bbb_286_sm_supportinginformation

advertisement

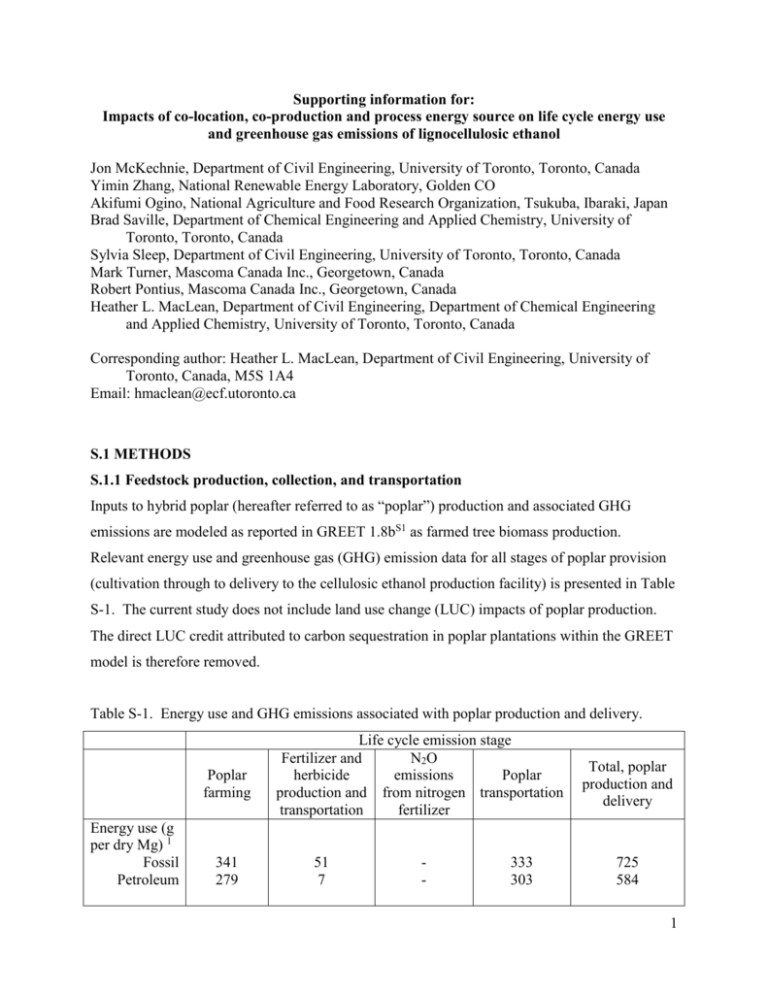

Supporting information for: Impacts of co-location, co-production and process energy source on life cycle energy use and greenhouse gas emissions of lignocellulosic ethanol Jon McKechnie, Department of Civil Engineering, University of Toronto, Toronto, Canada Yimin Zhang, National Renewable Energy Laboratory, Golden CO Akifumi Ogino, National Agriculture and Food Research Organization, Tsukuba, Ibaraki, Japan Brad Saville, Department of Chemical Engineering and Applied Chemistry, University of Toronto, Toronto, Canada Sylvia Sleep, Department of Civil Engineering, University of Toronto, Toronto, Canada Mark Turner, Mascoma Canada Inc., Georgetown, Canada Robert Pontius, Mascoma Canada Inc., Georgetown, Canada Heather L. MacLean, Department of Civil Engineering, Department of Chemical Engineering and Applied Chemistry, University of Toronto, Toronto, Canada Corresponding author: Heather L. MacLean, Department of Civil Engineering, University of Toronto, Canada, M5S 1A4 Email: hmaclean@ecf.utoronto.ca S.1 METHODS S.1.1 Feedstock production, collection, and transportation Inputs to hybrid poplar (hereafter referred to as “poplar”) production and associated GHG emissions are modeled as reported in GREET 1.8bS1 as farmed tree biomass production. Relevant energy use and greenhouse gas (GHG) emission data for all stages of poplar provision (cultivation through to delivery to the cellulosic ethanol production facility) is presented in Table S-1. The current study does not include land use change (LUC) impacts of poplar production. The direct LUC credit attributed to carbon sequestration in poplar plantations within the GREET model is therefore removed. Table S-1. Energy use and GHG emissions associated with poplar production and delivery. Poplar farming Energy use (g per dry Mg) 1 Fossil Petroleum 341 279 Life cycle emission stage Fertilizer and N2O herbicide emissions Poplar production and from nitrogen transportation transportation fertilizer 51 7 - 333 303 Total, poplar production and delivery 725 584 1 Emissions 1 (g per dry Mg) CH4 30 4 28 2 N2O 0 1 16 1 CO2 25,831 3,213 24,754 Notes: 1. Data from GREET 1.8b.S1 2. Zero value due to rounding. 62 19 53,798 S.1.2 Poplar conversion to ethanol Figure S-1 shows the process of ethanol production from input poplar. Input poplar undergoes uncatalyzed steam explosion pretreatment. Enzymes are input to the hydrolysis stage to convert cellulose and hemicelluloses to C5 and C6 sugars. Following fermentation and distillation, residual biomass is further processed. Uses of residual biomass differ by ethanol production scenario, being: employed to provide process energy for ethanol production; to produce excess electricity or steam for export; and/or to produce fuel pellets. Upstream energy use and associated emissions for poplar production and delivery are reported above. Ongoing development of cellulase technology prevents accurate estimation of enzyme inputs and associated upstream impacts. Enzyme inputs are therefore not included in this study, despite the potential contribution to ethanol life cycle emissions and energy use.S2 Energy and inputs required for co-product production are included within in the ethanol production stage. Figure S-1. Flowchart of ethanol production from poplar. 2 3 S.1.3 Co-location, process energy, and co-product scenarios We consider a range of ethanol plant configuration scenarios, differing by co-location (standalone, adjacent to steam-consuming facility, adjacent to steam and/or electricity exporting facility), process energy source (generation on-site from residual biomass, import of grid electricity, on-site steam production from natural gas, import of steam and/or electricity from adjacent facility), and co-product (electricity, pellets, steam). Ethanol plant operations data is presented in Table 1 of the main text. S.1.3.1 Process energy sources Process energy requirements for ethanol and co-product production are provided by Mascoma and reported in Table 1 of the main text. Associated energy use and GHG emissions for the various process energy sources are reported in Table S-2. Non-CO2 GHG emissions resulting from residual biomass combustion are estimated based on GREET 1.8b for farmed tree biomass combustion in small boiler. Steam production from natural gas assumes a boiler efficiency of 85%. Upstream energy use and GHG emissions related to natural gas production and delivery, as well as GHG emissions during steam production, are modeled based on reported values in GREET 1.8b. Imported electricity is assumed to be U.S. Midwest grid average. The mix of electricity generation sources in MidwestS3 is input to GREET to determine GHG emissions associated with the average electricity mix. Two scenarios (“3-steam, electricity” and “3-steam”) assume all or a portion of process energy is imported from an adjacent facility, modeled based on a pulp mill. Scenario “3-steam, electricity” assumes the pulp mill employs black liquor gasification and provides both steam and electricity for export. With gasification, pulp mills produce excess electricity for export. NonCO2 GHG emissions from black liquor gasification modelled based on electricity generation in the GREET biomass gasification turbine pathway. Waste steam from electricity generation via gasification is assumed to be used within the pulp mill.S4 To provide steam to the ethanol facility, we assume that a portion of syngas produced from black liquor is diverted to a boiler. Efficiency of steam generation is determined through a series of back-calculations of efficiencies reported in GREET, all assuming equal efficiency electricity and steam generation from syngas and natural gas. The biomass gasification turbine pathway reports electricity generation 4 efficiency of 40% compared to 53% for a natural gas turbine; this indicates a 75% biomass gasification efficiency. Steam generation from natural gas is assumed to be 85% efficient; applying this to the biomass pathway results in an overall efficiency of 63% for converting biomass to steam via gasification. The final scenario, “3-steam”, assumes the pulp mill employs black liquor combustion, producing excess steam that would be available for export. We treat this excess steam as a waste product of pulping chemical recovery and electricity generation at the pulp mill; therefore associated emissions are attributed to the pulp mill. Table S-2. Process energy sources: associated energy use and GHG emissions. Parameter Value Residual biomass Characteristics Energy content (GJ/dry Mg) Combustion energy use and emissions (MJ or g per GJ biomass) Fossil energy Petroleum energy Data source and notes 20.0 0 0 CH4 N2O CO2 3.63 10.43 01 Natural gas (steam generation) Characteristics Steam production efficiency 85% Upstream energy use and emissions (kJ or g per GJ natural gas) Fossil energy Petroleum energy 72,385 4,269 CH4 N2O CO2 186 0* 4,992 Steam production energy use and emissions (kJ or g per GJ natural gas) Fossil energy Petroleum energy CH4 N2O S1 S1 * zero value due to rounding 1,000,000 0 1 1 5 CO2 56,283 Coal Petroleum Natural gas Other gases Nuclear Hydroelectric Other renewables Other 70.6 % 0.4 % 4.1 % 1.8 % 20.2 % 0.9 % 2.0% 0.1 % Based on data from S3 Energy use and emissions (kJ or g per kWh electricity) 3 Fossil energy Petroleum energy 9, 014 146 Calculated from S1 Imported Midwest electricity Generation mix 2 CH4 1 N2O 0* CO2 891 Imported steam and electricity from adjacent facility Black liquor gasification Electricity generation efficiency 40% Steam production efficiency 63% 4 * zero value due to rounding Calculated from S1 Emissions (g/GJ biomass) CH4 N2O CO2 4 10 97,022 Black liquor combustion Treated as waste product; all emissions allocated to the exporting pulp mill Notes: 1. Biomass is considered to be immediately carbon neutral so biomass-based CO2 emissions are not counted. 2. Midwest consists of 8 states: Illinois, Indiana, Iowa, Michigan, Minnesota, Missouri, Ohio, and Wisconsin. 3. To match with available GREET electricity pathways, generation source data is adapted as follows: “petroleum” is modeled as “residual oil”; “other gases” is modeled in GREET as “natural gas”; additional generation sources not modeled in GREET are included in the category “other”. Energy use and GHG emissions are then calculated in GREET by inputting the following generation mix parameters: coal (70.6%); nuclear (20.2%); natural gas (5.9%); oil (0.4%); and other (3.0%). 4. Steam production efficiency calculated based on GREET data (description in text). 6 S.1.3.2 Co-products GHG emissions and energy use associated with co-product production are included in the “Ethanol Production” stage. For all cases, biomass-based CO2 emissions are assumed to not increase atmospheric GHGs (biomass is immediately “carbon neutral”). Excess electricity is exported to the U.S. Midwest grid and is assumed to displace grid-average electricity. The sensitivity analysis considers the impact of displaced electricity GHG intensity on life cycle GHG emissions. Non-CO2 GHG emissions from lignin combustion are estimated as farmed tree combustion in small biomass boiler in GREET.S1 Co-product pellets are assumed to be co-fired with coal in retrofit coal generation stations; in the Sensitivity Analysis, we consider the use of pellets to displace natural gas. Transport distance between ethanol facility and coal generating station is estimated as 160 km (100 miles). Pellets are shipped by heavy duty diesel truck; associated energy use and GHG emissions data are extracted from GREET 1.8b.S1 Pellet combustion at coal generating stations is assumed to not incur any loss of generation efficiency (i.e., pellets displace an equivalent quantity of coal based on energy content). GHG emissions and energy use related to combustion of pellets and coal at the GS, and upstream activities related to coal production and delivery, are modeled using data from GREET 1.8b. Steam generation from residual biomass uses data from GREET for farmed tree biomass combustion in a small boiler to estimate non-CO2 GHG emissions. We assume steam production that is displaced in the adjacent energy importing facility would have been produced from natural gas (85% efficiency). Energy use and associated GHG emissions data for the coproduct options and displaced products are shown in Table S-3. Table S-3. Energy use and associated GHG emissions of co-products and displaced products Parameter Co-product electricity Displaced grid average electricity Energy use and emissions (kJ or g per kWh electricity) Value Data source and notes As reported in Table S2 for imported Midwest electricity Co-product pellets Pellet transportation Mode Heavy duty diesel truck Distance (km) 160 7 Energy use and emissions (MJ or g per dry Mg pellet) Fossil energy Petroleum energy CH4 N2O CO2 Pellet combustion Fossil fuel substitution efficiency 463 420 S1 39 1 34,380 100% Pellet combustion emissions (g per GJ pellet) CH4 N2O CO2 Displaced coal Energy use and emissions (MJ or g per GJ) 2 Fossil energy Petroleum energy CH4 N2O CO2 4 10 01 S1 1,020 14 S1 114 1 104,239 Displaced natural gas Energy use and emissions (MJ or g per GJ) 2 Fossil energy Petroleum energy 1,072 4 CH4 N2O CO2 187 1 61,275 Co-product steam Displaced steam generation Fuel source Steam production efficiency Energy use and emissions (MJ or g per GJ) 1 S1 Natural gas 85% As reported above for displaced natural gas 8 S.1.4 Fuel use in light-duty vehicle Ethanol is denatured with gasoline (2.75%) before blending to E85 fuel (blend of 85% denatured ethanol; 15% gasoline). This results in an E85 volumetric ethanol content in of 82.9%. Gasoline in 2015 is assumed to be a mixture of conventional (35%) and reformulated (65%). Energy use and GHG emissions during the vehicle operation stage are reported in Table S-4. Table S-4. Vehicle operation: energy use and associated GHG emissions Parameter Ethanol (blended as E85 fuel) Fuel economy Value Data source and notes 10.1 Lgasoline equivalent/100 S1 km Energy use and emissions (kJ or g per km driven) Fossil energy Petroleum energy 772 772 CH4 N2O CO2 0* 0* 39 1 Gasoline Fuel economy 10.1 L/100 km Energy use and emissions (kJ or g per km driven) Fossil energy Petroleum energy CH4 N2O CO2 * zero value due to rounding S1 3,125 3,125 0* 0* 234 * zero value due to rounding Notes: 1. Biomass based CO2 emissions are not counted. 9 S.2. RESULTS The California Low Carbon Fuel Standard requires fuel GHG intensity be reported in terms of gCO2eq/MJ of fuel. Results from the present study are presented in this format in Table S-5. Table S-5. Well-to-wheel (WTW) results for ethanol pathways and reference gasoline pathway, reported in terms of gCO2eq/MJ Production scenarios Life cycle stage WTT, ethanol WTT, gasoline Vehicle operation 1 Total WTW emissions 1Electricity 1-Pellet 1-Max Pellet 2-Steam 3-Steam, electricity gCO2eq/MJ 3-Steam GREET ethanol2 GREET gasoline3 -13.2 -25.7 -45.7 -8.7 -86.4 -75.5 2.4 - 5.1 5.1 5.1 5.1 5.1 5.1 5.1 21.4 12.8 12.8 12.8 12.8 12.8 12.8 12.8 73.5 4.7 -7.8 -27.8 9.2 -68.5 -55.6 20.3 95.0 Notes: 1. Includes credit for biogenic carbon content of ethanol. 2. GREET ethanol is default farmed tree-to-ethanol pathway (Version 1.8b, NREL conversion process with electricity coproduct displacing average Midwest grid generation). 3. GREET gasoline is expected composition in 2015 (35% conventional, 65% reformulated gasoline) S.2.1 Ethanol yield and GHG emissions Improved GHG emission performance accompanying lower ethanol yield results from two factors: with lower ethanol production, more residual biomass is available for co-products, increasing the co-product credit; and this co-product credit is divided over a smaller output of ethanol. To disaggregate the contribution of these two factors, we calculate GHG emissions on the basis of one dry Mg of poplar. Table S-6 shows results on this basis for the “1-Pellet” scenario wherein a portion of residual biomass is combusted on site to provide process steam and electricity, with the remaining residual biomass pelletized and utilized off-site to displace coal. The trend of greater emission reductions with lower ethanol yield remains from the perspective of GHG emissions per Mg poplar. As reported elsewhere,S5 biomass-based solid fuels displacing coal provide a greater GHG reduction than producing liquid fuels (e.g., ethanol) to displace gasoline. This is primarily due to the carbon intensity of the displaced fuel (coal is more carbonintensive than gasoline). With lower ethanol yields more of the input biomass is allocated to the co-product pellet stream, resulting in greater GHG emission reductions. 10 Table S-6. GHG emissions for ethanol production scenario “1-Pellet” employing functional unit of one dry Mg poplar. Low ethanol yield Parameter Poplar production Poplar transportation Ethanol production Co-product credit Ethanol transport and distribution Upstream gasoline Vehicle operation Total WTW Displaced gasoline TOTAL 35,416 25,737 Base case ethanol High ethanol yield yield gCO2eq./Mg poplar (dry) 35,416 35,416 25,737 25,737 19,179 - 554,527 7,374 18,724 - 315,048 9,673 18,345 - 146,024 11,306 34,204 85,323 - 347,294 - 618,009 - 965,304 44,868 111,924 - 68,708 - 810,684 - 879,392 52,446 130,828 128,054 - 947,610 - 819,556 Given the limited availability of land for bioenergy production, it is important to consider GHG emissions reductions on the basis of land area dedicated to biomass production (e.g., gCO2eq/ha/yr). This is the product of GHG emissions per unit of biomass input (gCO2/Mg) and biomass yield (odt/ha/yr). In the current study, we employ general assumptions regarding poplar production under ‘average’ U.S. conditions as the primary focus is on ethanol production decisions. Without taking into account possible variations in biomass yield (e.g., due to biomass feedstock selection, genetic stock selection, location, and intensity of agricultural inputs), GHG emissions assessed on a per unit area basis are proportional to GHG emissions assessed on a per unit biomass input basis and would be similarly affected by ethanol yield. Depending on production location within the U.S. and other factors, poplar yield has been reported to vary from 7.3 to 13.5 Mg/ha/yr.S6 Assuming a mean poplar yield of 10.4 Mg/ha/yr, the ‘low ethanol yield’ scenario would result in GHG emissions of -10.0 MgCO2eq/ha/yr; the ‘base case ethanol yield’ scenario would result in GHG emissions of -9.2 MgCO2eq/ha/yr; and the ‘high ethanol yield’ scenario would result in GHG emissions of -8.5 MgCO2eq/ha/yr. Future work incorporating biomass production decisions could expand on the existing framework to allow for a comprehensive assessment of land use effectiveness for reducing GHG emissions and energy use. 11 S.2.2 WTW fossil energy use Fossil energy use for the ethanol production scenarios and reference gasoline pathway is shown in Figure S-2. Petroleum energy use for all ethanol scenarios, resulting primarily from the gasoline content of blended E85 fuel, is significantly reduced compared to gasoline. Total fossil energy use, the balance of fossil inputs to ethanol and co-product production and credits due to co-products displacing fossil fuels, is near zero or negative for the ethanol scenarios. Import of primarily non-fossil or waste process energy results in negative WTW fossil energy use for ethanol production. Figure S-2. Well-to-wheel (WTW) fossil energy use. S.2.3 Comparison with GREET biochemical farmed tree to ethanol pathway The default GREET pathway for biochemical ethanol production from farmed trees provides the reference NREL model comparison. We adjust the several input values in GREET for consistency with the Mascoma pathways: the year of analysis is set to 2015; direct land use change emissions are set to zero (GREET does not include indirect land use change impacts); 12 and the electricity generation mix is adjusted to the Midwest average calculated in the current study (reported in Table S-3). All other inputs remain “as-is”. S.2.4 Sensitivity Analysis The sensitivity analysis considers the GHG intensity of imported electricity for ethanol production and electricity displaced by co-product electricity exported from the ethanol facility, inclusive of both upstream operations (e.g., fuel production, transportation) and electricity generation. GHG emissions data for natural gas boiler and coal generation facilities are extracted from GREET 1.8b.S1 GHG emissions associated with electricity generation from natural gas combined cycle facility are from Zhang et al.S7 We consider the sensitivity of results for pellet co-product scenarios to the fossil fuel that pellets displace. Displacing natural gas with pellets provides a much smaller co-product credit due primarily to the lower carbon content of natural gas compared to coal. This reduces the GHG mitigation performance of ethanol where pellets are produced as a co-product. For all scenarios investigated here, however, ethanol significantly reduces GHG emissions relative to gasoline regardless of whether pellets displace coal or natural gas (Figure S-3). 13 Figure S-3. Sensitivity of life cycle GHG emissions to fuel displaced by pellets. NG = natural gas. 14 S.3 LITERATURE CITED S1. Argonne National Laboratory, The Greenhouse Gases, Regulated Emissions, and Energy Use in Transportation (GREET) Model. Version 1.8b. Argonne, IL (2010). http://www.transportation.anl.gov/modeling_simulation/GREET/index.html [accessed 29 November 2010]. S2. MacLean, HL, Spatari, S, The contribution of enzymes and process chemicals to the life cycle of ethanol. Environ. Res. Lett. 4:10 pages (2009). S3. US Energy Information Administration . Annual Energy Outlook 2010. Report # DOE/EIA0383(2010). Washington, DC (2010). S4. Consonni, S, Larson, ED, Kreutz, TG, Berglin, N, Black liquor gasifier/gas turbine cogeneration. Trans. ASME. 120:442-449 (1998). S5. McKechnie, J, Colombo, S, Chen, J, Mabee, W, and MacLean, HL, Forest bioenergy or forest carbon? Assessing trade-offs in greenhouse gas mitigation with wood-based fuels. Environ. Sci. Technol. In Press. S6. Walsh, M, De La Torre Ugarte, DG, Shapouri, H, Slinsky, SP, Bioenergy crop production in the United States. Environ. Resource Econ. 24:313-333 (2003). S7. Zhang, Y, McKechnie, J, Cormier, D, Lyng, R, Mabee, W, Ogino, A, MacLean, HL, Life cycle emissions and cost of producing electricity from coal, natural gas, and wood pellets in Ontario, Canada. Environ. Sci. Technol.. 44:538-544 (2010). 15