references aromatic

advertisement

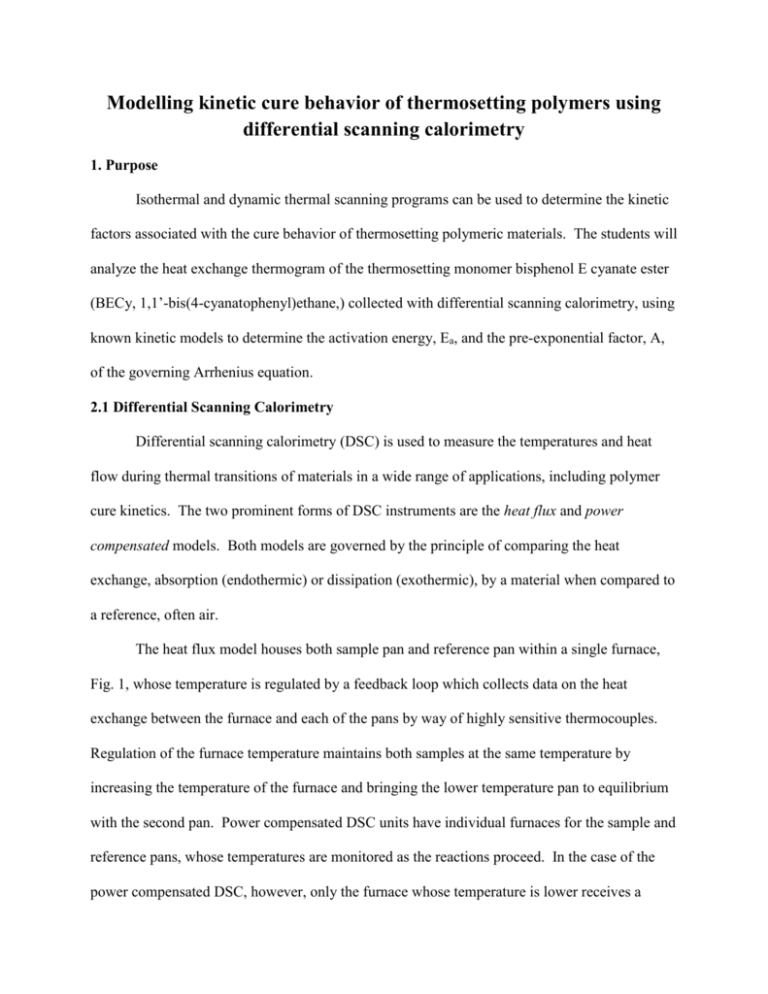

Modelling kinetic cure behavior of thermosetting polymers using differential scanning calorimetry 1. Purpose Isothermal and dynamic thermal scanning programs can be used to determine the kinetic factors associated with the cure behavior of thermosetting polymeric materials. The students will analyze the heat exchange thermogram of the thermosetting monomer bisphenol E cyanate ester (BECy, 1,1’-bis(4-cyanatophenyl)ethane,) collected with differential scanning calorimetry, using known kinetic models to determine the activation energy, Ea, and the pre-exponential factor, A, of the governing Arrhenius equation. 2.1 Differential Scanning Calorimetry Differential scanning calorimetry (DSC) is used to measure the temperatures and heat flow during thermal transitions of materials in a wide range of applications, including polymer cure kinetics. The two prominent forms of DSC instruments are the heat flux and power compensated models. Both models are governed by the principle of comparing the heat exchange, absorption (endothermic) or dissipation (exothermic), by a material when compared to a reference, often air. The heat flux model houses both sample pan and reference pan within a single furnace, Fig. 1, whose temperature is regulated by a feedback loop which collects data on the heat exchange between the furnace and each of the pans by way of highly sensitive thermocouples. Regulation of the furnace temperature maintains both samples at the same temperature by increasing the temperature of the furnace and bringing the lower temperature pan to equilibrium with the second pan. Power compensated DSC units have individual furnaces for the sample and reference pans, whose temperatures are monitored as the reactions proceed. In the case of the power compensated DSC, however, only the furnace whose temperature is lower receives a surge of electrical current, which will raise the temperature of the pan to match the higher temperature pan. (The Perkin-Elmer instruments found in the MSE teaching labs are examples of power compensated DSC.) Fig 1: Schematic representation of heat flux DSC sample cell, containing both reference and sample pans. 2.2 DSC Samples The sample to be characterized is sealed in an aluminum pan and placed alongside an empty aluminum reference pan in the DSC furnace. The sample and the reference pan are heated at the same rate by a heating element in the furnace. Thermal transitions such as melting or crystallization involve release or absorption of heat which leads to a difference in temperature between the sample and reference. The DSC measures the difference in heat flow required to maintain the sample and the reference at the same temperature. A purge gas such as helium or nitrogen may be used to ensure thermal efficiency and to remove evolved volatiles. 2.3 Bisphenol E cyanate ester Bisphenol E cyanate ester (BECy) is a diisocyanate monomer containing two phenyl rings along the backbone of the monomer, Fig. 2. The monomer exhibits attractive processing Fig. 2: Monomer form of BECY and structural properties, including low viscosity (0.09 – 0.12 Pa·s), long pot life and low volatile emissions, while fully cured BECy has an onset glass transition temperature ca. 270°C which makes it suitable for lightweight, high strength, and high temperature matrix applications. The appeal of these chemical species is the highly efficient polymerization process and the high storage modulus; attributed in large part to the presence of the aromatic rings which inhibit polymer chain mobility. Additionally, BECy exhibits a range of attractive characteristics: resistance to radiation, fire and moisture, mechanical and electrical stability over a broad range of temperatures, and excellent compatibility with metals and fiber reinforcing agents. Fig. 3: Trimerization accounts for the high thermo-mechanical properties of BECy. 2.4 Kinetic Behavior Models Kinetic modeling refers to the use of DSC data to determine the parameters of a reaction’s kinetics: reaction order (n), extent of conversion (), activation energy (Ea) and the Arrhenius pre-exponential coefficient (A). Isothermal tests provide enthalpy information which is analyzed to determine the degree of conversion, , of monomer into polymer. The rate of conversion (d/dt) is written in terms of Equation 1. 𝑑𝛼 𝑑𝑡 = 𝐴𝑒 −𝐸𝑎⁄ 𝑅𝑇 (1 − 𝛼)𝑛 𝛼 𝑚 (1) Where n and m are the reaction order factors of the autocatalytic model. The order of the reaction (i.e. the various competing chemical pathways from reactants to products), n + m, can be determined by performing least squares regression between the model and data. Dynamic thermal scans generate data used to calculate the values Ea and A using isoconversional models: Kissinger model, Ozawa model, and Friedman analysis. The Kissinger model relates the increase in peak temperature (Tp) of polymerization to the increase in heating rate (, Equation 2. 𝐴𝑅 𝐸 𝛽 ln ( ⁄𝑇 2 ) = ln( 𝐸 ) 𝑅𝑇𝑎 𝑎 𝑝 𝑝 (2) Plotting ln (/Tp2) vs. 1/T(K) for each heating rate yields the Ea and A values of the reaction, Fig. 4. Ozawa also provides a model based on the heating rate, but goes on to include a function of the ln (/Tp2) monomer conversion, g(). Equation 3 shows the relationship between , Ea and A’. Equation 4 shows the relationship between A’ and g(. log 𝛽 = −0.4567𝐸𝑎 𝑅𝑇𝑖 + 𝐴′ Fig. 4: Linear fit of dynamic thermal program data collected with DSC. Line slope corresponds to activation energy of isoconversional model. (3) 𝐴𝐸 𝑎 𝐴′ = 𝑙𝑜𝑔 [𝑔(𝛼)𝑅 ] − 2.315 (4) Once again a plot of log b vs. 1/T(K) yields a best fit line for each degree of conversion whose Ea and A’ can be uniquely extrapolated. The Friedman analysis also uses a conversional function, f(), and is written in the form of Equation 6. As with the previous models the plot of ln (d/dt) vs. 1/T(K) yields values of Ea and A for the various degrees of conversion. 𝑑𝛼 ln ( 𝑑𝑡 ) = 𝑙𝑛𝑓(𝛼)𝐴 − 3. 𝐸𝑎⁄ 𝑅𝑇 (5) Experimental Procedure **Fill up DSC container with dry ice (CO2) and allow temp. to equilibrate ~30 min. 3.1 Sample and Reference Pans Preparation 1) Measure the weight of one empty reference pan with lid and four sample pans with lids; record the mass. 2) Weigh out four samples of BECy monomer (yellow liquid) using the mg-scale balance, ~10mg each, by placing one pan and cover with lid at a time on the scale and using a disposable pipette to add BECy one drop at a time. 3) To close the sample use the sample press, place the pan on the die and position it under the press. Gently pull the handle forward to seal the pan. Repeat the sample preparation procedure for each BECy sample. NOTE: Remember to keep track of sample mass in each pan! 3.2 DSC measurements using Perkin Elmer Pyris 1 1) Turn on nitrogen cylinder along north wall. The delivery pressure should be 35 psi. 2) Turn on air cylinder along north wall. The delivery pressure should be 40 psi. 3) Click “Pyris” button to launch the software and use Pyris Manager to select the instrument to connect to the program. The “Method Editor” window will open and information can be entered into the fields under each tab. 4) In the “Sample Info” tab enter the sample name, operator’s name, pertinent comments AND sample weight. 5) Click on the “file name” box, then the “browse” button to select the correct folder for your data files. <C:\\Program Files\Pyris\Data\MatE 453 F14\group name>. Click on save. 6) In the “Program” tab, use the buttons on the right side to “Add a Step” a. Heat sample 1 from 40°C to 350°C at 2.5°C/min. 7) Set the initial temperature in the “Initial State” tab to 40°C and set the Yvalue to zero. 8) To load reference and sample pan, press the air shield button. 9) Remove the platinum covers with the suction-cup tool. Place the sample in the left furnace and the reference in the right furnace. Replace lids and make sure these are flat and level. 10) Enter the starting temperature on the right hand column and click on “go to Temp” button. Once the temperature has stabilized start the run by clicking on the “run experiment” button. 11) At the end of the run, the program will return to the starting temperature. Carry out the data collection with each BECy sample. Change Program tab accordingly: a. Heat sample 2 from 40°C to 350°C at 5°C/min. b. Heat sample 3 from 40°C to 350°C at 10°C/min. c. Heat sample 4 from 40°C to 350°C at 15°C/min. Post-test: 1. When runs are complete and DSC is cooled, close the nitrogen and air gas valves and dispose of the samples in the solid waste. 2. To export a text copy of your data, go to File/Export Data/ASCII Data and save a copy to the same file as your original data. 3. Pyris Analysis: 1. Open the file for the data collected located in your group folder: < C:\\Program Files\Pyris\Data\MatE 453 F14\group name > 4. After opening the data file use the analyze drop-down list to determine … Assignment 1. Using the autocatalytic isothermal model, calculate the activation energy of the cured BECy sample given the data in Table 1. Recall that the reaction rate, k, takes the form 𝑘(𝑇) = 𝐴𝑒 −𝐸𝑎⁄ 𝑅𝑇 Cure Temp. (°C) k*10-4/s-1 160 36 170 54 180 74 200 150 2. Use the dynamic scanning data collected for the BECy sample and the Kissinger model to calculate Ea (J/mol K) and A for the 1%, 3% and 5% nanoclay samples cured at 2.5°K/min, 5°K/min, 10°K/min, 15°K/min. Plot ln(/Tp2) vs. 1/Tp and find the best linear fit to show the relationship between the slope and activation energy values. 3. Using the Ozawa model, calculate the Ea (J/mol K) values for your BECy data set. How do the activation energies for the different nanoclay loadings compare for the Kissinger vs. Ozawa models. 4. Qualitatively discuss the meaning of the shoulder observed in your polymerization thermograms, with respect to the order of the cure reaction.