SupplementalMaterials-revised_Final_1377708860_1

advertisement

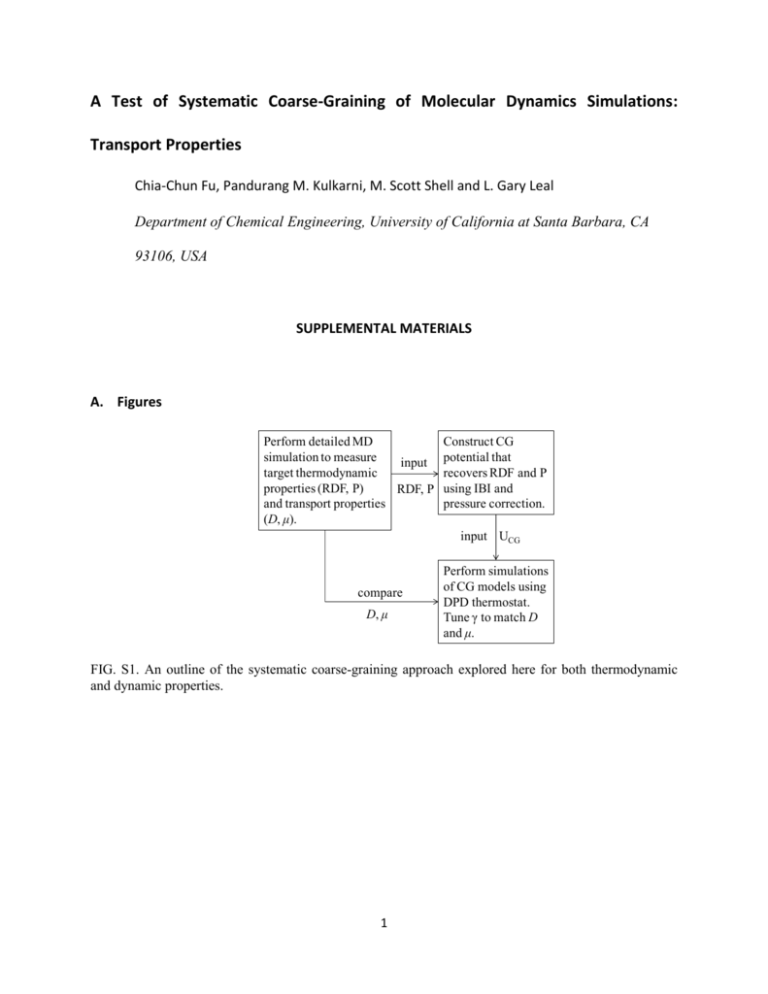

A Test of Systematic Coarse-Graining of Molecular Dynamics Simulations: Transport Properties Chia-Chun Fu, Pandurang M. Kulkarni, M. Scott Shell and L. Gary Leal Department of Chemical Engineering, University of California at Santa Barbara, CA 93106, USA SUPPLEMENTAL MATERIALS A. Figures Perform detailed MD simulation to measure input target thermodynamic properties (RDF, P) RDF, P and transport properties (D, μ). Construct CG potential that recovers RDF and P using IBI and pressure correction. input UCG compare D, μ Perform simulations of CG models using DPD thermostat. Tune γ to match D and μ. FIG. S1. An outline of the systematic coarse-graining approach explored here for both thermodynamic and dynamic properties. 1 FIG. S2. The CG potential obtained from IBI method with pressure correction for different coarsegraining levels ϕ and their corresponding optimum cutoff lengths. The latter are chosen to meet the criterion that the structure- and pressure matched CG potentials can be generated with computational efficiency. Reproduced with permission from J. Chem. Phys. 137, 164106 (2012). Copyright 2012 American Institute of Physics. FIG. S3. The RDFs obtained in DPD simulations for CG models using ϕ = 0%~ 70%, as compared to that of the target MD system. All the lines show excellent agreement, as expected since the thermodynamic properties should not be affected by the choice of dynamical parameters in the DPD approach. 2 FIG. S4. The CG potentials obtained from pure IBI/RDF-matched (short dashed lines) and IBI with the pressure correction (solid lines) for different coarse-graining levels ϕ and their corresponding optimum cutoff lengths. P is the pressure when only the RDF is matched. Reproduced with permission from J. Chem. Phys. 137, 164106 (2012). Copyright 2012 American Institute of Physics. FIG. S5. The CG potentials obtained using the modified IBI procedure with the pressure correction for ϕ = 50% and with rcut = 3.0-4.5. Reproduced with permission from J. Chem. Phys. 137, 164106 (2012). Copyright 2012 American Institute of Physics. 3 FIG. S6. The CG potential obtained using IBI and the pressure correction for ϕ = 50% and rcut=3.5, for T*=1.0, 2.0 and 4.0. Reproduced with permission from J. Chem. Phys. 137, 164106 (2012). Copyright 2012 American Institute of Physics. FIG. S7. The CG potentials obtained from pure IBI (solid lines) and IBI with the pressure correction (dashed lines) for ϕ = 0-70% and using a cutoff equal to half of the simulation box length, L/2. Reproduced with permission from J. Chem. Phys. 137, 164106 (2012). Copyright 2012 American Institute of Physics. 4 B. Cutoff radius In section III A, we presented the dynamic properties for ϕ = 0%-70% when using a ϕ dependent optimum cutoff length. In this section, we obtain results for the same range of coarsegraining but in each case using the same and longest possible rcut at half of the simulation box length, L/2. The CG potentials derived from these cutoff schemes using the IBI procedures are shown in Figure S7. Here too, as shown in Figure S8, we find that the changes in the tails of the CG potentials due to that the pressure matching do not have significant effect on the transport properties and that the viscosity becomes overestimated when a longer cutoff radius is used. The effective γ still increases with ϕ; however, its value is lower than before when using a shorter cutoff (Figure S8b). Again, to validate the argument in section III C that shorter Rcut is favorable when the standard weighting function is used, we use the optimum cutoff radius, from which we are able to find a self-consistent γ at Section III A, as Rcut for ϕ = 0%-70% while rcut is L/2. The optimum cutoff length, according to our previous study, increases with increasing ϕ. The same trend can be observed from Figure S8(a) since we learn from ϕ = 50% that a shorter Rcut gives a lower viscosity. Except the non coarse-grained ϕ = 0% case, which uses a minimal γ to control the temperature rather than account for any missing degrees of freedom, the decay of the overestimated viscosity for ϕ = 30% - 70% shows that Rcut should increase as ϕ increases. As given in Table sI, the results demonstrate once more that the values of the effective γ are the same as those in Figure 4(b) and using a shorter cutoff radius for dissipative and random forces can prevent the mismatch in diffusion coefficient and viscosity. 5 FIG. S8. (a) The diffusion coefficient D and viscosity μ for ϕ = 0%-70% and rcut = 5.4 (L/2), using a DPD thermostat and the effective value of γ for each rcut that matches D. These effective values are shown in (b). The open markers are the results for the systems with RDF-matched potentials; the solid markers are those from the RDF- and pressure-matched potentials. TABLE S1. The diffusion coefficient D and viscosity μ for CG systems using DPD thermostats at T* = 1.0 with standard weighting functions, s = 2. Numbers in parentheses give uncertainties. rcut Rcut γ D μ ϕ (%) 0 2.5 0.1 0.065(0.001) 1.98(0.046) L/2 (5.4) 30 3.0 4.5 0.066(0.003) 2.05(0.169) 50 3.5 6.0 0.062(0.001) 2.23(0.316) 70 4.0 8.0 0.065(0.003) 1.72(0.231) 6