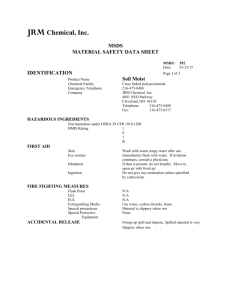

MSDS ADDITIONAL INFORMATION S200 CONTAINS S200 is an

advertisement

MSDS ADDITIONAL INFORMATION S200 CONTAINS S200 is an unsaturated fatty acid crystal matrix, designed specifically to bond with hydrocarbons in a proactive manner. (It chases hydrocarbons). S200 is not flammable and will in fact act as a fire retardant. It is inert, non toxic and contains no artificial microbes or bacteria. It should be kept at room temperature. There are no special handling requirements required apart from common sense. SECTION 5 OF THE MSDS DOCUMENTATION – FIRE – ADDITIONAL INFORMATION Listed on the MSDS is only the raw material of concern to the European environmental and H&S group. A residential house fire has more toxic elements than any fire with the S-200. S200 contains nitrogen in it will completely decompose in a fire. Oxides will formas a result of the nitrogen burning. It is a similar story for the phosphate and carbon. In fact when S200 is used to degrade hydrocarbons an oxide of carbon is formed, namely (CO²). PLASTIC CONTAINERS The plastic drum containers will create oxides of carbon when it burns. S200 itself is non hazardous. The only toxic element in a fire would be the melting plastic containers. The reaction Pyrolysis is listed last in section 5.3 of the MSDS documentation. Temperatures in a fire would have to reach a magnitude of 430 degrees C or 800 degrees F for this to occur. It is a possible resultant reaction resulting from the incineration of the plastic containers and its organic contents under a) high pressure and b) high temperatures. Pyrolysis is a form of incineration that chemically decomposes organic materials by heat in the absence of oxygen. Pyrolysis typically occurs under pressure and at operating temperatures above 430 ¡C (800 ¡F). In practice, it is not possible to achieve a completely oxygen-free atmosphere. Because some oxygen is present in any pyrolysis system, a small amount of oxidation occurs. Organic materials are transformed into gases, small quantities of liquid, and a solid residue containing carbon and ash. SECTION 6 OF THE MSDS DOCUMENTATION – ACCIDENTAL RELEASE MEASURES Best practice methodology is applied in soaking up any spills that might occur with S200 as it is in itself an inert and non toxic product. It contains no toxins, dangerous chemicals or added bacteria. There are two ways to clean up a spill of S200. 1. You would apply normal absolvent material to the spill to soak it up. The soaked material can be placed into a standard trash bin. 2. If you want to get rid of the spilled S200 in under 5 seconds, simply apply any standard Hydrocarbon fuel to the liquid, kerosene or standard octane works best. S200 and hydrocarbons neutralize each other. The residue left over is CO² and water.