Word

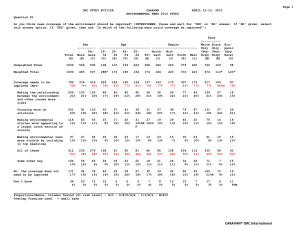

advertisement

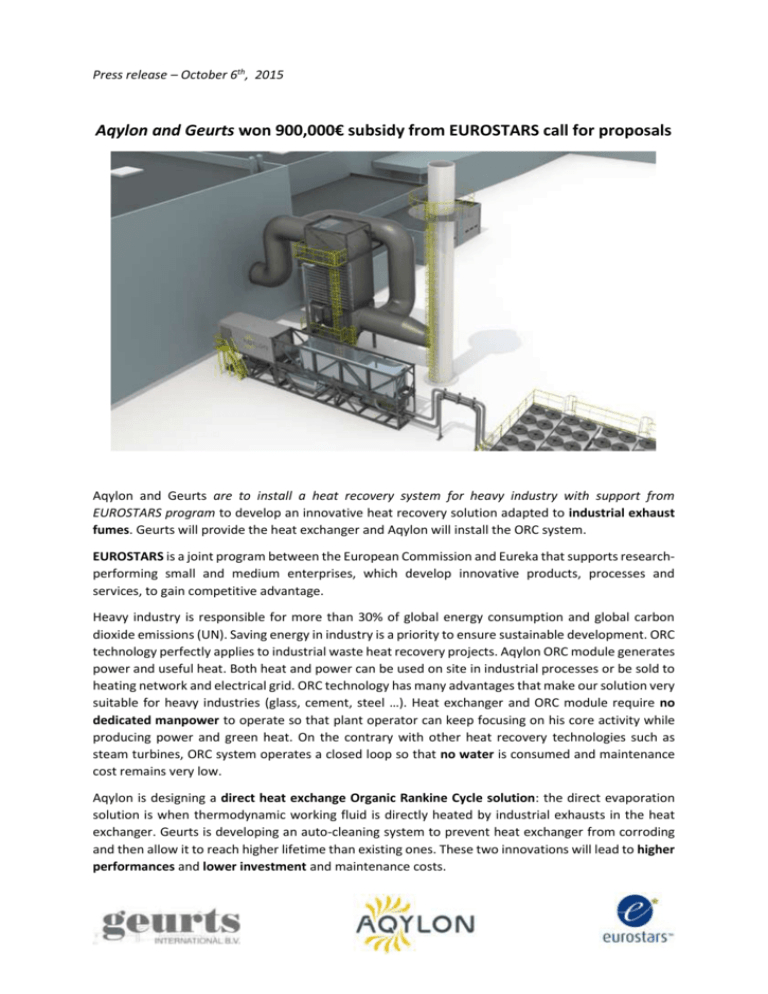

Press release – October 6th, 2015 Aqylon and Geurts won 900,000€ subsidy from EUROSTARS call for proposals Aqylon and Geurts are to install a heat recovery system for heavy industry with support from EUROSTARS program to develop an innovative heat recovery solution adapted to industrial exhaust fumes. Geurts will provide the heat exchanger and Aqylon will install the ORC system. EUROSTARS is a joint program between the European Commission and Eureka that supports researchperforming small and medium enterprises, which develop innovative products, processes and services, to gain competitive advantage. Heavy industry is responsible for more than 30% of global energy consumption and global carbon dioxide emissions (UN). Saving energy in industry is a priority to ensure sustainable development. ORC technology perfectly applies to industrial waste heat recovery projects. Aqylon ORC module generates power and useful heat. Both heat and power can be used on site in industrial processes or be sold to heating network and electrical grid. ORC technology has many advantages that make our solution very suitable for heavy industries (glass, cement, steel …). Heat exchanger and ORC module require no dedicated manpower to operate so that plant operator can keep focusing on his core activity while producing power and green heat. On the contrary with other heat recovery technologies such as steam turbines, ORC system operates a closed loop so that no water is consumed and maintenance cost remains very low. Aqylon is designing a direct heat exchange Organic Rankine Cycle solution: the direct evaporation solution is when thermodynamic working fluid is directly heated by industrial exhausts in the heat exchanger. Geurts is developing an auto-cleaning system to prevent heat exchanger from corroding and then allow it to reach higher lifetime than existing ones. These two innovations will lead to higher performances and lower investment and maintenance costs. Typical industrial waste heat sources are combustion exhausts from: - Cement kiln Fume incinerator Glass melting furnace Aluminum reverberatory furnace Boiler By designing an ORC turbine for medium temperature industrial hot gases recovery (240°C – 600°C), Aqylon confirms he is becoming a global leader of waste heat recovery market. Aqylon already installed ORC systems to recover waste heat contained in flue gases and cooling system of internal combustion engines (biogas, heavy fuel oil, gas …). “Innovation is in Aqylon’s DNA. We are very enthusiast about developing a direct exchange ORC solution for waste heat recovery applications. Designing a single loop Organic Rankine Cycle is a real technical challenge that will allow Aqylon ORC modules to reach unmatched net efficiency, up to 25% gross efficiency, while reducing maintenance costs. The state-of-the-art ORC power module developed for EUROSTARS project is an excellent solution for cement, glass and steel factories to improve their energy efficiency and reduce their ecological footprint” says Guillaume JEANGROS, Aqylon COO and co-founder. About Aqylon Aqylon is a fast growing company created in 2009. The company already hires 17 employees, 15 of whom are engineers. Aqylon has offices on three continents in Paris, Casablanca, and Miami and is about to open a new office in Jakarta. The company offers a standard range of 500 kWe, 1 MWe, 2 MWe, and 5 MWe ORC modules for two main applications: Waste heat Recovery - Engine’s flue gas heat recovery (gas, biogas, diesel and heavy fuel oil) - Industrial waste heat recovery (Heat to Power, Waste to Power) Renewable energies - Biomass power plants with or without cogeneration - Geothermal plants - Solar thermal plants 46/48 rue René Clair, 75018 Paris – FRANCE Tel: +33 (0)1 42 57 41 53 contact@aqylon.com - www.aqylon.com About Geurts Geurts International is a European leading designer and manufacturer of heat exchangers. The company has a long standing experience in the supply of heat exchanging equipments and heat transfer solutions such as air pre-heaters. Geurts has invested in its production facility more than 2 million euros over the past 10 years and employed two full-time engineers for Research & Development. Verlengde Hoge Klei 18, 2242 NS Wassenaar - NETHERLANDS Tel: +31 70 5123300 - Fax: +31 70 5145705 info@geurtsheatexchangers.com