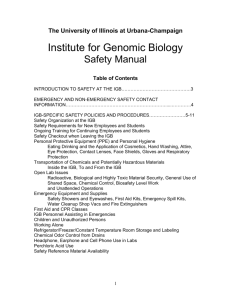

IGB Chemical Hygiene Plan - Carl R. Woese Institute for Genomic

advertisement