Cooling Tower Pumping Pressure Drop

advertisement

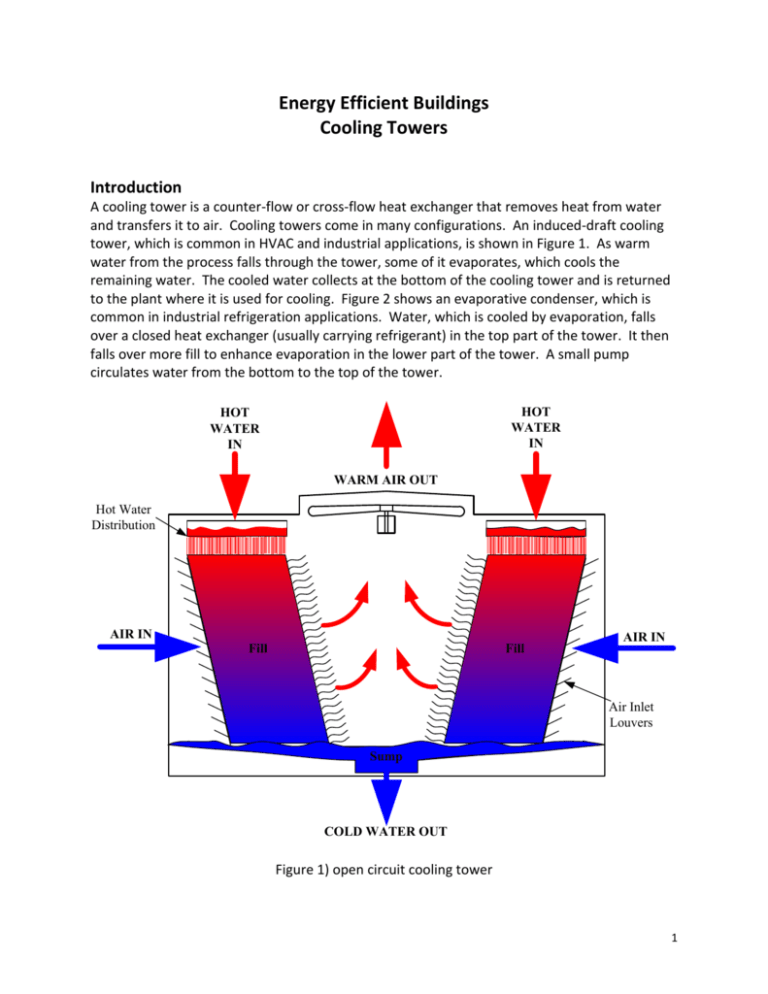

Energy Efficient Buildings Cooling Towers Introduction A cooling tower is a counter-flow or cross-flow heat exchanger that removes heat from water and transfers it to air. Cooling towers come in many configurations. An induced-draft cooling tower, which is common in HVAC and industrial applications, is shown in Figure 1. As warm water from the process falls through the tower, some of it evaporates, which cools the remaining water. The cooled water collects at the bottom of the cooling tower and is returned to the plant where it is used for cooling. Figure 2 shows an evaporative condenser, which is common in industrial refrigeration applications. Water, which is cooled by evaporation, falls over a closed heat exchanger (usually carrying refrigerant) in the top part of the tower. It then falls over more fill to enhance evaporation in the lower part of the tower. A small pump circulates water from the bottom to the top of the tower. HOT WATER IN HOT WATER IN WARM AIR OUT Hot Water Distribution AIR IN Fill Fill AIR IN Air Inlet Louvers Sump COLD WATER OUT Figure 1) open circuit cooling tower 1 Hot Water Distribution WARM AIR OUT Refrigerant Liquid Out Heat Exchange Coil Refrigerant Vapour In Fill AIR IN Secondary Recirculating Pump Air Inlet Louvers Figure 2) closed circuit evaporative cooling tower The temperature difference of water through a tower, dT = Tw1-Tw2, is determined by the load, Ql, and the mass flow rate of water, mw. Neither the size of the tower nor the state of the outside air influences the temperature difference; however, larger towers or lower outdoor air wet-bulb temperatures will decrease the exit water temperature, Tw2. Sensible and Latent Cooling Depending on the entering air and water temperatures, the water may be cooled by sensible and latent cooling of the air, or simply by latent cooling of the air. In either case, latent, i.e. evaporative, cooling is dominant. For example, consider the case in which the air enters at a lower temperature than the water (Figure 3a). The air will leave completely saturated and the cooling is part sensible and part latent. The sensible portion occurs as the air temperature increases by absorbing heat from the water. The latent portion occurs as some of the water evaporates, which draws energy out of the water. 2 If the air enters at the same wet bulb temperature as before, but at a higher dry-bulb temperature than the water, then the air will cool as it saturates (Figure 3b). Thus, the sensible cooling component is negative, and the all the cooling is due to evaporation. In general, cooling is dominated by latent cooling. A2 ωA 2 Qlat Qtot Qsen ωA1 A1 A2 ωA 2 Qlat Qtot -Qsen ωA1 A1 Figure 3. Psychrometric process lines for air through a cooling tower, if the entering air temperature is a) less than the entering water temperature, and b) greater than the entering water temperature. The total cooling, ma (ha2 – ha1) is the same for both cases since enthalpy is a function of wetbulb temperature alone. However, the dry-bulb temperature significantly influences the evaporation rate, mwe = ma (wa2-wa1). The rate of evaporation increases as the dry-bulb temperature increases for a given wet-bulb temperature. 3 Cooling Towers as Heat Exchangers Based on the previous discussion, it is clear that cooling tower performance is a function of the wet-bulb temperature of the entering air. In an infinite cooling tower, the leaving air wet-bulb temperature would approach the entering water temperature, and the leaving water temperature would approach the web-bulb temperature of the entering air. The difference between the leaving water temperature and the entering air wet-bulb temperature is called the approach. The relationship between air wet-bulb and water temperature is shown in the figure below. In an infinite cooling tower, the approach would be zero. Source: ASHRAE Handbook, HVAC Systems and Equipment, 2004. Neglecting fan power and assuming steady state operation, an energy balance on a cooling tower gives: mw1 cpw Tw1 – mw2 cpw Tw2 + ma (ha1 – ha2) = 0 Assuming steady state operation, a mass balance on water flow gives: mw1 – mw2 + ma (wa1 – wa2) = 0 mw2 = mw1 + ma (wa1 – wa2) Substituting mw2 into the energy balance gives: mw1 cpw Tw1 – [mw1 + ma (wa1 – wa2)] cpw Tw2 + ma (ha1 – ha2) = 0 mw1 cpw Tw1 – mw1 cpw Tw2 - ma (wa1 – wa2) cpw Tw2 + ma (ha1 – ha2) = 0 4 The fraction of incoming water that is evaporated, ma (wa2-wa1) / mw1, is typically less than 1%. Thus, ma (wa1 – wa2) is much less than mw1, and the term ma (wa1 – wa2) cpw Tw2 can be neglected with negligible error to give: mw1 cpw (Tw1 – Tw2) = ma (ha2- ha1) Both sides of this equation represent the total cooling capacity of the tower. The effectiveness, E, of a heat exchanger is the ratio of the actual to maximum heat transfer. E = Qactual / Qmax For a heat exchanger, Qmax occurs if the air leaves the cooling tower completely saturated at the temperature of the incoming water. Thus, cooling tower effectiveness is E = Qactual / Qmax = [mw1 cpw (Tw1 – Tw2)] / [ ma (ha,sat,tw1- ha1)] With negligible error (due to water evaporation), the cooling tower effectiveness can also be expressed as E = Qactual / Qmax = [mw1 cpw (Tw1 – Tw2)] / [mw1 cpw (Tw1 – Twb1)] E = Qactual / Qmax = (Tw1 – Tw2) / (Tw1 – Twb1) Example: Calculate the approach and effectiveness for a cooling tower with inlet water at 95 F, outlet water at 85 F, and air wet-bulb temperature = 78 F. Approach = leaving water temperature - entering air wet-bulb temperature Approach = 85 F – 78 F = 7 F E = (Tw1 – Tw2) / (Tw1 – Twb1) E = (95 F – 85 F) / (95 F – 78 F) = 58.8% Note that the leaving water temperature can be above or below the entering air dry-bulb temperature. For example, for the conditions specified here, if the entering air were (Twb = 78 F, RH = 90%), the entering air dry-bulb temperature would be about 80 F. Thus in humid conditions like this, the leaving water temperature (85 F) would be greater than the air dry-bulb temperature (80 F). However, if the entering air were (Twb = 78 F, RH = 40%), the entering air dry-bulb temperature would be about 99 F. In dry conditions like this, the leaving water temperature (85 F) would be less than the air dry-bulb temperature (99 F). 5 Example: Calculate the approach and effectiveness for the same cooling tower now operating with inlet water at 69 F, outlet water at 59 F, and air wet-bulb temperature = 40 F. Approach = leaving water temperature - entering air wet-bulb temperature Approach = 69 F – 40 F = 29 F E = (Tw1 – Tw2) / (Tw1 – Twb1) E = (69 F – 59 F) / (69 F – 40 F) = 34.5% Thus, cooling tower approach increases and effectiveness decreases at lower wet-bulb temperatures. Example: Calculate the approach and effectiveness for the same cooling tower now operating with inlet water at 91 F, outlet water at 71 F, and air wet-bulb temperature = 40 F. Approach = leaving water temperature - entering air wet-bulb temperature Approach = 91 F – 40 F = 51 F E = (Tw1 – Tw2) / (Tw1 – Twb1) E = (91 F – 71 F) / (91 F – 40 F) = 39.2% Thus, cooling tower effectiveness increases at higher inlet-outlet water temperature ranges. Energy Efficiency of Counterflow and Crossflow Towers The two most common tower designs for HVAC applications are forced-air counterflow and induced air cross-flow. Cooling tower energy use is a function of fan and pump power. To generate the same quantity of cooling, forced-air counterflow towers require more fan and more pump energy then induced-air crossflow towers. Thus, induced-air crossflow towers are almost always more energy efficient. 6 Forced-air counterflow towers require more fan energy because centrifugal fans are made to generate low flow against high pressure, but cooling towers generally need high flow at low pressure. In comparison, induced air crossflow towers use propeller fans, which generate high flow against low pressure, which is more suited to cooling towers. Forced-air counterflow towers require more pump energy because these towers are taller in order to facilitate the counterflow heat transfer as the water falls through the tower. This height increases elevation head in the piping system. In addition, forced-air counterflow towers spray water through nozzles, which increases pressure drop. In comparision, inducedair crossflow towers are shorter and wider since the path of the air through the water is horizontal. In addition, the supply water simply drains from feeding pans into fill, which eliminates the need for nozzles. A comparison of cooling tower energy use for the same loads is shown below. 7 Comparison of F.D. Blower Tower vs I.D. Propeller Tower for 400 Tons Cooling Operating Fan Tower Additional Total Tower Fan Motor Motor Pump Head Pump Motor Operating Type HP KW (1) FT. (2) KW (3) KW Counterflow with Blower 40 32.4 23 6.9 39.3 Crossflow With Propeller 20 15.2 10 3.0 19.2 Source: Marley Technical Report H-001A, “Cooling Tower Energy and Its Management”, October, 1982. Cooling Tower Control In HVAC applications, chiller evaporator loads vary depending on weather and building occupancy, and the quantity of heat rejected by the condenser varies accordingly. The cooling tower will always reject the all the heat from the condenser. However, the temperature of the cold water return to the condenser will decline at lower loads. Various methods are used to control cooling tower capacity to generate the desired cold water return temperature. The two control points for cooling towers are water flow and air flow. However, cooling tower manufacturers strongly recommend that water flow remain constant at all times. Thus, primary control methods generally rely on varying air flow. The common control methods are listed below. Run Fans Continuously This type of control results in the coldest possible return water temperature, which reduces chiller energy use. However, it also results in the highest cooling tower fan energy use. Because the improvement of chiller efficiency with lower condenser water temperature is asymptotical at some minimum temperature, this method of control rarely results in the best overall energy efficiency. Cycle Fans On and Off This type of control reduces excess fan energy use at cold outsider air temperatures, and is widely used. At relatively cold temperatures, however, the fan may cycle on and off too frequently. The maximum number of fan cycles is about 8 per hour. Thus, many cooling towers are equipped with water bypass loops. In most applications, water bypass control is only used at low temperatures when fan cycling could be a problem. Use Two-Speed Fan This method of control adds an intermediate level of cooling between full-on and full-off. This results in considerable fan energy savings, since fan energy varies with the cube of flow. Thus, fan energy at 50% air flow is only 12% of the fan energy at full air flow. This type of stepped 8 control can be further extended with two cell towers with one fan in each cell. This leads to four possible steps of control. A typical relationship between cold water temperature and fan flow is shown below. Continuously Control Fan Speed with VSD This method results in the lowest fan energy use by continuously achieving savings, due to the fan law that fan energy varies with the cube of flow. Vary Air Flow Using Inlet Air Dampers Before VSDs, cooling towers were sometimes controlled by running the fan at full speed while varying the inlet air dampers to modulate air flow. This method of control results in intermediate energy savings between fan cycling and continuous VSD control. However, is rarely used now that the VSD control is now commonplace. Comparison of Energy Use with Various Methods of Cooling Tower Control Total chiller and cooling tower energy use for these control methods for a typical HVAC application are shown below. Comparative Energy Usage with Various Methods of Control Propeller Blower Operating Hours of Average KW Fan Energy Fan Energy Situation Operation Usage (kW hr) (kW hr) Constant Operation P = 16.2 at Full Capacity 1202.2 B = 32.4 19475.6 38951.2 Single-Speed P = 765.3 P = 16.2 Fan Cycling B = 852.7 B = 32.4 12397.9 27627.5 Two-Speed P = 1132 P = 4.3 Fan Cycling B = 1146 B = 8.55 4867.6 9798.3 Variable Control P = 2.72 at Constant Speed 1202.2 B = 5.44 3270 6540 Variable Speed P = 1.99 Control 1202.2 B = 3.98 2392.4 4784.8 Source: Marley Technical Report H-001A, “Cooling Tower Energy and Its Management”, October, 1982. Variable Cold Water Set-Point Temperature The energy efficiency of all the control discussed above can be improved by varying the cold water set-point temperature with the outdoor air wet bulb temperature. This type of control takes into account the fact that towers can only produce water at a few degrees above the wetbulb temperature (this temperature difference is called the “approach”); hence fan energy can 9 be reduced when that temperature is achieved, since continued fan operation results in minimal further reductions in cold water temperature. Fan Motor Power with Fan Speed and Air Volume Flow Rate The figure below shows fan motor power draw as a function of input frequency for a cooling tower fan equipped with a VFD. The fan affinity laws would predict a relationship between fraction power (FP) and fraction speed (FS) of: FP = FS3 Regression of the data show a slightly better fit using the exponent 2.8: FP = FS2.8 Since fan speed is proportional to volume flow rate, this relation also hold for fraction volume flow rate, FV. FP = FV2.8 The slightly reduced exponent is caused by declining VFD, motor and fan efficiencies at reduced speed. ASD Performance Input Power and Fan Speed vs Frequency 2000 35 1800 30 25 1400 1200 20 1000 15 800 Fan Speed (RPM) Input Power (kW) 1600 600 10 I np 5 ut Po r we 400 200 peed Fan S 0 0 5 10 15 20 25 30 35 40 45 50 55 60 65 ASD Frequency (Hz) Source data: “An Application of Adjustable Speed Drives for Cooling Tower Capacity Control”, Welch, W. and Beckman, J. 10 Variable-speed cooling tower fans generate the least savings compared to constant-speed fans during warm weather and when the cooling tower set point temperature is low because the fan runs more frequently at these times. Alternately, variable-speed fans generate the greatest savings during cool weather and when the cooling tower set point temperature is high because the fan runs less frequently at these times. The CoolSim output screens shown below demonstrate these concepts. Thus, variable frequency drives on cooling tower fans will generate the greatest savings on year-round cooling applications with relatively high set-point temperatures characteristic of industrial process applications. Cooling Tower Bypass Plumbing Bypass control is typically used only at low outdoor air wetbulb temperatures in order to reduce fan cycling. Bypass should not be used in sub-freezing temperatures since this can lead to tower freeze up. The preferred tower bypass plumbing is shown below. The preferred valve is a single two-way butterfly valve placed in the bypass line. Basic Tower Bypass Methods 11 Cooling Tower Pumping Pressure Drop Typical cooling tower pressure drops are shown below. The Estimated Head Loss column is for a standard condenser and 15 year old piping. The Actual Head Loss column is for a lowpressure loss condenser and new piping. The same tower system will be evaluated; estimated head will be compared with actual head loss. Condenser Valves, Strainer, etc. 150' Piping (15 year Old) Total Flow-Friction Static or Open Total Pump Head Estimated Head Loss 25' 7' 6' 38' ⊕12' 50' Actual Head Loss 8' 7' 3' 18' ⊕12' 30' Cooling Tower Selection In HVAC applications, the starting place for cooling towers selection is typically to match the “nominal cooling tower tons”, as supplied by the tower manufacturer, to the cooling capacity of the chiller or chiller plant. The water flow rate through the cooling tower is initially set at 3 gpm per “nominal cooling tower ton”. Subsequent design optimization may occur from this starting point. Engineering data for a typical model of induced-air crossflow cooling towers are shown below. Based on these data, fan motor hp is about 0.1 hp/ton and air flow rates are about 2,000 cfm/hp. A “nominal cooling tower ton” is defined as cooling 3 gpm of water from 95 F to 85 F at an air wetbulb temperature of 78 F. Thus, the actual cooling associated with a “nominal cooling tower ton” is: Qact = 3 gpm x 8.33 lb/gal x 60 min/hr x 1 Btu/lb F x (95 – 85) F = 15,000 Btu/hr This strange convention exists to make it easy for users to select cooling towers by matching the “nominal cooling capacity” of the chiller with the chiller cooling capacity. The convention works because most chillers have a COP of about 3, and total heat rejected by the condenser to the cooling tower is about 15,000 Btu/hr for every 12,000 Btu/hr through the evaporator. Model Number 3240A 3272A 3299A 3473A 3501A 3985A 31056A Norminal Tonnage 240 272 299 473 501 985 1056 Motor HP 10 15 20 25 30 60 75 Weights (lbs) Fan Heaviest (CFM) Operating Shipping Section 62,790 14,770 6,790 6,790 71,340 14,900 6,920 6,920 78,110 14,960 6,980 6,980 118,870 23,090 10,190 10,190 125,900 23,140 10,240 10,240 229,950 40,240 15,560 9,460 246,700 40,330 15,650 9,550 Dimensions L 8'-5 3/4" W 18'-0 1/2" H 9'-3 5/8" A 8'-7 3/4" 11'-9 3/4" 21'-6 1/2" 10'-10 1/8" 9'-11 3/4" 11'-9 3/4" 21'-6 1/2" 21'-8 7/8" 20'- 9 1/2" 12 Source data: BAC Product and Application Handbook, Volume 1, 2005. Model 8601 8603 8605 8607 8608 8610 8611 8613 8614 Nominal Tons 100 150 200 250 300 350 400 450 500 Length 5'-4 1/2" 7'-3 1/2" 7'-3 1/2" 7'-10 1/2" 7'-10 1/2" 9'-4 1/2" 9'-4 1/2" 9'-4 1/2" 9'-4 1/2" Width 12'-0" 12'-0 1/4" 13'-7 5/8" 15'-3 1/4" 16'-7 3/4" 16'-7 3/4" 17'-7 3/4" 19'-3 3/4" 19'-3 3/4" Height 8'-9 5/8" 9'-8 3/8" 9'-8 3/8" 10'-7 3/8" 10'-7 3/8" 10'-7 3/8" 11'-6 1/8" 11'-6 1/4" 13'-3 7/8" Shipping Wt. 3430 4610 5130 6640 7800 8690 9860 10700 11990 Operating Wt. PVC 5500 7120 8260 10880 12200 13980 15520 17280 19260 Motor HP 5 7 1/2 10 10 15 20 20 25 25 RPM 666 547 547 547 427 427 427 427 427 CFM 29820 50000 54820 58610 69050 82630 91920 94760 105270 GPM (min.) 100 120 175 190 200 210 240 250 280 GPM (max.) 500 750 960 1250 1440 1715 1880 2160 2500 Source data: Marley Cooling Towers, 2000. Cooling Tower Performance The performance of typical cooling towers at water flow rates of 3 gpm/ton and 5 gpm/ton is shown below. Similar performance data for specific cooling towers can usually be obtained from the manufacturer. These curves predict the temperature of the cold water leaving the cooling tower as a function of the water temperature range (Th-Tc) and entering air web bulb temperature. Temperature range is generally known and can be used as an input value in these charts, since the temperature range is set by the water flow rate and heat rejection rate of the condenser. 13 Source: ASHRAE Handbook, HVAC Systems and Equipment, 2004. Relations for the temperature of cooling water leaving the tower, Tc, can be derived from regressing data from the 3 gpm/ton and 5 gpm/ton curves shown above. The relation and regression coefficients are shown below. The R2 for these relations exceeds 0.995 and the average error, [abs(Tc – Tc,pred)], is less than 0.8 F. Tc = a + b Twb + c Tr + d Twb2 + e Tr2 + f Tr Twb Coef a b c d e f 3 gpm/ton 16.790751 0.6464308 2.2221763 0.0016061 -0.0159268 -0.015954 5 gpm/ton 24.6299229 0.45007792 3.32229591 0.00261818 -0.0324886 -0.0190476 These equations can be incorporated into software to predict cooling tower performance with varying ambient conditions. For example, CoolSim (Kissock, 1997) calculates exit water temperatures, and the fraction of time that a cooling tower can deliver water at a target temperature, based on water temperature range Tr and TMY2 weather data. This information is useful in determining how often a cooling tower can replace a chiller in cooling applications. Cooling Tower Performance at Reduced Air Flow Rates Comparison of the 3 gpm/ton and 5 gpm/ton performance maps can be used to predict cooling tower performance at reduced air flow rates. For example, for a cooling tower operating with a water flow rate of 3 gpm/ton, the 3 gpm/ton performance map shows tower performance at a set water-to-air flow rate ratio. The 5 gpm/ton chart shows tower performance for a higher water-to-air flow ratio, or, inversely, at a lower air-to-water flow rate ratio. Thus, the 5 gpm/ton performance map indicates tower performance if water flow rate is held steady while the air flow rate is reduced to 3/5 = 60% of maximum airflow. Regressing the data from the 3 gpm/ton and 5 gpm/ton performance curves, with fraction of air flow, FV, set to 1.0 for the 3 gpm/ton data and 0.6 for the 5 gpm/ton data gives the following relation for the temperature of cooling water leaving the tower, Tc, at reduced air flow. The R 2 for this relation is R2 = 0.978 and the average error [abs(Tc – Tc,pred)] is 1.9 F. Theoretically, the fraction of air flow, FV, could vary between 0 and 1.0. However, this relation was generated using data that represent peak air flow at 0.6 and 1.0. Thus, it is not recommended that this relationship be used outside of this range. Tc = a + b Twb + c Tr + d Twb2 + e Tr2 + f Tr Twb + g FV Coef Value 14 a b c d e f g 39.24367 0.548254 2.772236 0.002112 -0.02421 -0.0175 -23.1667 Evaporation Rate As discussed in the previous section, cooling in cooling towers is dominated by evaporation. The evaporation rate can be calculated from the psychrometric relations in the previous section, if the inlet and exit conditions of the air are known. For example, consider the case in which the cooling load, Ql, mass flow rate of air, ma, (which can be calculated based on the fan cfm and specific volume of the inlet air), and inlet conditions of air are known. The enthalpy of the exit air, ha2, can be calculated from an energy balance. Ql = ma (ha2 – ha1) ha2 = ha1+ Ql / ma The state of the exit air can be fixed by assuming that it is 100% saturated with an enthalpy ha2. The evaporation rate, mwe, can be determined by a water mass balance on the air. mwe = ma (wa2- wa1) The fraction of water evaporated is: mwe / mw Using this method for entering air temperatures from 50 F to 90 F, we determined that the fraction of water evaporated typically ranges from about 0.5% to 1%, with an average value of about 0.75%. Another way to estimate the fraction of water evaporated is to assume that all cooling, Ql, is from evaporation, Qevap. The cooling load Ql, is the product of the water flow rate, mw, specific heat, cp, and temperature difference, dT. The evaporative cooling rate is the product of the water evaporated, mwe, and the latent heat of cooling, hfg. Ql = Qevap mw cp dT = mwe hfg Assuming the latent heat of evaporation of water, hfg, is 1,000 Btu/lb, and the temperature difference of water through the tower, dT, is 10 F, the fraction of water evaporated is: 15 mwe / mw = cp dT / hfg = 1 (Btu/lb-F) x 10 (F) / 1000 (Btu/lb) = 1% If on average, 75% of the cooling were from evaporation and 25% from sensible cooling, then the evaporation rate would be: 75% x 1% = 0.75% Thus, both methods suggest that 0.75% is a good estimate of the rate of evaporation; however, we have seen manufacturer data indicating average evaporation rates as low as 0.30%. Water lost to evaporation should not be subjected to sewer charges. Typical sewer charges are about $2.20 per hundred cubic feet. Some water may be lost as water droplets are blown from the tower by oversized fans or wind. This type of water loss is called “drift”. Drift rates are typically about 0.2% of flow (ASHRAE Handbook, HVAC Systems and Equipment, 2000); however, we generally assume that drift losses are included in the 0.75% evaporation rate. Water Treatment and Blow Down Rate Cooling tower water must be treated to prevent bacterial growth and maintain the concentration of dissolved solids at acceptable levels to prevent scale and corrosion. Bacterial Growth The typical method of controlling bacterial growth is to add biocides at prescribed intervals and to keep the cooling tower water circulating. If the tower will not be operated for a sustained period of time, then the cooling water should be drained. Dissolved Solids Water evaporated from a cooling tower does not contain dissolved solids. Thus, the concentration of dissolved solids will increase over time if only enough water is added to the tower to compensate for evaporation. To maintain the dissolved solids at acceptable levels, most towers periodically discharge some water and replace it with fresh water. This process is called blow down. It the level of dissolve solids increases too high, scale will be begin to form, and/or the water may become corrosive and damage piping, pumps, cooling tower surfaces and heat exchangers. Usually, the primary dissolved solid to control is calcium carbonate CaCO3. Blow down can be accomplished by continuously adding and removing a small quantity of water, periodically draining and refilling the cooling tower reservoir, or by metering the conductivity of water and adding fresh water only when needed. By far the most efficient method is to meter the conductivity of water, which increases in proportion to the level of dissolved solids, and add fresh water only when needed. 16 The required quantity of blow down water depends on the acceptable quantity of dissolved solids in the tower water, PPMtarget, the quantity of dissolved solids in the makeup water, PPMmu, and the evaporation rate, mwe. The target level of dissolved solids is typically quantified in cycles, where: Cycles = PPMtarget / PPMmu For example, if the quantity of dissolved CaCO3 in the makeup water, PPMmu, is 77 ppm and the maximum level to prevent scaling, PPMtarget, is 231, then the cooling tower water must be maintained at three cycles: Cycles = PPMtarget / PPMmu = 231 ppm / 77 ppm = 3 By applying mass balances, it can be shown that the blow down water required to maintain a certain number of cycles is mwbd = mwe / (Cycles –1) The total makeup water required mwmu, is the sum of the water added for evaporation and blow down: mwmu = mwe + mwbd For example for a 1,000 gpm tower with a 0.75% evaporation rate and CaCO3 concentration at 3 Cycles, the quantity of makeup water required would be about: mwe = (mwe/mw) x mw = 0.75% x 1,000 gpm = 7.5 gpm mwbd = mwe / (Cycles –1) = 7.5 gpm / (3 – 1) = 3.75 gpm mwmu = mwe + mwbd = 7.5 gpm + 3.75 gpm = 11.25 gpm The overall makeup water rate would be about: 11.25 gpm / 1,000 gpm = 1.1% 17