here - Cal Poly Pomona

advertisement

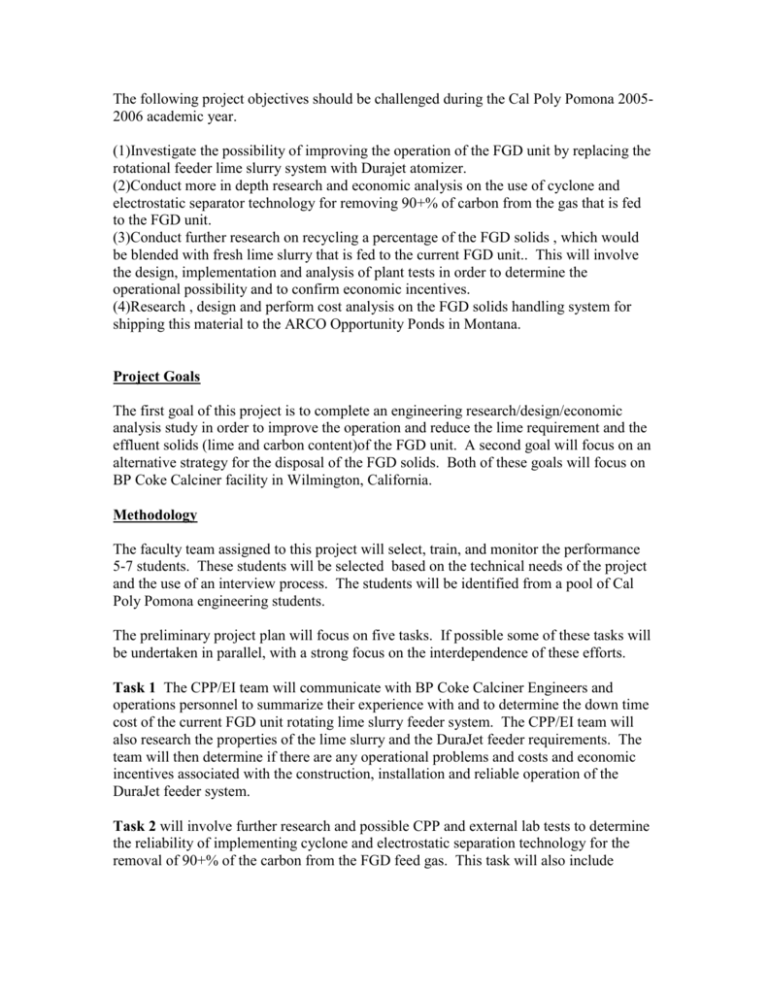

The following project objectives should be challenged during the Cal Poly Pomona 20052006 academic year. (1)Investigate the possibility of improving the operation of the FGD unit by replacing the rotational feeder lime slurry system with Durajet atomizer. (2)Conduct more in depth research and economic analysis on the use of cyclone and electrostatic separator technology for removing 90+% of carbon from the gas that is fed to the FGD unit. (3)Conduct further research on recycling a percentage of the FGD solids , which would be blended with fresh lime slurry that is fed to the current FGD unit.. This will involve the design, implementation and analysis of plant tests in order to determine the operational possibility and to confirm economic incentives. (4)Research , design and perform cost analysis on the FGD solids handling system for shipping this material to the ARCO Opportunity Ponds in Montana. Project Goals The first goal of this project is to complete an engineering research/design/economic analysis study in order to improve the operation and reduce the lime requirement and the effluent solids (lime and carbon content)of the FGD unit. A second goal will focus on an alternative strategy for the disposal of the FGD solids. Both of these goals will focus on BP Coke Calciner facility in Wilmington, California. Methodology The faculty team assigned to this project will select, train, and monitor the performance 5-7 students. These students will be selected based on the technical needs of the project and the use of an interview process. The students will be identified from a pool of Cal Poly Pomona engineering students. The preliminary project plan will focus on five tasks. If possible some of these tasks will be undertaken in parallel, with a strong focus on the interdependence of these efforts. Task 1 The CPP/EI team will communicate with BP Coke Calciner Engineers and operations personnel to summarize their experience with and to determine the down time cost of the current FGD unit rotating lime slurry feeder system. The CPP/EI team will also research the properties of the lime slurry and the DuraJet feeder requirements. The team will then determine if there are any operational problems and costs and economic incentives associated with the construction, installation and reliable operation of the DuraJet feeder system. Task 2 will involve further research and possible CPP and external lab tests to determine the reliability of implementing cyclone and electrostatic separation technology for the removal of 90+% of the carbon from the FGD feed gas. This task will also include economic analysis to determine the financial incentives for implementing these methods of carbon removal. Task 3 will be a research, test design, plant test, data analysis and cost analysis strategy for implementing FGD solids recycling. The CPP/EI team will research the literature and contact other manufacturing facilities who are operating an FGD unit and have experience with FGD solids recycling. The team will design , observe the implementation and analyze the data obtained from a series of plant tests that will involve mixing various percentages of FGD solids with fresh lime slurry that is fed to the FGD unit. Chemical analysis of the resulting FGD solids will be performed at either the CPP unit operations lab or an external lab testing facility. The CPP/EI team will then use this plant test data to design the required units and determine the costs and incentives of implementing FGD solids recycling. Task 4 will involve researching, designing and determining the cost and incentives of the new Wilmington Coke Calciner Plant FDG solids handling facilities. This will be required for loading the FGD solids on rail cars for shipment to the ARCO Opportunity Ponds in Montana. The CPP/EI team will also confirm the shipping and operations costs and incentives associated with using the FGD solids at the ARCO facility. Task 5 will involve documentation of all aspects of this study.