Public Furniture Research Project Link

advertisement

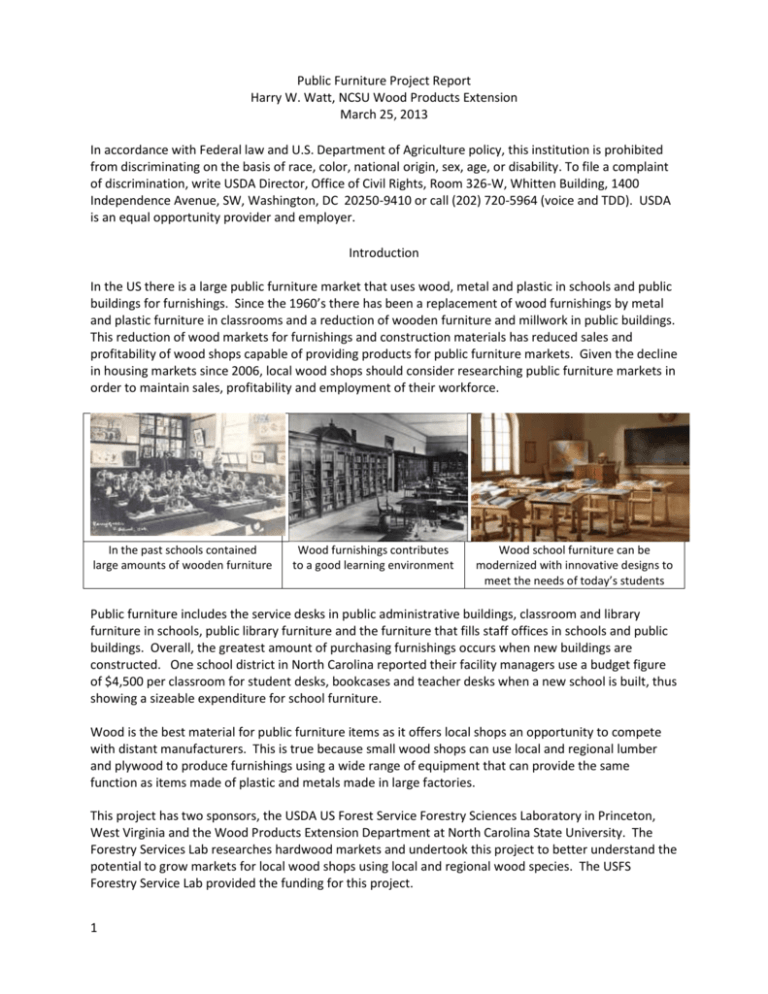

Public Furniture Project Report Harry W. Watt, NCSU Wood Products Extension March 25, 2013 In accordance with Federal law and U.S. Department of Agriculture policy, this institution is prohibited from discriminating on the basis of race, color, national origin, sex, age, or disability. To file a complaint of discrimination, write USDA Director, Office of Civil Rights, Room 326-W, Whitten Building, 1400 Independence Avenue, SW, Washington, DC 20250-9410 or call (202) 720-5964 (voice and TDD). USDA is an equal opportunity provider and employer. Introduction In the US there is a large public furniture market that uses wood, metal and plastic in schools and public buildings for furnishings. Since the 1960’s there has been a replacement of wood furnishings by metal and plastic furniture in classrooms and a reduction of wooden furniture and millwork in public buildings. This reduction of wood markets for furnishings and construction materials has reduced sales and profitability of wood shops capable of providing products for public furniture markets. Given the decline in housing markets since 2006, local wood shops should consider researching public furniture markets in order to maintain sales, profitability and employment of their workforce. In the past schools contained large amounts of wooden furniture Wood furnishings contributes to a good learning environment Wood school furniture can be modernized with innovative designs to meet the needs of today’s students Public furniture includes the service desks in public administrative buildings, classroom and library furniture in schools, public library furniture and the furniture that fills staff offices in schools and public buildings. Overall, the greatest amount of purchasing furnishings occurs when new buildings are constructed. One school district in North Carolina reported their facility managers use a budget figure of $4,500 per classroom for student desks, bookcases and teacher desks when a new school is built, thus showing a sizeable expenditure for school furniture. Wood is the best material for public furniture items as it offers local shops an opportunity to compete with distant manufacturers. This is true because small wood shops can use local and regional lumber and plywood to produce furnishings using a wide range of equipment that can provide the same function as items made of plastic and metals made in large factories. This project has two sponsors, the USDA US Forest Service Forestry Sciences Laboratory in Princeton, West Virginia and the Wood Products Extension Department at North Carolina State University. The Forestry Services Lab researches hardwood markets and undertook this project to better understand the potential to grow markets for local wood shops using local and regional wood species. The USFS Forestry Service Lab provided the funding for this project. 1 The Wood Products Extension Department at North Carolina State University supports the wood industry of North Carolina and undertakes research projects that promote the US wood products industry. The Wood Products Extension Department is active in assisting individual wood products businesses to improve their businesses and also promotes the use of US wood species. NCSU WPE performed the field work of this project. This project supports the economic growth of US communities by supporting local wood shops to become better competitors in public furniture markets. Wood shops contribute strongly to the local community by being buyers of locally produced lumber and plywood products, its employment of local citizens and the payment of property, generation of sales and income taxes to state and local governments. The world is currently experiencing increased costs and environmental problems using depletion resources like metals and plastics, thus needing to convert to renewables for furnishings, like wood, in order to sustain the current level of the economy and insure future social and political stability. Continued use of metals and plastics in public furniture will result in quickening the time when depletion resources shortages result in hardships and higher costs. Project Goals and Objectives The research efforts of this project were directed at learning how school districts and local government purchasing departments bought furnishings for new buildings and remodeling projects. The purchasing departments operate in the public interest to properly spend taxpayer funds for furnishings that will last from many years with little repair and replacement. The purchasing departments are professionally managed with employees of many years of service. They have formal purchasing guidelines and are supported by state purchasing and contract offices. The goals and objectives of this project included: 1. To interview purchasing department buyers in three states and at three levels of local populationlarge, medium and small. Approximately thirty local government and school district purchasing departments were contacted to fill out a survey instrument that contained fifty-five questions. Twenty purchasing departments cooperated by completing and returning the surveys. 2. To design fifty wood products that schools and local governments are buying and create a 3-D model for each item with supporting parts list and example costing/pricing worksheet. The models would be instructive to the traditional wood shop that may design products manually and may be using a low tech engineering support system. Also these models designed in SketchUp would be helpful to modern shops that use design software and use computer controlled equipment. These fifty items are available as downloads on the project website at www.cnr.ncsu.edu/publicfurniture. 3. An outreach effort to wood shops included contacting wood shops in each of the study counties as well as writing publications for wood products industry media publications. The project website included short publications about the public furniture market and ideas of how to enter this market by local wood shops. The outreach effort will include information about writing specifications and how specifications influences who wins bids. 2 4. An outreach effort to the purchasing departments included contacting the purchasing departments in the study counties as well as contacting state and national public professional buying associations. 5. An outreach effort was made in each study county to the leaders of schools and local governments supporting the purchasing of products by schools and local governments. 6. The project website contains many items of interest to wood shops and purchasing departments supporting the growth of sales of locally made wood products that emphasized lumber and veneer core plywood. The website contains a large number of downloads of 3-D models as well as short publications. 7. This project summary publication is created to gather the analysis of research of buying practices as well as information on product design and construction. Overview of Marketing for Small Local Wood Shops Small wood shops typically lack strong marketing efforts and often operate at lower levels of their potential capacity. Since the housing decline of the mid 2000’s, many local wood shops have scaled down their operations or have closed. This project supports the idea of these shops entering the public furniture market and focusing on replacing products being purchased made of depletion materials like metals and plastics with locally processed lumber and plywood. It is natural for local school districts and governments to want to support local business given the large economic boost local firms return to the community. In order to compete in a market that has significant regulations and professionalism, local shops will have to implement more formal business practices that include: 1. Ability to function in a formal bid process where one has to obtain documents, analyze the documents in a bid package, design products that need the specifications and compete against other wood shops that have long been successful in the public furniture market. 2. Any wood shop that wants to be listed in the offerings of a state’s purchasing and contracts office has to meet the vendor requirements set forth by the purchasing and contracts office. These offices set performance thresholds that insure weak and poor performing businesses are not accepted as vendors. 3. Wood shops marketing to the public furniture market on a local basis will have to successfully act as the manufacturer and seller unlike national wood products manufacturers typically that have a sales distribution network. The distribution brokers perform the needed function of looking for bidding opportunities, generating bids, promoting the use of specifications of its manufacturers, and installing products at schools and government buildings. Local shops selling to local governments have to perform as manufacturer and sales agent themselves. 3 Wood shops should challenge themselves to develop wooden alternatives to furniture made of metal and plastic This is an example of a wooden alternative to the modern metal and plastic student desk. Painted desks can be in a school’s colors as a bonus feature. These sycamore panels can be used for school and government furnishings and support the local economy from the landowner to the wood shop Survey of School District Purchasing Departments The project collected seven surveys from local school districts in West Virginia, North and South Carolina. A copy of the survey instrument for school purchasing department is on the project website, as is a summary of the returned school surveys on the project website. The survey consisted of fifty-five questions that focused on the process of buying furniture and preferences of the purchasing agents. A summary of the results from the purchasing survey for schools included these points: 1. About half of the respondents reported being a member of a professional public purchasing association. 2. The average of school district student population was 16,412 and 44.6 schools per district. 3. The average count of new schools in the last four years was 2.1 per district. 4. There was a slight preference for wooden furniture over metal and plastic. 5. Species preference positive for oak, cherry, maple, birch and beech. Yellow poplar, sweetgum and pine were not preferred. 6. Painted furniture was less preferred to stain and clear wood finishes. 7. A strong preference for domestic over imported school furniture. 8. The buyers thought wooden furniture should be preferred over metal and plastic in staff offices, libraries and media rooms, and arts and crafts rooms. 9. Buyers thought it would be helpful for wood shops to support the educational aspects of wooden furniture by using local species, using school logos and colors, identifying wood species on furniture and using innovative designs. 10. Solid lumber construction was strongly preferred over alternative wood construction. 4 11. Buyers wanted wood products manufacturers to provide information about their products, have competitive prices, offer detailed specifications and good warranties. 12. Buyers thought wood was more sustainable and “green” than metal and plastic school furniture. 13. Most purchasing departments reported the process for buying new furniture was to seek the inputs of users and staff, research options, write specifications and put out the request for bids. 14. There were mixed responses to having $ threshold limits for approval for bidding versus purchase orders. 15. Buyers did not report having purchasing policies favoring specific groups or goals. 16. About half the responders reported having state procurement policies affecting their purchasing methods. 17. Buyers reported that users are included in the process of buying furniture, as well as finance personnel, upper level administrators, principals and district facility managers. 18. Outside professionals who also were reported to assist with furniture purchases included designers and architects, sales reps and consultants. 19. A majority of survey respondents reported having the RTB package available online. 20. Buyers reported that new construction involved the greatest $ amount of furniture purchases in any given time period. 21. A majority of respondents reported having a written policy manual for buying furniture. 22. Buyers reported using multiple methods for buying furniture that included using state contracts, cooperatively bid contracts, competitive bidding, putting out requests for bids, no bid contracts and negotiated bidding. 23. The buyers reported that they frequently used the Internet to research vendors and products before creating RTB. 24. Buyers reported that price, meeting specifications and service were the most important factors to select winning bidders. 25. Buyers reported they wanted more interaction with wood shops on wood species and construction, to see samples and to have more opportunities for their administrators to meet with local wood shops. 5 Ideas to Grow Sales to School Districts Wood shops can apply these concepts to become involved in their local communities to sell wood products to school districts: 1. The companies now selling to schools are national manufacturers with independent regional sales representatives. These vendors scout posting of RTB from local school districts and the state’s purchasing and contracts office. They are also active in pushing their manufacturer’s specifications and the ones to use in RTB documents in order to improve their chances of winning bids. Local wood shops cannot break into this market unless they are proactive and research this market. Local shops must network with the purchasing department buyers and the school district staff and administrators to have an opportunity to sell products in this market because of needed knowledge and personal contacts that result from good networking efforts. 2. Local wood shops can gain an advantage by using local wood species and offering local elements to their product offerings. This includes using school colors and designs in the furniture that add local themes that national and global manufacturers cannot easily duplicate that adds value in the eyes of local government and school district buyers. CNC routers can easily create school logos and educational designs in item components. 3. School buyers want more attention and information from vendors that allows local shops an advantage by being close by and easier to meet face-to-face with purchasing department staff. 4. Local shops can offer more customization and can respond to slight modifications in the design of products than distant manufacturers. It is important to work with the purchasing department staff well in advance of when RTB are announced to get these elements into the RTB specifications. Architects are another important group in the design of school facilities and local shops should network with current and past architectural firms involved in local school projects. Local forests can supply wood for furnishing local schools and government buildings 6 Schools can incorporate lessons of sustainability using the wooden furniture located in the school and how forests provide wood for schools This $16 million middle school was LEED certified and contained almost no wood furnishings but was full of depletion resource materials like metals and plastics. None of the furnishings were made locally. Survey of Local Government Purchasing Departments This project received thirteen completed surveys from the states of West Virginia, North and South Carolina in three sizes of community-large, medium and small population. Below is a summary of the responses: 1. Most buyers were not members of a professional public purchasing association. 2. The average government unit had 362 employees, supported 15.5 buildings and built 1.1 new buildings in the last four years. 3. Buyers preferred wooden furniture for government buildings over metal and plastic furniture. 4. Buyers did indicate a preference for birch, cherry and oak when presented a choice of species, but were not well knowledgeable of wood species. 5. There was a wide range of preferences when asked of the preference between painted finishes versus clear and stain finishes, but overall a preference for clear and stain finishes. 6. A strong preference for domestic wood products over imported wood products. 7. Buyers reported good prices as the most important element wood products manufacturers can possess, but also mentioned was good designs, good support information and long warranties. 8. Solid lumber wood products was the most preferred construction for wood products. 9. A strong preference was noted for wood over metal and plastic government furniture. 10. Buyers when reporting purchasing methods were seen to be more formal with increased size of the government unit. In smaller size government units each department purchased for its own needs out of its own budget. Many units buy off state purchasing and contracts listings. Many put out request for bids after developing a list of specifications. 11. Most buyers report that with larger sized purchases that more formal procedures are followed. 12. Most buyers report that there are polices to encourage the purchase of locally made goods. 13. Department managers were the most reported position in the governmental unit that initiates furniture purchases. 14. Other persons reported to be involved included in the purchasing process included users, facility personnel, finance department members and upper level administrators. 15. Vendor reps were the most mentioned outside professionals assisting in furniture purchases. 16. About half of the respondents reported having bid information online. 17. Many respondents reported that their department created a vendor’s list for furniture based upon bad bidders. Some mentioned using the list of state approved vendors. 7 18. Only one purchasing department reported having a manual that explained to vendors the department’s purchasing policies. 19. Only two buyers reported using the state’s prison system’s workshop for purchases. 20. Buyers reported using a wide variety of purchasing methods that included state contracts, cooperatively bid contracts, competitive bidding and putting out RTB, no bidding and negotiated contracts. 21. Eight buyers reported using the Internet for small $ purchases and researching products and specifications. 22. One buyer reported having difficulty finding courtroom furniture made of solid lumber. Also mentioned regarding problems was the request that wood shops attend meetings with the purchasing department staff to provide education on wood furniture and have more opportunities to see the products that wood shops make. Preferences for Wood as Indicated by School and Government Public Furniture Buyers-Scale From 1 to 5 (5 is the most preferred): 5 4.5 4.5 4.4 4.3 3.9 4 3.5 3.8 3.2 Average of Wood vs. metal/plastic 3 2.5 2.2 Average of painted wood vs. stain/clear 2.3 Average of domestic vs. imported wood furniture 2 1.5 Average of wood is greener than metal/plastic 1 0.5 0 Government(n=13) 8 School (n=7) This city government administration building built in 2003 used almost no wood products in its construction or furnishings This county administration building opened in 2012 and local shops were asked to bid on its $750,000 of cabinetry, furniture and millwork This service counter is an example of a built-in that local shops are well suited to provide for schools and local government service centers Important Role of State Purchasing and Contracts Offices State purchasing and contracts offices provide an important service to local school districts and governments in reviewing products and vendors to insure taxpayer dollars are spent properly. These state agencies are professionally managed to support the purchase of supplies, equipment and furnishings. Furniture and related furnishing items offered by vendors are reviewed and have to meet the written specifications for their category to be accepted. These state purchasing and contracts offices develop purchasing policies and guidelines that are used by state agencies and universities, and may be used by local governments and school districts. These policies and guidelines support transparency and fairness to vendors. These state agencies set up term contracts with approved vendors who will make products available to government and school buyers at set prices for a specific length of time. There are rules to follow for pricing of installation. Buyers are free to choose to purchase at these published prices or can set up a RTB (Request to Bid) for a project that can involve larger purchase amounts. New vendors that want to be approved and listed in the term contracts program have to submit proof of their competency and ability to perform. There are educational supports for new and existing vendors with workshops and webinars by the Purchasing and Contracts offices. The websites of the Purchasing and Contracts office will list open RTB projects and vendor sales representatives regularly visit these websites for projects to bid. Small shops that want to learn more about the public furniture market should attend the educational workshops and webinars and review open RTB to educate themselves about the public furniture market. Buyers Create RTP and Purchase Orders for Items They Want to Buy The secret point of knowledge that wood shops need to understand is that public furniture buyers research their needs and compare those needs to what is available in the market, then they construct RTB packages, then buy based on the least cost qualified buyer. Thus if local wood shops want the orders from local governments and school district buyers, then they have to be in the research pool of providers. One has to be visible to the buyers and the following actions can help insure the local wood shop can compete with distant manufacturers: 1. Meet and greet-take time to network with the key persons in the decision process for buying public furniture = users, principals, department managers, purchasing department staff, architects and designers and facility managers. 9 2. Develop local wood shop product items that can compete with products schools and government buyers are currently purchasing, especially items made of metal and plastic. 3. Develop products that distant manufacturers are making that do not meet the needs of schools and local government buildings. Innovation in design and use of materials with wood can create products significantly better and different than those made of metal and plastic. 4. Understand that buyers are not looking for cheapest price but best value for taxpayer dollars. They want products that last for many years, have low repair and maintenance costs and have low disposal problems. It is possible with wood products to design with the next use preplanned for the wood parts to add sustainability virtues that are valued by public furniture buyers who are instructed to pursue sustainability goals and objectives. 5. There is an increased level of attention being paid to the cost of transportation for products bought by public entities as well as reducing packaging costs. Locally made wood products can be delivered far closer and cheaper than products from distant locations and with blanket wrapping products, can avoid disposing of packaging materials to landfills. State purchasing and contracts departments are specifying packaging being made of recycled materials and that installers have to recycle packaging materials. Locally made wood products can be delivered wrapped in reusable blankets and save costs and offer greater sustainability than products made globally or nationally. Understanding How Writing the Specifications Helps Win the Bid The sales representatives that are most aggressive in getting their manufacturer’s specifications written into the state purchasing and contract office’s specifications and those of local purchasing offices in purchase orders and RTB’s have the inside track to winning bids. When the specifications of a manufacturer are used by the purchasing departments it gives the manufacturer and their representative a lower cost of manufacturing the products due the being set up to manufacture the products using their standard materials, methods and equipment. Local wood shops can also use this marketing edge by promoting the use of local wood species and construction methods that the distant manufacturers do not use. Many large public furniture manufacturers will not bid a RTB when there are strong differences from their standards. Knowing Who is Managing New Projects is Important When new facilities are under construction, it is important for the local wood shop to understand how the project is being managed as this determines who is the key player in the furnishings contracts. When the local school or government unit is managing the project, then their purchasing department will be putting out the RTB. When the furnishings responsibilities are part of the construction contract, then the construction company and the architects may be in charge of the furnishing contracts and the RTB will be coming from them. There is more flexibility in the selection of furnishings when the construction company and the architects are responsible for the furnishings contracts. 10 Public Furniture Project Website The project website can be found at www.cnr.ncsu.edu/publicfurniture. This website contains information about the project including: 1. Project goals and objectives 2. Project webinar 3. 3-D design software and engineering systems 4. Model files and parts list for fifty public furniture wood products 5. Short articles on using lumber and plywood for public furniture 6. Additional resources 7. Using local species for public furniture 8. Results from a survey of buyers of public furniture 9. Economic impacts of buying local wood products 10. Marketing advice for wood shops wanting to enter the public furniture market 3-D designs-50 items 3-D modeling software is what cutting edge wood shops are using to better design and engineer their wood products. Modeling software allows designers and engineers to create the parts of a wood product and create items where the parts fit and the software can help the user create parts lists. Given that most wood products are only slightly different from a company’s earlier products, 3-D modeling software is helpful in creating new designs with less time and effort. Finally, solid modeling 3-D software can supply data files that computer controlled machinery can use to saw and machine parts. Example 3-D model of a storage drawer unit 11 Example 3-D model of a computer desk with a flip up top for electrical cables Example 3-D model of an elementary school student locker for books and clothing 3-D modeling software starts with a blank screen with three axis. The user creates parts that are assembled into a model of the item. Paper surface modelers like SketchUp are more useful for design purposes while solid modelers are able to export data file to run CNC machinery. The software creates the third axis when surfaces like circles and rectangles that are pulled and pushed for depth. The 3-D solid modeling software typically has support engineering capabilities that can create bills of materials, parts lists and drawings. This support is especially helpful for manufacturers of public furniture as new buildings project bids typically require drawings to support construction methods. This project used SketchUp, a paper surface modeler, to create fifty example public furniture products to show as examples of items local shops can produce. The project website posted downloads of the SketchUp skp files as well as a MS Excel spreadsheet with worksheets for a parts list, blank costing and pricing, and an example costing and pricing worksheet. These supporting documents are important to reduce the time and effort wood shops require to bid and produce products for the public furniture market. The fifty items included: 1-Mobile bookcase 4-Elementry arts/crafts table 7-48” tall bookcase 10-Medium work table 13-Teacher/gov’t employee desk 16-Computer desk 2 19-Storage drawer unit 4x3 22-Two drawer file cabinet 25-Public library table 28-Modular computer desk 31-Starter library shelving 34-Computer stand 37-Reference hutch table 40-Magazine rack 43-Wall storage cabinet 46-Table top display cabinet 49-Early grades storage locker 2-Traditional student desk 5-Square edge slab bench 8-72” tall bookcase 11-Large work table 14-Teaching assistant/staff employee desk 17-Shallow wall display 20-Storage drawer unit 5x3 23-Step stool 3-Student desk 2 6-30” tall bookcase 9-Small work table 12-Sloped top arts/crafts table 15-Computer desk 1 26-Library computer stand 29-Public library chair 32-Adder library shelving 35-Drop book truck 38-Replacement wooden book cart 41-Base storage cabinet 44-Announcement board 47-Wall coat rack 50-Service counter 27-Library shelving end 30-Lumber bench 33-Book truck 1 36-Double panel study carrel 39-Book stand cart 42-Cubbie storage cabinet 45-Low cubbie storage unit 48-Slot storage cabinet 18-Storage drawer unit 3x3 21-Four drawer file cabinet 24-Slant hutch study carrel Using Local Wood Species Offers Advantages Local shops have many advantages when using local wood species for public furniture products when these woods are specified for public furniture projects. National public furniture competitors are typically working with a few of the major species, such as hard maple, cherry, oak, etc. When local wood shops work with local public furniture and the species specified are more regional and minor species such as elm, hickory, sweet gum, hackberry, worm red maple, beech and sycamore, the local shops gain a significant advantage in winning the bid. Solid lumber products are seen by buyers as superior to other construction materials, including metals and plastic, according to our surveys of school and local government buyers. Solid lumber is a more affordable option when using the minor species that are lower in cost than premium wood species. 12 Solid lumber is a good option for bookcases, chairs, etc. and other products where large flat surface areas are not needed. Local landowners, sawmills, veneer mills, lumber drying operations and wood shops benefit greatly when local woods are used in public furniture. It is possible for local wood shops to buy locally sourced logs and have them sawn into lumber that can be used in local school and government projects. This is also true in urban areas due to the large number of small portable sawmills found in urban areas. Plywood is also an option for local shops who can lay up their own plywood panels as well as by from local and regional pressing operations. Plywood works best for larger flat surfaces and veneer core plywood can utilize such species as yellow poplar and sweetgum for its inner plies with other woods as faces. The choice of joinery typically is made by the manufacturer, but many buyers and state purchasing and contract offices do have preferences in some cases. One case came up in an interview with the North Carolina Purchasing and Contracts Office where it was learned that the P and C office staff preferred to write specifications for drawer construction using dovetail joints in the drawer box corners over other methods. Local government and school purchasing departments can aid local shops when they specify construction methods and joinery that is different from that used by importers and national public furniture manufacturers. These distant competitors do not like to use joinery methods that are not their standard and will often not bid projects that step outside their standard construction. Many design trends in the public furniture market depend upon colors, such as having furnishings in a school’s colors. Many lower cost local wood species work well in painted finishes, including wormy red maple, yellow poplar, sweetgum, beech and sycamore. Another advantage of wood products is the ability with computer controlled routers to carve school and local government logos and other graphic designs into the parts of the furniture, including tops, end panels, etc. It is possible to create an enhanced educational environment in a library or classroom to carve graphics of text, portraits, figures, etc. that will complement the educational experience of students. Importance of School Districts Markets for Wood Shops School districts are important buyers of furnishings for their school buildings as well the furnishings for buildings used by their administrative staff. When new buildings are built there is the greatest opportunity for local shops to bid on items that are used in the classroom, library, staff offices, auditoriums, work rooms, arts and crafts room, etc. Remodeling buildings provides additional opportunities for local wood shops to provide wooden furnishings products. While most of the products purchased by school districts have similar standard designs, there are also purchases made of custom items where the district seeks to offer its students and staff more customized furnishings. This often occurs in service desks at the school’s main office and also in computer rooms and media centers. In these cases the wood shop can assist the school district buyer in designing the items and insuring the items work as needed. The school district in growing areas of the US open schools builds new schools when student populations reach the limits they believe are too large for a good educational experience. The local wood shops should research how fast the district’s student population is growing and anticipate the need for new schools and remodeling. It is a long process to plan and build a school and the local wood 13 shops should attempt to enter the discussion of school design and furnishing selection as early as possible. Millwork shops should attempt to educate the school district facility planners and architects of the advantages of using wood in schools as well as the benefits to the local community. In our returned surveys of school district buyers we learned that the buyers want more educational information about how to use wood in school, how wood joinery and construction methods vary and what choices can they make when researching wood options would offer more value to the taxpayer. Wood shop classes can use local woods to teach skills and sustainability lessons. Local wood shops can supply overstock materials to schools for classes Wood shop classes can teach design and construction principles that students can use in later careers Wooden benches are needed in public lobby areas in schools and government buildings and offer local wood shops a great product to make with local wood species Importance of Local Governments Local governments are important buyers of furnishings for their administrative and work buildings. When new buildings are built there is the greatest opportunity for local shops to bid on items that are used in the lobby, staff offices, storage rooms, auditoriums, conference rooms, etc. Some local governments are also responsible for libraries and hospitals where local shops can provide wooden furnishings and millwork. Remodeling buildings provides additional opportunities for local wood shops can provide items on a bid or purchase order basis. While most of the products purchased by local governments have similar standard designs, there are also purchases made of custom items where the district seeks to offer its students and staff more customized furnishings. This often occurs in service desks at the offices and also in computer rooms and back room work areas. In these cases the wood shop can assist the buyer in designing the items and insuring the items work as needed. The local governments in growing areas of the US open new facilities when additional levels of service are needed. The local wood shops should research how fast the local government’s population is growing and anticipate the need for new facilities and remodeling. It is a long process to plan and build a government building and the local wood shops should attempt to enter the discussion of design and furnishing selection as early as possible. Millwork shops should attempt to educate the facility planners and architects of the advantages of using wood in schools as well as the benefits to the local community. In our returned surveys of local government buyers we learned that the buyers want more educational information about how to use wood in buildings, how wood joinery and construction methods vary and what choices can they make when researching wood options would offer more value to the taxpayer. They also want wood shops to visit them and their leaders in order to promote the local wood shops as important contributors to the local tax coffers. 14 Project Webinar-Slide Show and Discussion On Tuesday, February 26th, 2013, we conducted a one hour webinar to support this project. The webinar consisted of a PowerPoint slide show and discussion by the project staff and attendees. The discussions included examples of furnishings that local shops can make that are being purchased by global and national furniture manufacturers. Attendees were located all over the US and represented manufacturers as well as support organizations like the USFS and universities. The slides from the webinar can be downloaded as a pdf file at the project website at www.cnr.ncsu.edu/publicfurniture. Also at this site is the link to NC State University’s website for webinar recordings where one can listen to the discussion. The discussion on the webinar focused on these points: Slide 6-depletion resources like metals and plastics are wonderful in the short run but are harmful to the world in the long run. Slide 7-public furniture exists in the 3,100+ US counties and many more cities and towns. Every year there are new public buildings going up and many remodeling projects that can provide orders to local wood product shops. Slide 8-the greatest boost to the local economy occurs when local wood shops use local lumber and plywood to make wood products for schools and local government buildings. Slide 9-we want to focus on public furniture as local governments and school districts should want to support local manufacturers as they are paying taxes on property, income and sales. Local governments and schools can promote the local community by incorporating local materials into their purchases. Slide 10-the return from the local spending of tax $ is greatest for local shops, then regional, then national. Slides 11 to 15-discusses the goals of this public furniture marketing project. Slide 16 to 17-discusses the importance of state purchasing and contract departments. Slides 18 to 24-discusses the survey results from local government and school district purchasing departments. Slide 25 to 29-the importance of how the purchasing departments manage the purchasing process. Slide 30-the advantages of wood over metals and plastics. Slide 31-the importance and examples of wood in public buildings. Slide 32-why 3-D software helps wood shops. Slide 33-why using local species can help local shops compete. 15 Slide 34 to 35-why greater efforts at marketing is needed by wood shops. Slide 36 to 37-why greater efforts to modernize helps local wood shops. Slide 38-adding educational features and local elements to products helps the local wood shops. Slide 39-a discussion of cooperation and networking with local wood shops. Slide 40-put marketing efforts to grow the size of the pie. Slides 41 to 44-summary and contact information. Marketing Ideas to Support Local Wood Shops This project presented many ideas to assist the local wood shops to compete in the public furniture market that are largely out of the local community. Given that local school districts and local governments may want to support local manufacturers, the local wood shops need to be proactive in developing the network of contacts needed to compete against more established and equipped manufacturers. Below are some ideas to support local wood shops to become competitive in the public furniture market: 1. Develop better negotiation skills-the public furniture market is a formal established market where buyers follow rules and regulations. Buyers typically follow the rule that the winner is the lowest cost qualified bidder, they evaluate the ability of the provider to deliver as promised and negotiation skills are needed to learn exactly what the buyer feels is important and to offer a solution that is affordable and practical. 2. Knowledge of specifications is the key to bidding public furniture jobs. Specifications are the key focus of sales reps who work strongly to present their manufacturer’s specification to be used by the buying entity. Sales reps typically pitch their company’s written specs as superior to others and when used gives them the inside track to winning the bid. 3. Minor and local wood species that get written into the specifications is a key advantage for local wood shops. In many locations there are suitable local species that are more affordable and allow local shops to be competitive. For example, in some locations in the US, elm is a local hardwood that is quite suitable for public furniture and can be obtained from the stream of mixed hardwoods that is used for pallets and other industrial wood products. 4. Network with the staff of purchasing departments and administrators-the local buyers of public furniture and administrators understand the need to support local businesses and want to support them when the local shops can provide satisfaction of being competent and equal to national and global manufacturers. Local wood shops need to invest time and energy at networking events and providing education on the benefits of wood over metal and plastic furnishings. 5. Wood shops can add educational elements at low cost that are helpful in justifying using wood over metal and plastic furniture products. These efforts can include using local species, identification of wood species used in products, providing posters that show trees and species of wood used 16 products, posters with photos of the products being manufactured including local persons employed by the local shops and planting trees in school yards that match the wood species used in products. 6. Promote the sustainability of wood as compared with metals and plastics. Photos of growing forests are more impressive than open pit mines and refineries. 7. The future will bring increasing costs to products made from depletion resources like metals and plastics while the prices of wood will be moderated by the ability to grow its supply. 8. Custom items are easier for local shops to produce than distant manufacturers. Local wood shops should seek out opportunities to offer custom items that may be more desirable to the users in public building projects and offer barriers to distant manufacturers. Outreach to the Wood Products Industry The outreach effort to the wood products industry has included these efforts: 1. Project webinar-held on February 26th, 2013-this discussion of the project and its findings attracted participants on a wide geographical basis as well as from both the private and public sectors. The webinar was recorded and the slide show is offered as a pdf file download on the project website. 2. Direct contact of wood shops in the targeted counties and cities where surveys were returned for both school districts and local government units. 3. Directing contact of buyers and administrators for public furniture in the counties and cities where surveys were returned for both school districts and local government units. 4. Direct contact to a selection of US lumber and plywood manufacturers and distributors. 5. Contacting wood industry trade associations with press releases and providing the project website information. 6. Providing short articles of the project’s findings to wood industry and public purchasing associations and providing the web address of the project website. 7. Providing short articles of the project’s findings to wood industry trade publications to be offered for both print and web editions. Support the Growth of Sales of US Woods for Public Furniture This project supported the growth of sales of US woods for public furniture by wood shops with the presentation of research of how local governments and school districts buy furniture. The surveys also detailed buyer preferences for wood in relation to metal and plastic furniture. This project also provided information through the website that can be accessed by purchasing departments seeking to better understand wood’s virtues in relation to metals and plastics for public furniture. Given that little information has been available to shops on the public furniture market, this project has been helpful to shops that need to find new markets to replace lost sales that have occurred due to the decline of the home construction marketing. 17 Markets for Wood Products Beyond Furnishings for Public Buildings There are opportunities to increase sales of wood products for public buildings beyond furnishings, such as millwork and wood for construction. Since 2000 wood has experienced lower price increases than metals and plastics and economists predict the same trend will continue in the future due to wood being a renewable resource. Millwork for public buildings can provide sales for products like mouldings and trim, interior doors, casework (base, wall and storage cabinets), stages in auditoriums, etc. Special rooms in schools where wooden millwork supports education include arts and crafts rooms, drama and literature classrooms, conference rooms and staff offices. Service counters are easily manufactured with a combination of lumber and plywood to custom fit the needs of service employees. Suppliers Can Assist the Effort to Promote Locally Made Wood Products for Schools and Government Buildings Small shops need the support of local vendors for lumber and plywood that is affordable and in smaller quantities than large factories require. There is an opportunity for a smaller lumber distributor to specialize in the minor species as most large lumber distributors already carry a large number of species and may not want to add minor species that can offer lower costs for small shops. Summary This project conducted research into the public furniture market by visiting school and local government purchasing departments and using a survey instrument to learn the process of how they buy furniture and what preferences they have for wooden furniture versus metal and plastic furniture. The goal of the project included identifying actions that local wood shops can utilize in order to grow their sales in this important local market. The US has approximately 3,100 counties and many more thousand local city governments in addition to the fifty state governments that are supportive of businesses in their regions. This project in its outreach efforts to wood shops, local public furniture buyers, wood products vendors and public official is supportive of growing sales of wood, given that it is a renewable material, unlike depletion materials, like metals and plastics. 18