08920-Glazed Aluminum Curtain Walls [spc]

advertisement

![08920-Glazed Aluminum Curtain Walls [spc]](http://s3.studylib.net/store/data/007256119_1-f8af010785ad837f00fad5261943e843-768x994.png)

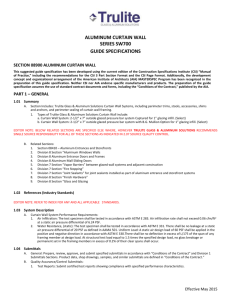

ST. VINCENT COLLEGE SIS AND HERMAN DUPRÉ SCIENCE PAVILION SECTION 08 44 00 - GLAZED ALUMINUM CURTAIN WALLS PART 1 - GENERAL 1.01 A. 1.02 A. 1.03 A. RELATED DOCUMENTS Drawings and general provisions of the Contract, including General and Supplementary Conditions and Division 1 Specification Sections, apply to this Section. SECTION SUMMARY Section includes: 1. Aluminum framed glass-glazed curtain wall systems with interior and exterior exposed metal framing. a. Stick system installation. 2. Multi-story, single-bay units; with sloping roof structure. 3. Prep to receive insulating glass, patterned glass in roof areas; field glazed. 4. Curtain walls system to be supported by independent structural steel system. RELATED SECTIONS Related Sections include: 1. 2. 3. 4. 5. 1.04 A. Section Section Section Section Walls. Section 06 07 08 08 10 92 41 51 00 00 00 13 - Rough Carpentry; Treated Wood Blocking. Joint Sealant. Aluminum Entrances and Storefronts. Aluminum Windows; Operable Sash in Curtain 08 80 00 - Glazing. SYSTEM DESCRIPTION Design requirements; stick system: Self supporting curtain wall system with pressure plate and covers attached to the tongue of back member. Glass shall be captured both vertically and horizontally on all 4 sides with no exposed fasteners unless absolutely necessary. Verticals and horizontals shall have a thermal break separator. All horizontal glazing pockets shall provided with weep holes to drain all accumulated water to the exterior. 1. Curtain wall manufacturer shall verify on shop drawings that the curtain wall system meets or exceeds performance requirements listed below. 2. Glazed aluminum curtain walls shall withstand movements of supporting structure as indicated on Drawings, including but not limited to, story drift, twist, column shortening, longterm creep, and deflection from uniformly distributed and concentrated live loads. GLAZED ALUMINUM CURTAIN WALLS 08 44 00 - 1 (45307035) ST. VINCENT COLLEGE SIS AND HERMAN DUPRÉ SCIENCE PAVILION 3. Failure also includes the following: a. b. c. d. e. 1.05 A. Thermal stresses transferring to building structure. Glass breakage. Noise or vibration created by wind and thermal and structural movements. Loosening or weakening of fasteners, attachments, and other components. Failure of operating units. PERFORMANCE REQUIREMENTS General: Provide the manufacturer's stock curtain wall system, adapted to the application indicated, that complies with performance requirements specified as demonstrated by testing the manufacturers corresponding stock systems according to test methods indicated. 1. Uniform Load Test: Basic wind speed at project site is 90 mph; refer to ANSI/ASCE 7-95 "Basic Wind Speed Map". B. Air Infiltration: Air leakage through the curtain wall system shall not exceed 0.06 cfm per sq. ft. of wall area when tested in accordance with ASTM E 283 at a minimum static air pressure differential of 1.57 lbs. per sq. ft.(75.23Pa) C. Water Penetration: There shall be no uncontrolled water leakage through the curtain wall system, as defined in AAMA 501, when tested in accordance with ASTM E 331 at a minimum differential pressure of 20 percent of inward design wind load but not less than 6.24 lbs. per sq.ft.(299Pa) or more than 12 lbs. per sq.ft (598Pa). D. Structural Performance: Curtain wall manufacturer shall design, engineer, fabricate, and install the glazed aluminum curtain wall system to withstand the effects of a wind load of 20 psf(958Pa) acting inward and 20 psf(958Pa) acting outward, normal to the plane of the wall, when tested in accordance with ASTM E 330, with no material failures or permanent deformation of structural members. Meet requirements of IBC International Building Code, current edition adopted by local governing authorities. 1. Structural test pressure shall be equal to 150 percent of the inward and outward acting design wind pressures. 2. Deflections: The curtain wall system shall be capable of withstanding building movements including wind loading and of performing within the following limitations. 3. Deflection of framing members perpendicular to the plane of the wall shall not exceed 1/240 of its clear span or 3/4 inch(19mm), whichever is less. GLAZED ALUMINUM CURTAIN WALLS 08 44 00 - 2 (45307035) ST. VINCENT COLLEGE SIS AND HERMAN DUPRÉ SCIENCE PAVILION 1.06 4. Deflection of members parallel to the plane of the wall, when carrying its full dead load, shall not exceed an amount that will reduce glass bits by less than 75 percent of the design dimension and shall not reduce edge clearance between itself and the panel, glass, or other fixed member immediately below to less than 1/8 inch(3.2mm). 5. Curtain walls systems that are to be supported by independent structural steel system, shall be designed in conjunction with the supporting steel to withstand the loading described above as an integral unit. 6. Thermal Movements: The glazed aluminum curtain wall system shall be capable of withstanding thermal movements resulting from an ambient temperature differential of 120o F(48.9 oC)., which may result in a metal surface temperature range of 180o F. (82.2 oC)within the curtain wall framing without causing buckling, stresses on glass, failure of joint sealants, damaging loads on fasteners, or other detrimental effects. 7. Condensation Requirements: The glazed aluminum curtain wall system shall be of thermal-break construction that has been tested in accordance with AAMA 1502.7 and certified by the manufacturer to provide a condensation resistance factory (CRF) of at least 45. 8. Sound Transmission: The average sound transmission loss through the glazed aluminum curtain wall system shall be a minimum of 30 db. for the standard frequency range of 125 to 4000 Hz when tested in accordance with ASTM E 90 with the glass type indicated. 9. Energy Performance: fixed glazed and framing areas shall have a U-factor of not more than 0.57 BTU/sq. ft. x H x Deg F (3.23 w/sq.m x K) as determined according to NFRC 100. SUBMITTALS A. Product Data: Include manufacturer's specifications for materials and fabrication, installation instructions, and recommendations for maintenance. Include test reports showing compliance with project requirements where test method is indicated. B. Shop Drawings: Show adaptation of manufacturer's standard glazed aluminum curtain wall system to the project; include typical unit elevations at 1/2 inch (12.7mm)scale and details at 3 inch (76mm)scale. Show dimensions, profiles of members, anchorage system, interface with building construction and glazing. 1. Include setting drawings, templates, and directions for the installation of anchor bolts and other anchorages installed as a unit of work under other sections. GLAZED ALUMINUM CURTAIN WALLS 08 44 00 - 3 (45307035) ST. VINCENT COLLEGE SIS AND HERMAN DUPRÉ SCIENCE PAVILION C. 1.07 A. Samples: Provide pairs of samples of each aluminum finish type and color on 12 inch (304.8mm)long sections of extrusions or formed shapes and on 6 inch squares of aluminum sheet or plate. Include 2 or more units in each sample set showing the extreme limits of variations expected in color and texture of finish. QUALITY ASSURANCE Installer Qualifications: Engage an experienced Installer who has successfully completed installation of glazed curtain wall systems similar in material, design, and extent to that indicated for the Project and who is acceptable to the curtain wall manufacturer. 1. Minimum 5 years of successful experience required. B. Glazing Standards: Comply with recommendations of Flat Glass Marketing Association (FGMA) "Glazing Manual" and "Sealant Manual" except where more stringent requirements are indicated. Refer to those publications for definitions of glass and glazing terms not otherwise defined in this section or referenced standards. C. Energy Performance Standards: Comply with NFRC for minimum standards of energy performance, materials, components, accessories, and fabrication. Comply with more stringent requirements if indicated. 1.08 A. 1.09 A. 1.10 A. PROJECT CONDITIONS Field Measurements: Take field measurements before fabrication; show recorded measurements on final shop drawings. Coordinate fabrication schedule with construction progress to avoid delay. SEQUENCING AND SCHEDULING Schedule installation of the glazed aluminum curtain wall system in sequence with related elements of the work specified in other sections to ensure that wall assemblies, including flashing, trim, and joint sealers, are protected against damage from effects of weather, age, corrosion, and other causes. WARRANTY General: Submit a written warranty signed by authorized representatives of the Contractor and Installer warranting that portions of the work involving glazed aluminum curtain wall are of good quality, free from defects, and in conformance with the requirements of the Contract Documents and further promising to repair or replace defective work during a 5-year period following completion of that portion of the work. Defective is defined to include the following: 1. 2. Glass breakage. Failure of operational parts to function normally. GLAZED ALUMINUM CURTAIN WALLS 08 44 00 - 4 (45307035) ST. VINCENT COLLEGE SIS AND HERMAN DUPRÉ SCIENCE PAVILION 3. 4. 5. 6. Deterioration or discoloration of finishes. Failure of the system to meet performance requirements. Water penetration through fixed glazing and framing areas. Noise or vibration created by wind and thermal and structural movements. B. The Warranty submitted under this Section shall not deprive the Owner of other rights or remedies that the Owner may have under other provisions of the Contract Documents and is in addition to the runs concurrent with other warranties made by the Contractor under requirements of the Contract Documents. C. Special Finish Warranty: Manufacturer's standard form in which manufacturer agrees to repair or replace components that show evidence of deterioration of factory-applied finishes within specified warranty period. 1. Deterioration includes, but is not limited to, the following: a. b. c. 2. Color fading more than 5 Hunter units when tested according to ASTM D 2244. Chalking in excess of a No. 8 rating when tested according to ASTM D 4214. Cracking, checking, peeling, or failure of paint to adhere to bare metal. Warranty Period: 20 years from date of Substantial Completion. PART 2 - PRODUCTS 2.01 A. B. C. 2.02 A. MANUFACTURERS EFCO Corp. Monett Missouri www.efcocorp.com (800)-221-4169. Kawneer Company, Inc. a Division of Alcoa, Norcross, GA www.alcoa.com/bcs/kawneer (404)-449-5555. Wausau Windows and Wall Systems, Wausau, WI www.wausauwindows.com (877)-678-2983. CURTAIN WALL SYSTEM Similar to Kawneer Company, Inc. "1600 curtain wall system"; outside glazed system. 1. 2. 3. 4. 2-1/2 inches wide x 7-1/2 inches deep(50.8mm x 190mm); including 3/4 inch (19mm)deep vertical mullion cap. 2-1/2 inches wide x 10 inches deep, with steel reinforcing by curtain wall manufacturer, ¾ inch (19mm) deep vertical mullion cap; for opening CW elevation 1,2,3,4, and 5. Thermally broken construction. Curtain wall system shall be from the same manufacturer as the aluminum windows. GLAZED ALUMINUM CURTAIN WALLS 08 44 00 - 5 (45307035) ST. VINCENT COLLEGE SIS AND HERMAN DUPRÉ SCIENCE PAVILION B. 2.03 A. Operable sash in curtain walls; Refer to Section 08 51 13 Aluminum Windows; similar. MATERIALS Aluminum: Provide alloy, temper and thickness recommended by the manufacturer for the type of use and finish indicated and with not less than the strength and durability properties of the alloy and temper designated below for each aluminum forum required. 1. 2. B. Glass and glazing: 1. C. Extruded bar and shapes: Comply with requirements of ASTM B221. Plate and Sheet: Comply with requirements of ASTM B 209. Refer to Section 08 80 00 - Glazing. Glass shall be 1 inch (25.4mm)thick insulating glass, unless otherwise noted. Safety glass where noted or required. Outside glazed. Mullion Configurations: Provide pockets to receive resilient estomeric glazing. Mullions and horizontals shall be one piece. Make provisions to drain moisture accumulation to the exterior. 1. Thermal break construction. barrier. Poured-in-place structural D. Brackets and Reinforcements: Manufacturer's standard high-strength aluminum units or stainless steel. E. Fasteners and Accessories: Provide manufacturer's standard noncorrosive fasteners and accessories compatible with materials used in the framing system and with exposed portions that match finish of the curtain wall system. Where movement is expected, provide slip- joint linings of sheets, pads, shims, or washers of fluorocarbon resin or a similar material recommended by the manufacturer. 1. 2. Concrete or Masonry Inserts: Cast-iron, malleable iron or hot-dip galvanized steel inserts complying with ASTM A 123/A 123M or ASTM 153/A 153M. Self-locking devices where fasteners are subject to loosening or turning out from thermal and structural movements, wind loads or vibration. D. Bituminous Coatings: Cold-applied asphalt mastic, SSPC-PAINT 12, compounded for 30-mil thickness per coat.. E. Weatherstripping: Manufacturer's standard replaceable stripping of wool, polypropylene or nylon woven pile, with nylon fabric and aluminum strip backing. F. Sealants and Gaskets: Use sealants and gaskets in the fabrication, GLAZED ALUMINUM CURTAIN WALLS 08 44 00 - 6 (45307035) ST. VINCENT COLLEGE SIS AND HERMAN DUPRÉ SCIENCE PAVILION assembly and installation of work, which are recommended and guaranteed by manufacturer to remain permanently elastic, non-shrinking, and non-migrating. G. Finish: PPG Industries "Duranar" coating system, or approved equal Kynar 500/Hylar 5000 based coating system. AAMA 2605, containing not less than 70% PVDF resin by weight in color coat. 1. 2. 2.04 Color Range: "Duranar" exotic 2-coat system. Color as selected by Architect from full range of available colors. Hardware finish as selected by Architect. FABRICATION A. General: Fabricate curtain wall system at the manufacturer's shop to the fullest extent possible and before applying finishes. Provide concealed fasteners. Make provisions to weep penetrating water and condensation to the exterior. B. Match exposed work to produce continuity of line. accurately and secure rigidly. C. Provide grid frame curtain wall members and components with joints neatly made, free of burrs, and tight fitting to provide hairline joints with ends coved, mitered, milled or machined as appropriate and approved, and securely welded, fastened or joined in the factory to develop full structural value of members and provide permanent water tight joints. D. Provide major framing members factory assembled in basic rectangular units sized for ease of erection and transportation. Systems using individual field fabricated and/or field assembled members are not acceptable. E. Where required, weld by methods recommended by manufacturer and AWS to avoid discoloration at welds. Grind exposed welds smooth. F. Conceal fasteners wherever possible. G. Provide tubular and/or solid extruded aluminum mullions with sharp, well defined corners and flush sight lines. H. Provide interlocking male/female type stack joints at adjacent grid frame members to allow for expansion and contraction of frame units. "Stick" system type one piece tubular members which do not allow for expansion and contraction in vertical members will not be acceptable. I. Glazing System: 1. Fit joints Exterior glazing; field glazed. Glazing system as supplied by curtain wall manufacturer; manufacturer's standard dry glazing system. Provide safety glass where indicated or required by code. GLAZED ALUMINUM CURTAIN WALLS 08 44 00 - 7 (45307035) ST. VINCENT COLLEGE SIS AND HERMAN DUPRÉ SCIENCE PAVILION J. Provide means to drain water passing joints, condensation within framing members and moisture migrating within curtain wall to exterior. PART 3 - EXECUTION 3.01 INSTALLATION A. Comply with manufacturer's instructions for protecting, handling, and installing fabricated curtain wall components, with particular care and attention to preservation of applied finishes. Discard or remove and replace damaged members. B. Anchor components securely in place in the manner indicated. Shim and allow for movement resulting from changes in thermal conditions. Provide separators and isolators to prevent corrosion, electrolytic deterioration, and freeze-up of moving joints. Rigidly secure nonmovement joints. C. Sealants and joint fillers: Comply with requirements specified in "Joint Sealers" sections. Joints between framing and building structure shall be sealed. Seal joints watertight unless otherwise indicated. D. Erection Tolerances: Install components plumb, level, accurately aligned, and located in reference to column lines and floor levels. Adjust work to conform to the tolerances indicated below. Tolerances indicated below are maximum and are not cumulative. 1. 2. 3. 4. E. 3.02 A. Plumb: 1/8 inch in 10 feet(3mm in 3.04m); 1/4 inch in 40 feet(6mm in 12.1m). Level: 1/8 inch in 20 feet (3mm in 6.08mm); 1/4 inch in 40 feet(6mm in 12.1m). Alignment: Limit offset of member alignment to 1/16 inch (1.58mm)where surfaces are flush or less than 1/2 inch(12.7mm) out of flush and separated by less than 2 inches(50.8mm) by a reveal or protruding work; otherwise limit offsets to 1/8 inch(3mm). Location: 3/8 inch (9.5mm) maximum deviation from the measured theoretical location of any member at any location. Fit joints to produce hairline joints free of burrs and distortion. CLEANING Clean the completed system, inside and out, promptly after erection and installation of glass and sealants, allowing for nominal curing of liquid sealants. The Installer shall advise the Contractor of proper and adequate procedures for protection and cleaning during the remainder of the construction period so that the system will be without damage and deterioration at the time of acceptance. GLAZED ALUMINUM CURTAIN WALLS 08 44 00 - 8 (45307035) ST. VINCENT COLLEGE SIS AND HERMAN DUPRÉ SCIENCE PAVILION B. At the time of Substantial Completion, clean curtain wall system thoroughly and polish glass. Demonstrate proper cleaning methods and materials to the Owner's maintenance personnel. END OF SECTION GLAZED ALUMINUM CURTAIN WALLS 08 44 00 - 9 (45307035)

![The mysterious Benedict society[1]](http://s2.studylib.net/store/data/005310565_1-e9948b5ddd1c202ee3a03036ea446d49-300x300.png)