2.0 technical specification - Washington Closure Hanford

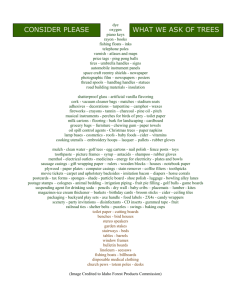

advertisement

EXHIBIT “E” TECHNICAL DESIGN SPECIFICATIONS 618-10 BURIAL GROUND: VERTICAL PIPE UNIT (VPU) OVERCASINGS Rev. Date 0 Washington Closure Hanford, LLC Reason for Revision Originator Issued for Use RIVER CORRIDOR CLOSURE CONTRACT Job No. 14655 Page 1 of 4 Checker Project Engr./Des TABLE OF CONTENTS 1.0 2.0 3.0 INTRODUCTION .................................................................................................. 3 TECHNICAL SPECIFICATION ........................................................................... 3 SUBMITTALS ....................................................................................................... 4 Page 2 of 4 Rev. 0 1.0 INTRODUCTION This Scope of Work is intended to document the design components and requirements for procurement of eighty-eight (88) steel over casings to be used for the remediation of vertical pipe units at Burial Ground 618-10. The over casings shall be: Forty-eight inch (48”) outside diameter; One-half inch (1/2”) wall; Overall length of twenty-eight feet four inches (28’4”); Spiral Welded (AWS D1.1); and Conforms to ASTM A 252 Grade 3 (66,000 psi tensile/45,000 psi yield). Six (6) of the over casings must be received no later than 15 August 2012. The remaining eighty-two (82) over casings must be received no later than 15 October 2012. 2.0 TECHNICAL SPECIFICATION 2.1 This specification covers nominal thickness of the steel over casings of cylindrical shape and applies to over casings in which the steel cylinder acts as a permanent load-carrying member, or as a shell to form cast-in-place concrete over casings. 2.2 The steel shall be made by one or more of the following processes: Martin/Bessemer furnace (open-hearth), basic-oxygen, or electric furnace. 2.3 The steel shall conform to the following requirements as to chemical composition: 2.3.1 2.3.2 Welded pipe: Martin furnace, basic-oxygen, or electric furnace Phosphorous, maximum (%): 0.050 2.4 Mechanical Properties Yield Strength, min. psi (MPa) Tensile Strength min. psi (MPa) Elongation in 2 in., min % GRADE 3 45,000 (310) 66,000 (455) 20% 2.5 Permissable Variations in Weights and Dimensions 2.5.1 The weight of any length of over casing shall not vary more than 15% over or 5% under the nominal thickness weight. Each length shall be weighed separately. The minimum wall thickness at any point shall not be more than 12.5% under the nominal wall thickness specified. The outside diameter of over casings shall not vary more than ±1% from the diameter specified. The length as specified shall be within a tolerance of ±1 inch. 2.5.2 2.5.3 2.5.4 Page 3 of 4 Rev. 0 2.6 Workmanship, Finish, and Appearance 2.6.1 The finished pipe over casings shall be reasonably straight and shall not contain imperfections in such number or of such character as to render the pipe unsuitable for pipe over casings. Surface imperfections, the depth of which does not exceed 12.5% of the nominal wall thickness, shall be permitted. These may be explored by grinding or filling to establish the depth. Surface imperfections, the depth of which exceeds 12.5% of the nominal wall thickness shall be considered defects. Repair of defects by welding will be permitted when the depth of defect does not exceed 33 1/3% of the nominal wall thickness. Before welding, the defect shall be completely removed. 2.6.2 2.6.3 2.7 Unless otherwise specified, material shall be furnished with either flame or machine cut plain ends. 2.8 One tension test shall be made on one length. 2.9 Over casings shall be ordered in uniform lengths with a tolerance of ±1 inch. 2.10 Upon request of the purchaser, in the contract or order, a manufacturer’s certification that the material was manufactured and tested in accordance with this specification together with a report of the chemical and tensile tests shall be furnished. 2.11 Each length of over casing shall be legibly marked by stenciling, stamping, or rolling to show the name of the manufacturer, heat number, the kind of pipe, the size, weight, length, and wall thickness, and the specification number and the grade. 3.0 SUBMITTALS A manufacturer’s certification that the material was manufactured and tested in accordance with this specification shall be submitted. Additionally, a report of the chemical and tensile tests shall be furnished. Page 4 of 4 Rev. 0