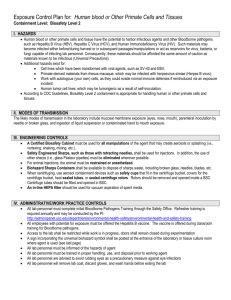

Sample Biological Material Standard Operating Procedure

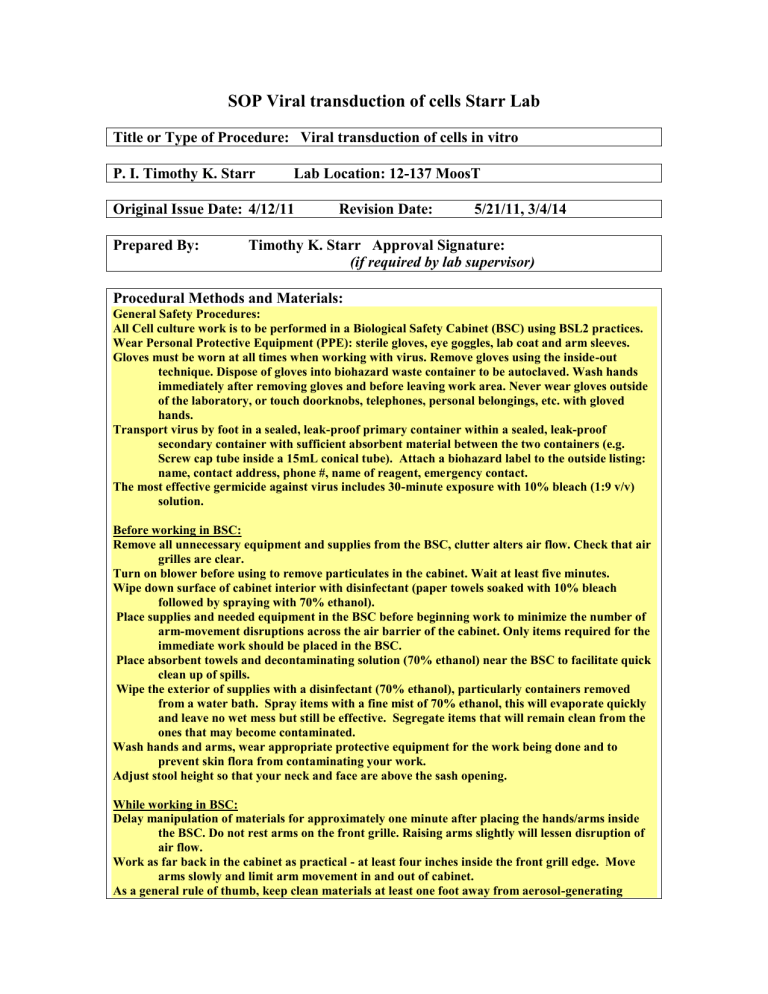

SOP Viral transduction of cells Starr Lab

Title or Type of Procedure: Viral transduction of cells in vitro

P. I. Timothy K. Starr Lab Location: 12-137 MoosT

Original Issue Date: 4/12/11

Prepared By:

Revision Date: 5/21/11, 3/4/14

Timothy K. Starr Approval Signature:

(if required by lab supervisor)

Procedural Methods and Materials:

General Safety Procedures:

All Cell culture work is to be performed in a Biological Safety Cabinet (BSC) using BSL2 practices.

Wear Personal Protective Equipment (PPE): sterile gloves, eye goggles, lab coat and arm sleeves.

Gloves must be worn at all times when working with virus. Remove gloves using the inside-out technique. Dispose of gloves into biohazard waste container to be autoclaved. Wash hands immediately after removing gloves and before leaving work area. Never wear gloves outside of the laboratory, or touch doorknobs, telephones, personal belongings, etc. with gloved hands.

Transport virus by foot in a sealed, leak-proof primary container within a sealed, leak-proof secondary container with sufficient absorbent material between the two containers (e.g.

Screw cap tube inside a 15mL conical tube). Attach a biohazard label to the outside listing: name, contact address, phone #, name of reagent, emergency contact.

The most effective germicide against virus includes 30-minute exposure with 10% bleach (1:9 v/v) solution.

Before working in BSC:

Remove all unnecessary equipment and supplies from the BSC, clutter alters air flow. Check that air grilles are clear.

Turn on blower before using to remove particulates in the cabinet. Wait at least five minutes.

Wipe down surface of cabinet interior with disinfectant (paper towels soaked with 10% bleach followed by spraying with 70% ethanol).

Place supplies and needed equipment in the BSC before beginning work to minimize the number of arm-movement disruptions across the air barrier of the cabinet. Only items required for the immediate work should be placed in the BSC.

Place absorbent towels and decontaminating solution (70% ethanol) near the BSC to facilitate quick clean up of spills.

Wipe the exterior of supplies with a disinfectant (70% ethanol), particularly containers removed from a water bath. Spray items with a fine mist of 70% ethanol, this will evaporate quickly and leave no wet mess but still be effective. Segregate items that will remain clean from the ones that may become contaminated.

Wash hands and arms, wear appropriate protective equipment for the work being done and to prevent skin flora from contaminating your work.

Adjust stool height so that your neck and face are above the sash opening.

While working in BSC:

Delay manipulation of materials for approximately one minute after placing the hands/arms inside the BSC. Do not rest arms on the front grille. Raising arms slightly will lessen disruption of air flow.

Work as far back in the cabinet as practical - at least four inches inside the front grill edge. Move arms slowly and limit arm movement in and out of cabinet.

As a general rule of thumb, keep clean materials at least one foot away from aerosol-generating

activities to minimize the potential for cross-contamination. The work flow should be from

"clean (left) to contaminated or dirty (right) ". Limit the movement of "dirty" items over

"clean" ones.

Remove media with vacuum and replace with serological pipettes.

After working in BSC:

Wipe down the surfaces of all containers and equipment with an appropriate disinfectant (70% ethanol) and remove from the BSC.

Wipe down the cabinet interior with disinfectant (paper towels soaked with 10% bleach followed by spraying with 70% ethanol.

Leave blower on for several minutes with no activity so that any airborne contaminants will be purged from the work area.

Remove gloves and dispose in Biological Hazards bag and wash hands.

Tips to prevent contamination:

Clean water baths frequently and/or treat water in bath.

Clean the inside of incubators frequently, particularly the water tray. Use treated di water in the bottom of the incubator or water tray.

Use HEPA filters on incubator CO2 and air intake lines. Replace regularly.

Lab coat sleeves can introduce contaminants to biological safety cabinets and incubators. Use coats designated for working in the biological safety cabinet or tissue culture area, launder frequently. Use disposable sleeve guards if contamination has been a problem.

Never pour media, remove with vacuum and replace with disposable pipettes.

Do not leave flasks of waste media in cabinet, clean after every use.

On a regular basis, decontaminate under the air grilles and wherever parts are removable. Media is commonly splattered on the front grille allowing fungus to grow undetected on the under surface of the grille.

Decontaminate the surface of carts or trays used to transfer culture flasks between the incubator and the biological safety cabinet or microscope.

Keep pipette aids cleaned, especially the nosepiece, and replace filters regularly.

Clean and disinfect vacuum tubing. This should be done by sucking up the disinfectant we place in the bottom of the waste flask after we have emptied it and reattached it.

Keep the water in the incubator's water jacket full. If water levels in the jacket drop, the ceiling of the incubator will be cooler causing condensate to form. Water then drops onto shelves and cell culture containers.

Check port plugs and septums for contamination in incubator interior; they may trap moisture and harbor fungi.

Materials:

Five packaging plasmids from Open Biosystems: (pTLA1-Pak, pTLA1-Enz, pTLA1-

Env, pTLA1-Rev and pTLA1-TOFF)

HEK293T/17 cells.

Arrest-In transfection reagent - a proprietary lipo-polymeric formulation

Control viruses (Non-silencing shRNA, Gapdh shRNA, GFP)

HEK 293T/17 cells: At 85-90% confluency should be about 10e6 cells in 9 cm plates or

50e6 in T-175 flasks. ATCC cat # CRL-11268..

Gelatin from Porcine Skin: Sigma G-2500

T-175 Tissue culture flasks (175 cm2) (Note: This is roughly 3x as large as a 100 mm plate)

Growing media: DMEM + 10% FBS + 1% pen/strep

Transfection media: DMEM

Transfection reagent media: Opti-Mem

Packaging plasmids: The five packaging plasmids come as a mix, depending on the Lot#

they are generally at 28.5 µg per 30 µl, which is what you need for one 100 mm plate.

Open Biosystems Cat # TLP4606 (Lot# C2509 use only 26 µl instead of 30 µl)

Plasmid of interest: The plasmid containing the LTRs and the psi packaging signals along with whatever gene/construct of interest you want. Protocol calls for 9 µg of this plasmid for each 100 mm plate).

Arrestin transfection reagent: 1 µg/µl stock. Open Biosystems Cat # EGN030409

Millex-HV 0.45µm PVDF filter from millipore

Procedure

Coat flasks with gelatin. Make a 0.1% gelatin solution in H2O and autoclave. Pour enough to cover surface of flask, incubate 2 hrs RT, aspirate off liquid. Do not need to wash.

Culture HEK293T/17 cells in T-175 flasks in 30 ml growing media until 85 to 90% confluent.

Prepare transfection DNA cocktail by diluting the following into 2.9 ml Opti-MEM:

90 µl (85.5 µg) packaging plasmid mix

27 µg pTRIPz or pGIPz plasmid with gene/construct of interest

Note: You can try varying these amounts if it doesn't work

Prepare transfection reagent by diluting 562.5 µl Arrestin (1µg/µl) into 2.44 ml Opti-

MEM

Add DNA cocktail to transfection reagent, mix rapidly, incubate 20 min RT.

Remove growing media from cells, wash once with PBS and replace with 9 ml transfection media

Gently layer on the 6 mls of transfection/DNA and incubate 3 to 6 hrs at 37ºC 5% CO2.

Remove media and replace with 30 ml growing media.

After 48 to 72 hrs harvest virus by transfering supernatant to 50 ml conical tubes.

Spin 3000 rpm for 20 minutes at 4ºC to remove cellular debris, transfer to new 50 ml conicals.

Filter virus through a 0.45 µm low protein binding filter.

Store at -70ºC in single use aliquots.

Hazard Identification and Risk of Exposure to the Hazards:

Sharps, exposure to replication incompetent virus

Possible exposure to viral vectors expressing oncogenes and proto-oncogenes (Note: this is especially hazardous for immunosuppressed or pregnant laboratory staff)

Exposure Controls Specific to Above Risk of Exposure:

PPE - Lab coats, safety goggles, mask, gloves, sleeves and sharps containers.

Biologic Safety Cabinet during all cell culture work

Secondary containment during centrifugation with metal buckets and during transport

All sharps and glass waste will be disposed of in an approved hard plastic sharps container (U Stores # CX40245, MS07407 or similar), No Cardboard sharps pouches.

In general, decontamination is done using bleach. Keep near the hood a bottle of freshly made 10% bleach (1:9 v/v) solution and a 70% ethanol spray bottle and a bottle of dH2O for rinsing

Decontamination of liquid waste (conditioned medium and virus containing samples) should be performed in final 10% bleach (1:9 v/v) solution for 30 minutes. It may then be sewered followed by copious amounts of water.

Wear a face protection shield (prevents splashes to your face while decontaminating).

Waste Generated and Disposal Methods:

Liquid waste will be collected in a flask or beaker containing bleach 10% (v/v) and will soak for 30 minutes before being sewered.

Solid waste decontamination

Each used pipette, plate, dish, tube and tip has to be washed with 10% bleach (1:9 v/v) solution before discarding it to the biohazard bag. Alternatively you can dip the used pipette in a box containing 10% bleach (1:9 v/v) solution (for example sharps box) provided that enough volume will be used to cover 20% of pipette height.

Used tips should be soaked in a plastic bottle (for example, cleaned used medium bottle) containing 10% bleach (1:9 v/v) solution.

Used plates/flasks have to be decontaminated with 10% bleach (1:9 v/v) solution for 30 minutes.

Discard all decontaminated solid waste in the biohazard bag for incineration.

Sharps containers will be sealed when ¾ full and placed in designated waste area.

Refer to the Biological Waste Disposal procedures posted on the Tissue Culture room door for more information

Spill Response Procedures:

For spill, splash or aerosol clean up:

In general, decontamination is done using bleach. Keep near the hood a bottle of freshly made 10% bleach (1:9 v/v) solution and a 70% ethanol spray bottle and a bottle of dH2O for rinsing

Decontamination of liquid waste (conditioned medium and virus containing samples) should be performed in final 10% bleach (1:9 v/v) solution for 30 minutes. It may then be sewered followed by copious amounts of water.

Decontaminating a small volume spill, large volume spill and any splashes

Wear a face protection shield (prevents splashes to your face while decontaminating),

Cover the spill with paper towel and gently pour on top 10% bleach (1:9 v/v) solution for

30 minutes, followed by a rinse with water to remove remaining bleach that may pit or etch work surfaces & equipment if needed, then followed by a 70% ethanol rinse

Collect the paper towels to the biohazard bag.

Refer to the Biological Decontamination and Spill Clean-up Plan posted on the Tissue culture room door for more information

Accident Response Procedures:

If Incident Results in a Hazard Exposure ( i.e. face or eye splash, cut or puncture with sharps, contact with non-intact skin):

• Encourage needle sticks and cuts to bleed, gently wash with soap and water for 5 minutes; flush splashes to the nose, mouth, or skin with water; and flush eyes at the nearest eyewash station with clean water for 15 minutes.

• Call 911 or seek medical attention.

- For urgent care employees may go to HealthPartners Occupational and

Environmental Medicine (M/F day time or Urgent Care after hours), or UMMC-

Fairview Hospital (24 hrs). You may seek medical attention at the closest available medical facility or your own healthcare provider.

- Follow-up must be done by HealthPartners Occupational and Environmental

Medicine.

• Report the incident to your supervisor as soon as possible, fill out the appropriate documentation.

- Employee First Report of Injury

- Supervisor Incident Investigation Report

• Send Incident Report Form to the IBC if exposure has occurred during work on an

IBC protocol.

• Report all biohazard exposures to the Office of Occupational Health and Safety (612-

626-5008) or uohs@umn.edu.

Note: It is important to fill out all of the appropriate documents to be eligible to collect workers compensation should any complications from the hazardous exposure arise in the future.

Notes:

References:

For further information view the UMN DEHS website containing Bio Basic Fact Sheets at http://www.dehs.umn.edu/bio_basicfacts.htm.

For general information on Biosafety, access the Biosafety in Microbiological and

Biomedical Laboratories (BMBL) 5th Edition from the CDC at BMBL http://www.cdc.gov/biosafety/publications/bmbl5/index.htm

For Material Safety Data Sheets access the Public Health agency of Canada website

MSDS http://www.phac-aspc.gc.ca/lab-bio/res/psds-ftss/index-eng.php.