Inorganic Materials Science (IMS)

advertisement

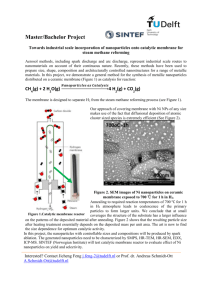

Vakgroepvoorlichting Research group information meeting C.T.S.G. Alembic 2014 2 Table of Contents Schedule .................................................................................................................................................. 4 Wednesday 8 January, HT500B........................................................................................................... 4 Wednesday 15 January, HT500B......................................................................................................... 4 Inorganic membranes (IM) ...................................................................................................................... 5 Catalytic Processes and Materials (CPM) ................................................................................................ 6 Sustainable Process Technology (SPT) .................................................................................................... 7 Biomolecular Nano Technology (BNT) .................................................................................................... 8 Controlled Drug Delivery (CDD); formerly Biomedical Chemistry (BMC)................................................ 9 Membrane Technology Group (MTG) ................................................................................................... 11 Mesoscale Chemical Systems group (MCS) ........................................................................................... 13 Soft matter, Fluidics and Interfaces (SFI) .............................................................................................. 15 Department of Biomaterials Science and Technology .......................................................................... 17 Materials Science and Technology of Polymers (MTP) ......................................................................... 18 Inorganic Materials Science (IMS) ......................................................................................................... 20 Molecular NanoFabrication (MnF) ........................................................................................................ 21 BIOS – lab on a chip group .................................................................................................................... 22 Photocatalytic Synthesis (PCS) Group ................................................................................................... 23 3 Schedule Wednesday 8 January, HT500B Time 13:45h 14:05h 14:20h 14:35h 14:50h 15:05h 15:20h 15:35h 15:50h Research group Opening Biomaterials Science and Technology Group BIOS Lab-on-a-Chip Inorganic Material Science Soft Matter, Fluidics and Interfaces Pause Inorganic Membranes Catalytic Processes and Materials Materials Science and Technology of Polymers 16:05h 16:20h ELAN (lerarenopleiding) Drink Lecturer Dirk Grijpma Séverine Le Gac Guus Rijnders Anne Benneker Arian Nijmeijer Leon Lefferts Joost Duvigneau & Sissi de Beer Fer Coenders Wednesday 15 January, HT500B Time 13:45h 14:05h 14:20h 14:35h 14:50h 15:05h 15:20h 15:35h 15:50h 16:05h 16:20h Research group Opening Molecular Nanofabrication Mesoscale Chemical Systems Controlled Drug Delivery Membrane Science and Technology Pause Biomolecular NanoTechnology Photocatalytic Synthesis Nano Ionics Sustainable Process Technology Drink Lecturer Tibor Kudernac Han Gardeniers Johan Engbersen Kitty Nijmijer Nathalie Katsonis Kasper Wenderich Stanley Lai Sascha Kersten 4 Inorganic membranes (IM) Chair: Internet site: Contact: e-mail: Phone: Room: prof. dr. ir. Arian Nijmeijer http://www.utwente.nl/tnw/im/ Louis Winnubst a.j.a.winnubst@utwente.nl +31 53 489 2994 Meander 348 Molecular separations using membranes have proven to be one of the most energy-efficient ways to separate gases and liquids. Inorganic materials are interesting candidates for membrane applications, because they can be applied at elevated temperature and under harsh chemical, corrosive, and mechanical conditions. In the Inorganic Membrane group research encompasses macro as well as micro scale phenomena. Some examples are: the development of new membrane materials, a better fundamental understanding of transport mechanisms, and the design of membrane processes, like membrane reactors. Research is subdivided in the following topics: 1. Advanced Ceramics Processing The objective is the fabrication of advanced ceramics and the examination of their microstructures. It involves preparation, processing, and microstructural characteristics of powders, ceramics and coatings. By understanding the chemistry and physics behind these processes, we can develop new, reliable ceramic membranes. 2. Solid State Ionics Within this topic we study the ionic and mixed ionic-electronic transport in dense ceramic materials as well as the interface and electrode reactions. Focus is on a better understanding of the fundaments for technological applications for membranes and solid oxide fuel cells (SOFC). 3. Porous Ceramic Membranes Here the objectives are the development of micro- and mesoporous ceramic membranes and the study of molecular transport within these, for the use in energy-efficient gas separation, pervaporation, and nanofiltration processes. Electron microscope picture of a porous membrane, showing supporting layers and a selective hybrid silica top layer (thickness: 0.1 μm; pore size: few Ångstroms). Electron microscope picture showing the surface of a two-phase dense, oxygen-selective, ceramic membrane. 5 Catalytic Processes and Materials (CPM) Within the group we study how and why we are able to influence chemical reactions by using solid catalysts, like for instance the surface atoms and purple clusters in the picture. The majority of the research projects within the Catalytic Processes and Materials group is performed along two main research lines: Catalytic biomass conversion and Catalysis in liquid phase. Catalytic biomass conversion The application of bio-related materials, like organic waste, crops like rape-seed oil and bio-oil produced via flashpyrolysis of biomass, is a promising route towards new, green, fuels and chemicals. However, the different reactants and reaction conditions (like the pH) ask for the development of new catalysts and new processes, since the traditional catalysts, that have been optimized for mineral oil and gas conversion, cannot be used anymore. Also the feedstock itself is less pure and needs further (catalytic) purification. Within our group we develop new catalysts based on insight in the catalytic mechanism and we test the performance of this catalysts in catalytic biomass conversion. Catalysis in liquid phase: mass transfer The application of solid catalysts in liquid phase reactions becomes also increasingly important because of the easy separation of catalyst and products. One of the problems, however, with this type of reactions is the transport of reactants to the active surface (mass transport limitations), since diffusion in liquids is roughly 1000 times slower than in gases. Due to mass transport limitations observed reaction rates are lower than the chemical reaction rate, thus lowering reaction rates. Very often also the selectivity is decreased due to consecutive reactions to unwanted products. We develop new combinations of catalyst-reactor systems that limit or prevent transport problems. Carbon fibres attached to structured catalyst supports, such as monoliths and metal foams, are a promising alternative for application of heterogeneous catalysis in liquid phase. The fibres create a “hairy” layer on the macrostructure thus increasing porosity and surface area. Further, carbon fibres are mechanically strong and chemically inert against acid and alkaline liquids, and can be easily used as support for catalytic active phases such as palladium or platinum. Catalysis in liquid phase: in-situ spectroscopy For both research lines in-situ characterization techniques are very valuable and we use and develop ways to study what is actually taking place on the catalyst’s surface, like for instance Attenuated Total internal Reflection infrared spectroscopy (ATR-IR) and Scanning Tunneling Microscopy (STM) in liquid phase. Scientific Staff Technical Staff 4 4 Post-docs PhD-students 5 14 Contact: Prof. Dr. Ir. L. Lefferts (L.Lefferts@tnw.utwente.nl) or Prof. Dr. K. Seshan (K.Seshan@tnw.utwente.nl) 6 Sustainable Process Technology (SPT) Internet site: Chair: Secretariat e-mail: Phone: Room: http://www.utwente.nl/tnw/spt Prof.dr. S.R.A. Kersten Yvonne Bruggert – ter Huurne y.c.h.bruggert-terhuurne@utwente.nl +31 53 489 2879 Meander 217 SPT (former TCCB group) is a relatively young research and education group on biomass as an energy source. Our research mission is: Creating and perfecting new thermo-chemical routes for the production of biomass derived solid, gaseous and liquid fuels for renewable and sustainable energy. Providing renewable and sustainable energy is one of the most important challenges of mankind. With biomass solar energy is captured using atmospheric CO2 as a carbon source which after utilization of the biomass and its derived fuels is recycled again to the atmosphere. In this way, in contrast to the use of fossil fuels, no additional CO2 is brought into the biosphere. Biomass fuels, once produced, easily fit in the present infrastructure for energy production including the transport sector. If production and conversion processes are carefully selected, biofuels are sustainable and do not compete with the food chain. Both biological and thermo-chemical conversion routes are possible for biomass but our group, because of its expertise, concentrates on thermo-chemical routes. This research neatly fits into the sustainable process technology spearhead of the University of Twente. 7 Biomolecular Nano Technology (BNT) Internet site: Chair: Secretariat e-mail: Phone: Room: http://www.utwente.nl/tnw/bnt/ Prof.dr. J.J.L.M. Cornelissen Izabel Can-Katalanc / Nicole Haitjema bnttnw@utwente.nl +31 53 489 2980 Carre 4.223 Research within the BNT group focuses on using biomolecules as building blocks to engineer smart, multifunctional bio-based materials. Inspired by nature, we use proteins and small molecules as building blocks of choice, to assemble highly-ordered architectures ranging from protein-cages and rods to liquid crystalline materials. Furthermore, by combining (macro)- and supra-molecular chemistry with molecular biology approaches, we use these assemblies as templates to develop functional materials for potential applications in (bio)catalysis, polymerisation, molecular sensing and therapeutics. For example, we employ protein building blocks to form nanometer-sized reactors and use the highly symmetric properties of these protein cages as scaffolds for functional materials. Techniques used in our laboratory range from synthetic chemistry and protein engineering to physical characterization using the state-of-the-art facilities available within MESA+ institute. Our group pursues a broad range of research interests. Potential BSc or MSc projects cover the following research topics: - Protein engineering, derivatization and assembly (Bio)-catalysis in nanometer confinement Hierarchical self-assembly of nanoparticles and other functional nano-objects Synthesis of novel molecular dopants for adaptive materials The BNT group is composed of: Scientific Staff Technical Staff 3 3 Post-docs PhD-students 1 9 From building blocks To supramolecular assemblies To functional materials 8 Controlled Drug Delivery (CDD); formerly Biomedical Chemistry (BMC) Internet site: Chair: Secretariat e-mail: Phone: Room: http://www.utwente.nl/tnw/cdd/ Prof. dr. J.F.J. Engbersen Karin Hendriks secretariat-cdd-tnw@utwente.nl +31 53 489 2968 Zuidhorst 246 Department of Controlled Drug Delivery is the new name that is adopted after merging of the Departments of Biomedical Chemistry and Targeted Therapeutics. The research themes of the department of Controlled Drug Delivery are organized in two sections, originating from the previous departments. The section Biomedical Chemistry is most relevant for students in Chemical Engineering as this section focuses on the utilization of expertise and skills in chemistry to translate biological properties into functional materials for targeting drug delivery and medical imaging. Therefore, design, synthesis, and characterization of multifunctional polymers that respond in a controlled manner to different biological environments (blood, tissue, intracellular domain) are current laboratory activities. Interesting polymers are further explored for design and development of micro- and nanoparticles for controlled drug and gene delivery (nanomedicines). Research in this area involves evaluation of biomedical properties (drug loading, drug release profiles, cellular uptake, cellular fate, cytotoxicity, endosomal escape, gene silencing, transfection, therapeutic response, imaging efficacy, etc.). CT-students who are interested to make a switch in their study towards cell biological research (e.g. BME master) may also consider to join a project of the section Targeted Therapeutics. Their approach is to utilize pharmaceutical and biological expertise and skills to develop new targeted therapeutics and image-guided drug delivery systems and their translation into clinical applications. Current laboratory activities include preparation and characterization of liposomes and alginate nanoparticles and investigating new target receptors/pathways, intracellular mechanisms, and cell-cell interactions. Some examples of projects for CT- students in the section Biomedical Chemistry are: Targeting Drug and Gene Delivery Systems Development of targeting and controlled therapeutic delivery systems gives an essential contribution to medical treatment of many different diseases, like cancer, diabetes, cardiovascular and nerve system diseases, musculoskeletal diseases, rheumatoid arthritis, well as treatments for eye and skin diseases. Targeted delivery of pharmaceuticals to an intended site of action in the body is considered as one of the most important issues for the next generation of therapeutics. In our group, multi-functionalized polymeric systems are designed to achieve controlled and/or targeted delivery of drugs and genes (DNA, RNA). Therefore, biodegradable, stimuli-responsive materials with preprogrammed properties, responding to physical, chemical, and/or biological triggers in the spatial-temporal domain are being developed. These materials show large and sharp physical-chemical changes in response to small physical stimuli such as temperature, light, ultrasound, or magnetic field and/or to chemical stimuli such as changes in pH and/or concentrations of biological molecules like hormones, etc. Examples are: nano-sized polymeric particles containing small anti-cancer drugs, DNA, or small RNAs for cancer treatment, nanogel particles for delivery of therapeutic peptides and proteins, matrices 9 for delivery of growth hormones, and nano-spheres for the prevention of restenosis after stent implantation. Nanoparticles for MRI and PET imaging and therapy of prostate cancer This theme has recently started and aims the development of multifunctional polymeric nanoparticles for in vivo application in dual-mode PET-MRI imaging to detect prostate cancer. Furthermore, prostate cancel targeting nanoparticles will be loaded with anti-cancer drugs to combine imaging with therapy (theranostics). Functional polymeric materials for (bio-)medical applications Research is focused on the design, synthesis and structure-property relationship of novel materials, which degrade at a predetermined rate, and which can be applied for various medical applications, such as bioresponsive hydrogels for controlled delivery of bioactive compounds, temporary supports like suture materials, and matrices for tissue engineering. The properties and applications of novel biodegradable materials are explored in different projects. Important classes of biodegradable polymers that are studied are polyamidoamines, boronic acid-functionalized polymers, and their copolymers. For more information on the Department of Controlled Drug Delivery visit the home page http://www.utwente.nl/tnw/cdd/ Contact: Prof. dr. J.F.J. Engbersen, j.f.j.engbersen@utwente.nl Dr. ir. J.M.J. Paulusse, j.m.j.paulusse@utwente.nl 10 Membrane Technology Group (MTG) Internet site: Chair: Secretariat e-mail: Phone: Room: http://www.utwente.nl/tnw/mtg Dr. Kitty Nijmeijer Greet Kamminga msttnw@utwente.nl +31 53 489 2950 Meander 326 The Membrane Technology Group (MTG) focuses on the multi-disciplinary topic of membrane science and technology for the separation of molecular mixtures. We aim at designing membrane morphology and structure on a molecular level to control mass transport phenomena in macroscopic applications. We consider our expertise as a multidisciplinary knowledge chain ranging from molecule to process. We distinguish three application clusters, i.e. Energy, Water and Life Sciences. Materials science Application studies Mass transport control Membrane design & synthesis Membrane characterization 11 Energy The research on Energy is dedicated to the molecular design and synthesis of polymer membranes for energy applications. Examples are CO2 capture, olefin/paraffin separation, biorefinery applications, fuel cells and the generation of electricity from the mixing of sea and river water (Salinity Gradient Energy or ‘Blue Energy’). Relevant materials science oriented aspects are control of structureproperties relationships, separation of multi-component mixtures (binary, ternary systems, effect of impurities), interaction of the feed components with the membrane (e.g. plasticization) and performance evaluation. Important process technological research aspects are e.g. improvement of hydrodynamics, membrane and spacer design, separation of complex mixtures, concentration polarization and fouling. Water Within the application area Water, research addresses the development of membranes and the application of membrane technology for water treatment. In particular it investigates the relation between membrane properties, hydrodynamic conditions and fouling behavior. Research topics include mPIV, microfluidic filtration, fouling control, membrane bioreactors and biofouling. Life Sciences Within the application cluster Life Sciences, we focus on the design of porous systems to separate complex multicomponent mixtures in pharmaceutical, food, beverage and diagnostics applications. Important subjects are tuning the material properties and structure (e.g. pore morphology and porosity), the development of functional materials (e.g. affinity separations of biomolecules) and the creation of new and/or improved processes (e.g. faster processes, higher yields, less fouling, etc.). Other aspects related to process design and industrial implementation, such as scale-up of novel membrane fabrication methods are investigated. Scientific Staff Technical Staff 6 3 Post-docs PhD-students 2 13 12 Mesoscale Chemical Systems group (MCS) Internet site: Chair: Secretariat e-mail: Phone: Room: http://mcs.tnw.utwente.nl/ Prof. dr. J.G.E. Gardeniers Brigitte Boogaard mcs@tnw.utwente.nl +31 53 489 2099 Meander ME 152 The MCS group, which is part of MESA+ Institute for Nanotechnology, studies downscaling and integration concepts, using microsystems and nanotechnology. The goals of the research are: - to enhance throughput and selectivity of chemical reactions and product purification - to improve the analysis of mass-limited chemical and medical samples - to contribute to the fundamental knowledge of molecular dynamics in nano-confinement. MCS develops micro devices with volumes of 1 nanoliter to 1 milliliter of a solution or gas, or of more complex two-phase systems like two immiscible liquids (e.g. for extraction) or gas-liquid systems (e.g. for hydrogenation). The behavior of fluids at such small dimensions is different from that in typical (largescale) batch reactor systems, because at the small scale where turbulence does not occur, diffusion is the main mechanism for mixing. However, due to the short distances for diffusion , chemistry can still be performed at appreciable rates, and in combination with the high surface-tovolume ratio that is obtained (and even enhanced by applying materials developed by nanotechnology) mass and heat transport rates can be very high. For this reason these microreactors have become more and more popular in industrial environments. Left: microstructured column for chemical (catalytic) synthesis or liquid chromatography on a chip; right: gas discharge (visible as glowing light pattern) in a microreactor immersed in beaker with cooling liquid Because of the small dimensions, it also becomes possible to apply new concepts for activation of chemical reactions, with the goal to find more sustainable routes for chemical processing and contribute to the field of process intensification. Examples are the activation of gas phase chemistry and control of adsorption of species on catalyst surfaces by electrical fields (collaboration with CPM group) or the use of light-to-electricity converting microstructures to activate electricity-driven chemistry in liquids (collaboration with MnF and PCS groups). It is also possible to integrate work-up functionality with the microreactors, like membrane extraction (collaboration with the SFI group) or 13 use microreactors at extreme conditions like high pressures and involving supercritical fluids, without the risks that are normally associated with such conditions. In the analytical chemistry field research is performed on small-scale chromatography methods and integrated spectroscopic techniques. Liquid chromatography "on a chip" has clear advantages over conventional LC, because nanostructuring leads to novel types of separation columns giving very fast and efficient separations. Separations at this small scale require special (integrated) injection and detection concepts, e.g. very-low-dead-volume interfaces with mass spectrometry. Related to this is the development of microfluidic NMR (Nuclear Magnetic Resonance), where at the moment we are able to achieve the same sensitivity and spectral resolution as in stateof-the-art conventional high-resolution NMR, but for a 1000 times smaller sample volume, i.e. in less than 1 microliter. This is very relevant for medical and biological studies where only tiny amounts of body fluids are available, but also for pharmaceutical industry in the early stages of drug development, or in organic chemistry to study reaction mechanisms and kinetics. Besides in these fields, miniaturized chemical analysis concepts are important in forensic and clinical applications, as well as in chemical process and environmental monitoring. A topic with increasing focus is proteins and enzymes in confinement, e.g. in a nanometersized liquid channel or immobilized on a surface. Immobilization has advantages over dissolved enzymes, like recovery and re-use and the possibility to perform a cascade of enzymatic reactions in a continuous flow reactor. The confinement also mimics the biological environment of a cell, where proteins exist in so-called "crowded solutions" or are fixed in lipid membranes. This research therefore helps in understanding processes like protein (mis)folding and clustering, which is of medical relevance, but is also important for industrial crystallization. Scientific Staff Technical Staff 2 1 Post-docs PhD-students 3 8 14 Soft matter, Fluidics and Interfaces (SFI) Internet site: Chair: Secretariat e-mail: Phone: Room: http://www.utwente.nl/tnw/sfi prof. dr. ir. R.G.H. Lammertink Lidy Harryvan a.g.harryvan@utwente.nl +31 53 489 4798 Meander 226 The chair of Soft matter, Fluidics and Interfaces is addressing interfacial phenomena that are relevant for (micro)fluidic processes. Such phenomena include multiphase flow, phase contacting, interface geometry, wetting, and separations, mostly related to mass/heat transport control. Careful interfacial design and fabrication will allow manipulating (multiphase) flow on a (sub)micrometer level. Fabrication of well-defined structures is foreseen as a crucial aspect, in order to study the fundamentals of interfacial phenomena. Here, computational tools will assist in proof-of-concept analysis and in specific structure design. 15 Current research topics include: Microfluidic solvent exchange (Yali Zhang) The goal of this research is to fabricate porous ceramic microreactors via simple replication processes. The new multiphase contacting in these microreactors is studied for relevant catalytic gas-liquid systems. Watercleaning microreactors (Damon Rafieian) The ultimate goal of the project is realization of a microreactor applied for water purification employing photocatalytic reaction technique (oxidation) and hydrogenation of nitrite/nitrate (reduction). The combination of these steps is believed to remove all contaminants form drinking water. Hybrid materials for selective adsorption (Vic van Dijk) Hybrid membranes that consist of an organic skeleton surrounded by an inorganic compound (e.g. silica) offer the opportunity to unite the best of both research fields. Such a hybrid membrane promises to be mechanically flexible due to its polymeric skeleton, while exhibiting separation properties of an (functionalized) inorganic membrane. Interfacial transport phenomena (Sander Haase) Interfacial transport phenomena often determine or limit process performance. Boundary layers that are involved in these processes are studied on a microscopic length scale. This research aims at understanding transport phenomena near permeable boundaries, so that processes can be improved by exploiting these phenomena. Overlimiting current electrodialysis (Joeri de Valenca) In electrodialysis, ions are transported through an ion selective membrane. Under severe concentration polarization, electroconvective phenomena are observed at the membrane boundary. The aim is to study surface heterogeneity in relation to these electroconvective phenomena. Microfluidic electrokinetics (Anne Benneker) Charge selective interfaces under the application of an electric field are prone to overlimiting current behavior. Theoretical and numerical studies show that hydrodynamic effects are of great importance in this overlimiting behavior. The aim of this research is to experimentally investigate the microfluidic behavior causing the overlimiting current and possibly linking it to theoretical and numerical predictions. 16 Department of Biomaterials Science and Technology (BST, http://www.utwente.nl/tnw/bst/ - Prof. Dr. D.W. Grijpma) The group conducts research on resorbable polymeric materials and structures for use in medical devices, tissue engineering and in the delivery of relevant biologically active compounds. Through purposeful design of the chemical structure and architecture of the polymer, tailored materials for use in a specific envisaged (medical) application can be prepared. From work on flexible resorbable materials, already one spin-off company has been created. Current work includes the development of advanced microstructures by photo-polymerization of functionalized degradable oligomers in stereolithography and research programs on the tissue engineering of cardiac muscle, heart valve leaflets and blood vessels and the synthesis and processing of composite materials for fracture reconstruction in maxillofacial surgery. Pre-designed anisotropic architectures based on biologically active materials are being developed to engineer musculoskeletal and cardiovascular tissues in bioreactors under conditions that mimic the natural environment. The release of biologically active compounds can be regulated by the proper design of delivery systems. For this, specific biodegradable polymers have been prepared and their effect on cellular behaviour has been studied. The release has been effectuated from degradable particles as well as from crosslinked networks. Research topics include: resorbable polymers for medical applications, structure-properties relationships in polymers, tissue engineering, bioreactor technology, patterned surfaces and microfluidics, drug delivery, ring opening polymerization, photo-polymerization and stereolithography. Bachelor- and Master research assignments can be performed within these areas. Depending on the background and interest of the student, multidisciplinary projects with other research groups within the MIRA and MESA+ institutes can be defined. Computer design of a tissue engineering scaffold, which is then built by stereolithography using a biodegradable polymeric resin. MicroCT analysis shows that the built structure precisely matches the design. 17 Materials Science and Technology of Polymers (MTP) Research focus: Macromolecular Nanotechnology The group Materials Science and Technology of Polymers (MTP), chaired by Professor G. Julius Vancso, studies a range of topics, which revolve around macromolecular nanotechnology and materials chemistry of nanostructured (macro)molecular materials. MTP’s mission is to establish approaches, devise and construct tools, and build materials platforms that enable studies of macromolecular structure, behavior and function from the nanometer length scale, bottom up, in a direct one-to-one control of the molecular objects. This knowledge is utilized to obtain advanced functional macromolecular materials and devices with enhanced or novel properties and functions for targeted applications. Overview of research in MTP Research in the group Materials Science and Technology of Polymers is focused on the molecular level understanding, manipulation and control of polymeric materials. Work is carried out in three clusters: 1. Materials chemistry of polymers with defined molecular and mesoscopic structures 2. Morphology development and molecular order of polymers on the nanoscale and 3. Engineering and analysis of polymer surfaces and interfaces, nanotechnology, nanofabrication, and self-assembly. Highlights Probing individual non-covalent interactions in supramolecular polymers by AFM; Single molecules fluorescence studies of polymer segment dynamics in thin films; Single molecule force spectroscopy and tunable complex stability in surface molecular recognition mediated by self-complementary quadruple hydrogen bonds. Some examples of projects carried out within MTP are given below. Layer-by-layer constructed porous architectures Colloidal particles of manganese carbonate covered with multilayers of high-molar mass double-stranded DNA and cationic poly(ferrocenylsilane) (PFS) polyelectrolytes (SEM image). The macroporous structures, confirmed also by AFM (inset image) were constructed by simple sequential supramolecular assembly controlled by the persistence length mismatch of the constituents. Upon MnCO3 core removal, porous capsules were obtained. The electrostatic self-assembly of polyelectrolytes with a high persistence length and chain length mismatch demonstrated here constitutes a new method for the fabrication of bio-compatible porous structures, which may have potential applications in new cell scaffold materials, gene therapy, biocompatible surfaces, and controlled, active molecular release systems. 18 Single molecules fluorescence studies By monitoring single molecule lifetime fluctuations, we were able to determine the number of polymer segments taking part in a rearrangement volume. Corresponding results provided us information on local polymer segment mobility, and its variation with temperature and with changes in confinement conditions. It was found that the effects the surface region has on the segment dynamics propagate deep into the polymer sample over distances larger than the radius of gyration (Rg = 10 nm) at temperatures far below the glass transition temperature. Redox stimulus responsive capsules Organometallic, iron containing, stimulus responsive polymers were used to fabricate responsive microand nanocapsules. The hollow containers were made in water by electrostatic layer-by-layer self-assembly. In this process, positively and negatively charged polyions are sequentially assembled on a microsphere template, which is chemically removed upon completion of the assembly process. The thin walls of the capsules obtained are held together by electrostatic interactions and have a molecular permeability which can be controlled by changing the oxidation state of iron in the polymer chains. Thus the capsules allow one to capture, retain and release molecules of predetermined sizes. Potential applications include encapsulation and release of cosmetic agents and drugs, and in bionanochemistry to encapsulate (and protect) single enzyme catalyst molecules. Image: confocal fluorescence microscopy images of empty and loaded PFS capsules (Nature Materials 2006, 5, 724-729). International collaborations: Münster University, Germany. IMRE, Singapore. Newcastle University, UK. Master Assignments For Master Assignments, including assignments of our spin-off company Aerotech Development, please visit: http://www.mtpgroup.nl/ or Contact Prof.dr. G.J. Vancso, CR 4.243, Tel. 2967 Dr. M.A. Hempenius, CR 4.239, Tel. 2975 Dr. P.M. Schön CR 4.405, Tel. 3170 Secretariaat: Geneviève Rietveld CR 4.241, Tel. 2974 19 Inorganic Materials Science (IMS) The IMS group works at the international forefront of materials science research on complex metal oxides and hybrids, and provides an environment where young researchers and students are stimulated to excel in this field. The research is focussed on the following activities: Nanoelectronic Materials The general objective of the chair NanoElectronic Materials (NEM) is the research in new inorganic materials for applications in nanotechnology, and to improve the existing ones. The research is based on current trends in nanomaterials science and developments within MESA+: controlled growth of materials, control of their structure, and understanding of the structure-property relations. Physics Of Complex Inorganic Nano-Materials The research in the IMS workgroup headed by dr. Gertjan Koster focuses on three areas: manipulated oxide thin film growth and modeling, oxide thin film meso materials and in situ spectroscopy. The research is centered on the COMAT system; a UHV pulsed laser deposition (PLD) system with in situ spectroscopies and imaging techniques (XPS, UPS, XPD, STM, AFM, PFM). Inorganic & Hybrid Nanomaterials Chemistry Activities are focused on the development functional inorganic and hybrid nanomaterials and nanostructures from colloidal and chemical solutions. The main emphasis within the research is on oxide and hybrid thin films for energy and electronic applications, soft lithographic microand nanopatterning of functional oxides, and the synthesis and applications of low-dimensional nanostructures like nanowires and nanosheets. Nanomaterials for energy The research aim is to develop new materials with novel advanced properties in which the functionality is controlled by nanoscale structures leading to improved energy applications. Currently research is focused on four topics: interface effects, thermoelectrics, hydrogen generation and solar CO2 conversion. For more information, please visit the following website: http://www.utwente.nl/tnw/ims. 20 Molecular NanoFabrication (MnF) Internet site: Chair: Secretariat e-mail: Phone: Room: http://www.utwente.nl/tnw/mnf/ Prof.dr.ir. J. Huskens Izabel Can-Katalanc / Nicole Haitjema mnf-tnw@utwente.nl +31 53 489 2980 Carre 4.223 The research in the MnF group is focused at fundamental and applied studies of molecular assemblies and nanofabrication. The group investigates the possibilities to build molecularly defined, organic and hybrid assemblies in two or three dimensions via non-covalent interactions between the constituents. Key aspects are: multivalency, materials assembly, biomolecular assembly, cell-surface interactions, surface patterning, chemistry in microfluidic channels, macrocyclic ligands for heavy metal ions, and combinations thereof. Applications lie in areas such as: sensing, materials, (nano)electronics, biomolecule arrays and assays, and tissue engineering. Potential BSc or MSc projects can involve themes such as: - host-guest recognition at interfaces - protein assembly at interfaces - patterning of self-assembled monolayers - motion of molecules and nanomaterials - soft and imprint lithography - chemistry in microfluidic systems - ligand synthesis and testing for heavy metal ion complexation Scientific Staff Technical and Support Staff 4 4 Post-docs PhD-students 5 20 21 BIOS – lab on a chip group ”We want to investigate and realize Labs on a Chip for healthcare and sustainable technologies” During the past decade the BIOS group has spent a lot of effort to develop Labs-on-a-Chip. This has resulted in enormous advancements in knowledge of (nano)sensors, micro- and nanofluidic phenomena and their application in the medical domain. Recently, we are also trying to apply the same technologies in sustainability such as for desalination of water and green energy. Our group is strongly multidisciplinary, and our members have highly diverse backgrounds such as electrical engineering, chemistry, physics, biology and medicine. In our group we spend a lot of effort in investigating cells and tissues on a chip. We investigate for instance how we can control mouse embryo’s growth the best way so that they can be reimplanted with the highest chance of successful pregnancy and birth. We investigate the toxicity of chemicals and nanoparticles on cells and tissues, and we are developing a so-called blood-brain-barrier (BBB) to study which drugs can or can not reach the brain. We try to develop a microsystem using high-speed microdroplets (up to >1000/s) that contain single hybridoma cells to efficiently produce sophisticated drugs. But we also investigate simple disposable medical Lab on Chip devices, for instance to measure the fertililty of human semen, to test breath for COPD patients or creatinine in blood for kidney patients. We are developing micro-needle electrodes in an attempt to better understand the occurrence of migraine attacks, in a collaboration with profs. Ferrari and Scheffer, and in a very ambitious program, we try to develop the essential elements for a nanopill that can detect hypermethylated DNA as early warning sign of intestinal cancer in-vivo. As part of the development of such medical Lab on Chip systems we continuously try to improve nanotechnological detection techniques using the NanoLab infrastructure. In one project we look at nanostructured surfaces for highly sensitive Surface Enhanced Raman Spectroscopy (SERS) analysis , while in other projects we investigate nanogap detection structures to develop untrasensitive DNA detection. We use a Scanning Electrochemical Microscope (SECM) to investigate and electrically stimulate single cells on the nanoscale, and investigate the use of nanoparticles for highly specific and sensitive biosensing. In recent initiatives we are exploring the use or micro and nanofluidic structures for sustainable technologies. In one project, we use microfluidic structures to analyse capacitive desalination, a technique used to desalinate brackish water, in order to optimize materials and procedures and perhaps obtain higher efficiencies. Another effort focuses at converting hydraulic energy directly into electrical energy with high efficiency using streaming current en potential. Finally, we are developing stand-alone, in-situ, wireless chloride sensors to monitor concrete degradation in bridges. For prospective students in our group we ask an open mind to multidisciplinary research with chemical, physical or medical/biological aspects. Enthusiasm for science, independent and critical working and thinking as well as a good team spirit is highly recommended. Please visit our group and talk to our staff and students for more detailed information! 22 Photocatalytic Synthesis (PCS) Group Internet site: Chair: Secretariat e-mail: Phone: Room: http://www.utwente.nl/tnw/pcs prof. dr. G. Mul Lidy Harryvan a.g.harryvan@utwente.nl +31 53 489 4798 Meander 226 Photocatalysis is based on the use of light activated catalysts in chemical conversion. Practical application is limited because of problems in light management, such as mismatch in catalyst sensitivity and solar spectrum, the limited ability of photo-excited states to induce electron transfer reactions, and lack of efficient light exposure of catalysts in reactors. We aim at understanding the role of both the physical and chemical properties of innovative materials in establishing photocatalytic transformations, targeting improved catalyst design. We also study the effect of process conditions and reactor geometry on performance, to establish operation of devices with high efficiency. 1. The conversion of solar energy into chemical energy, i.e. to drive thermodynamically uphill reactions such as the synthesis of hydrocarbons by reaction of CO2 with H2O 2. The high selectivities that can be obtained in alkane oxidation over photon excited catalysts 3. Photocatalytic purification of waste streams (air and water) Several exciting projects in these application areas are conducted in the group. An example is the investigation of the role of metal nanoparticles in improving photocatalytic activity of TiO 2. Advanced synthesis of the metal nanoparticles allows us to systematically study the effect of size and (alloy) composition, while we also investigate the effect of process parameters such as light intensity, effect of water vapor, and reactant concentrations. Another interesting project is the development of an electrochemical process to convert CO2 and water into CO or hydrocarbons with high efficiency. Such process could be a means to store electricity in times when production is exceeding demand. We study the effect of electrolyte (solvent), temperature, and pressure on the performance of various electrode compositions. Additional themes for potential BSc or MSc projects can involve: - Construction of Z-scheme based devices for photocatalytic water splitting - Design and construction of silicon based devices combining optimal light absorption and catalysis - Study of the effect of synthesis parameters on morphology and electronic properties of mixed metal oxides - Studying the behaviour of photocatalysts in purification of water containing multiple toxins - Developing improved water oxidation catalysts - Detailed Infrared studies of photocatalytic processes - Analysis of light propagation in slurry reactors 23 24