uvex übernimmt Verantwortung

advertisement

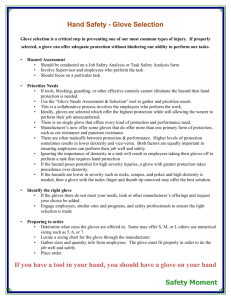

uvex Phynomic The market for hand protection has seen exponential growth in the last few years, as both employers and actual glove wearers become increasingly aware of the need to avoid potential accidents and injuries and as a result there is now a vast and ever-increasing selection of protective gloves made from a wide variety of materials available for use in the workplace. Yet despite the huge choice available, selecting the correct glove for the specific task being performed is really quite straightforward as long as the appropriate criteria are applied. The HSE advises basing the choice of suitable glove on the work, the wearer, and the environment in which they work, recommending consideration of five factors: The substance being handled, its form, concentration and temperature, which affects the type of material, design and thickness of the glove Exposure to other hazards, such as abrasion, cuts, tears, heat splashes or sparks, biological and mechanical hazards The type of contact, such as immersion or direct contact, and its duration and frequency – occasional or continual The user – gloves must be a good fit, comfortable and allow the hand to breathe and move freely. Any known allergies must be considered The task in hand –for example does it involve oils and grease or water, need gloves to be sterile, or need optimum precision and dexterity. One of the most important of these criteria is perfect fit, particularly when the glove is to be used for precision work. Wearer acceptance of personal protective equipment (PPE), including gloves, should be encouraged by employers who put safety high on their list of values, but many of them encounter difficulty in persuading their employees to wear their safety gloves – and keep them on – when they should. Glove fit is closely linked to comfort. When they are inflexible they can increase perspiration, leading to poor hygiene, discomfort, hand fatigue and related injuries. Equally, gloves that are too loose or unwieldy can impair dexterity, slip off the hands and make performing the work more difficult, leading to potentially dangerous situations. As well as the gloves being unsuitable for the job or fitting badly, workers may also lack awareness of potential hazards and may have not been trained in how hand protection should be used. Whatever the reason, they will not wear badly-fitting gloves and cannot carry out their work properly without gloves that fit like a second skin. To maintain safety and good grip, the glove must have optimum function and be perfectly tailored to the area of application. Good grip is essential, especially in oily, greasy, wet, or soapy conditions, to avoid potential accidents and injury from loss of secure control, and here the coating on the glove comes into play, repelling water, absorbing oil or giving excellent dry grip. Gloves that grip properly will also reduce hand fatigue and potential musculoskeletal injuries, and will enable wearers to work efficiently. In addition, the employer gains from reduced costs and waste and increased productivity – there is always a financial benefit for the business from good health and safety practice. Another factor to take into consideration is the risk of allergy, which could have serious consequences such as eczema or dermatitis and impair ability. For example, the new pure standard from uvex is establishing new benchmarks in the purity of safety gloves. In stringent dermatological testing conducted by the proDERM institute in Hamburg and to the highest medical standards, the uvex phynomic glove range was subjected to a human “skin patch reaction test”, where both coating and liner were applied to the body over a constant 24 hour period, and any effect on the test subject measured alongside two control substances consisting of water and soap. The result of this exercise was zero reaction to the uvex phnomic whilst water showed up a very slight trace and soap significantly higher. Therefore, users of the uvex pure standard phynomic glove range are reassured that they have selected the most skin friendly option available to combat the possibility of allergic reactions caused by the wearing of gloves. Whilst the coating has also been proven not to leave an impression on sensitive surfaces and is also silicone-free. Uvex phynomic gloves are also certified in accordance with the international testing system OekoTex Standard 100. This ensures they are free of 100 of the most harmful irritants to the skin including harmful solvents such as dimethylformamide (DMF), a possible carcinogen, or triethanolamine (TEA). Leading glove manufacturers continually carry out research into developing new and improved innovations, such as the phynomic range, to help perfect their gloves. Good manufacturers will always provide advice and guidance to employers on the appropriate glove for a particular task, so that they, in turn, can provide satisfactory and relevant information to the end-user about the products’ purpose and the reasons for their selection and so encourage regular wear. The latest available HSE statistics are a stark reminder of what can happen when workers do not wear the correct hand protection. There were over 40,000 reported major or over-three-day injuries to hands, wrists, fingers and upper limbs in 2009/10, not including less serious or unreported incidents – representing a massive sum of pain, distress and lost working time. This highly important area of PPE should never be ignored. ENDS For further information contact: Agency: Lee Morrison – In Association – 020 8697 6976 - lee@inassociation.co.uk Client: Clair Weston - (01252) 731200 – c.weston@uvex.co.uk