Flow rate: 1.0 mL/min

advertisement

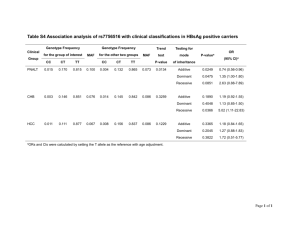

SOME ANALYTICALMETHODS OF FOOD ADDITIVES AND RELATED SUBSTANCES BY CHROMATOGRAPHIC TEHNIQUES AT EUROFINS SAC KY HAI DANG COMPANY Nguyen Huynh Tuan Anh, DinhThi Ha Long, Do Vu Phuong Thao, Vuong Quang Huy, Nguyen Vu Khanh, Pham Thi Anh, Diep Ngoc Suong, Chu Pham Ngoc Son. 1. INTRODUCTION 1.1. Food additives A food additive is any chemical substance that is added to food during the preparation or storage and either becomes a part of the food or affects its characteristics for the purpose of achieving a particular technical effect. Substances that are used in food to maintain its nutritive quality, enhance its keeping quality, and make it attractive or to aid in its processing, packaging or storage are all considered to be food additives. However, some substances that aid in the processing of food, under certain conditions, are considered to be food processing aids, not food additives. Examples of food additives include colouring agents that give foods an appetizing appearance, preservatives that prevent or delay undesirable spoilage in food, and certain sweeteners that are used to sweeten foods without appreciably adding to the caloric value of the foods. 1.2 Categories The Ministry of Health has issued the decision No 3742/2001/QD-BYT of August 31/2011, setting the list of food additives allowed in food. Under this decision, Food additives can be divided into several groups(Table 1). Trang 1 / 19 Table 1:Group of food additives No. Group Functions Some compounds in group 1. Acidity regulators Acidity regulators are used to change or otherwise control the acidity and alkalinity of foods. 41 compounds such as:potassium acetate, citric acid, orthophosphoric acid… 2. Flavor enhancers Flavor enhancers enhance food's existing flavors. 8 compounds such as:glutamic acid, monosodium glutamate, guanilic acid, inosinic acid… Stabilizers, thickeners and gelling agents, like agar or pectin (used in jam for example) give foods a firmer texture 13 compounds such as:polivinylpyrrolidone, Calcium carbonate, potassium chloride… Preservatives prevent or inhibit spoilage of food due to fungi, bacteria and other microorganisms. 29 compounds such as:sorbic acid, sodium sorbate, potassium bisulfite… Anticaking agents keep powders such as milk powder from caking or sticking. 14 compounds such as:trimagnesium orthophosphate, ammonium citrate… Antioxidants prevent foods from being oxidized, or going rancid. 15 compounds such as: ascorbic acid, a lpha tocopherol, TBHQ, BHA…. Antifoaming agents reduce or prevent foaming in foods. 4 compounds such as: polypropylene glycol, polyethyleneglycol, polyoxyethylene(20), sorbitan, monooleate,polydimethylsiloxane Bulking agents such as starch are additives that increase the bulk of a food without affecting its taste. 3 compounds such as microcrystalline cellulose, carnauba wax, sodium alginate. Sweeteners are added to foods for flavoring. Sweeteners other than sugar are added to keep the food energy (calories) low, or because they have beneficial effects for diabetes mellitus, tooth decay and diarrhea. 7 compounds such as: mannitol, acesulfame potassium, saccharin, …. Modified starches are used practically in all starch applications, such as in food products as a thickening agent, stabilizer or emulsifier 19 compounds such as: dextrins, roasted starch white and yellow, acidtreated starch Enzymes are catalysts in food processing 6 compounds such as: amylase, protease, glucose oxydase 3. Stabilizers 4. Preservatives 5. Anti Caking agents 6. Antioxidants 7. 8. 9. 10. 11. Antifoaming agents Bulking agents Artificial Sweeteners Modified starches Enzyms Trang 2 / 19 Propellants help propelling food from a container. 2 compounds such as: nitrogen, nitrogen dioxide Glazing Glazing improves appearance and able to protect food. 6 compounds such as: beeswax, mineral oil (food grade),… 14. Thickeners Thickening agents are substances which, when added to the mixture, increase its viscosity without substantially modifying its other properties. 20 compounds such as:alginic acid, carrageenan,… 15. Humectants Humectants keep foods moist. 2 compoundssuch ass: glycerol, calcium dihydrogendiphosphate Firming agents are food additives added in order to precipitate residual pectin, thus strengthening the structure of the food and preventing its collapse during processing. 8 compounds such as: calcium citrate, calcium chloride, calcium sulfate,… Emulsifiers allow water and oils to remain mixed together in an emulsion, as in mayonnaise, ice cream, and homogenized milk. 24 compounds such as: mono-and diglycerides of fatty acids, lactic and fatty acid esters of glycerol,… 12. Propellants 13. 16. Firming agents 17. Emulsifiers 18. Coloring agents Coloring agents enhance or add colour. 24 synthetic coloring agents and 11 natural coloring agents such as: curcumin, tartrazine, quinoline,… 19. Sequestrants Sequestrants improve the quality and stability of the food products. Sequestrants form chelate complexes with polyvalent metal ions. 14 compounds such as: Isopropylcitrate, calcium disodiumetylendiamintetraacetate, sodium polyphosphate, sodium gluconate,… 20. Raising agents Raising agents increase the volume of food through the use of gases 2 compounds such as: ammonium carbonate, sodium carbonate Flour treatment agents improve baking quality. 1 compound: azodicarbonamide Flavouring agents improve the taste or flavour of the foods 60 compouds including natural and synthetic flavouring agents 21. 22. Flour treatment agents Flavouring agents 1.3 National technical regulation on food additive National technical regulation on food additive follow: QCVN 4-1/2010: National technical regulation on food additive – Flavour Enhancer QCVN 4-2/2010: National technical regulation on food additive– Humectants Trang 3 / 19 QCVN 4-3/2010: National technical regulation on food additive– Raising agents QCVN 4-4/2010: National technical regulation on food additive– Anticaking agents QCVN 4-5/2010: National technical regulation on food additive– Colour retention agent QCVN 4-6/2010: National technical regulation on food additive– Antioxidant agents QCVN 4-7/2010: National technical regulation on food additive– Antifoaming Agent QCVN 4-8/2010: sweeteners National technical regulation on food additive– Artificial QCVN 4-9/2010: National technical regulation on food additive– Firming agents QCVN 4-10/2010 National technical regulation on food additive– Colours QCVN 4-11/2010: National technical regulation on food additive– Acidity regulators QCVN 4-12/2010: National technical regulation on food additive– Preservatives QCVN 4-13/2010: National technical regulation on food additive– Stabilizers QCVN 4-14/2010: National technical regulation on food additive– Sequestrants QCVN 4-15/2010: National technical regulation on food additive– Flour treatment agents QCVN 4-16/2010: National technical regulation on food additive– Bulking agents QCVN 4-17/2010: National technical regulation on food additive– Propellants QCVN 4-18/2011: National technical regulation on food additive– Modified starches QCVN 4-19/2011: National technical regulation on food additive– Enzyme QCVN 4-20/2011: National technical regulation on food additive– Glazing agent QCVN 4-21/2011: National technical regulation on food additive– Thickeners QCVN 4-22/2011: National technical regulation on food additive– Emulsifier QCVN 4-23/201: National technical regulation on food additive– Foaming agent 1.4 Purpose of food additive analysis Assess that food additive is in the lists of permitted food additives Assess food additive quality Control the abuse of non-permitted food additives. Quantify food additive There are several advantages and disadvantages in food additive analysis. Trang 4 / 19 1.5 Advantages Most of analytical methods for food additives and related subtances in food are available. Equipments for food additive analysis such as: HPLC, IC, GC, AAS, Spectrophotometers….are also available in our company 1.6 Disadvantages High matrix effect in food additive analysis. Numerous and complex food matrices 2. SOME ANALYTICAL METHODS OF FOOD ADDITIVES AND RELATED SUBSTANCES BY CHROMATOGRAPHY TEHNIQUES AT EUROFINS SAC KY HAI DANG COMPANY 2.1. Orange II and 2,4-diaminoazobenzene in chicken, roast pork 2.1.1. Principle Orange II and 2,4-diaminoazobenzene were extracted with 1 % acetic acid in acetonitrile. The extracted solution was cleaned by Primary Secondary Amine (PSA) and C18 sorbent, filtered through a 0.45 µm filter and analyzed by HPLCUV. Trang 5 / 19 2.1.2. Molecular formula Orange II 2,4-diaminoazobenzene 2.1.3. Equipment HPLC-UV with C18 column (250mm × 4.6 mm × 5µm). 2.1.4. Sample preparation Step 1: Weigh 5 g of sample into 50 mL centrifuge tube. Step 2: Add 15 mL of 1 % acid acetic in acetonitrile solution and vortex for 5 min. Step 3: Add mixture I of 1.5 g of CH3COONa and 6.5 g of MgSO4, shaken for 1 min and centrifuge at 5000 rpm for 5 min. Step 4: Transfer supernatant solution into new centrifuge tube and add mixture II of 0.15 g PSA and 0.15 g C18, shaken for 1 min and centrifuge at 5000 rpm for 5 min. Step 5: Pipet 5 mL of supernatant solution into 50 mL round bottom flask and then evaporate the solvent Step 6:Redissolve the residue in 1 mL of acetonitrile; filter the solution through a 0.45 µm filter before injection into HPLC-UV equipment. 2.1.5. HPLC operating conditions Wavelength: λOrangeII = 492 nm λ2,4-diaminoazobenzene = 437 nm Eluent: Acetonitrile : pH 4.8 buffer acetate (20:80) Flow rate: 1.0 mL/min Injection volume: 10 µL Trang 6 / 19 2.1.6. Calibration range The calibration curves represented area versus concentrations. Table 2 showed the corresponding linear equations for orange II and 2,4-diaminoazobenzene with excellent correlation coefficients (0.9999 – 1.000) Table 2: Linear equations representing area versus concentrations of orange II and 2,4diaminoazobenzene Equation Compound Range of concentration Equation coefficient (R2) Orange II Between 0.01 and 1 mg/L y=406763x-271.44 0.9999 2,4-diaminoazobenzene Between 0.01 and 1 mg/L y=4109696x-1586.8 1.000 Orange II Between 1 and 20 mg/L y= 413961x-12529 1.000 Between 1 and 20 mg/L y =437899x-24054 1.000 2,4-iaminoazobenzene Figure 1: 0.5 mg/L standards of orange II and 2,4-diaminoazobenzene 2.1.7. Limit of Detection (LOD) The limits of detection of 2, 4-diaminoazobenzene and orange II in chicken and roast pork were shown in table 3. Trang 7 / 19 Table 3: LOD of orange II and 2, 4-diaminoazobenzen in chicken and roast pork The matrices Chicken Roast pork Compound (mg/Kg) Orange II 0.045 2,4-diaminoazobenzene 0.046 Orange II 0.042 2,4-diaminoazobenzene 0.044 0.62 mg/Kg of 2,4-diaminoazobenzene in chicken LOD 8.35 mg/Kg of orange II in roast pork Figure 2: Analytical results of orange II and 2,4-diaminoazobenzene 2.2. Cyclamate in fried fish Trang 8 / 19 2.2.1. Principle Cyclamate was extracted with acetonitrile : water (2:8) solution. The extracted solution was cleaned on C18 SPE, filtered through a 0.45 µm filter and analyzed by ion chromatography (IC). 2.2.2. Molecular formula Sodium cyclamate 2.2.3. Equipment Metrohm 850 Professional IC with Metrosep A Supp7 250/4.0 2.2.4. Sample preparation Step 1: Weigh 0.5 g of sample into 50 mL centrifuge tube. Step 2: Add 10 mL of acetonitrile: water (2:8) solution, vortex for 1 min, sonicate for 10 min. Step 3: Centrifuge at 5000 rpm for 5 min. Step 4: Transfer supernatant solution into 50 mL volumetric flask Step 5: Repeat step 2, 3, 4 two times and make up to 50 mL with bi-distilled water. Step 6: Transfer extracted solution into a C18 column after being conditioned with 10 mL of acetonitrile), discard the first 3 mL of solution. Step 7: Then collect 7 mL of solution and filter through a 0.45 µm filter before injection into IC equipment. 2.2.5. IC operating conditions Injection Volume: 20 µl Flow rate: 0.7 mL/min Detector: conductivity Suppression: H2SO4 0.1 M Eluent: Na2CO3 3.6mM Trang 9 / 19 2.2.6. Calibration range The calibration curves represented area versus concentrations. Figure 3: Standard curve of cyclamate from concentrations of 0.5 to 50 mg/L Figure 4: Chromatogram of cyclamate 2.2.7. Limit of Detection (LOD) The limit of detection of cyclamate in dried fish is 10 mg/Kg. Trang 10 / 19 Figure 5: Chromatogram of dried fish containing cyclamate 2.3. Acesulfame potassium and Saccharin in candy, jam and beverage 2.3.1. Principle Acesulfame potassium and saccharin were extracted with distilled water, filtered through a 0.45 µm filter and analyzed by HPLC-UV. Trang 11 / 19 2.3.2. Molecular formula Acesulfame potassium Saccharin 2.3.3. Equipment HPLC-UV with C18 column (250 mm × 4.6 mm × 5 µm). 2.3.4. Sample preparation Step 1: Weigh 5 g of sample into 50 mL centrifuge tube. Step 2: Add 30 mL of distilled water, vortex and sonicate for 10 min. Add 5 mL of 20 % Zn(CH3COO)2 and 5 mLof Na2HPO4saturated solution Step 3: Vortex for 5 min, centrifuge for 10 min at 5000 rpm. Step 4: Transfer the supernatant into 100 mL volumetric flask. Step 5: Repeat step 3, 4. Step 6: Make up to 100 mLwith distilledwater and filter through a 0.45 µm filter into a vial and inject into the HPLC-UV. 2.3.5. HPLC operating conditions Wavelength: 220 nm Eluent: ACN: pH 3.4 phosphate buffer (10:90) Flow rate: 1.0 mL/min Injection volume: 10 µL 2.3.6. Calibration range The calibration curves represented area versus concentrations. Trang 12 / 19 Standard curves of Acesulfame potassium Between 0 and 250 mg/L Between 0 and 15 mg/L Equation : y = 11004 x + 13346 Equation : y = 11168 x + 1049 Figure 6: Standard curves of Acesulfame potassium Standard curves of saccharin Between 0 and 250 mg/L Between 0 and 15 mg/L Equation : y = 188370 x + 24412 Equation : y = 19185 x + 729,1 Figure 7: Standard curves of Saccharin Trang 13 / 19 Figure 8:Chromatogram of 10 mg/L of Acesulfame potassium and Saccharin solution 2.3.7. Limit of Detection (LOD) The limits of detection of acesulfame potassium and saccharin in candy, jam and beverage were respectively 20 ppm and 10 ppm. Trang 14 / 19 2.4. Sodium benzoate and potassium sorbate in grilled chopped fish and beef meatball 2.4.1. Principle Sodium benzoate and potassium sorbate were extracted with distilled water, filtered through a 0.45 µm filter and analyzed by HPLC-UV. 2.4.2. Molecular formula Sodium benzoate Potassiumsorbate 2.4.3. Equipment HPLC-UV with C18 column (150 mm × 4.6 mm × 5 µm). 2.4.4. Sample preparation Step 1: Weigh 5 g of sample into 50 mL centrifuge tube. Step 2: Add 1 mL of HCl (1M) and 10 mL of distilled water, vortex and sonicate for 15 min. Step 3: Add 20 mL of diethyl ether into sample, vortex for 5 min, centrifuge for 5 min at 5000 rpm. Step 4: Transfer the supernatant into 100 mL round bottom flask. Step 5: Repeat step 3, 4. Trang 15 / 19 Step 6: Evaporate the solvent. Step 6: Redissolve the residue in 1 mL of acetonitrile; filter through a 0.45 µm filter before inject into HPLC-UV equipment. 2.4.5. HPLC operating conditions Wavelength:λsodium benzoate= 225 nm λpotassiumsorbate = 250 nm Eluent: ACN: pH 3.4 formate buffer (15:85) Flow rate: 0.8 mL/min Injection volume: 20 µL 2.4.6. Calibration range The calibration curves represented area versus concentrations. 4500000 4000000 y = 81548x + 2385.5 3500000 2 R =1 3000000 2500000 2000000 1500000 1000000 500000 0 0 10 20 30 40 50 60 Figure 9: Standard curve of sodium benzoate from concentrations of 0.5 to 50 mg/L 14000000 y = 233013x + 20520 12000000 2 R =1 10000000 8000000 6000000 4000000 2000000 0 0 10 20 30 40 50 60 Figure 10: Standard curves of potassium sorbate from concentrations of 0.5 to 50 mg/L Trang 16 / 19 Figure 11:Chromatogram of sodium benzoate and potassiumsorbate 2.4.7. Limit of Detection (LOD) The limit of detection of sodium benzoate and potassium sorbate in grilled chopped fish and beef meatball was 10 mg/Kg Figure 12: Beef meatball containing 26.3 mg/Kg of sodium benzoate Trang 17 / 19 Figure 13: Grilled chopped fish containing 18.3 mg/Kg of sodium benzoate and 11 mg/kg of potassium sorbate. 3. CONCLUSION Food additive analysis is very important in assessing food quality. As different methods are today available, choice of appropriate one depends on food matrices and the range of concentrations to be determined. 4. REFERENCES [1]. TCVN 8471 - Foods – Analysis of Acesulfame potassium, Aspartame and Saccharin by HPLC (2010). [2]. TCVN 8472 - Foods – Analysis of cylamate by HPLC (2010). [3] AOAC official method 2007.01 - Pesticide residues in food by acetonitrile extraction and partitioning magnesium sulfate, Gas chromatography/Mass spectrometry and Liquid chromatography/Tanden mass spectrometry. [4] QinL., Xiao-Yan Z., Shu-Kun .H et al - Simultaneous High Performance Liquid Chromatographic Determination of Chrysoidine, Auramine O and Safranine T in Food.Food Science 30 (14), 194-196 (2009). Trang 18 / 19 [5] Wang X.,Song G., Wu W., Zhao J., Hu Y - Determination of the Food colorant, Chrysoidine, in Fish by GC/MS, Chromatographia 68, 659-662 (2008). [6] Guui W., Xu Y., Shou L., Zhu G., Ren Y - Liquid chromatography- tandem mass spectrometry for the determination of chrysoidine in yellow-fin tuna, Food Chem 122, 1230-1234 (2010). [7]. QCVN 4 to QCVN 12 – National Technical Regulations concerning Food Additives and Preservatives (2010). Trang 19 / 19