Good Practice_1

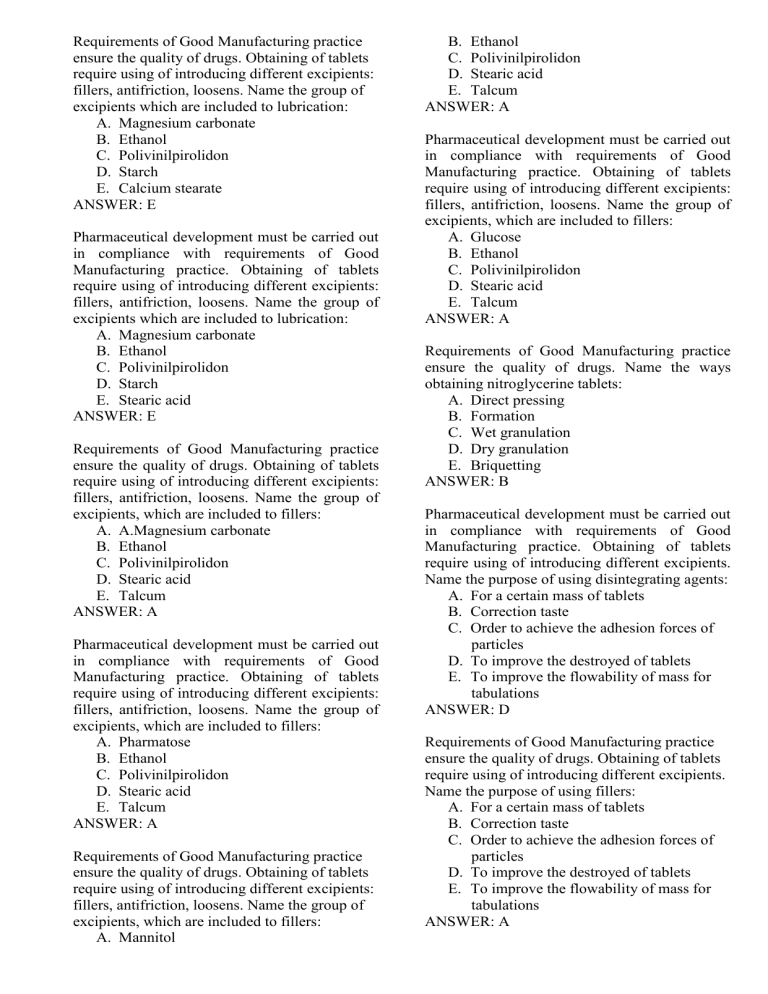

Requirements of Good Manufacturing practice ensure the quality of drugs. Obtaining of tablets require using of introducing different excipients: fillers, antifriction, loosens. Name the group of excipients which are included to lubrication:

A.

Magnesium carbonate

B.

Ethanol

C.

Polivinilpirolidon

D.

Starch

E.

Calcium stearate

ANSWER: E

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Obtaining of tablets require using of introducing different excipients: fillers, antifriction, loosens. Name the group of excipients which are included to lubrication:

A.

Magnesium carbonate

B.

Ethanol

C.

Polivinilpirolidon

D.

Starch

E.

Stearic acid

ANSWER: E

Requirements of Good Manufacturing practice ensure the quality of drugs. Obtaining of tablets require using of introducing different excipients: fillers, antifriction, loosens. Name the group of excipients, which are included to fillers:

A.

A.Magnesium carbonate

B.

Ethanol

C.

Polivinilpirolidon

D.

Stearic acid

E.

Talcum

ANSWER: A

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Obtaining of tablets require using of introducing different excipients: fillers, antifriction, loosens. Name the group of excipients, which are included to fillers:

A.

Pharmatose

B.

Ethanol

C.

Polivinilpirolidon

D.

Stearic acid

E.

Talcum

ANSWER: A

Requirements of Good Manufacturing practice ensure the quality of drugs. Obtaining of tablets require using of introducing different excipients: fillers, antifriction, loosens. Name the group of excipients, which are included to fillers:

A.

Mannitol

B.

Ethanol

C.

Polivinilpirolidon

D.

Stearic acid

E.

Talcum

ANSWER: A

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Obtaining of tablets require using of introducing different excipients: fillers, antifriction, loosens. Name the group of excipients, which are included to fillers:

A.

Glucose

B.

Ethanol

C.

Polivinilpirolidon

D.

Stearic acid

E.

Talcum

ANSWER: A

Requirements of Good Manufacturing practice ensure the quality of drugs. Name the ways obtaining nitroglycerine tablets:

A.

Direct pressing

B.

Formation

C.

Wet granulation

D.

Dry granulation

E.

Briquetting

ANSWER: B

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Obtaining of tablets require using of introducing different excipients.

Name the purpose of using disintegrating agents:

A.

For a certain mass of tablets

B.

Correction taste

C.

Order to achieve the adhesion forces of particles

D.

To improve the destroyed of tablets

E.

To improve the flowability of mass for tabulations

ANSWER: D

Requirements of Good Manufacturing practice ensure the quality of drugs. Obtaining of tablets require using of introducing different excipients.

Name the purpose of using fillers:

A.

For a certain mass of tablets

B.

Correction taste

C.

Order to achieve the adhesion forces of particles

D.

To improve the destroyed of tablets

E.

To improve the flowability of mass for tabulations

ANSWER: A

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Obtaining of tablets require using of introducing different excipients.

Name the purpose of using antifriction agents:

A.

For a certain mass of tablets

B.

Correction taste

C.

Order to achieve the adhesion forces of particles

D.

To improve the destroyed of tablets

E.

To improve the flowability of mass for tabulations

ANSWER: E

Requirements of Good Manufacturing practice ensure the quality of drugs. Obtaining of tablets require using of introducing different excipients.

Name the purpose of using loosens:

A.

For a certain mass of tablets

B.

Correction taste

C.

Order to achieve the adhesion forces of particles

A.

D.To improve the destroyed of tablets

D.

To improve the flowability of mass for tabulations

ANSWER: D

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Obtaining of tablets require using of introducing different excipients: fillers, antifriction, loosens. Name the group of excipients which are included to lubrication:

A.

Magnesium carbonate

B.

Ethanol

C.

Polivinilpirolidon

D.

Starch

E.

Magnesium stearate

ANSWER: E

Requirements of Good Manufacturing practice ensure the quality of drugs. Obtaining of tablets require using of introducing different excipients: fillers, antifriction, loosens. Name the group of excipients, which are included to fillers:

A.

A.Saccharose

B.

Ethanol

C.

Polivinilpirolidon

D.

Stearic acid

E.

Talcum

ANSWER: A

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Obtaining of tablets require using of introducing different excipients: fillers, antifriction, loosens. Name the group of excipients, which are included to fillers:

A.

A.Lactose

B.

Ethanol

C.

Polivinilpirolidon

D.

Stearic acid

E.

Talcum

ANSWER: A

Requirements of Good Manufacturing practice ensure the quality of drugs. Obtaining of tablets require using of introducing different excipients: fillers, antifriction, loosens. Name the group of excipients, which are included to fillers:

A.

Sodium chloride

B.

Ethanol

C.

Polivinilpirolidon

D.

Stearic acid

E.

Talcum

ANSWER: A

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Obtaining of tablets require using of introducing different excipients: fillers, antifriction, loosens. Name the group of excipients, which are included to fillers:

A.

Microcrystalline cellulose

B.

Ethanol

C.

Polivinilpirolidon

D.

Stearic acid

E.

Talcum

ANSWER: A

Requirements of Good Manufacturing practice ensure the quality of drugs. Obtaining of tablets require using of introducing different excipients: fillers, antifriction, loosens. Name the group of excipients, which are included to fillers:

A.

Sorbitol

B.

Ethanol

C.

Polivinilpirolidon

D.

Stearic acid

E.

Talcum

ANSWER: A

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Obtaining of tablets require using of introducing different excipients: fillers, antifriction, loosens. Name the group of excipients, which are included to fillers:

A.

Dextrin

B.

Ethanol

C.

Polivinilpirolidon

D.

Stearic acid

E.

Talcum

ANSWER: A

Requirements of Good Manufacturing practice ensure the quality of drugs. Obtaining of tablets require using of introducing different excipients: fillers, antifriction, loosens. Name the group of excipients, which are included to fillers:

A.

Pectin

B.

Ethanol

C.

Polivinilpirolidon

D.

Stearic acid

E.

Talcum

ANSWER: A

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Obtaining of tablets require using of introducing different excipients: fillers, antifriction, loosens. Name the group of excipients, which are included to antifriction – sliding:

A.

Pectin

B.

Ethanol

C.

Polivinilpirolidon

D.

Stearic acid

E.

Talcum

ANSWER: E

Requirements of Good Manufacturing practice ensure the quality of drugs. Obtaining of tablets require using of introducing different excipients: fillers, antifriction, loosens. Name the group of excipients, which are included to antifriction – sliding:

A.

Pectin

B.

Ethanol

C.

Polivinilpirolidon

D.

Stearic acid

E.

Starch

ANSWER: E

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Obtaining of tablets require using of introducing different excipients: fillers, antifriction, loosens. Name the group of excipients, which are included to antifriction - sliding

A.

Pectin

B.

Ethanol

C.

Polivinilpirolidon

D.

Stearic acid

E.

Aerosil

ANSWER: E

Requirements of Good Manufacturing practice ensure the quality of drugs. Fillers are used to obtain a certain mass for tablets. Choose them:

A.

Talcum

B.

Aerosil

C.

Stearic acid

D.

Ethanol

E.

Fructose

ANSWER: E

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Fillers are used to obtain a certain mass for tablets. Choose them:

A.

Talcum

B.

Aerosil

C.

Stearic acid

D.

Ethanol

E.

Mannitol

ANSWER: E

Requirements of Good Manufacturing practice ensure the quality of drugs. Fillers are used to obtain a certain mass for tablets. Choose them:

A.

Talcum

B.

Aerosil

C.

Stearic acid

D.

Ethanol

E.

Starch

ANSWER: E

Requirements of Good Manufacturing practice ensure the quality of drugs. Fillers are used to obtain a certain mass for tablets. Choose them:

A.

Talcum

B.

Aerosil

C.

Stearic acid

D.

Ethanol

E.

Pharmatose

ANSWER: E

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Fillers are used to obtain a certain mass for tablets. Choose them:

A.

Talcum

B.

Aerosil

C.

Stearic acid

D.

Ethanol

E.

Amylopectin

ANSWER: E

Requirements of Good Manufacturing practice ensure the quality of drugs. Fillers are used to obtain a certain mass for tablets. Choose them:

A.

Talcum

B.

Aerosil

C.

Stearic acid

D.

Ethanol

E.

Magnesium carbonate basic

ANSWER: E

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Fillers are used to obtain a certain mass for tablets. Choose them:

A.

Talcum

B.

Aerosil

C.

Stearic acid

D.

Ethanol

E.

Sodium chloride

ANSWER: E

Requirements of Good Manufacturing practice ensure the quality of drugs. Amount of excipients is regulated in the tablet. Specify limit the amount of pharmatose in a tablets:

A.

1 %

B.

2%

C.

3%

D.

10%

E.

Not limited

ANSWER: E

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Amount of excipients is regulated in the tablet. Specify limit the amount of starch in a tablets:

A.

1 %

B.

2%

C.

3%

D.

10%

E.

Not limited

ANSWER: E

Requirements of Good Manufacturing practice ensure the quality of drugs. Amount of excipients is regulated in the tablet. Specify limit the amount of glucose in a tablets:

A.

1 %

B.

2%

C.

3%

D.

10%

E.

Not limited

ANSWER: E

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Amount of excipients is regulated in the tablet. Specify limit the amount of mannitol in a tablets:

A.

1 %

B.

2%

C.

3%

D.

10%

E.

Not limited

ANSWER: E

Requirements of Good Manufacturing practice ensure the quality of drugs. Amount of excipients is regulated in the tablet. Specify limit the amount of Sodium chloride in a tablets:

A.

1 %

B.

2%

C.

3%

D.

10%

E.

Not limited

ANSWER: E

Requirements of Good Manufacturing practice ensure the quality of drugs. Obtaining of tablets require using of introducing different excipients: fillers, antifriction, loosens. Name the group of excipients, which are included to improves the wettability:

A.

Starch

B.

Ethanol

C.

Polivinilpirolidon

D.

Stearic acid

E.

Water

ANSWER: A

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Obtaining of tablets require using of introducing different excipients: fillers, antifriction, loosens. Name the group of excipients, which are included to improves the wettability:

A.

Talcum

B.

Ethanol

A.

C.Rice starch

C.

Stearic acid

D.

Water

ANSWER: C

Requirements of Good Manufacturing practice ensure the quality of drugs. Obtaining of tablets require using of introducing different excipients: fillers, antifriction, loosens. Name the group of excipients, which are included to improves the wettability:

A.

Talcum

B.

Ethanol

C.

Water

D.

Stearic acid

E.

Aerosil

ANSWER: E

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Obtaining of tablets require using of introducing different excipients: fillers, antifriction, loosens. Name the group of excipients, which are included to improves the substances that form gas:

A.

Talcum

B.

Ethanol

C.

Mixture of sodium bicarbonate with tartaric acid

D.

Stearic acid

E.

Aerosil

ANSWER: C

Requirements of Good Manufacturing practice ensure the quality of drugs. Obtaining of tablets require using of introducing different excipients: fillers, antifriction, loosens. Name the group of excipients, which are included to improves the substances that form gas:

A.

Talcum

B.

Ethanol

C.

Mixture of sodium bicarbonate with citric acid

D.

Stearic acid

E.

Aerosil

ANSWER: C

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Obtaining of tablets require using of introducing different excipients: fillers, antifriction, loosens. Name the group of excipients, which are included to improves the swelling:

A.

Talcum

B.

Agar-agar

C.

Mixture of sodium bicarbonate with citric acid

D.

Stearic acid

E.

Aerosil

ANSWER: B

Requirements of Good Manufacturing practice ensure the quality of drugs. Obtaining of tablets require using of introducing different excipients: fillers, antifriction, loosens. Name the group of excipients, which are included to improves the swelling:

A.

Talcum

B.

Ethanol

C.

A mixture of sodium bicarbonate with citric acid

D.

Starch rice

E.

Aerosil

ANSWER: D

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Obtaining of tablets require using of introducing different excipients: fillers, antifriction, loosens. Name the group of excipients, which are included to improves the swelling:

A.

Talcum

B.

Ethanol

C.

A mixture of sodium bicarbonate with citric acid

D.

Gelatin

E.

Aerosil

ANSWER: D

Requirements of Good Manufacturing practice ensure the quality of drugs. Obtaining of tablets require using of introducing different excipients: fillers, antifriction, loosens. Name the group of excipients, which are included to improves the swelling:

A.

Talcum

B.

Ethanol

C.

A mixture of sodium bicarbonate with citric acid

D.

alginic acid

E.

Aerosil

ANSWER: D

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Obtaining of tablets require using of introducing different excipients: fillers, antifriction, loosens. Name the group of excipients, which are included to improves the swelling:

A.

Talcum

B.

Ethanol

C.

A mixture of sodium bicarbonate with citric acid

D.

Amylopectin

E.

Aerosil

ANSWER: D

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Amount of excipients is regulated in the tablet. Specify limit the amount of microcrystalline cellulose in a tablets:

A.

1 %

B.

2%

C.

3%

D.

10%

E.

Not limited

ANSWER: E

Requirements of Good Manufacturing practice ensure the quality of drugs. Amount of excipients is regulated in the tablet. Specify limit the amount of lactose in a tablets:

A.

1 %

B.

2%

C.

3%

D.

10%

E.

Not limited

ANSWER: E

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Amount of excipients is regulated in the tablet. Specify limit the amount of gelatin in a tablets:

A.

1 %

B.

2%

C.

3%

D.

10%

E.

Not limited

ANSWER: E

Requirements of Good Manufacturing practice ensure the quality of drugs. Amount of excipients is regulated in the tablet. Specify limit the amount of Twin-80 in a tablets:

A.

1 %

B.

2%

C.

3%

D.

10%

E.

Not limited

ANSWER: A

Requirements of Good Manufacturing practice ensure the quality of drugs. Amount of excipients is regulated in the tablet. Specify limit the amount of stearic acid in a tablets:

A.

1 %

B.

2%

C.

3%

D.

10%

E.

Not limited

ANSWER: A

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Amount of excipients is regulated in the tablet. Specify limit the amount of magnesium stearate in a tablets:

A.

1 %

B.

2%

C.

3%

D.

10%

E.

Not limited

ANSWER: A

Requirements of Good Manufacturing practice ensure the quality of drugs. Amount of excipients is regulated in the tablet. Specify limit the amount of calcium stearate in a tablets:

A.

1 %

B.

2%

C.

3%

D.

10%

E.

Not limited

ANSWER: A

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Amount of excipients is regulated in the tablet. Specify limit the amount of talcum in a tablets:

A.

1 %

B.

2%

C.

3%

D.

10%

E.

Not limited

ANSWER: C

Requirements of Good Manufacturing practice ensure the quality of drugs. Amount of excipients is regulated in the tablet. Specify limit the amount of Aerosil in a tablets:

A.

1 %

B.

2%

C.

3%

D.

10%

E.

Not limited

ANSWER: D

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Amount of excipients is regulated in the tablet. Indicate name of excipients which should be not more than 1 % in the tablet:

A.

Aerosil

B.

Starch

C.

Talcum

D.

Calcium stearate

E.

Gelatin

ANSWER: D

Requirements of Good Manufacturing practice ensure the quality of drugs. Amount of excipients is regulated in the tablet. Indicate

name of excipients which should be not more than 1 % in the tablet:

A.

Aerosil

B.

Starch

C.

Talcum

D.

Magnesium stearate

E.

Gelatin

ANSWER: E

Requirements of Good Manufacturing practice ensure the quality of drugs. The size of tablets ranging from 4 to 25 mm. What is the most common size of tablets:

A.

1-4 mm

B.

6-20 mm

C.

10-25 mm

D.

4-12 mm

E.

15-23 mm

ANSWER: D

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. What are used to improve the flowability of mass for tableting:

A.

Gelatin

B.

Magnesium stearate

C.

Talcum

D.

Calcium stearate

E.

Mannitol

ANSWER: C

Requirements of Good Manufacturing practice ensure the quality of drugs. What are used to improve the flowability of mass for tableting:

A.

Gelatin

B.

Magnesium stearate

C.

Starch

D.

Calcium stearate

E.

Mannitol

ANSWER: C

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. What are used to improve the flowability of mass for tableting:

A.

Gelatin

B.

Magnesium stearate

C.

Aerosol

D.

Calcium stearate

E.

Mannitol

ANSWER: C

Requirements of Good Manufacturing practice ensure the quality of drugs. Depending by the localization of oral capsules are classified:

A.

soluble, insoluble, prolonged

B.

sublingual absorption, gastro-soluble, oral solution

C.

subcutaneous, intravenous, rectal

D.

Pressed, with one shell, with a few shells

E.

For obtaining microcapsules different methods are used

ANSWER: A

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Please specify which methods belong to physicochemical methods:

A.

method of dispersion in system

“liquid-liquid”:

B.

method of spray-coating in fluidized bed

C.

centrifugal micro-capsulation

D.

electrostatic method

E.

inter-phase polycondensation

ANSWER: C

Requirements of Good Manufacturing practice ensure the quality of drugs. There are two methods of producing capsular base. What is the main feature of the method of obtaining basis of capsular without process swelling of gelatine:

A.

gelatine is mixed with excipients and dissolved in heated water

B.

gelatine is melted in water and then add excipients

C.

excipients are dissolved in water, then add gelatine

D.

water is added to gelatine batches when mixing with the addition of excipients

E.

gelatine is grinded with excipients and dissolved in heated water

ANSWER: C

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Elasticity of capsules governed by containing plasticizers. How many plasticizers are added to obtain hard capsules:

A.

15-20 %

B.

0,3-1,0 %

C.

0,1-10 %

D.

20-45 %

E.

45-65 %

ANSWER: B

Requirements of Good Manufacturing practice ensure the quality of drugs. There are different dosages forms, while production of which medicinal substances are placed in a shell. What

technological principle corresponds hard capsules:

A.

Filling the capsule until it is soft and elastic, and then, after further processes, membrane elasticity is lost completely or partially

B.

Separately produce capsule, then when it becomes hard, filling her drugs

C.

Solution of film formation, which makes drying shell, coated on a hard drug

D.

Receiving a continuous spherical shell, this is cut around the perimeter and fill drug

E.

Shell and nucleus are simultaneously produced

ANSWER: B

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. For which method obtaining gelatine capsules is used capsules base derived from the process of swelling of gelatine:

A.

the drooping method

B.

the method of indentation

C.

pressing method

D.

disk method

E.

the granulation method

ANSWER: C

Requirements of Good Manufacturing practice ensure the quality of drugs. While production of gelatinous base at the end of the technological stage to the reactor, where is the mass, connect the vacuum. For what is purpose it done:

A.

to remove the vapours of organic solvents

B.

to remove of air bubbles from the mass

C.

for accurate dosing

D.

to control viscosity

E.

to increase the concentration of gelatine

ANSWER: B

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. To produce microcapsule shells water-soluble substances are used. Point out them:

A.

Gelatin, Starch, Polyvinylpyrrolidone

B.

Ethyl Cellulose, Polyethylene,

Polypropylene

C.

Magnesium oxide, Talc, Magnesium carbonate

D.

Citric acid, Vanillin, sugar

E.

Vegetable oils, Twins, Sugar syrup

ANSWER: A

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Amount of excipients is regulated in the tablet. Indicate name of excipients which should be not more than 1 % in the tablet:

A.

Aerosol

B.

Starch

C.

Talcum

D.

Stearic acid

E.

Gelatin

ANSWER: E

Requirements of Good Manufacturing practice ensure the quality of drugs. Amount of excipients is regulated in the tablet. Indicate name of excipients which should be not more than 1 % in the tablet:

A.

Aerosol

B.

Starch

C.

Talcum

D.

Twin-80

E.

Gelatin

ANSWER: D

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Amount of excipients is regulated in the tablet. Indicate name of excipients which should be not more than 3 % in the tablet:

A.

Aerosil

B.

Starch

C.

Talcum

D.

Calcium stearate

E.

Gelatin

ANSWER: C

Requirements of Good Manufacturing practice ensure the quality of drugs. Amount of excipients is regulated in the tablet. Indicate name of excipients which should not be more than 10 % in the tablet:

A.

Aerosil

B.

Starch

C.

Talcum

D.

Calcium stearate

E.

Gelatin

ANSWER: A

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Amount of excipients is regulated in the tablet. Indicate name of excipients which are not normalized in the tablet:

A.

Aerosol

B.

Magnesium stearate

C.

Talcum

D.

Calcium stearate

E.

Gelatin

ANSWER: E

Requirements of Good Manufacturing practice ensure the quality of drugs. Amount of excipients is regulated in the tablet. Indicate name of excipients which are not normalized in the tablet:

A.

Aerosil

B.

Magnesium stearate

C.

Talcum

D.

Calcium stearate

E.

Starch

ANSWER: E

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Amount of excipients is regulated in the tablet. Indicate name of excipients which are not normalized in the tablet:

A.

Aerosil

B.

Magnesium stearate

C.

Talcum

D.

Calcium stearate

E.

Glucose

ANSWER: E

Requirements of Good Manufacturing practice ensure the quality of drugs. Amount of excipients is regulated in the tablet. Indicate name of excipients which are not normalized in the tablet:

A.

Aerosil

B.

Magnesium stearate

C.

Talcum

D.

Calcium stearate

E.

Pharmatose

ANSWER: E

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Amount of excipients is regulated in the tablet. Indicate name of excipients which are not normalized in the tablet:

A.

Aerosil

B.

Magnesium stearate

C.

Talcum

D.

Calcium stearate

E.

Lactose

ANSWER: E

Requirements of Good Manufacturing practice ensure the quality of drugs. Amount of excipients is regulated in the tablet. Indicate name of excipients which are not normalized in the tablet:

A.

Aerosol

B.

Magnesium stearate

C.

Talcum

D.

Calcium stearate

E.

Mannitol

ANSWER: E

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Amount of excipients is regulated in the tablet. Indicate name of excipients which are not normalized in the tablet:

A.

Aerosil

B.

Magnesium stearate

C.

Talcum

D.

Calcium stearate

E.

microcrystalline cellulose

ANSWER: E

Requirements of Good Manufacturing practice ensure the quality of drugs. To obtaining microcapsules different methods are used. Please specify which methods belong to physical methods:

A.

method of spray-coating in fluidized bed

B.

micro-capsulation, based on coacervation

C.

micro-capsulation by phase separation

D.

electrostatic method

E.

inter-phase polymerization

ANSWER: A

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Several categories of capsules may be distinguished (by Eu. Ph.).

What categories of capsules do not exist?

A.

hard capsules

B.

persistent intestinal

C.

soft capsules

D.

gastro-resistant capsules

E.

modified-release capsules

ANSWER: B

Requirements of Good Manufacturing practice ensure the quality of drugs. There are two methods of producing capsular base. What is the

main feature of the method of obtaining basis of capsular with process of swelling gelatine:

A.

gelatine is mixed with excipients and dissolved in heated water

B.

gelatine is melted in water and then add excipients

C.

excipients is dissolved in water, then add gelatine

D.

water is batched to gelatine add when mixing with the addition of excipients

E.

gelatine is grinded with excipients and dissolved in heated water

ANSWER: B

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. To obtaining microcapsules different methods are used. Please specify which methods belong to chemical methods:

A.

method of pelleting

B.

method of spraying

C.

method of dispersion in system

“liquid-liquid”

D.

micro-capsulation, based on coacervation

E.

inter-phase polymerization

ANSWER: E

Requirements of Good Manufacturing practice ensure the quality of drugs. For which method obtaining gelatine capsules derived by the process of swelling of gelatine base of capsules is used:

A.

the drooping method

B.

the method of indentation

C.

pressing method

D.

disk method

E.

granulation method

ANSWER: C

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. To producing microcapsule shells substances, which dissolve in organic solvents are used. Call them:

A.

Gelatin, Starch, Polyvinylpyrrolidone

B.

Ethyl Cellulose, Polyethylene,

Polypropylene

C.

magnesium oxide, talc, magnesium carbonate

D.

citric acid, vanillin, sugar

E.

vegetable oils, twins, sugar syrup

ANSWER: B

Requirements of Good Manufacturing practice ensure the quality of drugs. To obtaining microcapsules different methods are used. Please specify which methods belong to physicochemical methods:

A.

method of pelleting,

B.

method of spraying

C.

micro-capsulation, based on coacervation

D.

inter-phase polymerization

E.

centrifugal micro-capsulation

ANSWER: C

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. There are different dosage forms, in which medicines are placed in the shell. What is technological principle for soft capsules:

A.

filling the capsule until it is soft and elastic, and then, after further processes, membrane elasticity is lost completely or partially

B.

separately produce capsule, then when it becomes hard, filling her drugs

C.

Solution of film formation, which makes drying shell, coated on a hard drug

D.

Receiving a continuous spherical shell, this is cut around the perimeter and fill drug

E.

Shell is pressed and grinded

ANSWER: A

Requirements of Good Manufacturing practice ensure the quality of drugs. Elasticity of capsules governed by containing plasticizers. How many plasticizers are added to obtain soft capsules:

A.

15-20 %

B.

0,3-1,0 %

C.

0,1-10 %

D.

20-45 %

E.

45-65 %

ANSWER: D

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. To obtaining microcapsules different methods used. Please specify which methods belong to physical methods:

A.

method of pelleting,

B.

micro-capsulation, based on coacervation

C.

micro-capsulation by phase separation

D.

inter-phase polymerization

E.

electrostatic method

ANSWER: A

Requirements of Good Manufacturing practice ensure the quality of drugs. In the course of tablet manufacturing can delaminate. What group of auxiliary substances is necessary for ensuring to gain resistant tablets?

A.

Fillers

B.

Antifriction substances

C.

Binding substances

D.

The loosening substances

E.

Correctors of taste.

ANSWER: C

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. For obtaining of necessary weight of tablets in tabletted mass you have add fillers. What is refers to this group:

A.

Glucose

B.

Tragacant

C.

Magnesium stearate

D.

Agar-agar

E.

Talc

ANSWER: A

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. Tablets are the solid dosed medicinal form. They name cakes if their diameter exceeds:

A.

25 mm

B.

40 mm

C.

28 mm

D.

30 mm

E.

35 mm

ANSWER: A

Requirements of Good Manufacturing practice ensure the quality of drugs. Medicinal substances should possess properties what provide their direct pressing. To these properties refer to:

A.

Irregular the form of crystals, good looseness, high adhesion to the press tool

B.

Regular the form of crystals, good friability, compactability, low adhesion to the press tool

C.

Irregular the form of crystals, good looseness, low adhesion to the press tool

D.

Wettability of pulverous substance, compactability, cohesion

E.

Regular the form of crystals, good friability, compactability, wettability, a coalescence of particles

ANSWER: B

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. In the course of manufacturing of tablets for reception of their certain weight in composition of compound for tabletting it is necessary to add:

A.

Fillers

B.

Antifriction substances

C.

Connecting substances

D.

The loosening substances

E.

Correctors of taste

ANSWER: A

Requirements of Good Manufacturing practice ensure the quality of drugs. While manufacturing of tablets apply different groups of auxiliary substances. Specify, for what are purpose connecting substances used:

A.

For reception of necessary weight of tablets

B.

For a taste adjustment

C.

For raise of mechanical durability of tablets

D.

For improving disintegrate tablets

E.

For improving of flow of a mix for tabulating

ANSWER: C

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. What excipients are used while manufacturing of tablets for improving of friability of compound:

A.

PVP

B.

Dairy sugar

C.

Agar-agar

D.

The twin-80

E.

Starch

ANSWER: D

Requirements of Good Manufacturing practice ensure the quality of drugs. Tablets are classified by different signs. By a way of reception they discriminate:

A.

The frame

B.

Formation

C.

The simple

D.

The single-layer

E.

Dragee

ANSWER: B

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. What are disadvantages of the method direct pressing for manufacturing of tablets:

A.

Possibility of stratification of tablets

B.

Exclusions of several positions of the equipment

C.

Decrease of a total surface of parts

D.

Adhesion of corpuscles of a different size

E.

Short technological cycle

ANSWER: A

Requirements of Good Manufacturing practice ensure the quality of drugs. While manufacturing of tablets different groups of auxiliary substances are applied. Specify, what are purpose use correctors of taste:

A.

For reception of certain weight of tablets

B.

For a taste adjustment

C.

For achievement of necessary mechanical durability of tablets

D.

For improving disintegrating tablets

E.

For martempering of flow of a mix for pressing

ANSWER: A

Pharmaceutical development must be carried out in compliance with requirements of Good

Manufacturing practice. While pressing of medicinal substances porosity sharply decreases and by that penetration of a liquid in a tablet is at a loss. To improving disintegrating apply:

A.

Fillers

B.

Antifriction substances

C.

Connecting substances

D.

The loosening substances

E.

correctors of teste

ANSWER:

Requirements of Good Manufacturing practice ensure the quality of drugs. While reception of tablets for tabulating it is necessary to induct the auxiliary substances what quantity does the

Pharmacopoeia into mass ration. How many

МKC 10 it is possible to entering into a tablet?

A.

1 %

B.

2 %

C.

3 %

D.

5 %

E.

It is not rationed

ANSWER: E