Section 122 - I-level ALSS

advertisement

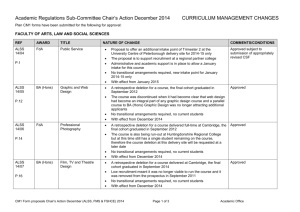

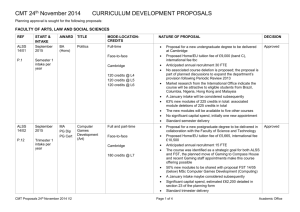

122. I LEVEL ALSS Page 1 of 11 122. INTERMEDIATE LEVEL (I-LEVEL) AVIATION LIFE SUPPORT SYSTEM(S) (ALSS) FUNDAMENTALS References: [a] OPNAVINST 4790.2H, Naval Aviation Maintenance Program (NAMP), Vol. I [b] NAVAIR 13-1-6.2, Emergency Personnel and Drogue Parachute Systems [c] NAVAIR 13-1-6.4-2, Oxygen Equipment (Regulators) [d] OPNAVINST 4790.2H, Naval Aviation Maintenance Program (NAMP), Vol. V [e] NAVAIR 06-30-501, Oxygen/Nitrogen Systems Technical Manual [f] A6-332AO-GYD-000, ABO Surveillance Program Laboratory and Field Guide .1 Discuss ALSS pool management. [ref. a, ch. 16] 1. General a. A pool of ALSS spare assemblies (parachutes, life rafts, SSKs, life preservers, survival radios, and miniature regulators) shall be established by IMA ashore. The spare ALSS assemblies are owned by the station/MALS Aviation Supply Officer and are inventoried, maintained, and stored by the local IMA. This material will be maintained, in a rotatable ALSS pool located in the IMA 800 Division. IMA personnel shall ensure all spare ALSS equipment is properly stored, RFI upon demand by O-level activities, and on hand quantities match those on the activity's supply records. b. When the deployment site does not have an ALSS pool, the supporting shore-based IMA is responsible for providing RFI Assemblies equal to 10 percent of those required for full outfitting of the deploying squadron or detachment to the deployed site. c. Deployed shipboard IMAs will be responsible for providing all repair parts and components required to support the embarked squadrons' ALSS equipment. d. Upon completion of deployment, the shipboard IMA is responsible for returning the same number of RFI assemblies originally provided by the supporting shore-based IMA. When the deployment site does not have an established IMA, the deployed site Supply Officer is responsible for the return of all unused assemblies and adequate documentation on the used material to guarantee proper stock replacement, carcass tracking, and charges. e. Personal survival equipment, such as helmets, survival vests, gloves, flight suits, or items of squadron equipment which are not normally inducted into the IMA for maintenance, are not to be included in ALSS pools. .2 Discuss the purpose and use of the SEATS/ICAP Program. [ref. a, ch. 10] * SEATS/ICAP is a microcomputer based system which provides a standardized method to manage, report and generate hard copy history records on ALSS components and installed explosive devices. SEATS - Survival Equipment Asset Tracking System ICAPS - Increased Capabilities .3 Discuss the unique QA requirements for ALSS equipment. [ref. a, chs. 14, 16] 1. General. 1. Activities having no or only one PR assigned shall designate in writing a properly cross trained QAR or CDQAR to inspect work performed on ALSS equipment maintained by Work Center 13A. This does not include parachute or life raft/life preserver packing/repacking or other Ilevel maintenance functions on ALSS equipment. Cross trained Created by LTJG KyungNho "TACO" Kim Reviewed by ENS Carol Yeiser 122. I LEVEL ALSS Page 2 of 11 QARs/CDQARs shall use NAVAIR 13-1-6 series manuals for technical guidance. Personnel performing ALSS equipment maintenance and QARs/CDQARs inspecting work performed shall be ordnance certified per OPNAVINST 8020.14. 2. O-level activities supported by contract maintenance shall use only qualified, certified civilian personnel to perform O-level maintenance on ALSS/egress system maintenance. (1) For Work Center 13A, only personnel who are graduates of Navy PR or equivalent Air Force or Army MOS course shall be allowed to perform ALSS system maintenance. (2) For Work Center 13B, only personnel who are graduates of Navy AME "A" School and CNATTU for specific T/M/S or T/M/S factory equivalent training course shall be allowed to perform egress system maintenance. (3) In addition to paragraphs (1) and (2) above, for contract maintenance personnel to be designated as a QA Inspector on ALSS/egress equipment, a documented working history with ALSS/egress equipment is required. 3. I-level activities using NALCOMIS shall assign SMQ passwords to all personnel designated as QARs, CDQARs, and CDIs. QA stamp numbers shall be required for ALSS inspection records, calibration METER cards, and all non-NALCOMIS maintenance documents, for example, VIDS/MAFs. These open purchased numbered impression stamps, which identify the inspector, will be used as required or as established by local policies. Stamps shall be closely controlled by QA and adequate storage facilities provided. A stamp may not be reassigned within a period of 3 months. NOTES: Cross training is not permitted into the following: AME areas of egress systems or PR I-level areas of responsibility. Only qualified Ilevel personnel (graduates of approved PR school) will be permitted to pack, repair, or perform calendar inspections on personnel parachutes, drogue chutes (excluding drogue chutes in nonremovable head boxes), SSKs, and inflatable survival equipment. Cross training under provisions are permissible for PR O-level functions only. ALSS O-level and I-level areas of responsibility are outlined in NAVAIR 13-1-6 series manuals and shall be strictly followed. .4 Discuss documentation requirements for ALSS equipment. [ref. a, ch. 16] 1. Records and Cards (1) The following records are designed to document ALSS components: (a) The Parachute Record (OPNAV 4790/101) is designed to provide the current configuration and inspection record of a parachute assembly and its components. The record is a single copy, single-sided SEATS generated form. The record is designed to be filed in the aircraft logbook or the ejection seat AESR where the parachute system is installed. (b) The Seat Survival Kit Record (OPNAV 4790/137) is designed to provide configuration and inspection information for an SSK and its components. The record is a single copy, single-sided SEATS generated form. The record is designed to be filed in the aircraft logbook or the ejection seat AESR in which the SSK is installed. (c) The Aircrew Systems Record (OPNAV 4790/138) is designed to provide a continuous configuration and inspection record of ALSS components, kits, and assemblies. This record is a single copy, singlesided SEATS generated form. Each item of ALSS requiring inspection at the I-level of maintenance shall have a separate Aircrew Systems Record. Created by LTJG KyungNho "TACO" Kim Reviewed by ENS Carol Yeiser 122. I LEVEL ALSS Page 3 of 11 The record shall be filed in the logbook of the aircraft in which the ALSS component, kit, or assembly is installed. For personnel mounted equipment or other equipment which is not aircraft mounted, the record will be maintained as directed by the MO. For amplifying instructions for this record refer to 4790, VOL I, Chapter 13 and NAVAIR 13-1-6 series manuals. (d) The Aircrew Personal Equipment Record (OPNAV 4790/159) shall be initiated by the cognizant O-level activity upon the initial issue of personal equipment to the aircrew member. The record provides the current configuration of all personal survival equipment issued to the aircrew member. Only items of ALSS requiring inspection at the O-level shall be documented on this record. The record shall be retained until new equipment can no longer be documented in allotted spaces. As an item is removed from service it will be deleted from the record by drawing a single red line through all information pertaining to that item. Information pertaining to the removed item's replacement will be annotated in the next available line below. When the card is filled, a new record shall be initiated and all current data transcribed to the new record. Upon verification of data, the old record may be destroyed. (e) When any ALSS equipment has been involved in an aircraft mishap, the records shall be forwarded per OPNAVINST 3750.6 and NAVAIR 13-1-6 series manuals. (2) Record Retention. Each aircrew member shall have a separate file containing the Aircrew Personal Equipment Record (OPNAV 4790/159) and separate Aircrew Systems Records (OPNAV 4790/138) as needed. The aircrew flight equipment file shall be constructed of a 9 x 12 manila folder. The Aircrew Personal Equipment Record (OPNAV 4790/159) will be firmly attached on the right side of the folder and all applicable Aircrew Systems Records (OPNAV 4790/138) will be placed on the left. All maintenance actions performed on an aircrew member's equipment shall be documented on a MAF. After normal processing of the VIDS/MAF, Copy 3 will be placed in the aircrew member’s flight equipment file beneath the Aircrew Personal Equipment Record (OPNAV 4790/159) until Copy 1 is received from the data services facility. Copy 3 can then be discarded. Copy 1 will be placed beneath the Aircrew Personal Equipment Record (OPNAV 4790/159) and retained for a minimum of 6 months. NOTE: All aircrew flight equipment records and files shall be maintained as directed by the MO. (a) When an item of ALSS is due for inspection or maintenance, Maintenance Control shall forward all appropriate records with the MAF or WO to the Aircrew Personal/Protective/Survival Equipment Work Center. (b) For record entry requirements for ALSS records refer to Chapter 13 and NAVAIR 13-1-6 series manuals. .5 Discuss special facility requirements for ALSS work centers. [ref. b, WP 003; ref c, ch. 3] 1. GENERAL. a. The wet locker and washroom shall be separate areas. The packing area, store rooms, and fabric areas should be separated if room is available. The packing tables shall be adequately spaced. The fabric area shall be kept clean. All local fire regulations shall be adhered to. b. packing area c. Fabric area d. Wet Locker e. Washroom. f. Storage facilities. Created by LTJG KyungNho "TACO" Kim Reviewed by ENS Carol Yeiser 122. I LEVEL ALSS Page 4 of 11 2. Environmental requirement. Parachutes should be inspected, repaired and packed under regulated temperature and humidity conditions. So, these conditions must be controlled in all parachute lofts. In general, the loft shall not be excessively damp or dusty. It shall be continuously or frequently ventilated. 1. REQUIREMENTS. a. The temperature and relative humidity in packing loft and dry locker shall be maintained within limits indicated in (Figure 3). Ideal conditions are a temperature of 24 C (75 F) and a relative humidity of 60%. Created by LTJG KyungNho "TACO" Kim Reviewed by ENS Carol Yeiser 122. I LEVEL ALSS Page 5 of 11 b. The shaded area on temperature-humidity chart, shown in (Figure 3), outlines the allowable environmental limits inside parachute loft and illustrates favorable and unfavorable conditions. Parachutes should not be packed when conditions are in the unacceptable zone. These limits are affected by two variables: relative humidity and temperature. Recordings of these variables shall be taken at least 3 times daily, using the relative humidity and temperature indicator to ensure that favorable conditions are maintained. NOTE: Do not pack parachutes when conditions are outside acceptable conditions. c. Relative humidity is ratio between amount of water vapor in air and amount the air could hold at a given temperature. Relative humidity is usually written as a percentage. Specific humidity is the weight of the water vapor found in a given volume of air. Relative humidity limits must be maintained to prevent condensation in actuators and other metal parts. Specific humidity limits must be maintained to prevent static electricity in canopy cloth. d. Given any two of these variables, it can be determined, by using the chart, if the packing loft and dry locker have safe environmental conditions. .6 Discuss training/qualification requirements for working on ABO equipment. [ref. c, ch. 3, Glossary-2; ref. d, ch. 5; ref. e, ch. 2] 1. General Shop supervisors shall be responsible for conducting a continuing training program stressing the significance of oxygen system cleanliness, personal cleanliness and the oxygen safety program. Conscientious adherence to all cleanliness requirements and safety regulations shall be observed at all times. 2. ABO analyzing equipment operators shall be: (1) Trained by one of the following: (a) Aviators Breathing Oxygen (ABO) Test Site Operator/Analyst course (Course C-670-2018). (b) Aircrew Survival Equipmentman Class A1 course (Course C-6022010). (c) Aviators Breathing Oxygen Contaminant Analyzer Intermediate Operator Maintainer course (Course C-750-3217). (d) ABO qualified NATEC (Code 3.1/3.2) personnel. (2) Actively involved with ABO analysis. Personnel who do not interpret sample scans within a two-year period shall be required to complete all initial certification requirements. (3) Knowledgeable with ABO sampling procedures and analyzing requirements of NAVAIR A6-332AO-GYD-000 and NAVAIR AG-115-SL-OMP-000. 3. Program manager shall Ensure ABO Surveillance Program indoctrination and follow-on training is provided to personnel. All personnel associated with the ABO Surveillance Program shall have a thorough knowledge of the characteristics of LOX/gaseous oxygen, hazards of contamination, and need for quality standards. They shall be familiar with and comply with procedures outlined in NAVAIR 06-30-501, NAVAIR 13-1-6.4-1, NAVAIR A6-332AO-GYD-000, NAVAIR AG-115-SL-OMP-000, NAVAIR 06-20-2, MIL-HDBK-1028/1C, NAVAIR 17-15-98, MIMs, and MRCs (as applicable) to the oxygen servicing/maintenance tasks they perform. Training shall include personnel responsibilities and shall be documented on the NAMP Indoctrination Training sheet in the individual's qualification/certification record. Created by LTJG KyungNho "TACO" Kim Reviewed by ENS Carol Yeiser 122. I LEVEL ALSS Page 6 of 11 .7 Discuss special tools required for working on ABO equipment. [ref. c, ch. 3] 1. General. All tools and equipment shall be maintained free of grease, oil and other combustible materials. Tools used on oxygen equipment shall not be used for any other purpose. Tools shall be marked OXYGEN USE ONLY, or other suitable methods of identification may be used. 2. Example of a special tool for AIRCRAFT DILUTER DEMAND OXYGEN REGULATORS TYPE AN6004-1, SERIES 2858-A1,2858-A1A, 2858-B1, AND 2858-C1 1. Aircraft Diluter Demand Oxygen Regulators Pioneer Type AN6004-1, Series 2858 (figures 4-1) are manufactured by Pioneer Central Division of Bendix Aviation Corp (CAGE 06840 and 19315). They are designed to regulate breathing oxygen to the aircrewmember during flight. Table 4-1 contains the leading particulars for the regulators. Created by LTJG KyungNho "TACO" Kim Reviewed by ENS Carol Yeiser 122. I LEVEL ALSS Page 7 of 11 3. REQUIRED SPECIAL TOOLS: Table 4-9 list special equipment required in connection with the work disassembly and assembly procedures. tools and test prescribed for .8 Discuss the requirements and equipment for testing liquid oxygen and liquid nitrogen. [ref. e, ch. 3; ref. f, ch. 2] Created by LTJG KyungNho "TACO" Kim Reviewed by ENS Carol Yeiser 122. I LEVEL ALSS Page 8 of 11 1. General. This section establishes procedures and requirements for the quality control of oxygen that is procured, generated, stored, transferred, and used at Naval and Marine Corps Air Stations or aboard aircraft carriers for breathing purposes by aircrews. This section is applicable to all personnel who are responsible for supervising or performing the operations associated with receipt, generation, storage, and transferring of, and servicing aircraft with aviators breathing oxygen. 2. OUALITY CONTROL REOUIREMENTS OF AVIATORS LIOULD BREATHING OXYGEN. 1. Procurement Limits, Aviators liquid and gaseous breathing oxygen, whether it is generated by Navy and Marine activities or procured from commercial sources, must meet the purity and contamination requirements as shown in table 2- 1. 2. Use limits are applicable to receiving/storage tanks, servicing equipment and converters in service shown in table 2- 1. 3. Emergency Use Limits. Following guidance is provided concerning use of ABO under emergency conditions when liquid ABO contains a greater concentration of contaminants than the use limit or has a low purity. In emergency situations where an immediate decision is essential, local commands may use the following guide for making onsite decisions on the use of such oxygen. The risk in usage is minor if nitrous oxide (in the total absence of acetylene), methane, and ethylene, do not exceed three times their respective use limits For example, if an analysis of LOX from a storage tank indicates that methane contamination is 150 ppm (3 times normal use limits), only minor risk would be involved in its usage in an emergency situation. However, LOX is not recommended for use when any of the following apply: nitrous oxide (in the presence of acetylene at any concentration) exceeds 4 ppm, carbon dioxide exceeds 20 ppm, acetylene exceeds 0.2 ppm, or high hydrocarbons (ethane equivalent) exceed 8 ppm. In the instance that gaseous aviators breathing oxygen is being tested, the following will also apply: Carbon dioxide and moisture may exceed their use limits by three times. It is imperative that the source of excessive contamination be determined and alleviated. Thus, if the LOX sampled at the aircraft converter outlet is found to contain excessive amounts of a particular constituent, not only should the converter be investigated for problems, but so should the service cart, transfer lines used, and any other possible sources until the fault is uncovered and corrected. Created by LTJG KyungNho "TACO" Kim Reviewed by ENS Carol Yeiser 122. I LEVEL ALSS Page 9 of 11 3. SAMPLING AND TESTING. Sampling and testing of LOX at specified intervals and points in the supply system provide the continuous monitoring of contamination that is essential to the quality control of ABO. However, if the sample taken does not truly represent its source, then test results cannot serve the intended purpose. Careful observation of operating instruction for LOX samplers is important to ensure representative samples. 1. ON-BASE TESTING. 1. Navy and Marine Corps Activities which produce liquid oxygen shall sample and test the contents of the generator in accordance with paragraph 2-14.1. Receipt of aviators breathing oxygen from a contractor shall also be tested in accordance with this paragraph, and by the following test for particulate matter, before unloading is permitted. Periodic surveillance of storage tanks, servicing trailers and aircraft converter systems shall be made. Table 2-2 lists the testing and sampling equipment required to perform the particulate test: Note: Test for particulate is only required when contamination is suspected. 2. Particulate Test. Approximately 200 mils of the sample shall be poured into a clean 400 ml beaker or similar container, without a filter paper in the bottom. A watch-glass cover or some other means of partially covering the top of the beaker shall be used as the 200 mils of liquid evaporate to dryness. When the frost on the outside of the beaker has melted, the outside of the beaker shall be wiped with a clean dry cloth and the beaker placed on clean white paper. The interior of the beaker shall be visually examined, without the aid of magnification for the presence of particles. 4. EOUIPMENT. Addition of contaminants from equipment shall be reduced or prevented by operating and maintaining generators, storage tanks, servicing carts, and aircraft oxygen systems in accordance with applicable technical manuals. 5. SAMPLER. 1. The function of a good cryogenic liquid batch sampler is to extract and hold a representative, unmodified sample for analysis. Ensure the sample is not modified in the course of progressing from the original sample point to the analytical instrument. Liquid oxygen is more volatile than the contaminating constituents are. There is a tendency for liquid oxygen to at least partially vaporize during the sampling process, increasing the apparent contamination level of the residual fluid. The higher contamination level may be high enough to result in the sample being rejected. Good sampling procedures and techniques are very important when drawing a sample to ensure that the sample is representative of the contents of the equipment. 2. The USAF TTU-131/E LOX Sampler is based on the shielded cup principle of operation. Liquid oxygen flows through the hollow shell of the internal sample cup, cooling and finally discharging through the, vent port. After the sample compartment is sufficiently cooled to prevent boiling when the sample is introduced, the inlet valve is opened and the cup begins to fill. When full, liquid again issues from the vent port and the inlet valve is closed, trapping an exactly measured liquid sample. The sample vaporizes into the outer sampler cavity; and the pressure increases to 450 psi due to evaporation. This provides the sample for analysis. The sampler can produce various Created by LTJG KyungNho "TACO" Kim Reviewed by ENS Carol Yeiser 122. I LEVEL ALSS Page 10 of 11 contamination values for a given sample because of a separation process that occurs in the sample cup. During the evaporation procedure, high boiling point contaminants such as nitrous oxide and solvent chemicals tend to remain in the liquid oxygen retained in the cup, while the low boiling point contaminants like methane evaporate nearly as fast as the oxygen. The passageway between the sample cup and the larger surrounding vapor cavity is rather narrow, a higher concentration of contaminants can be expected in the cup than in the cavity, what is in the cavity is not representative of the extracted sample. One remedy for this situation is to turn the sampler upside down immediately after filling, an action that causes the liquid oxygen and contaminants to flow out of the cup and into the cavity where the liquid oxygen vaporizes as a homogeneous mixture. 3. The MODEL FCS 2001 Cryogenic Sampler employs the same basic principals of the USAF TTU-131/E LO2 Sampler. The charging manifold of the sampler consists of two cups, one inside the other. The inner cup is a high-pressure vessel. During operation, the cryogenic liquid being sampled is allowed to flow between the shielding cup (outer) and the sampling cup (inner) until the sampling cup has been cooled to the temperature of the cryogenic liquid. Once the inner cup has been cooled to the temperature of the liquid, the inlet valve is opened to fill the inner sampling cup. The inlet valve is closed to retain a known volume of liquid in the cup. The charging manifold and sample cylinder are inverted. The pressure in the sample cylinder is allowed to build to 1300 - 1800 psig. The sample extraction valve on the cylinder assembly is then closed and the charging manifold vented. The use of a sample cylinder alleviates the weight problem mentioned with the previous sampler. The sample bottle is removed from the charging manifold and delivered for analysis. 6. ANALYSIS. 1 The acquisition of a representative sample by one of the methods in the previous section provides us now with material for analysis. NAAG-332AO-GYD-000 sets the contamination limits, and most procurement specifications stipulate that these limits must be met without detailing the analytical techniques that may be used to determine conformance with the specification. Depending on the constituent or family of constituents being investigated, more than one method of analysis may be feasible. NA-A6-332AO-GYD-000 provides a list of contaminates which are of The interest. The sample should also be inspected for moisture, and total percentage of oxygen in the sample. There are several methods used to arrive at the percentage of oxygen in a sample. 2. Oxygen Volumetric (Orsat type) analysis with a suitable oxygen absorbing agent is the recommended method in this application. Paramagnetic analyzers. because of their simplicity in field operations, may be of some use although they are of marginal precision +I percent at almost 100 percent oxygen concentrations. Direct gas chromatographic analysis for oxygen is of marginal precision. 3. The Servo Mex is designed to continuously monitor the content of a sample gas stream, which is clean, dry and non-corrosive. Oxygen content of the sample gas is determined by measuring the relative magnetic susceptibility The paramagnetic susceptibility of the oxygen, is significantly greater than that of other common gases. This means Created by LTJG KyungNho "TACO" Kim Reviewed by ENS Carol Yeiser 122. I LEVEL ALSS Page 11 of 11 that oxygen molecules are attracted much more strongly than are molecules of other gases, most of which are slightly diamagnetic, repelled by a magnetic field. The test Cell measures the force developed by a strong non-uniform magnetic field on a diamagnetic test body suspended in the sample gas. The oxygen molecules are attracted to the magnetic field enhancing the magnetic fields affect on the diamagnetic body, two nitrogen filled quartz spheres. This causes the spheres to move in the field. By measuring the movement of the spheres the amount of oxygen in the sample can be determined. 4. The 8220A Analyzer is used to measure trace contaminants in oxygen. The system gauges these contaminants by measuring the intensity and frequency of infrared energy after it has passed through an oxygen sample. Every chemical functional group absorbs frequencies of infrared radiation uniquely. A plot of radiation intensity versus frequency would fingerprint an identifiable chemical group that had polluted an oxygen sample. The 8220A Analyzer is a modularized, bench-mounted unit used to support flight operations. This unit is capable of scanning aviators breathing oxygen samples for up to 15 contaminates, only 11 of these contaminates are monitored. The unit provides an output of the quantitative results within the limits of an established table. The analysis shall be performed on oxygen samples at 16 psi. 5. Contaminant analysis time is IO minutes, The comparison library has a built-in system for unknown substance composition analysis. The system modulates radiation from an infrared source. The modulated beam is directed into a gas cell that contains the oxygen to be sampled. A detector monitors the gas cell and recovers information over the range of the infrared spectrum to which the detector is sensitive. The data that is collected is passed to data processing components for analysis and reporting. Infrared frequencies enter through the compartment window . Reflecting mirrors route and focus the energy into the gas cell containing the gas sample during analysis. The cell is a multi-pass cell. A beam of infrared light, entering through the gas cell input window is reflected back and forth between the mirrors within the gas cell to achieve a greater path length, and is passed through the output window to a elliptical mirror and reflected to the detector. With increased path length there is no requirement for a larger gas cell. The cell has a IO-meter path length. The detector element is sensitive to IR energy and produces an output in proportion to the energy striking the element. The sample has absorbed some of the energy produced by the source, depending on the chemical make up of the sample. The absorption produces “absorption bands” that allow the data station to identify sample contaminates. The IR detector produces an analog voltage output. An analog to digital converter is used to translate the signal into a digital signal. This allows the computer to process the data. This information is converted to a spectrum, which completes the analysis process. The sample analysis is sent to the system printer or stored on the hard drive or floppy disk. Created by LTJG KyungNho "TACO" Kim Reviewed by ENS Carol Yeiser