production span

advertisement

Introduction

Topological sorting is a common operation performed on

directed acyclic graphs (dags). It arises in numerous applications

including task scheduling, serialization and dependency

determinations, and graph drawing. The goal of this project is to

manipulate graph representations, perform topological sorting on a

dag, and use the topological numbers in a longest path computation

as well as in a heuristic solving a scheduling problem.

Degree-based Topological Sort

Given is a dag G=(V,E), V={0, 1, … ,n-1}, having n vertices and

m edges. The graph is represented in the form of adjacency lists. For

each vertex u, Aout[u] points to a list containing all vertices v such

that <u,v> is an edge from u to v and Ain[u] points to a list containing

all vertices v such that <v,u> is an edge from v to u. The length of list

Aout[u] is the out-degree of node u and the length of list Ain[u] is the

in-degree of node u.

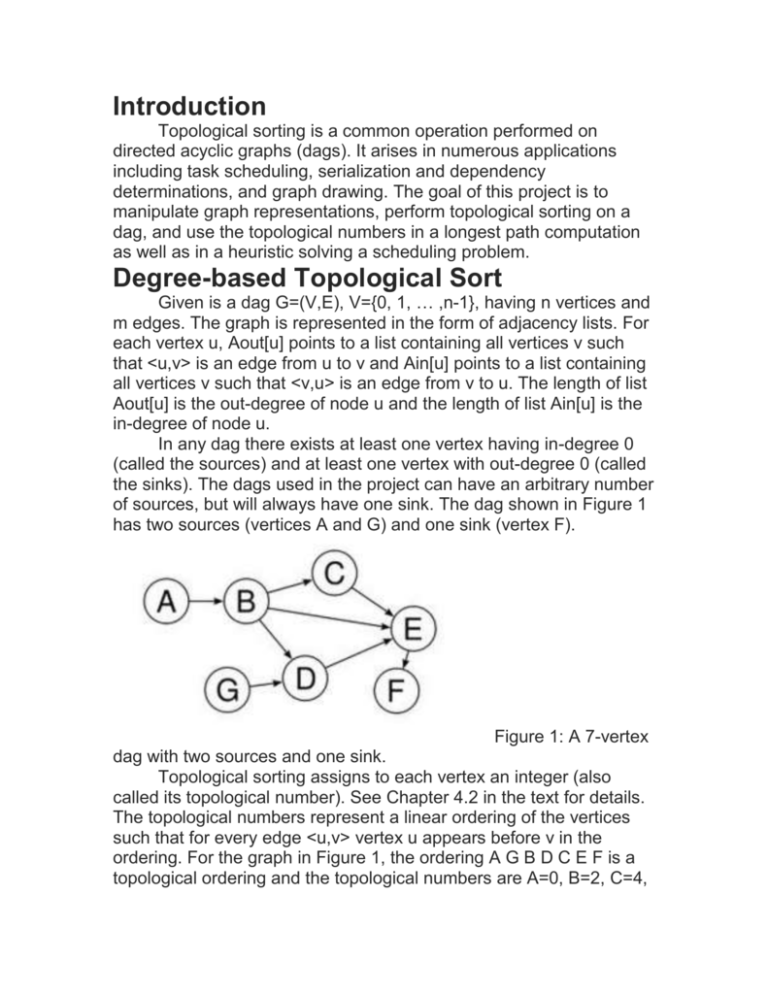

In any dag there exists at least one vertex having in-degree 0

(called the sources) and at least one vertex with out-degree 0 (called

the sinks). The dags used in the project can have an arbitrary number

of sources, but will always have one sink. The dag shown in Figure 1

has two sources (vertices A and G) and one sink (vertex F).

Figure 1: A 7-vertex

dag with two sources and one sink.

Topological sorting assigns to each vertex an integer (also

called its topological number). See Chapter 4.2 in the text for details.

The topological numbers represent a linear ordering of the vertices

such that for every edge <u,v> vertex u appears before v in the

ordering. For the graph in Figure 1, the ordering A G B D C E F is a

topological ordering and the topological numbers are A=0, B=2, C=4,

D=3, E=5, F=6, G=1. Note that topological orderings are not unique.

We note that the textbook presents topological sorting as an

application of DFS (Algorithm 4.5 in Chapter 4.2). Another approach

is a non-recursive implementation based on a degree-driven graph

exploration. In this project you need to implement the degree-based

topological sorting approach described below.

All source vertices are ready to be placed. For Figure 1,

vertices A and G can be placed right away. Once a vertex u has all

the vertices incident to its incoming edges placed, u can be placed.

This observation forms the basis of degree-based topological sorting

algorithm.

The algorithm uses a queue TSQ. Whether one uses a FIFO or

a LIFO (i.e., stack) queue does not matter for determining a

topological ordering (different queues will produce different

orderings). The topological numbers are maintained in an array, say

array T.

The high-level description of the degree-driven algorithm is as

follows:

1 Make all initializations; includes a variable count set to 0 and

placing all sources in queue TSQ.

2 u = dequeue() and we set T[u]=count

3 All of u’s out-going edges are examined. For each edge <u,v>,

reduce the number of edges into v by 1. Once all incoming

edges of vertex v have received topological numbers, this count

would be zero and v is placed into TSQ.

4 Repeat steps 2 to 3 until TSQ is empty.

The needed book-keeping details are yours to work out. In

particular, you need to decide how to manage the counts into vertices

used in step 3. Keep in mind that the running time of step 3 needs to

be proportional to the number of v's outgoing edges.

You can assume that all sinks can be reached from at least one

source. The algorithm implementation needs to run in O(n+m) time.

Longest Path Computation and Scheduling

Assume the dag describes a manufacturing process and each

vertex corresponds to one production step. Production step u cannot

start until all production steps associated with the incoming edges

incident to u have been completed. A topological ordering now

represents one possible production sequence. Manufacturing times at

different production steps vary in applications, but in this project we

assume that every production step takes the same amount of time.

When there is no limit on the number of production steps that can be

carried out simultaneously, what is the minimum time in which all

production steps can be completed? We refer to the time needed to

complete a manufacturing process as the production span. The

production span cannot be shorter than the length of the longest path

from any source to the sink, plus 1 (because the longest path counts

the number of edges).

The longest paths is also called the critical path length (critical

as reducing the production span needs to shorten the length of the

longest paths in the dag.) You need to determine the length of the

longest path in the dag and a manufacturing schedule which

achieving minimum production span. The number of production steps

that can execute at the same time is not limited.

Figure 2: A 8-vertex dag with a longest path of 3.

The DAG in Figure 2 has a longest path of length of 3. This

means that it is possible to schedule the eight production steps in a

production span of 4. Here is a possible schedule: A, (B, C, D), (E, F,

G), H. At time 0, production step A is the only one executing; at time

1, three production steps are executing simultaneously, etc. At any

point, no more than 3 stations are used simultaneously (and thus no

more than 3 production steps execute simultaneously).

Algorithm 4.10 in Section 4.4 of the text presents an O(n+m) time

shortest path algorithm for a DAG. By changing the vertex relaxation,

the algorithm can be changed into the needed longest path algorithm.

See your class notes for more detail.

Scheduling with k Stations

Assume now that at most k manufacturing stations can be used

at any time. You have already developed solutions for two cases:

when k=1 and when the value of k can be as large as needed.

Assume k>1. It turns out that generating a schedule using at most k

stations simultaneously and minimizing the production span is not an

easy problem. You will implement an algorithm that is a natural

generalization of the two earlier algorithms. The algorithm will never

use more than k manufacturing stations, but the resulting production

span may not be the smallest possible (for k stations). This means

that the algorithm will make decisions on which production steps to

assign to stations at times steps that may to not result in the best

possible production span. However, your algorithm will be be fast run in O(n+m) time - and will never use more than k stations.

You are asked to develop an O(n+m) time algorithm for

scheduling the n manufacturing steps when at any time at most k

stations are available. Thus, k tasks can execute simultaneously at

any time. The value of k is given. Your algorithm should assign to

each vertex u a level number L(u) such that

▪ every level contains at most k vertices, and

▪ for every edge <u,v>, we have L(u)<L(v).

The largest level represents the achieved production span.

You need to work out a number of implementation details in your

scheduling algorithm. Make sure it runs in O(n+m) time. Your

algorithm should be based on the following approach:

1 The vertices are considered in topological order. For each vertex v,

assign v to a level p if (i) level p is at least one level higher than

the largest level assigned to any of v’s incoming edges, and (ii)

level p does not already have k vertices assigned to it. If more

than one vertex qualifies for placement, an arbitrary one is

chosen.

2 Repeat the process until all vertices have been scheduled.

3 Report the schedule and the achieved production span.

Summary of Tasks

This project asks you to implement the following tasks. Each task

needs to have an O(n+m) time implementation.

1 For a given dag G, determine the topological number of each vertex

using the degree-based topological sorting algorithm.

2 For a given dag G, determine for the length of the longest path.

3 For a given dag G, use the topological numbers and the longest

paths entries to generate a schedule that completes all

manufacturing steps in the shortest production span. Return the

schedule.

4 For a given dag G and an integer k, 1< k < n, use the topological

numbers to determine a schedule using at most k stations.

Return the schedule.

For those interested in using graph visualization tools, we provide the

following links to resources:

▪ Network Workbench - http://nwb.cns.iu.edu/index.html

▪ graphviz http://www.linuxdevcenter.com/pub/a/linux/2004/05/06/graphviz

_dot.html

▪ Cytoscape - http://www.cytoscape.org/

Programming Assignment

The skeleton code contains a number example dags. Each dag file

has the following format:

<number of vertices> vertices, <number of edges> edges

0:

In: <incoming edges for vertice>

Out: <outgoing edges for vertice>

1:

In: <incoming edges for vertice>

Out: <outgoing edges for vertice>

...

n:

In: <incoming edges for vertice>

Out: <outgoing edges for vertice>

For example, for a 4-vertex dag the input can look like:

4 vertices, 6 edges

0:

In: 2

Out: 1 3

1:

In: 0 2

Out: 3

2:

In:

Out: 3 0 1

3:

In: 2 0 1

Out:

Represent each dag so that it maintains for each vertex the list

of out-edges as well as in-edges. You need to define a class Digraph

that you can adapt from the one given from Princeton library. Add

additional entries as needed.

For tasks 3 and 4, the generated schedule is represented as

described in Schedule.java. The data structure resembles the

structure of adjacency lists: it is an array of lists. The size of the array

equals the production span and the list at the j-th entry of the array

contains the steps executing simultaneously at time j (listed in

arbitrary order). Do not modify Schedule.java. You can use methods

in Schedule.java to construct a schedule.

You must implement the following methods of the

DagUtilities class:

▪ public static int[] topologicalSort(Digraph G)

▪

perform topological sort on dag G and assign topological

numbers.

▪ public static int longestPath(Digraph G)

▪

return the length of the longest path in the dag G.

▪ public static Schedule minProdSpanSchedule(Digraph G)

▪

for dag G, return a schedule minimizing the production span.

▪ public static Schedule spanKStations(Digraph G, int k)

▪

for dag G and integer k, return a schedule using at most k

stations.

▪ public static Digraph readGraphFromFile(File file)

▪

Read a dag from input file and return the dag

Testing

You have been provided with several example trees which you

should use to test your code. To run our main function, use the

following command:

$ java -cp <colon separated path(s) to classes>

Project5Test [Graph_File_Path]

If you want to specify the number of stations for task 4, use the

following command:

$ java -cp <colon separated path(s) to classes>

Project5Test [Graph_File_Path] -s [Number_Of_Stations]

Analysis Questions

Your report must answer each question briefly and clearly.

1 State and explain the asymptotic performance of your algorithm

determining the topological numbers.

2 State and explain the asymptotic performance of your algorithm

determining the longest path in the dag.

3 State and explain the asymptotic performance of your algorithm

determining a schedule achieving minimum production span.

4 State and explain the asymptotic performance of your algorithm

determining a schedule using no more than k stations.

5 Give an example of a dag consisting of at least 15 vertices on

which your k-station algorithm fails to find a schedule

minimizing the production span for k>1. Explain at what point

your algorithm makes the wrong decision.

6 Give an example of a dag consisting of at least 15 vertices on

which your k-station algorithm generates a schedule achieving

minimum production span, k>1.

7 For the dag you used in question 6: Does your algorithm produce a

schedule achieving minimum production span when the

topological ordering used is the one generated by executing a

DFS on the dag? Explain and illustrate your answer.

For the dag in file dagQ8.txt(400 vertices, 850 edges) create a plot

having k on the x-axis (starting with k=1) and the resulting production

span on the y-axis. Note that the dag has a longest path length of 17

and thus the minimum production span possible is 18 (it requires 107

stations). Discuss your plot.

Project 5: Implement four tasks on dags, each having O(n+m) time

performance.

1.For a given dag G, determine the topological number of each vertex using the

degree-based topological sorting algorithm.

• Do not use the DFS approach, but the described degree-based approach

2.For a given dag G, determine for the length of the longest path.

• Use the topological numbers and edge relaxation(on max)

17

Longest path of length is3

Shortest production span is4

Possible schedule:

A, (B, C, D), (E, F, G), H

Possible schedules if only two

stations are available:

A, (B,C), (D,E), (F,G), H A, (B,D), (C,F), (E,G, H

18

Project 5: implement four tasks on dags, each having O(n+m) time

performance.

3. For a given dag G, use the topological numbers and the longest paths entries

to generate a schedule that completes all manufacturing steps in the shortest

production span. Return the schedule.

4. For a given dag G and an integer k, 1< k < n, use the topological numbers to

determine a schedule using at most k stations. Return the schedule.

The schedule for k=1 is the topological order

No benefit when having more stations than long

About the dags and schedules

Take a careful look at the input format

Dags can have multiple sources, but have only one sink

Determine what is needed in class Digraph on entries and methods

Class schedule cannot be changed

Size of the array corresponds to the production span

Linked list at index j lists production steps executing at time j Longest linked list

determines how many stations are used

There are other representations of schedule, but you need to use the one given

20

Analysis question 5

Give an example of a dag consisting of at least 15 vertices on which your k-station algorithm

fails to find a schedule minimizing the production span for k>1.

Explain at what point your algorithm makes the wrong decision.

For small dags, you can check whether your schedule is feasible and whether it

generates minimum production span.

For large dags, you can write a simple methods to check whether your schedule

is feasible. However, determining whether it produces minimum production span

is not easy.

Choose a k (2 or 3) and a dag such that your scheduling algorithm makes a

mistake.You have to do more than find a counterexample. The example has to fool

your algorithm!

21

About the schedules

The graph were generated by a dag library and they seem to be “schedule

friendly”

For k>1, two students may generate schedules having a different production

span.

For every production span, there generally exist a number of valid schedules.

Finding an example where your algorithm fails corresponds