WORLD`S FIRST FULLY PATTERNED 450MM WAFERS

advertisement

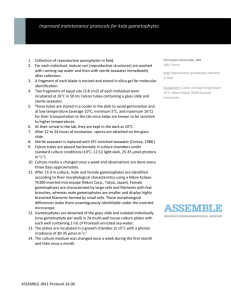

SUNY College of Nanoscale Science and Engineering SUNY Institute of Technology Alain E. Kaloyeros, Ph.D. Chief Executive Officer and Officer in Charge For Release: Contact: Immediate – July 8, 2014 Jerry Gretzinger, Vice President of Strategic Communications and Public Relations (518) 956-7359 | ggretzinger@albany.edu WORLD’S FIRST FULLY PATTERNED 450MM WAFERS UNVEILED AT SEMICON WEST Major Milestone in 450mm Transition Reached as Nikon Delivers Wafers Patterned Using Immersion Lithography Albany, NY – Demonstrating significant progress in the industry transition to 450mm wafer technology, and in support of New York Governor Andrew M. Cuomo’s commitment to New York’s leadership in the development of next generation technologies, the newly merged SUNY College of Nanoscale Science and Engineering (CNSE)/SUNY Institute of Technology (SUNYIT), along with Global 450mm Consortium (G450C) partner Nikon Corporation, today announced the world’s first fully patterned 450mm wafers will be revealed at SEMICON West. The wafers will be on display throughout the exhibition and showcased in the 450 mm Technology Development Session on Thursday July 10th, closing out the 3-day event in San Francisco, California with the most exciting news of the conference. In July of 2013, Governor Cuomo announced a $350 million partnership between the newly merged CNSE/SUNYIT and Nikon to develop next generation 450mm photolithography technology. Nikon and the newly merged CNSE/SUNYIT worked tirelessly to bring a first of its kind immersion lithography scanner online in less than 12 months, enabling the vital wafer exposures that will further advance the industry’s transition from the current 300mm wafer platform to the next generation 450mm wafer platform. The wafers that will be presented at SEMICON West are the first produced in support of the G450C, a publicprivate partnership headquartered at the NanoTech complex in Albany, NY. “These first 450mm wafers are tangible proof that the industry’s transition to this next generation technology is on track and gaining momentum,” said Paul Farrar, Jr., Vice President for Manufacturing Innovation of the newly merged SUNY CNSE/SUNYIT institution and General Manager of the G450C. “Governor Cuomo understood very early on that the transition to 450mm wafer technology was an industry necessity, and he was determined to make it happen in New York State. Through the Governor’s leadership, this historic initiative continues to enable cutting edge innovation and business opportunities, as we set the standard for tomorrow’s technologies.” The Nikon immersion scanner will join existing 450mm infrastructure at the Albany NanoTech Complex in April of 2015 in accordance with the project timeline. This critical milestone will enable G450C founding members and CNSE to perform 10nm and below, full wafer photolithography, while optimizing tool configuration and performance. Over the last few years, photolithography has become the critical enabling step in the manufacturing of nanometer size transistors that are the building blocks of today's computer chips. "Nikon is very pleased to have achieved this key milestone, and we are intent on beginning the next phase of this program, said Nikon Corporation Senior Vice President and Semiconductor Lithography Business Unit General Manager, Toshikazu Umatate. “450mm scanner development is progressing on target to deliver the performance and productivity innovations that will deliver reduced cost per die, which is essential for the continuation of Moore’s Law.” To date, more than $350 million in 450mm wafer tools have been installed at the Albany NanoTech Complex. With the arrival of the Nikon immersion photolithography tool, the investment will swell to over $700 million. A collection of the first fully patterned 450mm wafers will be on display at SEMICON West at the newly merged SUNY CNSE/SUNYIT exhibit, booth number 517, located in the Moscone Center’s South Hall. Representatives will be available Tuesday, July 8, through Wednesday, July 9, from 10 a.m. to 5 p.m.; and on Thursday, July 10, from 10 a.m. to 4 p.m. #################### About SUNY CNSE. The SUNY College of Nanoscale Science and Engineering (CNSE) is the world leader in the emerging disciplines of nanoscience, nanoengineering, nanobioscience, and nanoeconomics. CNSE represents the world’s most advanced university-driven research enterprise, with more than $20 billion in high-tech investments and over 300 corporate partners. The 1.3 million-square-foot Albany NanoTech megaplex is home to more than 3,100 scientists, researchers, engineers, students, and faculty. CNSE maintains a statewide footprint, operating the Smart Cities Technology Innovation Center (SCiTI) at Kiernan Plaza in Albany, the Solar Energy Development Center in Halfmoon, the Photovoltaic Manufacturing and Technology Development Facility in Rochester, and the Smart System Technology and Commercialization Center (STC) in Canandaigua. CNSE co-founded and manages the Computer Chip Commercialization Center (Quad-C) at SUNYIT and is lead developer of the Marcy Nanocenter site in Utica, as well as the Buffalo High-Tech Manufacturing Complex, Buffalo Information Technologies Innovation and Commercialization Hub, and Medical Innovation and Commercialization Hub. For information, visit www.sunycnse.com. About SUNYIT. SUNYIT, the State University of New York Institute of Technology at Utica/Rome, is New York’s public polytechnic, offering undergraduate and graduate degree programs in technology and professional studies. Its academic offerings in technology, including engineering, cybersecurity, computer science, and the engineering technologies, and its programs in professional studies, including business, communication, and nursing, are complemented by athletics, recreational, cultural and campus life programs, events and activities. Founded in 1966, SUNYIT is a unique high-tech learning environment on hundreds of acres, offering degree programs online as well as on campus. The SUNYIT family of alumni now numbers 25,000. For information, visit www.sunyit.edu. About Nikon. Since 1980, Nikon Corporation has been revolutionizing lithography with innovative products and technologies. The company is a worldwide leader in lithography equipment for the semiconductor manufacturing industry with more than 8,000 exposure systems installed worldwide. Nikon offers the most extensive selection of production-class photolithography systems serving the semiconductor industry. Nikon Precision Inc. provides service, training, applications and technical support, as well as sales and marketing for Nikon lithography equipment in North America. For more information about Nikon, visit www.nikonprecision.com.