supplementar material-fabrication and

advertisement

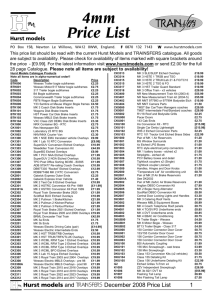

Supplementary Material Biomolecule recognition using piezoresistive nanomechanical force probes Giordano Tosolini1, Filippo Scarponi2, Salvatore Cannistraro2, Joan Bausells1,a) 1 Barcelona Microelectronics Institute, IMB-CNM (CSIC), 08193 Bellaterra, Spain 2 Biophysics and Nanoscience Centre, CNISM-DEB, Universitá della Tuscia, Largo dell’ Universitá, 01100 Viterbo, Italy 1. Probes fabrication process Figure S1. Process flow for the fabrication of the nanomechanical force probes (the sketches are not in scale). a) The sensors are fabricated from (100) silicon-on-insulator (SOI) wafers, from Soitec, with a 340 nm thick device layer, a 1 m thick buried oxide (BOX) and total wafer thickens of 450 m. The device layer is p-type silicon with a resistivity of 0.1-10 cm. b) The windows for the implantation are lithographically defined along the <100> crystallographic direction so that they form an angle of 45º with respect to the wafer flat. Arsenic is implanted at a power of 50 keV with a dose of 1x1015 ions/cm2. c) The cantilever is lithographically patterned in the <100> direction and etched via SF6/C4F8 reactive ion etching (RIE). The doping ions are activated by a thermal treatment at 900ºC for 75’ in oxidizing atmosphere. In this step also a 38 nm protective oxide is grown. The thermal oxide protects the piezoresistors and the crystalline silicon against the following surface micromachining processes. 300 nm of oxide are deposited via tetraethylorthosilicate/O2-plasma enhanced chemical vapor deposition (PECVD) at 400º C, lithographically patterned, and the contacts windows are opened by buffered oxide etch (BOE) solution. d) 1 m of aluminum alloy (Al + 0.5% Cu + 0,75% Cu) is deposited, patterned and etched via BCl3/Cl2/N2 RIE. If Al-particles remained on the surface, then commercial Defreckling Aluminum Etchan (DAE) solution is used to remove them completely. During these etchings the thermal oxide is partially etched. e) 100 nm of silicon nitride are deposited by SiH4/NH3-PECVD at 375 ºC, patterned and etched via CHF3/CF4 RIE. The silicon nitride layer provides to the chips a good electrical isolation, once they are in liquid environment. f) An aluminum layer of 1 m of is sputtered on the wafer backside, patterned and etched via BCl3/Cl2/N2 RIE. A 1,5 m thick photoresist layer is spinned on the component side and hard backed at 200º C for 30 minutes. The resist protects the devices during the following steps. The 450 m of bulk silicon are etched via SF6/C4F8 Bosh deep reactive ion etching process (DRIE). The etching stops at the BOX but additional 30 second of SF6 RIE is performed in order to eliminate all the residues of the passivating polymer. g) The BOX is etched by 49% HF vapors at 32º C, in a custom made HF vapor etcher. At the end, the protective resist is etched by O2 plasma. 2. Cantilever and substrate functionalization All the starting materials were purchased from Sigma-Aldrich. The phosphate buffer solution (PBS) used for the functionalization or washing had a strength of 50 mM with a pH of 7,5. All the cleanings and functionalizations were performed immersing the substrate in Petri dishes and the cantilevers into microcapillaries. Substrates and cantilever were washed in acetone for 10 minutes. The immobilization procedures for both consisted of 5 steps: hydroxyl group exposure silanization linker molecule deposition receptor, or ligand, coupling passivation of active linker CANTILEVER The hydroxyl groups of the silicon oxide were formed by exposing the cantilevers to UV light (200W Hg-Xe lamp) for 30 minutes. Subsequently the cantilever were immersed into freshly prepared 6.3% v/v 99% 3-amino-propyltriethoxysilane (APTES) solution in chloroform for 3 minutes, washed in chloroform (3 x 5 min) and dried under nitrogen. The linker molecule deposition was carried out in 1% v/v grade II 25% glutaraldehyde solution in milli-Q water for 3 minutes. Later, the cantilevers were cleaned in milli-Q water (3 X 5 min) and dried under nitrogen. The incubation of the receptor was performed overnight via a 10 M neutravidin solution in PBS. The cantilevers were cleaned in PBS (3 x 5 min) and in milli-Q water (1 x 5 min). The active sites of the glutaraldehyde that didn’t reacted with the neutravidin, were blocked by immersing the cantilevers into 60% wt ethanolamine hydrochloride solution in water for 5 minutes. Finally the cantilevers were washed with PBS and with milli-Q water. SUBSTRATE The functionalization of the substrate followed similar steps. The chips were exposed to UV light for 30 min, immersed in 2% APTES solution in chloroform for 3 hours, washed in chloroform (3 x 5 min) and dried under nitrogen. Afterwards they were immersed into 1% v/v glutaraldehyde solution in milli-Q water for 3 minutes, washed with water (3 x 5 min) and dried under nitrogen. Finally the samples were immersed into a 10 M biotinylated bovine serum albumin (b-BSA) solution in PBS, washed with PBS and with water. Cantilevers and substrate were used for atomic force spectroscopy measurements just after the functionalization.