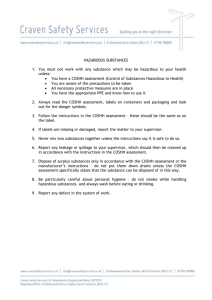

Guidance on COSHH Regulations for Hazardous Substances

advertisement

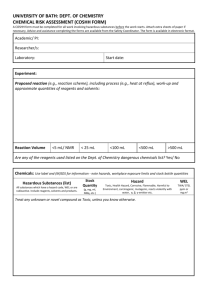

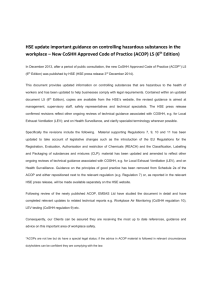

Guidance on COSHH Regulations for Hazardous Substances. Introduction The Control of Hazardous Substances to Health Regulations are aimed at eliminating or controlling the risks at work from a wide range of substances. While this guidance will introduce you to the main requirements of these regulations and how to comply with them, staff who have a line management or supervisory capacity for work which involves potentially hazardous substances are strongly recommended to read the HSE Approved Code of Practice , Control of Substances Hazardous to Health [5th Edition], which can be ordered from HSE books at www.hse.gov.uk. In addition, School, Departmental and Divisional safety officers or coordinators have been issued with copies by OSHEU. Which substances are covered by COSHH? These include: [1] Chemicals which are classified under the Chemicals (Hazard Information and Packaging for Supply) Regulations [CHIP] as on or more of the following: Very toxic Toxic Harmful Corrosive Irritant Sensitising Carcinogenic Mutagenic Toxic to reproduction [2] Substances which have been assigned a Workplace Exposure Limit [WEL] because of the potential risk from their inhalation. These limits are published in EH40/2005 Workplace Exposure Limits which can be ordered from HSE books at www.hse.gov.uk. In addition, School, Departmental and Divisional Safety Officers or Coordinators have been issued with copies by OSHEU] [3] Dusts of any kind whose average concentration in air exceed the levels specified in the COSHH regulations. [4] Asphyxiant gases, which act by reducing the oxygen content of the atmosphere. These include inert gases, such as nitrogen and argon, but also certain flammable gases. [5] Biological agents which can cause harm to human health. This harm may be through infection, allergy, toxicity, or some other mechanism. Biological agents include microoorganisms, such as bacteria and viruses, fungi and prions; parasites and their infectious forms. Further advice on working with biological agents is also given in the Biological Safety section of this website. [6] Carcinogens and mutagens Because of the particular risks posed by these agents, COSHH provides specific advice. You must read the information provided later in this guidance if you are considering using either carcinogens or mutagens in your work. [7] Any other substance hazardous to health not specifically covered by CHIP [e.g. medicines, pesticides, cosmetics] Which Substances are not covered by COSHH? These include: [1] Substances which are only hazardous because they are: Radioactive Have explosive or flammable properties At high pressure At extreme temperatures [You should note that the use of radioactive substances is separately covered by the Ionising Radiation Regulations (IRR) and use of explosive or highly flammable substances is covered by the Dangerous Substances and Explosive Atmospheres Regulations (DSEAR). Work involving high pressures or extreme temperatures must be assessed and controlled as hazards under the more general Management of Health and Safety at Work Regulations. [2] Asbestos or lead, which have their own regulations [3] Biological agents over which you have no control, e.g. someone catching a cold from another person in the laboratory. What COSHH Requires If your work involves the use of any potentially hazardous substances, then you must comply with the COSHH Regulations, the main requirements of which are detailed below. The stipulated Steps to follow shown below are the same as those given in, ‘COSHH: a brief guide to the Regulations’, which can be downloaded from the HSE website - www.hse.gov.uk You should also plan the work according to the principles of good practice for the control of exposure to substances hazardous to health detailed in Schedule 2A of the COSHH ACOP and listed in Table 1 Table 1 Principles of good practice for the control of exposure to substances hazardous to health Design and operate processes and activities to minimise emission, release and (a) spread of substances hazardous to health. (b) Take into account all relevant routes of exposure - inhalation, skin absorption and ingestion (c) - when developing control measures. Control exposure by measures that are proportionate to the health risk. Choose the most effective and reliable control options which minimise the escape (d) and spread of substances hazardous to health. Where adequate control of exposure cannot be achieved by other means, provide, (e) in combination with other control measures, suitable personal protective equipment. Check and review regularly all elements of control measures for their continuing (f) effectiveness. Inform and train all employees on the hazards and risks from the substances with (g) which they work and the use of control measures developed to minimise the risks. Ensure that the introduction of control measures does not increase the overall (h) risk to health and safety. Step 1 Assess the Risk Risk assessment is central to the COSHH Regulations and it is essential that you carry out a ‘suitable and sufficient’ assessment following the process recommended by the HSE. These steps are explained in the HSE leaflet, Five Steps to Risk Assessment, available free of charge from www.hse.gov.uk or from OSHEU. OSHEU has prepared a Generic Risk Assessment Form which follows these Five Steps and strongly recommends that you use it for this purpose. It can be downloaded from the OSHEU website as a Word form, together with associated guidance on how to carry out the assessment. If, however, you decide that you have good reason for not using this form, then you must ensure that your own follows and includes the Five Steps, otherwise it may well not comply with the requirement in the Regulations to be ‘suitable and sufficient’ Do not forget that, when you do a risk assessment for a procedure, you must consider all the associated hazards, not only those related to COSHH. For example, there may be hazards specifically related to the equipment (electrical, mechanical, noise, etc) or the substances may be flammable or explosive. Gathering information on the substances Before you are able to properly assess the risks from the substances which you will be using you must have sufficient information on any hazardous properties it may have. This can be obtained in various ways: [A] Chemical agents There is a number of different sources for obtaining information on chemicals. By law, a Materials Safety Data Sheet [MSDS] must be provided by the supplier of a chemical and these provide a lot of information on the associated hazards and recommended control measures. If you do not have the manufacturer’s MSDS, these may be obtained from CD-Rom databases provided by subscription from some of the large chemical suppliers, e.g. Sigma and Fisher. These services are expensive and only include MSDSs for those chemicals supplied by the manufacturer, but your School may subscribe, so you should check on this. Alternatively, some of the large chemical suppliers also provide MSDS information via their Internet websites, again only for their own products.. There are also some very useful independent websites for obtaining MSDS information, including: www.physchem.ox.ac.uk , www.cdc.gov , and http://ull.chemistry.uakron.edu/erd/. Free information leaflets are available on a number of specific chemicals via the HSE website www.hse.gov.uk, which also supplies information on Chemical Hazard Alert Notices (CHANS) and Methods for the Determination of Hazardous Substances (MDHS), providing guidance on identifying and promoting good practice for hazardous chemicals. . Finally, it is essential to provide adequate information when disposing of the chemical waste. Further information and advice on disposal of hazardous chemical waste can be obtained from Environmental Safety at OSHEU Other points to consider: [a] the physical form of the substance can affect the hazard it poses, e.g. it may not be hazardous as a solid, but may become so as a fine, breathable powder or vapour. [b] impurities can increase hazard, e.g. crystalline silica is often present in other wise low hazard minerals [c] some substances have a fibrous form which, due to its shape or size, makes it more hazardous to health [d] some substances are known to adversely affect health, but by an as yet undetermined mechanism, e.g. byssinosis caused by certain textile dusts. [e] exposure to two or more substances at the same time or in sequence can produce an added, or synergistic, effect [f] an unexpected event or emergency, such as a dangerous chemical reaction or fire may produce a substance hazardous to health; if such an event is foreseeable it should be considered in your risk assessment and included in your emergency action plan. [B] Biological Agents Further advice on working with biological agents is also given in the Biological Safety section of this website, which should be consulted. In order to be able to carry out a Risk Assessment you should know to which hazard group the biological agent belongs. This information can be obtained by checking the most recent Approved List of Biological Agents provided by the Advisory Committee on Dangerous Pathogens (ACDP) and published by the HSE (http://www.hse.gov.uk/pubns/misc208pdf). The latest website version should always be consulted as it is updated periodically. Organisms in Hazard Group 1 are not included. If you are working with an unlisted organism however, you should not automatically assume that it is Hazard Group 1. Information needs to be gathered about the organism and then a decision made when measured against the criteria for each Hazard Group (see Genetically Modified Organisms and Biological Agents, OSHEU website). Information can be obtained from a number of sources, including websites such as: Health Protection Agency http://www.hpa.org.uk/ Public Health Agency of Canada http://www.phac-aspc.gc.ca/msdsftss/index.html References such as Topley and Wilson’s ‘Microbiology and Microbial Infection’ can be used. Checks should also be made in scientific literature for information. Information gleaned from the above will give the hazardous properties of biological agents with regard to human health. Before carrying out the Risk Assessment it should also be checked whether or not the biological agent appears in the DEFRA Groups listed in the Animal Pathogens Order 1980, available on http://www.defra.gov.uk/animalh/diseases/control/animal_pathogens.htm. and also whether or not the biological agents is a plant pathogen. If the work is being carried out with substances which may contain biological agents, e.g. blood and body fluids, sewage, effluent from landfill sites, then you should consider which biological agents are likely to present and prepare the Risk Assessment accordingly. Consideration must also be given as to whether the experimental procedure may result in inadvertent culture. Advice on carrying out Risk Assessment for work with biological agents is given in the guidance “Biological agents: managing the risks in laboratories and healthcare premises” which is available to download from the HSE website at http://www.hse.gov.uk/biosafety/biologagents.pdf Selection of the control measures for work with biological agents is largely dictated by the requirements of COSHH. The minimum required is that the Containment Level matches the Hazard Group of the agent used [Schedule 3, COSHH Regulations 2002 (as amended)]. Step 2 Decide what precautions are needed If your Risk Assessment reveals a significant risk to health from the substance[s], then the COSHH Regulations require that you must decide on which measures you should implement in order to completely prevent exposure. Only if that is not practicably possible, should you select measures designed to reduce the risk of exposure to an acceptable level. In the latter case, your risk assessment should indicate the extent to which prevention or substitution of a process were considered. In considering this aspect, refer to the principles of good practice for the control of exposure to substances hazardous to health detailed in Schedule 2A of the COSHH ACOP and listed in Table 1 Step 3 Prevent or Adequately control exposure Prevention of Exposure This can best be done by one of the following: [1] Select a different procedure, which eliminates the need to use this substance [2] Substitute the substance with one, which is safe [3] Where the substance is being produced as a waste product, modify the process to eliminate its production Control of Exposure Only where you have concluded that it is not reasonably practicable to prevent exposure, should you select measures, which are designed only to control exposure as a means of reducing the risk to an acceptable level. To achieve the appropriate level of control you should select and apply the appropriate control measures from those approved by the COSHH Regulations. These are set out in a list, which is in order of priority. That is, you should always select a measure from as high up the list as reasonably practicable. For example, you should not select Personal Protective Equipment when you are reasonably able to use a method such as a fume cupboard to contain the hazard. [1] Enclose the process This involves the installation and use of equipment designed to completely enclose or isolate the process. Such equipment would include fully sealed isolator cabinets [e.g. Sealed Glove boxes for chemicals and Class III Microbiological Safety Cabinets for biological agents. These may also be remote systems, where the process is situated in a contained enclosure and operated from a distance by computer. [2] Contain the process and remove hazardous substance by exhaust ventilation The most common form of this in laboratories would be fume cupboards or Class I and II Microbiological Safety Cabinets. Other examples are local exhaust ventilation [LEV] systems to remove fume from welding operations and in wood-working where wood dust is created. [3] Change the systems of work in order to minimise exposure [i] Look for methods of work, which minimise emission of or potential exposure to the hazardous substance. For example, production of hazardous dusts can be reduced by wet-working; use of chemicals in pellet, rather than powder form. [ii] Reduce the time, frequency and amount of exposure. Fro example, use the minimum amount necessary for the minimum period [iii] Minimise the number of people exposed [4] Provide safe systems for handling, storage, transport and disposal as waste of hazardous substances [i] handling should only be done by means which minimise the risk of exposure. [ii] storage must be in appropriate, labelled containers in a suitable location. [iii] transport within a site must utilise appropriate, secure and robust containers. Transport outside a site must conform to the appropriate Regulations [iv] waste disposal must only be by approved routes and in accordance with the university policy on disposal of hazardous waste provided elsewhere on the OSHEU website [5] Provide good hygiene and housekeeping There should be: [i] adequate facilities for washing, changing and storage of clothing and PPE [ii] arrangements for laundering contaminated clothing [iii] separate accommodation for clothing worn at work which may become contaminated [iv] prohibition of eating, drinking and smoking in contaminated areas which may result in the ingestion of hazardous substances [6] Provide safe methods of work and appropriate supervision You should ensure that there is appropriate supervision of those working with the hazardous substances to ensure that they follow good practice and any defined methods of work at all times. An important part of this is a written Standard Operating Procedure, which details the precautions to be taken during the work in order to minimise the risk of exposure. [7] Provide Personal Protective Equipment [PPE] PPE should be used when it is not possible to achieve adequate control over exposure by any of the other means shown above. Even then, it should be used only in addition to the other appropriate measures and should always be seen as the measure of last choice. If PPE is required, then it must be carefully selected to be appropriate and properly maintained and serviced, including cleaning, and staff should be fully trained in its use. Anyone considering the use of PPE should consult the specific guidance given elsewhere on the OSHEU website. Control of exposure to substances which cause occupational asthma Hazardous substances which may cause occupational asthma are subject to additional duties under COSHH. A list of such substances is provided on the HSE website at www.hse.gov.uk/asthma/causes.htm. If you are planning to use any of these or your work may involve exposure to them, you should inform Occupational Health at OSHEU and obtain appropriate advice. Substances subject to a Workplace Exposure Limit [WEL] A wide range of subjects can cause harm by inhalation from the air and many of these are subject to a statutory Workplace Exposure Limit [WEL] which limits the amount in the air to which a person can be exposed over a standard period of time. These are published in EH40/2005 Workplace Exposure Limits which can be ordered from HSE books at www.hse.gov.uk, together with guidance on how and when to apply them. If you are using s substance which is listed as an inhalation hazard on its MSDS, then you must consult this document and act appropriately. Further advice on occupational hygiene monitoring may be obtained from Environmental Safety at OSHEU Step 4. Ensure that control measures are used and maintained It is your responsibility to ensure that anyone under your supervision makes proper use of all of the control measures which have been provided for the procedure in question and that they report any defects which they find. An important component of this is information and training and an appropriate level of supervision COSHH also requires that you ensure that any control measures are properly maintained and continue to perform as originally intended. This includes both systems of work and maintenance checks on items of equipment. For some equipment, such as local exhaust ventilation [LEV], which includes fume cupboards, microbiological safety cabinets and extract ventilation for machinery, there is a statutory requirement for regular testing, which must be complied with. If you use such equipment, you should read the OSHEU guidance on this web site Step 5. Monitor Exposure COSHH requires that you measure the concentration of hazardous substances in the air where your assessment concludes: a) there could be serious risks to health if control measures failed or deteriorated b) exposure limits might be exceeded c) control measures might not be working properly This is not required if you can show by another method of evaluation that you are preventing or adequately controlling exposure to your employees. Air monitoring of the worker’s breathing zone must be carried out when employees are exposed to certain substances and processes stated in schedule 5 of the COSHH Regulations. Records must be maintained of any exposure monitoring for at least 5 years. Where an employee has a health record, monitoring results relevant to them must be kept with their health record. Step 6 Carry out appropriate health surveillance For certain substances, which are known causes of ill health, health surveillance is appropriate. For this to be the case, the following criteria need to be met: (a) an identifiable disease or adverse health effect may be relate to exposure to the substance, (b) there is a reasonable likelihood that the disease or effect may occur under the conditions of this work, and (c) there are valid techniques for detecting indications of the onset of this disease or effect. If you believe from the information you have about the substance that this may be the case, consult Occupational Health in OSHEU for further advice Step 7 Prepare plans and procedures to deal with accidents, incidents and emergencies It should be a normal part of the risk assessment procedure that you consider the need for special procedures to be used in the event of an accidental release or exposure to the substance(s) in question. However, COSHH also requires that you prepare special written emergency plans and procedures where the potential risks from such an exposure go well beyond those associated with normal day-to-day work. Examples given in the COSHH ACOP of events which may fall within this category are: [1] any serious process fire which could give rise to a serious risk to health [2] any serious spillage or flood of corrosive agent liable to make contact with an employee’s skin [3] any failure to contain biological, carcinogenic or mutagenic agents [4] any acute process failure that could lead to a sudden release of chemicals, e.g. an exothermic reaction that results in the release of toxic fumes. [5] Any threatened significant exposure over a WEL Special emergency plans and procedures should be capable of: [a] mitigating the effects of the incident [b] restoring the situation to normal as soon as possible [c] limiting the extent of any risks to the health of any employees and anyone else likely to be affected [e.g. people in the neighbourhood] Further details of the required content of such a plan are given in the COSHH ACOP. Step 8 Ensure that employees are properly informed, trained and supervised You must ensure that anyone working with the substance(s) in question receives suitable and sufficient information instruction and training. This should include: [1] [2] [3] [4] [5] [6] The associated hazards and risks and the main findings of your risk assessment The relevant control measures and how and when to use them The defined method of work [standard operating procedure] If PPE is required, its correct use, storage and cleaning Cleaning, storage and waste disposal procedures The procedures to be followed in the event of an emergency It is important that this information and training is appropriate to the level of risk and in a form, which will be understood by those involved in the work. It is also vital to keep the information up to date, taking into account any significant changes in the type of work or the methods used. Your control measures will not be effective if those involved n the work do not know their purpose, how to use them properly, or the importance of reporting faults. Training records It is good practice to keep records of training given to individual employees. This can act as a useful checklist and confirmation that appropriate information, instruction and training has been received. Such a record can consist of a simple list of entries for each aspect of training, with the date given and signed by trainer and trainee. Carcinogens and Mutagens COSHH includes special provisions for preventing or adequately controlling exposure to carcinogens and mutagens (additional information Appendix 1 of the ACOP). The major reasons for this are that the development of the clinical effects may take many years after first exposure, often with no early warning of adverse effects, and that cancer is frequently fatal. Definitions of Carcinogen and Mutagen Carcinogen COSHH defines a as a substance or preparation (i.e. a mixture or solution of two or more substances) which either: a. is classified for labelling purposes as carcinogenic category 1 or 2 carrying the risk phrases R45 ‘May cause cancer’, or R49 ‘May cause cancer by inhalation’; or b. would be so classified if the European system for classifying substances and preparations dangerous for supply was applied (even if the law does not require this, as with certain pharmaceutical products or by-products such as hardwood dust). Substances or processes listed in Schedule 1 to the Regulations are also included in the definition, because of historic evidence of a risk of cancer in humans, though the precise agent may be unclear. The descriptors assigned to the three categories of carcinogens are: Carcinogenic Category 1 - substances known to cause cancer on the basis of human experience; Carcinogenic Category 2 – substances which it is assumed can cause cancer on the basis of reliable animal evidence; Carcinogenic Category 3- substances where there is only evidence in animals, which is of doubtful relevance to human health (i.e. the evidence is not good enough for Category 1 or 2.) In the case of mutagens, there are three similar categories with analogous descriptors, based on the strength of evidence for heritable genetic damage. Category 3 carcinogens, with the risk phrase R40 ‘Limited evidence of a carcinogenic effect’, and Category 3 mutagens, with the risk phrase R68 ‘Possible risk of irreversible effects’ are not included in the COSHH definitions of ‘carcinogen’ and ‘mutagen’ respectively, but are subject to the general requirements of COSHH. A comprehensive list of substances defined as carcinogens or mutagens for the purposes of COSHH is in HSE’s publication EH40/2005 Workplace exposure limits Mutagen COSHH defines a mutagen as a substance or preparation which either: a. is classified for labelling purposes as mutagenic category 1 or 2 carrying the risk phrase R46 ‘May cause heritable genetic damage’; or b. would be so classified if the European system for classifying substances and preparations dangerous for supply was applied (even if the law does not require this). Prohibitions relating to certain substances A number of known carcinogens are prohibited substances. If you are planning to use a carcinogen, you should check the list of these substances in Schedule 2 to the Regulations. If the carcinogen in question is listed in Schedule 2, your must contact OSHEU for further guidance. The importance of the risk assessment and control of the risk Because of the peculiar nature of the risks associated with carcinogens and mutagens risk assessment has an especially vital role to play and the COSHH ACOP gives specific guidance on this aspect. The basic principles are no different from those for risk assessment of other hazardous substances as described elsewhere in COSHH and in this guidance, but due care should be taken to properly take into account the peculiar and insidious nature of the risk. When selecting the appropriate measures for controlling the risk, you must take into account the potential for long-term and possibly fatal effects, which provide a compelling reason why you should make every effort to substitute the chemical in question with a non-carcinogenic or non-mutagenic alternative. If you have considered such alternatives and found them to be not reasonably practicable you must state this in your assessment, giving your reasons. If you are synthesising chemicals you should choose synthetic routes which: [a] avoid the use of carcinogenic or mutagenic substances at the start, or as part of any process or activity; and [b] avoid if possible the formation of by-products, intermediates, wastes or residual containments consisting of or containing carcinogenic or mutagenic substances and the conditions under which substances are used. Further guidance on substitution is provided in the ACOP (see paragraphs 8992) and in HSE’s publication. Seven steps to successful substitution of hazardous substances. If no suitable alternative to the carcinogen or mutagen is available, your objective must be to try to prevent exposure to the chemical by the best practicable means and following the hierarchy of control measures given earlier in this guidance. Again, because of the nature of the risks posed by carcinogens and mutagens, it is particularly important that you select the most effective measure possible and your first choice of control measure should always be the use of totally enclosed systems, unless this is not practicably possible. In all circumstances, employers should prevent or adequately control exposures by measures other than personal protective equipment (PPE), so far as is reasonably practicable. However, PPE, e.g. gloves, coats etc., and respiratory protective equipment (RPE) in particular, may be used as secondary protection in combination with other control methods, if those methods do not adequately control exposure by themselves. If the use of PPE and clothing is unavoidable, e.g. during a plant failure or maintenance operations, employers should follow the guidance in the ACOP on the standards for PPE, and the considerations that apply to the use of RPE. Incidents Involving Carcinogens and Mutagens In your risk assessment you must consider what actions may be needed in the event uncontrolled release of a carcinogen or mutagen into the workplace. If you conclude that this may result in the need for RPE which is capable of providing adequate control of exposure to the carcinogenic or mutagenic substances concerned, then you must make sure that they are provided and that the staff concerned made aware of the circumstances in which it may be required and are trained in their use.. Use, storage, labelling and disposal You should: c. keep carcinogenic or mutagenic substances to be used in the workplace to the minimum needed for the process and, where appropriate, store and transport them on site in closed containers, clearly labelled and with clearly visible warning and hazard signs. d. clearly label and securely store carcinogenic or mutagenic waste products until they are removed according to the official University procedures for removal of hazardous waste. e. clearly identify the areas in which exposure to carcinogens or mutagens may occur and take measures to prevent the spread of contamination within and beyond these areas. The number of people likely to be exposed to carcinogenic or mutagenic substances and the duration of their exposure must be kept to the minimum necessary for the work. Non-essential personnel must be excluded. Monitoring exposure in the workplace (regulation 10) 2. Monitoring employees’ exposure to carcinogens or mutagens is normally necessary because of the increased risk of serious health effects if controls fail. Where the assessment concludes that air monitoring is necessary, the employer should set up and follow a monitoring programme to determine the extend of employees’ exposure, so that the results can be compared with approved workplace exposure limits. If there is no approved limit for a particular carcinogenic or mutagenic substance, it is important that the employer sets an in-house occupational exposure limit to detect any deterioration in standards of control. Information, instruction and training The risk of cancer from exposure to a hazardous substance cannot in most cases be presumed to be reduced to zero except by eliminating exposure. Furthermore, the adverse effects may not show in the short term. It is, therefore, especially important to ensure the information, instruction and training is of an appropriately high standard. Employers should ensure that employees are aware not only of the need to maintain control of exposure, but also the additional compounding risks due to smoking. Smokers appear to face an increased risk of occupational cancer, since they take a mixture of substances into their lungs with the smoke. In addition to the information specified by COSHH and the ACOP, employers should keep employees and their safety representatives, and any other people likely to be exposed to carcinogenic or mutagenic substances, aware of: a. the type or form of the risk; b. the special features of carcinogenic and mutagenic substances; and c. the circumstances in which they may be exposed to carcinogenic or mutagenic substances. Health surveillance You should be aware of the objectives of health surveillance and its limitations in the case of carcinogenic or mutagenic substances. Health surveillance has its limitations in identifying people at risk or in detecting signs of cancer early enough for treatment to aid a full recovery. For this reason, it is largely restricted to keeping health records, through skin cancer is a good example where appropriate health surveillance can detect the condition at an early stage when it can be cured. Medical surveillance by a medical inspector of HSE’s Employment Medical Advisory Service or appointed doctor is, however, required for employees exposed to any of the substances and who are working in the related processes listed in Schedule 6 of the COSHH ACOP. Some of the substances listed are carcinogens. [1] Health surveillance is appropriate where employees are exposed to carcinogenic or mutagenic substances, unless the result of the risk assessment indicates that exposure is so adequately controlled that there is no reasonable likelihood of an identifiable disease or adverse health effect resulting from the exposure. [2] Where there is evidence from safety data sheets, risk phrases on labels etc. that a substance is known to cause, or is suspected of causing, cancer of the skin, e.g. arsenic, coal soot, coal tar, non-solvent refined mineral oils, contaminated used mineral oils, health surveillance should include: [a] regular skin inspection by a suitably qualified person; or [b] regular enquiries by a responsible person about symptoms, following self-inspection by the employees concerned. [3] Where [1] and [2] do not apply, employers need only keep a health record, as described in paragraph 235(a) of the ACOP. There is usually a long time delay between exposure to a carcinogenic substance and any related health effect. Therefore, employers should provide employees who have been exposed with information about any need for continuing health surveillance after exposure has ended, e.g. where a substance may cause cancer of the urinary tract.