution of acrylamide/acrylic acid mixture. 10 15 20 25 30 35 40 40 Dose (kGy) Fig. 2. Effect of irradiation dose on swelling ratio of polyacrylamide/polyacrylic acid blend hydrogel in distilled water prepared from defferent concentration of acrylamide/acrylic acid. 52 Md. Mahfujur Rahaman, Salma A. Iqbal Dr. M. Zainal Abedin and Dr. Nirmal Chandra Dafader 25 1.5:1.0 (Acrylamide:Acrylic acid) 1.1:1.1 (Acrylamide:Acrylic acid) 1.0:1.5 (Acrylamide:Acrylic acid) 20 20 18 Swelling ratio Swelling Ratio 16 14 10 kGy 15 kGy 20 kGy 25 kGy 30 kGy 35 kGy 12 10 8 15 10 5 6 4 0 0.0 2 0.0 0.5 1.0 1.5 2.0 1.0 1.5 2.0 2.5 Concentration of NaCl solution, gms/100mL H2O Concentration of NaCl solution (gm/100mL H2O) Fig. 3. Effect of ionic strength of NaCl solution on the swelling ratio of poly acrylamide/poly acrylicacid blend hydrogel prepared from 1.0:1.0 ratio of acrylamide and acrylic acid at different g radiation dose. Fig. 4. Effect of ionic strength of solution and acrylamide ratio on the swelling of poly acrylamide/poly acrylic acid blend hydrogel prepared from different ratios of acrylamide and acrylic acid at 25kGy. 100 120 10 kGy 15 kGy 20 kGy 25 kGy 30 kGy 35 kGy 80 80 Swelling ratio 100 Swelling ratio 0.5 2.5 60 1.0:1.0 (Acrylamide:Acrylic acid) 1.0:1.5 (Acrylamide:Acrylic acid) 1.5:1.0 (Acrylamide:Acrylic acid) 60 40 40 20 20 0 0 3 4 5 6 7 8 9 4 10 pH 6 7 8 9 10 pH Fig. 6. Effect of pH on the swelling ratio of poly acrylamide/poly acrylic acid blend hydrogel prepared from aqueous solution of acrylamide and acrylicacid at 25 kGy Fig. 5. Effect of pH on the swelling ratio of poly acrylamide/ poly acrylic acid blend hydrogel prepared from aqueous solution of acrylamide and acrylicacid ( 1:1 ) mixture. 60000 16000 14000 50000 10 kGy 15 kGy 20 kGy 25 kGy 30 kGy 35 kGy 40000 30000 Water absorption (%) % water absorbed 5 20000 10000 1.0:1.0 (Acrylamide:Acrylic acid) 1.5:1.0 (Acrylamide:Acrylic acid) 1.0:1.5 (Acrylamide:Acrylic acid) 12000 10000 8000 6000 4000 2000 0 0 0 24 48 72 96 120 Standing time [hrs] Fig. 7. Effect of radiation dose on water absorption of polyacrylamide/polyacrylicacid blend hydrogel prepared from acrylamide and acrylic acid (1:1) mixture. 0 24 48 72 96 120 Standing Time, hrs Fig. 8. Effect of acrylamide ratio on the water absrorption of polyacrylamide/polyacrylic acid blend hydrogel prepared from different ratios of acrylamide and acrylic acid at 25kGy. Preparation and Characterization of Polyacrylamide/Polyacrylic Acid Blend Hydrogel Using Gamma Irradiation Techniques 120 100 100 % water desorped % water desorped 80 60 40 15 kGy 10 kGy 20 kGy 25 kGy 30 kGy 35 kGy 20 20 40 60 80 100 1.0:1.0 ( Acrylamide:Acrylic acid) 1.5:1.0 ( Acrylamide:Acrylic acid) 1.0:1.5 ( Acrylamide:Acrylic acid) 60 40 20 0 0 80 120 Time interval (hrs) Fig. 9. Water desorption rate of polyacrylamide/polyacrylicacid blend hydrogel prepared from aqueous solution of acrylamide and acrylic acid (1:1) mixture: 0 1 12 23 34 45 56 67 78 Time intervals, hrs Fig. 10. Effect of acrylamide ratio on the desorption of water of polyacrylamide/polyacrylic acid blend hydrogel prepared at 25kGy. 53