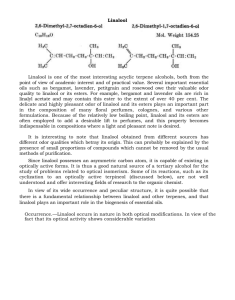

Perfumery and Flavoring Synthetics, Linalool, pgs 267

advertisement

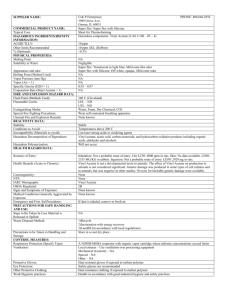

LINALOOL 3,7-Dimethy1-1,6-octadien-3-ol C 1-1 0 Mol.Wt. 154.25 10 18 Related materials: Ethyl linalool and Esters Isobutyl linalool and Esters One of the most interesting terpene alcohols found in nature, linalool is also one of the most widely occurring, in its free state and in the form of its esters, in both optical modifications. Because of its structure, it can be regarded as a basic material for a very large range of other terpenoids. Linalool can be converted to terpineol, geraniol and citral, and used in the preparation of citronellol, the ionones, Vitamin A, farnesol and sesquiterpenes. These transformations present a fascinating challenge to the imagination and ability of the organic chemist. To the perfumer, linalool and its esters represent a source of fragrances which no other material can provide. A good grade of linalool has a soft sweetness quite different from its isomeric primary alcohols, geraniol or citronellol. Moreover, having a lower boiling point than these alcohols, it serves as a natural and desirable top note in perfumes. Its esters, particularly the acetate, impart the predominant note in essential oils such as bergamot, lavender and petitgrain. The acetate, with its fresh citrus note, is an excellent base for old-fashioned but still popular cologne-type fragrances. Linalool is used in large quantities in soap and detergent products, and has been found to be stable and non-discoloring. In addition, its mellow character and fresh odor are of value in giving a natural character to perfumes based on synthetic aromatics. These properties extend the use of linalool to a wide range of floral and non-floral fragrances. Linalyl acetate is also used in large quantities in soaps and detergents, including liquids of high alkalinity, and possesses the same properties as linalool. A number of other esters are put in soaps and cosmetics. The formate is used where a high citrus character is desired, as in lavender and cologne-type fragrances, although it is perhaps somewhat less stable than the higher esters. The propionate is particularly helpful in imparting a bergamot note in soaps and cosmetics. The isobutyrate is needed mainly for its lavender note and because it supports the acetate in soaps. This property is due to its lower volatility resulting from its higher molecular weight. Numerous other esters of linalool are available on the market but their application in soaps and cosmetics is limited. It is noted that increase in molecular weight is accompanied by a marked reduction in the odor strength of the ester. Linalool and many of its esters have been identified as constituents of the flavors of many fruits and as natural components of many essential oils used in flavorings, mainly of the citrus type. Numerous natural and artificial flavorings in beverages, candies, ice creams and baked goods contain varying amounts of linalool and its esters. The GRAS list of flavoring ingredients published in 1965 lists linalool and nine of its common esters. Although linalool undergoes a wide range of transformations under drastic conditions, it is a stable aromatic for all practical purposes. The quality depends largely upon its source. The odor of commercial linalool formerly betrayed its origin because it retained trace constituents of the oil from which it was made. Today, the major portion of linalool on the market is synthesized either from naturally occurring pinene or entirely synthetically through a series of complex reactions. Both of these processes are described in some detail later in this chapter. There is no doubt that the synthetic linalools are purer and offer the perfumer greater scope in his formulations. As an aliphatic long-chain alcohol, linalool is clearly soluble in most solvents, including mineral oil. It has high solubility in diluted alcohols. It is also soluble in fluorinated hydrocarbons used as propellants in the aerosol industry. From an academic viewpoint, linalool is interesting because it has an asymmetric carbon atom and is capable of existing in optically active forms. It is a readily available tertiary alcohol for the study of problems related to optical isomerism. Some of its reactions, such as its cyclization to an optically active terpineol having a different asymmetric carbon atom, can be approached only by the application of modern concepts of reaction mechanisms. It is noteworthy that the higher homologs of linalool, namely, ethyl and isobutyl linalool and their esters, are now produced commercially. Occurrence. Linalool and its esters have been identified in the essential oils of several hundred plants'. In some instances, linalool is the main component of the oil, as in Brazilian rosewood where it is found to the extent of 90 per cent in its laevo form, or in coriander where it constitutes, in its dextro form, about 70 per cent of the oil. In citrus and certain flower oils, it is present in its free state only in very small amounts. When esterified, particularly as the acetate, it represents the main constituent of the oils of bergamot, petitgrain and others. In view of its widespread occurrence and peculiar structure, it is possible that a fundamental relationship exists between linalool and other terpenoids and terpenes, and that linalool plays an important role in the biogenesis of many essential oils. Isolation and Identification. Linalool was among the first terpene alcohols to be reported in the literature'. Its empirical formula was established, in 1881, by Grosser' as C H 0, and its structure elucidated not long afterward as a result of thorough investigations by Barbier, Tiemann and Semmler. Bertram and Walbaum found that on chromic oxidation linalool yielded an aldehyde similar to or identical with citral. This was rather puzzling as it was already known that the primary alcohol, geraniol, gave citral on similar treatment and that linalool possessed an asymmetric carbon atom — — 10 18 4 since it exhibited optical activity. Barbier , who was also devoting much time to the study of this compound, discovered that it possessed two ethylenic linkages and noted that on prolonged heating with acetic anhydride it gave the ester of an alcohol which was different from linalool. This alcohol was later shown by Bouchardat to be geraniol and the aldehyde which Barbier obtained by the oxidation of linalool to be citral. A further advance in the study of the constitution of linalool was made when Barbier and Bouveault found that oxidation of linalool with chromic acid gave not only citral but also acetone and methyl heptenone. As a result of these experiments, numerous structural formulas were put forward which, however, were later shown to be incorrect. In 1895, Tiemann and Semmler oxidized linalool (I) first with potassium permanganate, then with chromic acid, and obtained acetone and levulinic acid (II). 5 6 7 8 This and other evidence led them to conclude that linalool was a tertiary alcohol and that the formation of geraniol was the result of isomerization under the influence of acids. The relatively low boiling point of linalool and other physical constants strongly favored its being a tertiary alcohol, and the constitution given above was accepted and later confirmed through its synthesis. An indirect proof of its structure was given by Barbier and Locquin who hydrogenated linalool (1) with platinum black and obtained tetrahydrolinalool (III). On 9 dehydration and oxidation, this gave a ketone which was identified as methyl isohexyl ketone (IV). When this ketone was treated with ethyl magnesium iodide, it gave an alcohol identical with tetrahydrolinalool (III). Finally, linalool (I) was synthesized by Ruzicka and Fornasir" through a very interesting series of reactions. Employing a reaction discovered earlier by Nefn, they condensed methyl heptenone (V) with sodium acetylide and obtained dehydrolinalool (VI). The acetylenic linkage was reduced with sodium to the ethylenic linkage to give dl- linalool (I). The problem of determining the position of the double bond in either 6 or 7 positions—once the subject of much controversy—has been settled unequivocally through GLC analysis . It appears that terpenes in nature have the double bond in position 6, but it is possible to shift the double bond and to prepare the isomer having the double bond in position 7 through chemical reactions. Methods of Preparation. Formerly, synthetic linalool could be prepared only by the method described by Ruzicka and Fornasir in 1919 . Both commercial linalool and linalool used in academic studies were obtained from natural sources. When, more recently, synthetic linalool of high purity became available from two different sources, the use of natural linalool declined and it has now largely been replaced by the synthetic product. One synthesis starts with acetone and acetylene to give methylbutynol, which is hydrogenated with a suitable catalyst to methylbutenol. The latter undergoes the Carroll reactionn with acetoacetic ester in the presence of aluminum alkoxides to give methylheptenone. The commercial process involves the reaction of methylbutenol with diketene to give the acetoacetate of that alcohol which rearranges into methylheptenone . Methylheptenone can then be subjected to the Nef reaction to produce dehydrolinalool in good yieldsl a. This, upon selective hydrogenation with palladium or a partially poisoned catalyst known as the Lindlar catalystn, gives linalool. These reactions are represented as follows : 12 - 10 14 4 One important advantage of this process is that linalyl esters can be produced in very high purity by first preparing the ester of dehydrolinalool, then hydrogenating it to the linalool ester. In this manner, there are no isomerizations into geranyl, terpenyl or other derivatives, as dehydrolinalool is much more stable than linalool during esterification reactions. A process which has become very important in the production of large quantities of linalool is based on pinene chemistry and has resulted in the availability of many other terpene derivatives. Beta pinene (VII) is pyrolyzed to 7-methy1-3-methylene-1,6- octadiene or myrcene (VIII) by passing it through a tube at about 600° C with a very short contact time. Yields as high as 90% of myrcene are obtained in this manner, the balance being mainly pseudo-myrcene and 1,2-dimethy1-3-isopropenylcyclopentane". When dry hydrogen chloride is passed into the dry myrcene with cooling, keeping the temperature below —10° C, addition takes place at the gem-dimethyl and conjugated double bonds as shown. When the addition of hydrogen chloride is conducted in the presence of a cuprous chloride catalyst, a preferential addition at the allylic double bonds takes place with the formation of a higher proportion of geranyl (IX) or neryl chloride (X), linalyl chloride (XI) and a little myrcenyl chloride (XII). Under controlled conditions, very high yields of linalyl chloride are obtained which can then be converted into linalyl acetate. Conversion of the chloride into the acetate can be carried out by treating the chloride with an alkali acetate under suitable conditons. A number of other syntheses have been reported which are also of interest to the chemist. With the discovery by Normant in 1953 that vinyl bromide forms a Grignard reagent in tetrahydrofuran, it became possible to use this reaction for a new synthesis of linalool. Thus, high yields of linalool (I) are obtained by treating vinyl magnesium bromide (XIII) with methylheptenone (V) . The reaction is as follows : 17 The reaction can also be carried out using the inexpensive and readily available vinyl chloride"a. It has also been reported that autoclaving geraniol with water at 200° C results in the formation of linalool". This conversion has been applied commercially but the process has not been disclosed. Geranyl chloride has been reported to give small quantities of linalool when reacted with alcoholic alkali°. Chemical Reactions. — An optically active tertiary alcohol, linalool possesses a double bond adjacent to the hydroxyl group and presents many properties of considerable academic interest. In view of these facts, its chemical reactions have been subjected to many studies. Because its complete separation in a pure state is extremely difficult, it is doubtful that an absolutely pure product has been prepared from natural or synthetic sources. Fortunately, however, a number of essential oils, notably Brazilian rosewood oil and Mexican linaloe oil, contain a very high percentage of linalool (about 80 per cent) and a careful fractional distillation of these oils under vacuum through an efficient fractionating column gives comparatively pure linalool. Linalool prepared in this manner always contains small amounts of certain substances. Petitgrain Bigarade is reported to contain optically pure linalyl acetate, thus being a source of optically pure linalooPa. The resolution of linalool was attempted by Paolini and Divisia" who prepared the strychnine salt of the phthalate of dl-linalool and subjected it to recrystallization in various solvents. The regenerated linalool had a rotation of +1.7° indicating partial resolution. Linalool is readily reduced to both the saturated alcohol and the corresponding hydrocarbon. On reducing it with sodium in alcohol, Semmler obtained dihydromyrcene". The same product resulted by the use of sodamide in liquid ammonia". Reduction by colloidal palladium or platinum gives both dihydro- and tetrahydrolinalool. Similar results are achieved by using Raney nickel catalysts". Comparatively pure samples of tetrahydrolinalool were obtained by Stevens and McNiven by carefully hydrogenating purified samples of linalool with platinum black and then treating the product with permanganate solution to remove unsaturated products. Using a nickel catalyst, Enklaar obtained not only tetrahydrolinalool but also the corresponding hydrocarbon, 2,6-dimethyloctane. Numerous other hydrogenation experiments have been reported with results somewhat similar to those mentioned above. Oxidation reactions of linalool yielding degradation products have been discussed and need not be repeated here. Linalool monoxide was first prepared by Prileschaev" by the action of benzoyl peroxide on linalool. Naves and Bachmann subjected this compound to a through study. It is interesting to note that this oxide occurs in oil of Mexican linaloe, apparently as a result of the oxidation of linalool in vivo in the tree. The occurrence of other oxides of linalool in nature is noteworthy a. The isomerization of linalool to geraniol and vice versa is of general academic interest as it constitutes a classic example of an ionotropic or allylic rearrangement. This type of rearrangement is common to the allyl type of alcohols. In the case of linalool the rearrangement to geraniol may be brought about by prolonged boiling with acetic anhydride. It is reported" that treatment of linalool with acetic anhydride containing 1 per cent phosphoric acid in the cold for twenty-four hours yields 41 per cent geraniol. 2³ 25 26 28 28 , A very similar process, known in the trade as "cold acetylation," was used for the preparation of linalyl acetate and other acetates of terpene alcohols. Conditions for the linalool—geraniol isomerization were studied in detail by Rivkin and Meerzon . They found that the reaction was reversible in the presence of water at high temperatures and pressures and in the absence of catalysts. Weak acids caused dehydration, whereas certain salts had a catalytic influence on the reaction. In all cases, the rearrangement took place only to a small extent. A thorough study of the mechanism of this type of reaction has been made by Prevost . Another very interesting property of linalool is the ease with which it undergoes cyclization. It was discovered in the early stages of the study of linalool that both dilute sulfuric acid" and strong formic acid converted it not only to geraniol and nerol but also to alpha terpin hydrate. The esters of these alcohols were obtained by treating linalool with acetic anhydride. It has long been known that on treatment with various acids, linalool gives small amounts of geraniol, nerol and significant quantities of terpineol. Furthermore, in all cases, laevo linalool was noted to cyclize to dextro terpineol, and dextro linalool to laevo terpineol. Examination of the structures of linalool and terpineol revealed that in the process of cyclization, the single asymmetric carbon atom of linalool is destroyed ³0 ³1 ³³ and a new asymmetric carbon atom created in terpineol. It was reasonable to expect that the destruction of the asymmetric carbon atom in linalool would lead to the formation of an optically inactive terpineol. That this is not the case has led to a number of studies and many speculative explanations a. It cannot be said that this reaction has been satisfactorily explained. Possibly, an intermediate compound such as terpin hydrate, still possessing the asymmetric carbon atom of linalool, directs the cyclization in such a manner that the asymmetric carbon atom in the resultant terpineol gives an optically active compound. When linalool is treated with strong acids or strong catalytic agents, complex transformations take place yielding a range of hydrocarbons. Thus, treatment of linalool with 30 per cent sulfuric acid at elevated temperatures gave myrcene, dipentene, terpinolene, p-cymene, alpha-terpineol, 1 :4-and 1 :8-cineole". Similar transformations are brought about by treatment of linalool with Japanese acid earth". Heating linalool at high temperatures with oxalic acid yielded a diterpene and alpha camphorene, among other products". ³³ Gentle dehydration of linalool by distilling it under vacuum in the presence of iodine has yielded myrcene", or a mixture of myrcene and ocimenes . This is an elegant method of dehydrating tertiary alcohols and is especially applicable to terpene alcohols. Linalool can be reacted to form a borate, a property which can be used to advantage in its separation and purification. The preparation of linalyl borate is best carried out by heating linalool with a low boiling alcohol borate such as butyl borate. Butyl alcohol distills off, leaving linalyl borate and any possible impurities in the reaction mixture. These impurities are then separated by distillation. The remaining linalyl borate is, for example, steam distilled and the purified linalool obtained as the distillate. Physical Properties. — The following properties have been reported for linalool and its esters : ³8 The Essential Oil Association of U.S.A. has adopted the following constants for Linalool derived from Brazilian Bois de Rose oil : Color and Appearance : Specific Gravity at 25/25° C: Optical Rotation : Refractive Index at 20° C: Solubility in Alcohol : Total Alcohol Content : Ester Content : Colorless liquid, having a pleasant floral odor. The better perfumery grades of linalool are relatively free of camphoraceous and terpenic odors. 0.860 to 0.867 (Temp. correction factor from n°/n° C: 0.00064 per °C) Plus 2 to minus 2 1.4600 to 1.4670 Clearly soluble in 4 volumes of 60% alcohol. Not less than 90% calculated as C„H„OH. Not more than 0.5% calculated as linalyl acetate. Synthetic linalool made by the acetylene process is highly pure, containing only traces of dehydrolinalool and dihydrolinalool. These are not objectionable since their odor is very similar to that of linalool. Linalool from pinene is also a very pure product, containing over 98 per cent linalool, the balance consisting of isomeric alcohols such as geraniol and nerol. It is thus seen that synthetic linalool has a much greater degree of purity than linalool derived from essential oils by fractional distillation. Linalyl acetate prepared from pinene is also highly pure, usually containing over 98 per cent linalyl acetate and the balance, acetates of isomeric alcohols. The Essential Oil Association of U.S.A. has adopted the following physical constants for Linalyl acetate 90% from Bois de Rose Brazilian : Color and Appearance : Specific Gravity at 25/25° C: Optical Rotation : Refractive Index 20° C: Acid Value : Ester Content : Solubility in Alcohol : Colorless to slightly yellow having a pleasant flowery odor. 0.902 to 0.914. (Temp. correction factor from n°/n° C: 0.00061 per °C) Minus 1 to plus 1. 1.450 to 1.458. Not more than 2. Not less than 90%. Soluble in 5 volumes of 70% alcohol. The standards adopted for Linalyl propionate are as follows : Appearance and Odor : Linalyl Propionate is an almost colorless liquid having a sweet floral odor reminiscent of Oil Bergamot. Specific Gravity at 25°/25° C: 0.895 to 0.902. (Temp. correction factor from n°/n° C: 0.00061 per °C) Optical Rotation : Minus 1 to plus 1. Refractive Index at 20° C: 1.4500 to 1.4550. Acid Value : 1 maximum. Ester Content: 92% minimum. Solubility in Alcohol: Clearly soluble in 7 volumes of 70% alcohol. Manufacture. — Linalool was formerly obtained entirely from natural sources. It was separated from other components of an essential oil by careful fractional distillation through efficient columns. At its best, natural linalool thus prepared contained small amounts of impurities which indicated its origin. Today, most of the commercial linalool is manufactured either through the acetylenic process or starting from beta pinene. An American patent describes the following procedure for the manufacture of linalool. The steps involve the conversion of dimethyl-vinylcarbinol to methyl heptenone, which is then treated with acetylene to give dehydrolinalool. ³9 Controlled hydrogenation gives the required linalool. Dimethyl-vinyl-carbinol is prepared by reacting acetone with acetylene, followed by limited hydrogenation. "A one-liter three-neck flask equipped with a stirrer, thermometer, dropping funnel and reflux condenser, protected by drying tubes, was charged with 172 g (2.0 mols) of dimethyl-vinyl-carbinol (which can also be designated 2-methyl-3- buten-2-ol), 170 ml of petroleum ether (b.p. 30-60°), 4 ml of pyridine and 4 ml of acetic acid. From the dropping funnel was added, dropwise, during three hours 184.8 g (2.2 mols) of diketene, while maintaining a reaction temperature of 25-30° by external cooling. Stirring was continued at that temperature for three hours after addition was complete. Then, the reaction mixture was washed successively with dilute sulfuric acid solution, followed by saturated sodium bicarbonate solution, and finally with water to neutrality. The organic solution was dried with anhydrous calcium sulfate, and the solvent was removed in vacuo. The product, dimethyl-vinyl-carbinyl acetoacetate, was obtained by fractionation in vacuo; b.p. 40-45° (1.5 mm); nD = 1.4370; yield, 330 g (97%). "The dimethyl-vinyl-carbinyl acetoacetate (330 g) was placed in a one-liter, three-neck flask provided with a stirrer, thermometer and reflux condenser connected via a solid carbon dioxide trap at the top to a gas meter. Aluminum tri(isopropoxide) (3.3 g) was added to the ester, and the mixture was heated by an oil bath to 145°, causing a vigorous evolution of carbon dioxide. Heating was continued at 145-155° until the evolution of gas had ceased. The crude product was then purified by fractional distillation. 6-Methyl-5-hepten-2-one was collected at 48-50° (6 mm); nD = 1.4372; yield, 199.4 g (81,5% of theory)." The one-step synthesis of linalool is described as follows: "24.2 g (1.05 gram atoms) of metallic sodium was dissolved in one liter of liquid ammonia, contained in a two liter flask fitted with a solid carbon dioxide condenser, a dropping funnel and a stirrer. Acetylene gas was bubbled into the reaction mixture until the blue color changed to white. The flow of acetylene was continued for an additional two hours. Then 126 g (1 mol) of 6methyl-5-heptene-2-one was dissolved in 150 ml of dry diethyl ether and was dropped into the stirred reaction mixture in one hour at reflux temperature. Stirring was continued overnight. The following morning, the ammonia was distilled off and was replaced with one liter of fresh liquid ammonia. "To the stirred mixture was added 56.2 g (1.05 mols) of ammonium chloride. After stirring for fifteen minutes, 264 g (2.0 mols) of ammonium sulfate was added. 46 g (2 gram atoms) of metallic sodium was cut up into small pieces and was added in two hours. "The ammonia was removed overnight, and the residue was taken up in one liter of water. The oily layer was separated, washed neutral, and distilled under vacuum. The product, a high grade linalool, boiled at 92° C/17 mm Hg: n 2, = 1.4600." The preparation of linalool from myrcene, via its acetate, is described in a patent" as follows : "One mole of myrcene hydrochloride was prepared by passing one mole of hydrogen chloride gas into one mole of fl pinene pyrolysate in the presence of 0.2% of cuprous chloride. The addition was conducted at 5 to 10°C over a period of 24 minutes. The resulting myrcene hydrochloride mixture was then added over a period of four minutes to 96.0 grams of stirred anhydrous ammonium acetate. The temperature 2 - was raised to 90° C and maintained at 90°-95° C for 61 hours with vigorous stirring. The mixture was then quenched in cold water and separated with the aid of a separatory funnel. Titration of the aqueous phase revealed that 77% chlorides were displaced. Analysis of the organic phase using vapor phase chromatography showed 41.6% linalyl acetate, 10.3% terpinyl acetate, and 35.7% geranyl and neryl acetates based on weight of starting myrcene contained in one mole of igpinene pyrolysate. The yield of mixed linalyl and geranyl esters is thus 77.3%." The linalyl acetate is hydrolyzed with alkali to yield linalool, which is then subjected to a fractional distillation purification. Two earlier patents disclosed the role of copper salts in directing the addition of hydrogen halides to myrcene4oa. Normant's reaction has also been patentee- and the manufacture of linalool is described as follows : "Magnesium (24 g) is introduced into dry tetrahydrofuran (200 ml) containing a trace of iodine and then a solution of vinyl bromide (107 g) in an equal weight of tetrahydrofuran is added to it, drop by drop, with stirring. The magnesium solution thus obtained is cooled in ice. A solution of 2-methyl-hept-2-en-6-one (101 g) in an equal volume of anhydrous ether is then added with vigorous stirring. When the addition is complete, the mixture is stirred for a further hour and then allowed to stand for 12 hours. A saturated aqueous solution of ammonium chloride is then added to decompose the magnesium complex formed. The mixture separates into two layers; the organic layer is decanted and dried over anhydrous potassium carbonate, freed from solvents by heating on a water bath, and then rectified by distillation under reduced pressure. dl-Linalool (103 g) of good purity, representing a yield of 83%, separates at 83-85° C under a pressure of 12.5 mm of mercury." In the acetylene process, dehydrolinalool is acetylated and the pure ester, which is free of any isomeric alcohol esters, is hydrogenated to yield pure linalyl acetate. In the myrcene process, the linalyl acetate is obtained and purified by careful fractional distillation. According to a British patent42, pure linalyl acetate is obtained by treating linalool with ketene in the following manner : "Ketene was passed into a reactor maintained at 20° C and containing 100 parts by weight linalool and 1 part by weight of paratoluenesulfonic acid. The ketene and linalool reacted to produce linalyl acetate. The ketene absorbed in the reaction was 0.83 mole of ketene per mole of linalool. The conversion of linalool to linalyl acetate was 73.5%, the yield of linalyl acetate was 86.5% based on the linalool consumed. No geranyl acetate was detected." The most recent development involving the preparation of terpene alcohols from pinene avoids the hydrohalogenation step but uses instead only Oxygen and hydrogen. The old process yielded products containing small amounts of chlorinated materials which were highly undesirable both from purity and olfactory considerations. With the new process, alpha or beta pinene can be used, or a mixture of the two. The pinene is hydrogenated to pinane which can be oxidized to pinane hydroperoxide. The latter on hydrogenation produces 2-pinanol. Thermolysis of pinanol opens the cyclobutane ring to give linalool . Linalool is readily converted to geraniol by means of special catalysts. Oxidation of geraniol yields citral for use in the manufacture of ionones and vitamins. 43 Toxicological Data.—Linalool, its anthranilate, benzoate, butyrate, cinnamate, formate, isobutytate, and propionate were granted GRAS status by FEMA and approved by the FDA for use in foods. At a level of 20% in petrolatum, linalool produced no irritation after a 48 -hour closed patch test on human subjects. In other closed patch tests on human skin, linalool caused no primary irritation on 28 normal subjects when applied at 20% concentration in Vaseline or ointment. Linalool tested at a concentration of 20% in petrolatum caused no sensitization. The esters of linalool tested at a concentration of 8% in petrolatum produced no irritation in a 48-hour closed patch test on human subjects. Tested at the same concentration on 25 volunteers, it produced no sensitization reactions. Trade and Commerce.—Over half a million pounds of linalool are used in the fragrance industry in the United States, and possibly twice that amount of the acetate. All the other esters are consumed in much smaller quantities. Linalool and its esters are shipped in glass or tin-lined containers. Good quality galvanized iron or black iron drums are also used. Poor quality esters of linalool may undergo slight hydrolysis on prolonged storage. The unpleasant odor of the free acid thus produced can be removed by washing with dilute sodium carbonate solution. Being an alcohol, linalool should not be stored in aluminum containers. Additional Literature J. L. SIMONSEN, The Terpenes, Vol. 1, pp. 57-68, Cambridge University Press, 1947. E. GILDEMEISTER AND F. HOFFMANN, Die Atherischen Ole, Ma, pp. 510-539, Akademie-Verlag, Berlin, 1960. E. GUENTHER, The Essential Oils, Vol. II, pp. 167-170, D. Van Nostrand Company, Inc. New York, 1949. References 1 GILDEMEISTER AND HOFFMANN, Die Atherischen Ole, Vol. Ma (1960) p. 510. 2 KAWALMR, J. Prakt. Chem., [1], 58 (1853) 226. 3 GROSSER, Ber., 14 (1881) 2485. 4 BERTRAM AND WALBAUM, J. Prakt. Chem., [2], 45 (1892) 599. 5 BARBIER, Compt. Rend., 114 (1892) 674; 116 (1893) 883, 993, 1062, 1200, 1459; Bull. Soc. Chim. France, [3], 9 (1893) 802, 914, 1002. 6 BOUCHARDAT, Compt. Rend., 116 (1893) 1253. 7 BARBIER AND BOUVEAULT, Compt. Rend., 118 (1894) 1208. 8 TIEMANN AND SEMMLER, Ber., 28 (1895) 2126. 9 BARBIER AND LocQurisr, Ann. Chim., [9], 2 (1914) 400. 10 RUZICKA AND FORNASIR, Helv. Chim. Acta, 2 (1919) 182. 11 NEF, Ann., 308 (1899) 264. 12 NAVES AND Oosumm, Bull. Soc. Chim. France, (1958) 377. 13 CARROLL, J. Chem. Soc., (1940) 704. 14 KIMEL AND COPE, J. Am. Chem. Soc., 65 (1943) 1993. 14a PASEDACH AND SEEFELDER, Ger. Pat. 1,081,883, March 21, 1960. 15 LINDLAR, Helv. Chim. Acta, 35 (1952) 446. 16 SULLY, Chem. and Ind., (1964) 263. DEAFER, Tappi, 46 [9] (1963) 513. 17 NORMANT, Compt. Rend., 240 (1955) 631. 17a RAMSDEN, LEEBRICK et al., J. Org. Chem., 22 (1957) 1602. 18 Schimmel & Co., Report, April 25 (1898) 27. 19 TIEMANN, Ber., 31 (1898) 837. 19a NAVES, Helv. Chim. Acta, 29 (1946) 555. 20 PAOLINI AND DIVISIA, Atti Accad. Nazi. Lincei, [5], 23, II (1914) 175. 21 SEMMLER, Ber., 27 (1894) 2520; 34 (1901) 3127; Schimmel & Co., Report, October (1911) 129. 22 CHABLAY, Ann. Chim., [9], 8 (1917) 193. 23 PAAL, Ger. Pat. 298,193. 2 4 PALFRAY, Bull. Soc. Chim. France, [5], 7 (1940) 404. 25 STEVENS AND MCNIVEN, J. Am. Chem. Soc., 61 (1939) 1295. 26 ENKLAAR, Rec. Tray. Chim., 27 (1909) 411.