22. Salt water intake and pipeline consisting of a slotted

1.

Foster Wheeler two drum boiler rated at 50,000 lb/hr, 900 psig, 900

0

F, 679 boiler hp., with Detroit Stoker water cooled vibrating inclined grate, tubular air heater, economizer, Bahco multi-cyclone dust collector, Detroit Stoker cinder classification and reinjection system, Coen light oil burner (40% capacity), Copes Vulcan sootblowers. Design boiler efficiency 73% with a flue gas temp of 149

0

C operating on 100% wood chip fuel. Approximate boiler dimensions 14 ft x 21 ft x 60 ft, less air heater and dust collector.

2.

Peter Brotherhood turbine and gear reducer operating at 10,251 rpm with output speed of 1,800 rpm coupled to a GEC 5,900 kVA, 60 cycle 4,160 V generator, with two pass divided water box seawater cooled condenser designed to operate at 0.084 bar A, extraction pumps, two bled steam points, vacuum pumps, lube oil system (AC and DC), barring gear, Woodward UG8 governor and controls

3.

Anderson water treatment plant for producing domestic and boiler feed water consisting of chlorine dosing and domestic water pumps, filtered water storage tank, two filter and demineralization trains each containing a multi media filter, organic trap, hydrogen cycle cation unit, string base cation unit, brine regeneration equipment, acid and caustic regeneration equipment, demineralized water storage tank and pumps. Also includes a waste neutralizing system, and controls. Design flow rate 30 USgpm.

4.

Foster Wheeler feedwater heater to heat 51,000 lb/hr of feedwater from 293 0 F to

365

0

F using 3,884 lb/hr steam at 181 psia and 600

0

F, with Crosby safety valves.

5.

A.S.Leitch deaerating heater rated for 60 psig, with a storage capacity of 9,900 lb

6.

Motor control centers

7.

Fisher Provox distributed control system

8.

Chemical feed system for hydrazine, ammonia and phosphate

9.

Compair V100A oil free reciprocating compressor with 25 hp motor, after cooler and receiver, 100 cfm at 100 psig

10.

Pumps, including:

10.1.1.

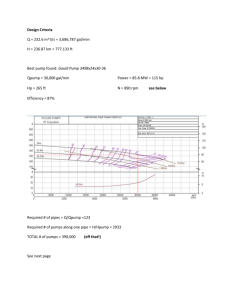

Two Gould vertical turbine 20GCC/1 VIT FF seawater circulating pumps,

4,700 USgpm, 43 ft TDH, 75 hp, 1,200 rpm

10.1.2.

Two Gould vertical turbine freshwater pumps 3171M 1 ½ x 3-13, 51

USgpm, 150 ft TDH, 15 hp, 1,750 rpm

10.1.3.

Two Gould horizontal end suction circulating pumps 3196ST 2 x 3 – 6

111 USgpm, 29 ft TDH. 2 hp, 1,750 rpm

10.1.4.

One Gould horizontal end suction pump 3196 ST 1 x 1 ½ - 6, 20 USgpm,

16 ft TDH, 1 hp, 1,750 rpm

10.1.5.

Two Sunstrand P3 boiler feed pumps 137 USgpm, 2,900 ft TDH, 200 hp,

3,600 rpm.

10.1.6.

Motors are all 575/60/3 phase, TEFC

11.

Cleaver Brooks heating boiler (hot water), P100-40HP-60 psig, oil fired, gross rating

1,339 MBH

12.

Miscellaneous fans, heat exchangers and other auxiliary equipment.

13.

Radar wood handling equipment, including:

13.1.1.

Recovery hopper, 25 m

3

with live bottom and discharge chute, 40 t/hr

13.1.2.

Drag chain discharge conveyor, 13 m long, 40 t/hr

13.1.3.

Disc screen, 40 t/hr

13.1.4.

Pneumatic feeder, 25 x 30, 5 hp, 40 t/hr

13.1.5.

Holmes blower, 125 hp

13.1.6.

Cyclone, 40 t/hr

13.1.7.

Push floor, 16m x 5 m, 4 sections, with hydraulics, 20 t/hr

13.1.8.

Metering screw, 406 mm diameter x 5.7 m long, 20 t/hr

13.1.9.

Drag chain conveyor, 9.2 m long, 20 t/hr

13.1.10.

Pneumatic feeder, 20 x 25, 3 hp, 20 t/hr

13.1.11.

Holmes blower, 75 hp

13.1.12.

Cyclone, 20 t/hr

13.1.13.

Wood chip storage bin, 56 m 3, with live floor, twin screw feed conveyor, 15 t/hr, with hydraulics

13.1.14.

Quantity of 8 5/8” OD pneumatic piping, elbows (including wear plate bends), 4 way pneumatic valve, 2 way pneumatic valve

2

3

13.1.15.

all the above with motors, controls and mounting hardware.

Motors are all 575/60/3 phase, TEFC

14.

Freestanding smokestack, of steel insulated double wall construction 2m outside diameter x 43m high with 0.87m diameter flue, aircraft warning lights, opacity and sampling ports, access ladder and platform.

15.

Truck weight scale

16.

Truck dumper

17.

A wood chip storage building, steel framed uninsulated metal sided building 19m x

33m x 5m high.

18.

Elevated ash silo, bottom outlet, cylindrical steel, 3 m in diameter x 10 m high

19.

Fresh water holding tank, 27,000 litre with reserve domestic water pump.

20.

Freshwater pump house 3 m x 5 m insulated metal building

21.

Powerhouse building consists of a steel frame metal sided building 20m x 30m x 24m high constructed on a reinforced concrete foundation with concrete floor.

22.

Salt water intake and pipeline consisting of a slotted and screened fiberglass cylinder located 150 m from shore at a depth of 8 m. It is 2m in diameter x 3 m long and weighted by concrete blocks and stone ballast. A 560 mm diameter polyethylene pipeline connects the intake to the pump house and is buried at a depth of 500 mm.

23.

Salt water pump house, 4 m x 4 m x 3 m high insulated metal building.

24.

A number of small equipment enclosures, warehouse and instrument housing buildings, generally wood framed and metal clad on concrete slab foundations.

25.

The facility contains numerous items of auxiliary equipment required a thermal electric plant, including such things as switchgear (excluding step up transformer), motor control centers, area lighting, fire protection, wood light poles, fire hydrants, water mains, piping, valves and numerous other items.

26.

All data contained herein represents the best information available at the time of preparation and is subject to verification and revision.