View

advertisement

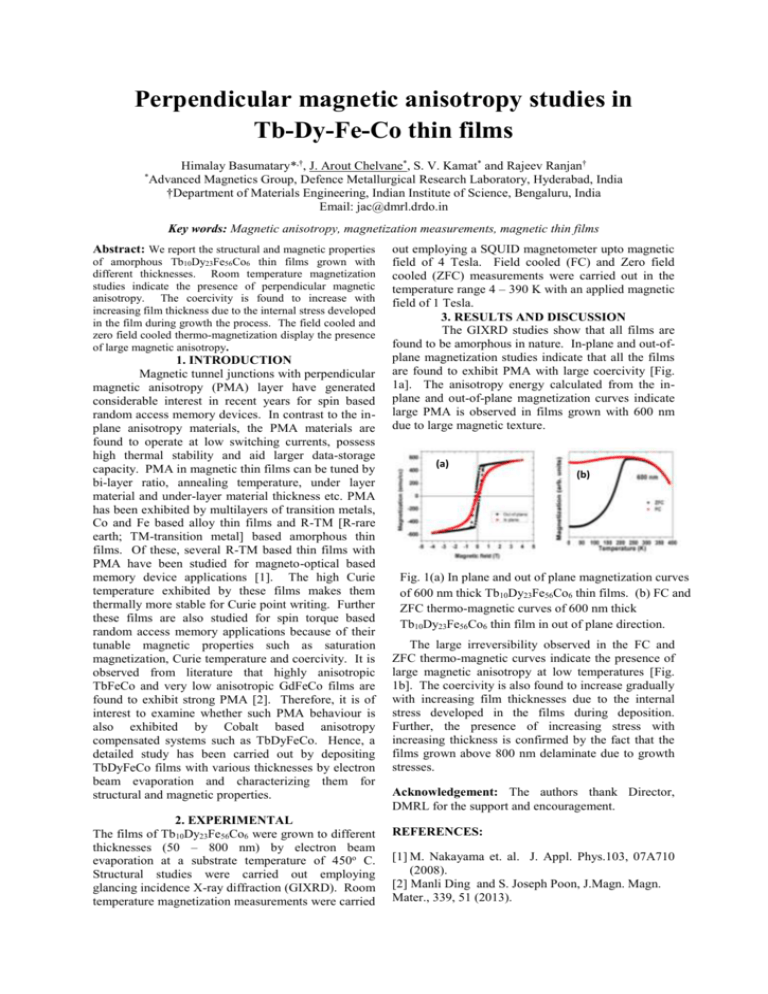

Perpendicular magnetic anisotropy studies in Tb-Dy-Fe-Co thin films * Himalay Basumatary*,†, J. Arout Chelvane*, S. V. Kamat* and Rajeev Ranjan† Advanced Magnetics Group, Defence Metallurgical Research Laboratory, Hyderabad, India †Department of Materials Engineering, Indian Institute of Science, Bengaluru, India Email: jac@dmrl.drdo.in Key words: Magnetic anisotropy, magnetization measurements, magnetic thin films Abstract: We report the structural and magnetic properties of amorphous Tb10Dy23Fe56Co6 thin films grown with different thicknesses. Room temperature magnetization studies indicate the presence of perpendicular magnetic anisotropy. The coercivity is found to increase with increasing film thickness due to the internal stress developed in the film during growth the process. The field cooled and zero field cooled thermo-magnetization display the presence of large magnetic anisotropy. 1. INTRODUCTION Magnetic tunnel junctions with perpendicular magnetic anisotropy (PMA) layer have generated considerable interest in recent years for spin based random access memory devices. In contrast to the inplane anisotropy materials, the PMA materials are found to operate at low switching currents, possess high thermal stability and aid larger data-storage capacity. PMA in magnetic thin films can be tuned by bi-layer ratio, annealing temperature, under layer material and under-layer material thickness etc. PMA has been exhibited by multilayers of transition metals, Co and Fe based alloy thin films and R-TM [R-rare earth; TM-transition metal] based amorphous thin films. Of these, several R-TM based thin films with PMA have been studied for magneto-optical based memory device applications [1]. The high Curie temperature exhibited by these films makes them thermally more stable for Curie point writing. Further these films are also studied for spin torque based random access memory applications because of their tunable magnetic properties such as saturation magnetization, Curie temperature and coercivity. It is observed from literature that highly anisotropic TbFeCo and very low anisotropic GdFeCo films are found to exhibit strong PMA [2]. Therefore, it is of interest to examine whether such PMA behaviour is also exhibited by Cobalt based anisotropy compensated systems such as TbDyFeCo. Hence, a detailed study has been carried out by depositing TbDyFeCo films with various thicknesses by electron beam evaporation and characterizing them for structural and magnetic properties. 2. EXPERIMENTAL The films of Tb10Dy23Fe56Co6 were grown to different thicknesses (50 – 800 nm) by electron beam evaporation at a substrate temperature of 450o C. Structural studies were carried out employing glancing incidence X-ray diffraction (GIXRD). Room temperature magnetization measurements were carried out employing a SQUID magnetometer upto magnetic field of 4 Tesla. Field cooled (FC) and Zero field cooled (ZFC) measurements were carried out in the temperature range 4 – 390 K with an applied magnetic field of 1 Tesla. 3. RESULTS AND DISCUSSION The GIXRD studies show that all films are found to be amorphous in nature. In-plane and out-ofplane magnetization studies indicate that all the films are found to exhibit PMA with large coercivity [Fig. 1a]. The anisotropy energy calculated from the inplane and out-of-plane magnetization curves indicate large PMA is observed in films grown with 600 nm due to large magnetic texture. (a) (b) Fig. 1(a) In plane and out of plane magnetization curves of 600 nm thick Tb10Dy23Fe56Co6 thin films. (b) FC and ZFC thermo-magnetic curves of 600 nm thick Tb10Dy23Fe56Co6 thin film in out of plane direction. The large irreversibility observed in the FC and ZFC thermo-magnetic curves indicate the presence of large magnetic anisotropy at low temperatures [Fig. 1b]. The coercivity is also found to increase gradually with increasing film thicknesses due to the internal stress developed in the films during deposition. Further, the presence of increasing stress with increasing thickness is confirmed by the fact that the films grown above 800 nm delaminate due to growth stresses. Acknowledgement: The authors thank Director, DMRL for the support and encouragement. REFERENCES: [1] M. Nakayama et. al. J. Appl. Phys.103, 07A710 (2008). [2] Manli Ding and S. Joseph Poon, J.Magn. Magn. Mater., 339, 51 (2013).