lab sheet - Faculty of Engineering

advertisement

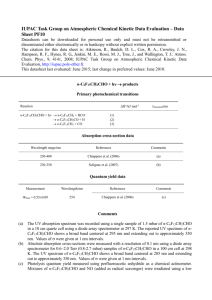

FACULTY OF ENGINEERING LAB SHEET ENT4066 NANOELECTRONIC MATERIALS AND DEVICES TRIMESTER 1 2012-2013 NM1: STUDY OF PHOTON ABSORPTION BEHAVIOUR OF SEMICONDUCTOR NANOCRYSTAL QUANTUM DOTS *Note: On-the-spot evaluation may be carried out during or at the end of the experiment. Students are advised to read through this lab sheet before doing the experiment. Your performance, teamwork effort, and learning attitude will count towards the marks. STUDY OF PHOTON ABSORPTION BEHAVIOUR OF SEMICONDUCTOR NANOCRYSTAL QUANTUM DOTS Contents: 1. Introduction to Photon Absorption Due to Interband Transitions 2. The Beer-Lambert Law 3. Density of States 4. Quantum Confinement in Low Dimensional Structures 5. Non-Radiative Auger Recombination Process 6. Quantum Dot Fabrication by Chemical Synthesis 7. Procedure for the Study 8. References 1 Introduction to Photon Absorption Due to Interband Transitions The room-temperature energy bandgap for CdSe semiconductor is 1.70 eV. To raise an electron from the valence band (VB) to the conduction band (CB) requires a photon energy greater than or equal to 1.70 eV. Since the optical absorption process involves elevating an electron to a new state, such transitions are called interband transitions, or electronic transitions. In principle, photons with longer wavelengths, such as visible light, cannot excite electrons across the bandgap, so they will not be absorbed by the material. In practice, the sharp absorption edge predicted by the simple band model is not observed. The transition from absorbing to transmitting usually follows a soft (exponential) curve as the wavelength changes. The bandgap of most semiconductor materials is not well defined in energy, and there is not a sharp edge energy that defines the conduction or valence bands. In addition, the thermal vibrations, the variety of molecular bonds or configurations in the material lead to alterations in individual electron energy distribution, and thus the band structure of the material. As a result, the onset of optical absorption in semiconductor is not a sharp function of wavelength, but rather is a smooth function of wavelength. 2 The Beer-Lambert Law Figure 1 Absorption of photons within a small elemental volume of thickness x . Suppose that Io is the intensity of a beam of photons incident on a semiconductor material. Thus, Io is the energy incident per unit area per unit time. If ph is the photon flux, then I 0 hph . (1) Suppose that I(x) is the light intensity at x and I is the change in the light intensity in the small elemental volume of thickness x at x due to photon absorption. Then, I will depend on the number of photons arriving at this volume I(x) and the thickness x . Thus (2) I Ix where is called the absorption coefficient of the semiconductor and it is therefore defined by I (3) I x When we integrate Eqn. (3) for illumination with constant wavelength light, we obtain the Beer-Lambert Law, the transmitted intensity decreases exponentially with the thickness of the semiconductor, (4) I ( x) I 0 exp( x) The absorption coefficient depends on the photon absorption processes occurring in the semiconductor. In the case of intraband absorption, the absorption coefficient increases rapidly with the photon energy above the bandgap. The general trend of the absorption coefficient vs the photon energy behaviour can be intuitively understood from the density of states diagram (see below and Figure 5). 3 Density of States Density of states, g(E) represents the number of states per unit energy per unit volume. The photon absorption process increases when there are more VB states available as more electrons can be excited. We also need available CB states into which the electrons can be excited, otherwise the electrons cannot find empty states to fill. The probability of photon absorption depends on both the density of VB states and the density of CB states. Figure 2 The absorption coefficient depends on the photon energy and hence the wavelength. Density of states increases from band edges and usually exhibits peaks and troughs. 4 Quantum Confinement in Low Dimensional Structures The use of semiconductor quantum well (QW) structures as lasing and opticalgain media resulted in important advances in semiconductor laser and LED technology [1]. It is well known that the quantum confinement in one dimension restricts chargecarrier motion in QWs to the remaining two dimensions. Consequently, QWs have a two dimensional step-like density of electronic states that is non-zero at the band edge, enabling a higher concentration of charge carriers to contribute to the band-edge emission and leading to a reduced lasing threshold, improved temperature stability, and a narrower emission line. A further enhancement in the density of states at the band edge and an associated reduction in the lasing threshold is, in principle, possible with quantum wires (QWs) and quantum dots (QDs), where the quantum confinement is in two- or three- dimensions, respectively. Figure 4 shows the general realization of those structures, viz., two-, one-, or even zero- dimensional depending on whether the potential barriers confine the charge carrier in one- (2-DEG), two- (QWs) or three- (QDs) dimension. These structures are known as low dimensional structures, whose dimensions are comparable with the interatomic distances in solids. The movement of charge carriers in these structures is constrained by potential barriers. Figure 3 The lowest energy level in a QW lies above the CB edge. The electronic-configuration spectrum of QDs consists of well-separated atomiclike states with an energy spacing that increases as the quantum dot size is reduced. In very small QDs, the spacing of the electronic states is much greater than the available thermal energy (strong quantum confinement), inhibiting thermal de-population of the lowest electronic states. Additionally, QDs in the strong quantum confinement regime have an emission wavelength that is a pronounced function of size, adding the advantage of continuous spectral tunability over a wide energy range simply by changing the size of the quantum dots. The design prospect of QD laser output-color can be controlled by manipulation of QD size and semiconductor composition has been a driving force in nanocrystal QD research for more than a decade. E2 E1 Figure 4 In low dimensional structure realizations, the quantum confinement changes the density of electron states, or specific energy levels, that will be filled by incoming electrons. 5 Non-Radiative Auger Recombination Process Excitation of a gas-phase or near-surface atom can eject a low-lying electron and leave a “hole” state within the atomic levels. A higher lying electron can recombine with this hole state, and the energy released in electron-hole (e-h) recombination can be emitted as a photon (radiative decay) or as an electron in the non-radiative Auger recombination process. The Auger process also occurs in bulk semiconductors, in which the emitted (re-excited) particle can be either an electron or a hole. There are substantial differences between the electronic and optical properties of nanocrystal QDs and those of epitaxially-grown quantum dots, mostly due to the smaller size of nanocrystal QDs. In particular, strong quantum confinement in nanocrystal QDs results in a large splitting of band-edge states and in an enhancement of intrinsic nonradiative Auger recombinations. In a “quantized” regime, Auger recombination is characterized by a set of discrete (Auger recombination) constants, characteristic of the decay of the 2-, 3-, …electron-hole pair QD states. Figure 5 The absorption coefficient depends on the photon energy and hence the wavelength. Density of states g(E) increases from band edges and usually exhibits peaks and troughs. Generally increases with the photon energy greater than Eg because more energetic photons can excite electrons from populated regions of the VB to numerous available states deep in the CB. Competition between radiative and non-radiative processes crucially affects optical gain. In nanocrystal QDs, non-radiative charge-carrier losses are dominated by surface trapping and multi-particle Auger relaxation. One can model the band-edge emissions in QDs using a simple, two-level system with twofold spin-degenerate states. Figure 6 Modeling of band-edge emissions in QDs. Schematics of transitions with “absorption” and “emission” in CdSe QDs along with intraband relaxation processes leading to a population buildup of the emitting transition. In this model, we find that the optical gain, i.e., population inversion begins at a carrier density of Neh = 1 (Neh is the number of e-h pairs per quantum dot on average.), with gain saturation (i.e., complete population inversion) at Neh = 2. This implies that the QD bandedge gain is primarily due to two e-h pair states. In CdSe nanocrystal QDs, non-radiative Auger relaxation of doubly excited nanoparticles, t2 is strongly size-dependent, i.e., approximately proportional to R3, where R is QD mean radius. The average QD population buildups are usually monitored with the high-sensitivity femtosecond (fs) transient absorption (TA) dynamics as well as with the continuous wave (cw) time-resolved photoluminescence (PL) spectra at room and liquid nitrogen temperatures, respectively. 6 Quantum Dot Fabrication by Chemical Synthesis An alternative approach to fabricating QDs that are small enough to show strong quantum confinement is through chemical synthesis. Chemical methods can provide routine preparations of semiconductor nanoparticles (nanocrystal QDs) with radii 1 nm to 6 nm and with size dispersions as small as 5%. In this size range, electronic interlevel spacings can exceed hundreds of meV, and size-controlled spectral tunability over an energy range as wide as 1 eV can be achieved. Additionally, nanocrystal QDs can be chemically manipulated and incorporated into polymer, glass matrices, microcavitities and photonic crystals. Nanocrystal QDs can also be assembled into close-packed ordered and disordered arrays (QD solids). Direct chemical synthesis method can produce colloidal QDs with narrow size distributions (dispersions) and improved surface passivation. In case of Evident Technologies EviDots™ a core QD of CdSe is overcoated with a shell (or capping) of ZnS (see Figure 7). In our present studies, we use the above, CdSe/CdS core shell QDs dispersed in toluene. One advantage of using the core shell QDs is the substantial suppression of surface trapping and resultant high quantum-efficiency PL spectra. Figure 7 CdSe/ZnS Core-Shell EviDots™ (Evident Technologies). References 1. V. I Klimov. et al., Optical Gain and Stimulated Emission in Nanocrystal Quantum Dots, Science, 290 (2000) 314-317. 2. M. Henini, The physics and technology of low dimensional structures, Microelectronics Journal, 25, 5 (1994) L29. 3. Images from www.evidenttech.com . 4. S. O. Kasap, Principles of Electronic Materials and Devices, McGraw-Hill, 2004. 5. C. R. Pollock, Fundamentals of Optoelectronics, Irwin, 1995. 6. C. Harenza, Quantum Dots ; Advanced Materials Catalog, Evident Technologies Inc. Figure 8 Sample: PbSe Core EviDots™ (Evident Technologies). Figure 9 Sample: PbSe Core EviDots™ (Evident Technologies) Absorption and Emission spectra. STUDY OF PHOTON ABSORPTION BEHAVIOUR OF SEMICONDUCTOR NANOCRYSTAL QUANTUM DOTS INTRODUCTION The Ocean Optics USB4000 Spectrometer is a compact, asymmetrically-crossed Czerny-Turner mounted spectrometer system, scanning the wavelengths from the visible to the near infrared (370nm - 985nm). The SpectraSuite is the operating software controlling the Ocean Optics USB spectrometer instrumentation and devices. The SpectraSuite framework is a completely modular, Java-based spectroscopy software platform that operates on Windows, Linus or Macintosh operating systems and every function in it can be altered or replaced. For instance, the data acquisition functions, the scheduling functions, the data processing function and rendering functions are all separate modules. You can add or delete modules to create a propriety user interface or functionality; create modules to perform calculations; automate experiment routines and more. You or an Ocean Optics application developer can easily customize SpectraSuite through Java code. The SpectraSuite is a platform-independent application software that provides graphical and numeric representation of spectra in one window. The SpectraSuite software provides the user with advanced control of episodic data capture attributes. For instance, a user can acquire data for a fixed number of scans or for a specific interval. Initiation of each scan can be externally triggered or eventdriven. Captured data is quickly stored into a system memory at speeds as fast as 1 scan per msec with speeds limited by hardware performance. The SpectraSuite software allows you to perform the three basic spectroscopic experiments: (1) absorbance, (2) reflectance, and (3) emission, as well as signalprocessing functions such as (a) electrical dark-signal correction, (b) stray light correction, (c) boxcar pixel smoothing and signal averaging. Scope mode, the spectrometer operating mode in which raw data (signal) is acquired. The basic concept for the software is that real-time display of data allows users to evaluate the effectiveness of their experimental setups and data processing selections, make changes to these parameters, instantly see the effects and save the data. Most spectrometer-system operating software does not allow such signal-conditioning flexibility. OBJECTIVES At the end of this experiment, students will learn the operations required for conducting experiment on measurement of photon absorption by semiconductor nanocrystal quantum dots, by using Ocean Optics USB4000 spectrometer and SpectraSuite spectrometersystem operating software. The objectives are: To perform data acquisition for photon absorption experiment To establish the flexible and signal-conditioning parameters To compute reference and dark spectra monitoring To control the setting system-function parameters To analyze the absorption spectra obtained from quantum dots NM- 1: STUDY OF PHOTON ABSORPTION BEHAVIOUR OF SEMICONDUCTOR NANOCRYSTAL QUANTUM DOTS PROCEDURE: 1. Installing the spectrometer a. Switch on the PC and the monitor. b. Connect the spectrometer and PC by using an USB cable provided. c. Click on the SpectraSuite icon to open it. 2. Running Ocean Optics SpectraSuite a. The spectrum graph window appears under the standard toolbars. b. If you have followed the correct installation of the spectrometer, the spectrometer is already acquiring data in Scope (S) mode. Even with no light in the spectrometer, SpectraSuite should display a dynamic trace in the bottom of the graph window. 3. Data Sources and Data Views panes a. The spectrometer model that you have installed is listed in upper left pane. b. The acquisition parameters that you set via the (integration time, scans-toaverage, boxcar smoothing). c. The properties (serial no., firmware level, total pixels, wavelengths) d. The optical bench (grating, filter wavelength, slit size) e. The detector (array coating mfg., array wavelength, etc.) f. Whether reference and/or dark spectra have been stored, the graph (A, B, C, etc.) associated with the spectrometer appears in lower left pane. 4. Measurement (A, T, R, I) a. Choose the type of measurement A (for Absorbance), T (for Transmission), R (for Reflection), I (for Irradiance), etc. The type of measurement you will take determines the configuration of the sampling optics for your system. Furthermore, your choice of reference and data analysis determines how SpectraSuite presents the results. -----------------------------------------------------------------------------------------------------------Note: For each measurement, you must first take a reference and dark spectrum before the experiment mode icon (A, T, R, I) on the toolbar becomes active. After you take a reference and a dark spectrum, you can take as many measurement scans as needed. However, if you change any sampling variable (integration time, scans-to-average, boxcar smoothing, fiber size, etc.), you must store a new reference and dark spectrum. ------------------------------------------------------------------------------------------------------------ Figure 10 Absorbance measurement set up. b. If the signal you collect is saturating the spectrometer (intensity greater than 4000 counts), you can decrease the light level on scale in Scope (S) mode by decreasing the integration time (e.g., 100ms-->60ms), using a smaller diameter fiber, or using a correct, neutral density filter (NDF). c. If the signal you collect has too little light, you can increase the light level on scale in Scope (S) mode by increasing the integration time, using a larger diameter fiber, or removing any optical filters. 5. Storing Reference and Dark Spectra Reference and dark spectra must be stored before collecting experimental data. If you pass the cursor over No-preprocessor line in either Data Sources or Data Views pane, a dialog box informs you whether reference and/or dark spectra have been stored. 1. Reference spectra a. Go to File NewAbsorbance measurement. b. Under Select spectral source wizard, select one spectral source from the table. c. Next. d. Check on Strobe/Lamp Enable. e. Change the integration time appropriately until the Last peak value has come closer to the Recommended peak value. You may select “Set Automatically” if Step (1.e) is not achieved. f. Next. g. Click on the Yellow lamp to store the Reference spectrum. You may load the Reference spectrum from a file. h. Next. 2. Dark spectra i. Uncheck on Strobe/Lamp Enable. j. Change the integration time to the value of Step (1.e). Press Next. k. Click on the Dark lamp to store the Dark spectrum. You may load the Dark spectrum from a file. l. Choose Finish to get the Reference and Dark spectrum on Graph window. 6. Absorbance Measurement Absorbance spectra are a measure of how much light a sample absorbs. For most samples absorbance relates linearly to the concentration of the substance. SpectraSuite calculates Absorbance (Aλ) using the following equation: S D (5) A log 10 R D where Sλ is the sample intensity at wavelength λ, Dλ is the dark intensity at wavelength λ, and Rλ is the reference intensity at wavelength λ. 6.1 Absorbance measurement setup a. The light source sends light via an input fiber into a cuvette in a cuvette holder. The light interacts with the sample. The output fiber carries light from the sample to the spectrometer connected to the computer. 6.2 Procedure b. Place SpectraSuite in Scope mode by clicking the “S” icon in the Experiment mode toolbar or selecting ProcessingProcessing ModeScope from the menu. Ensure that the entire signal is on scale. The intensity of the reference signal’s peak differs depending on the device being used. If necessary, adjust the integration time until the intensity is appropriate for your device. c. Select FileNewAbsorbance Measurement from the menu or click ‘A’ to start the Absorbance measurement Wizard. d. Select the source of your absorbance measurement and click ‘Next’. The second page of the wizard appears. e. Turn on your light source. f. Set your acquisition parameters so that the peak value reached the recommended level. g. Click ‘Next’. The third page of the wizard appears. h. If you have not already done so, place a sample of solvent into a cuvette to take a reference spectrum. You must take a reference spectrum before measuring absorbance. -------------------------------------------------------------------------------------------------------Note: Do not put the sample itself in the path when taking a reference spectrum, only the solvent. -------------------------------------------------------------------------------------------------------i. Click the Store Reference Spectrum icon on the screen. This command merely stores a reference spectrum in memory. Click the Save Spectra icon on the toolbar or select FileSaveSave Spectra Collection from the menu bar to permanently save the reference spectrum to disk. j. Click ‘Next’. The fourth page of the wizard appears. k. Block the light path to the spectrometer, uncheck the Strobe/Lamp Enable box, or turn the light source off. Take a dark spectrum before measuring absorbance. l. This command merely stores a dark spectrum in memory. Click the Save Spectra icon on the toolbar or select FileSaveSave Spectra Collection from the menu bar to permanently save the dark spectrum to disk. --------------------------------------------------------------------------------------------------------Note: If possible, do not turn off the light source when taking a dark spectrum. If you must turn off your light source to store a dark spectrum, allow enough time for the lamp to warm up again before continuing your experiment. After the lamp warms up again, store a new reference. ---------------------------------------------------------------------------------------------------------m. Put the sample in place and ensure that the light path is clear. Then, click ‘Finish’. If you have already taken one or more absorbance measurements, a dialog box appears asking you to specify whether to display the new data in a new graph, or on the existing graph. Note the following changes on the screen: 1. The experiment mode listed in the Data Sources and Data Views panes changes to Absorbance Mode. 2. The units listed on the Graph pane changes to Absorbance (OD). n. To permanently save the spectrum to disk, click the Save Spectra icon on the toolbar. --------------------------------------------------------------------------------------------------------Note: If you change any sampling variable (integration time, averaging, smoothing, fiber size, etc., you must store a new reference and dark spectrum. --------------------------------------------------------------------------------------------------------- REPORT WRITING The lab report should include the following information: (i) (ii) (iii) (iv) The processed spectra of all samples provided. Analysis of the Results Discussions Conclusion Marking Scheme Lab (10%) Assessment Components Hands-On & Efforts (2%) On the Spot Evaluation (2%) Lab Report (6%) Details The hands-on capability of the students and their efforts during the lab sessions will be assessed. The students will be evaluated on the spot based on the lab experiments and the observations on the quantum dots absorption characteristics. Each student will have to submit his/her lab final report within 7 days of performing the lab experiment. The report should cover the followings: 1. Introduction, which includes background information on absorption measurement and their relationship with semiconductor nanomaterials. 2. Experimental section, which includes the general summary of the lab experiment work. 3. Results and Discussions, which include the absorption measurement results, analysis, and evaluations, with neat graphs/images of the results and recorded data. 4. Conclusion, which includes a conclusion on the experimental. 5. List of References, which includes all the technical references cited throughout the entire lab report. The report must have references taken from online scientific journals (e.g. www.sciencedirect.com, http://ieeexplore.ieee.org/xpl/periodicals.jsp, http://www.aip.org/pubs/) and/or conference proceedings (e.g. http://ieeexplore.ieee.org/xpl/conferences.jsp). Format of references: The references to scientific journals and text books should follow following standard format: Examples: [1] William K, Bunte E, Stiebig H, Knipp D, Influence of low temperature thermal annealing on the performance of microcrystalline silicon thin-film transistors, Journal of Applied Physics, 2007, 101, p. 074503. [2] Hodges DA, Jackson HG, Analysis and design of digital integrated circuits, New York, McGraw-Hill Book Company, 1983, p. 76. Reports must be typed and single-spaced, and adopt a 12-point Times New Roman font for normal texts in the report. Any student found plagiarizing their reports will have the assessment marks for this component (6%) forfeited. The lab report has to be submitted to the NanoLab1 staff. Please make sure you sign the student list for your submission. No plagiarism is allowed. Though the absorption spectrum of the measured sample from the same group can be similar, the report write-up cannot be duplicated for group members. The individual report has to be submitted within 7 days from the date of your lab session. Late submission is strictly not allowed.