Resistivity Survey

advertisement

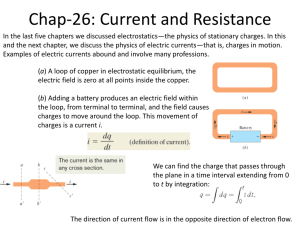

Robin Connelly, Landon Mutch EOS 480 Lab 5: Resistivity Survey Introduction Objective: The objective of this lab is to determine the subsurface structure by conducting a resistivity survey. Using the Wenner Array method a MiniSting resistivity meter was used to produce a vertical electrical-sounding profile. By following the outlined procedures and analysing the resulting data, the resistivity, number of layers, and thicknesses of each layer was obtained. Background/Theory: The MiniSting survey meter applies current through electrodes into the ground, measures potential flow through subsurface materials, and then calculates the apparent resistivity (Hutchinson, Leonard 2015). The Wenner Array method consists of 4 electrodes that are staked into the ground with equal spacing between each electrode. These electrodes are connected to cables on spools that connect to the MiniSting meter. The resistivity meter applies an external field across the electrodes: the outer 2 electrodes put current into the ground, while the middle 2 electrode are the potential electrodes (Hutchinson, Leonard 2015). When the electrodes are spaced close together, measurements of the shallow subsurface can be obtained. As the distance between the electrodes is increased, the current can flow progressively deeper, and thus the resistivity of deeper subsurface features can be measured (Kearey, et al. 2002). The data recorded on the MiniSting meter is then graphed on a log-log graph, with apparent resistivity along the y-axis and spacing for the electrodes along the x-axis. A master curve method is then used to determine the resistivity, thickness, and electrical reflection coefficient for each layer. The exact procedure is described further in the calculations section. Experimental Techniques Equipment: Resistivity Meter with charged internal battery: AGI MiniSting 4 stainless steel electrode stakes 4 electrode cables on spools 5 wooden stakes Hammer Tape measure Compass 1 clipboard Notepaper 2 x log-log graph paper Master curve transparent overlay Calculator Robin Connelly, Landon Mutch EOS 480 Experimental Setting: The experiment took place on the University of Victoria property at the corner of Cedar Hill Crossing Rd. and Gordon Head Rd. (Figure 1). The area was grassy with some rock outcrops, bushes, and trees along the inside edge of the property. It was an overcast breezy day, and there was no precipitation over the course of the survey. Figure 1: Survey location with survey area highlighted in red (Google Earth). Methods and Procedures: Upon arrival, the trend of one line was first chosen, and the first profile was measured out with the measuring tape along this line. The tape was stretched out to its maximum of 90m, a stake was placed at the centre of the line, and markers were placed at either end of the survey line. At exactly 90˚ to the first profile a second profile was measured out (also 90m in length) which shared a center point with the first survey line. The perpendicular layout of the survey lines was used in order to determine any potential heterogeneity in the subsurface features which would show up in any major differences between the two profiles obtained. Beginning at the center of the first profile line, 4 electrodes were placed in the ground at an initial minimum even distance (0.1 m) between each other, with two electrodes on either side of the center stake (which was the half-way point between the 2 electrodes in the center). Each electrode had its own cable spool which connected the electrodes to the MiniSting resistivity instrument – the A and B cables were connected to the outside electrodes and the M and N cables were connected to the inner electrodes. Robin Connelly, Landon Mutch EOS 480 The resistivity instrument was placed near the central point of the surveys. It was calibrated for date, time, spacing, and current strength (50 mA). A surveyor was assigned to each electrode and was responsible for moving it to the correct location for each measurement spacing, and two additional surveyors double checked for the correct electrode placement before each measurement. The resulting measurements from each reading were recorded individually by two other surveyors who also plotted individual curves of the data over the course of the survey to ensure no mistakes were made. After each measurement the spacing between the electrodes was increased, while maintaining equal spacing between all electrodes, and the resistivity instrument was calibrated for the appropriate spacing. Between measurements the device periodically switched between 50mA and 20mA currents depending on which was most appropriate for each given measurement. Measurements were collected until the maximum 90m length was achieved. The perpendicular survey was carried out in the exact same method as the first, with exactly the same spacing intervals as the first. Experimental Results Data/Calculations Calculations: Once the survey was complete and all the data was compiled (Table 1 & 2), log-log plots were drawn up for apparent resistivity (ρa) versus survey distance (a), and curves drawn to connect the data points (Figures 2 & 3). Each segment of the curve was interpreted as representing a subsurface layer. A transparent master curve interpretation overlay was aligned with the axis of the Wenner Array, log-log graph and was moved horizontally and vertically in order to determine a best fit for each curve segment. The curves on the master sheet are representative of the electrical reflection coefficient (k), and thus k was determined for each subsurface layer. By tracing along the converging curves on the master sheet to the apparent resistivity axis, ρa, and then down along the vertical line to the spacing axis, a, the apparent resistivity and depth, z, for each layer was also determined. These values were then used to calculate the apparent resistivity of each layer (Hutchinson, Leonard 2015). For example, lining up the master curve with the first segment of the first survey line, the k value was determined to be -0.7, as the plotted curve lay between the -0.6 and -0.8 master curves. Tracing the master curve back to the ρa axis, ρ1 was determined to be 270 Ωm (Table 3). From these values, ρ2 was then calculated: 𝜌2/3 = 𝜌2 = (𝑘 + 1) 𝜌 (1 − 𝑘) 1/2 (1 − 0.7) ∙ 270 𝛺𝑚 = 47.6 (1 + 0.7) Robin Connelly, Landon Mutch EOS 480 By repeating the above master curve process for the next curve, its ρ2 value was also determined, and the average between this result and the calculated value of ρ2 was then calculated (Table 3): 𝜌2 = 50 𝛺𝑚 + 47.6 𝛺𝑚 = 48.8 𝛺𝑚 2 The depth of the first layer was determined by following the solid vertical line on the overlay down to the distance axis and was found to be 0.48m (Table 3) – which is also the thickness (h1) of the first subsurface layer. By lining up the master curve with the final segment of the first survey line, the k value was found to be 0.95 – as the plotted curve lay between the 0.9 and 1.0 master curves. From these values, ρ3 could then be calculated: 𝜌3 = (0.95 + 1) ∙ 50 𝛺𝑚 = 1950 𝛺𝑚 (1 − 0.95) Finally, the depth of the third subsurface layer, 3.2m (Table 3), was determined by following the solid vertical line on overlay down to the distance axis, and the thickness of the second layer, h2, was calculated: ℎ2 = 3.2 𝑚 − 0.46 𝑚 = 2.74 𝑚 The same procedures were carried out for the data from the second survey line. As the respective results from the two surveys were in general agreement with one another, with no significant deviations, the average thicknesses and apparent resistivities were taken (Table 4) in order to smooth any potentially unnoticed regional subsurface anomalies beneath any one survey line. Robin Connelly, Landon Mutch EOS 480 Data: Table 1: Measurements collected from the first survey line. First Line Strike 277 Spacing 0.1 0.2 0.3 0.4 0.5 0.6 0.8 1 1.5 2 3 4 5 6 8 10 15 20 25 30 dV/I 349.6 214.1 116.8 82.88 61.78 45.07 28.21 16.95 6.19 4.409 3.298 3.177 3.186 3.233 3.414 3.68 4.313 4.72 3.844 2.861 Apparent Resistivity 219.7 269.1 220.2 208.3 194.1 169.9 141.8 106.5 58.34 55.4 62.16 79.84 100.1 121.9 171.6 231.2 406.5 593.1 603.8 539.3 Error 0.1% 0.1% 0.1% 0.1% 0.1% 0.1% 0.1% 0.1% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.1% 0.0% Current (mA) 50 50 50 50 50 50 50 50 50 50 20 20 50 50 50 20 20 20 20 20 Robin Connelly, Landon Mutch EOS 480 Table 2: Measurements collected from the second survey line. Second Line Strike Spacing 0.1 0.2 0.3 0.4 0.5 0.6 0.8 1 1.5 2 3 4 5 6 8 10 15 20 25 30 10 dV/I 328 221.6 125.3 84.28 62.82 44.91 24.7 16.08 6.948 4.486 3.194 3.08 3.087 3.112 3.158 3.204 2.865 2.694 2.377 1.924 Figure 2: see attached plots Figure 3: see attached plots Apparent Resistivity 206.1 278.5 236.2 211.8 195.8 169.3 124.2 101 65.498 56.37 60.2 77.4 96.98 117.3 158.8 201.3 270 338.6 373.4 362.7 Error 0.1% 0.1% 0.1% 0.1% 0.1% 0.1% 0.1% 0.1% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.1% 0.1% 0.0% Current (mA) 50 50 50 20 20 20 50 50 20 50 20 20 50 50 50 50 50 50 50 20 Robin Connelly, Landon Mutch EOS 480 Table 3: Interpreted and calculated results from Figures 2 and 3 for apparent resistivities, electrical reflection coefficients, and thicknesses. Line 1 ρa ρ1 ρ2 ρ2 average Line 2 ρ1 ρ2 ρ2 average Apparent Resistivity (Ωm) Interpreted 270 50 48.8 285 44 47.2 Line 1 ρa ρ1 ρ2 ρ3 Line 2 ρ1 ρ2 ρ3 Apparent Resistivity (Ωm) Calculated 47.6 1950 50.3 880 Line 1 k k1 k2 Electrical Reflection Coefficient -0.7 0.95 Line 1 z z1 z2 Depth (m) 0.48 3.2 Line 2 k1 k2 -0.7 0.95 Line 2 z z1 z2 0.43 3.0 Table 4: Averages of interpreted and calculated values from Table 3 for each subsurface layer. Apparent Resistivity ρ (Ωm) Layer 1 2 3 277.5 48 1415 Thickness h (m) 0.46 2.74 N/A Figure 4: Estimated model of subsurface layer structure beneath the survey area. Robin Connelly, Landon Mutch EOS 480 Interpretation Results and Discussion The resulting measurements of the two surveys conducted along lines 1 and 2 ended up being similar, with any differences generally within error margins (Table 3). From this we can assume that there was not significant regional heterogeneity in the subsurface structures along the survey lines, and thus that the data collected was not significantly affected by non-symmetric subsurface features (Burger et al., 2006). Because this was the case, we could take the average of the various calculated layer properties (Table 4) to be a good approximation of the actual subsurface properties and thus minimize any local abnormalities in either of the surveys by averaging the variables for each layer. From Table 4 we can see that our resulting calculated properties indicate three layers within the depth range of our surveys. It seems there is a lower resistivity layer that separates a more resistive surface layer (0-0.46 m) from an underlying much more resistive bottom layer (0.47-3.1 m), as is also depicted in Figure 4. As subsurface water reservoirs can dramatically affect resistivity, the contrast between the top two layers is potentially owing to differences in water saturation with depth. Because water is very conductive, we expect increased water saturation to decrease measured resistivity; so we may interpret layer 2 to be more fresh-water saturated than layer 1 due to its lower resistivity relative to layer 1. Another likely possibility is that layer 1 is less compact than layer 2 and thus contains more aerated pore-space. Because air is a very poor conductor, this would effectively increase layer 1’s resistivity compared to the possibly more compact layer 2. The contrast between the top two layers is probably due to a combination of these two factors. From a plot of the resistivity values of various rock types (Burger et al., 2006) and the observed regional geology, layer 1 is likely to be unconsolidated, clay-rich top-soil or till, and layer 2 is likely to be of similar composition but more compacted and/or water saturated. The resistivity data suggest that it’s also possible layer 2 is a clay-rich, shale or sandstone, although this interpretation is not supported by the previous seismic study of the area (Connelly et al., 2015). Layer 3, however, shows a much more significant difference in resistivity, compared to layers 1 and 2, could be due to a change in lithology. This is likely the case because of layer 3’s much higher measured resistivity relative to the first two layers. From the plot of resistivities of various rock types and observed regional geology, layer 3 is likely to be either sand, gravel, limestone/dolostone, or igneous rock which has possibly been metamorphosed and/or weathered to some degree (Burger et al., 2006). Now, if we compare these results to those of the previous week’s seismic survey of the same area (Connelly et al., 2015) we can see that the layer 1-2 interface at 0.46 m corresponds fairly closely with the same layer 1-2 interface (0.64-0.71 m) found during the seismic survey. Also the thickness of layer 2, found here to be 2.74m, falls within the thickness margins found during the seismic survey (2.7-2.9 m), which is well within the calculated margin of error for the seismic survey (Connelly et al., 2015). These slight differences in determined depth are very likely artifacts of the necessary weight-averaged inclusion of shallower layers (i.e. layers 1 and 2) while collecting data on the underlying deeper layers (i.e. layer 3). From the seismic survey (Connelly et al., 2015) lithologies were estimated to be un- Robin Connelly, Landon Mutch EOS 480 compacted top-soil (layer 1), compacted soil and/or soft rock (layer 2), and sandstone/limestone (layer 3). Factoring in the results of this resistivity survey, it seems likely that layer 1 is top-soil (which was indeed observed on location during the surveys), layer 2 is more compact, clay-rich, water saturated soil or soft sedimentary rock, and layer 3 is either limestone/dolostone or igneous rock with some degree of weathering and/or metamorphism. The seismic velocity of layer 3 (Connelly et al., 2015) appears too low to be igneous rock and the resistivity appears to be too high to be sandstone, thus we may tentatively surmise that layer 3 is likely to be limestone or dolostone, although there were no locally observed carbonate outcrops to confirm this result. Conclusion In summary, a resistivity survey was conducted on the University of Victoria grounds (Figure 1), and an appropriate handling of the resulting data led to a model of the subsurface structure shown in Figure 4. This model turned out to be in general agreement with a subsurface model generated by a seismic survey conducted at the same location (Connelly et al., 2015), and the results of the two surveys revealed the 3 layer subsurface model detailed in Figure 4. References: Burger, Jones and Sheehan, 2006, Introduction to Applied Geophysics, W.W Norton & Company, New York Connelly, R., and Mutch, L., 2015, Lab 3 Seismic Survey Report, University of Victoria, B.C. Hutchinson, J., and Leonard, L., 2015, EOS 480 Applied Geophysics Lab Manual: Resistivity Survey, University of Victoria, p 1-4, p 16-17. Instruction Manual for the MiniStingTM and SwiftTM, 2013, Advanced Geosciences Inc., Austin, Texas Kearey, Brooks & Hill, 2002, An Introduction to Geophysical Exploration, 3rd edn., Blackwell Pub. Leonard, L. (2015), EOS 480: Applied Geophysics Lecture Notes “UVIC.” 48˚27’39.03” N and 123˚19’10.97” W. Google Earth. 2015