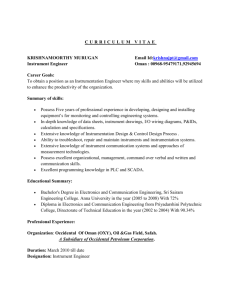

Instrumentation - Group Express Employment Services Abu Dhabi

advertisement

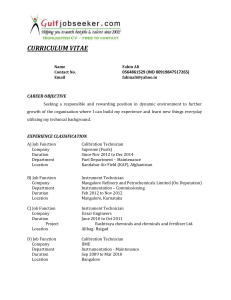

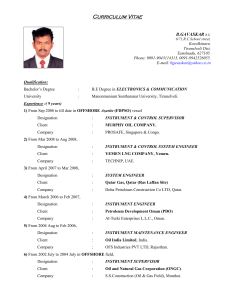

RENJITH RAJ Seeking a challenging career in Instrumentation field ____________________________________________________________________________________________ Summary Contact Information Al Karama, Dubai United Arab Emirates +971502978731 (UAE) +91469 2609521 (India) renjithrajahara@gmail.com RENJITH RAJ A.R renjithraj.ar1 A Competent professional with 6 years of qualitative experience in Oil & Gas industry that includes Commissioning, Installation engineering activities, Vendor document review, Inspection, Supervision of installation, Calibration, Loop checking, Pre-commissioning &commissioning/start-up activities, Functional test and Maintenance activities, well trained in Yokogawa DCS and hands on experience in ICS, F&G system and General Monitor H2S System. Experience dealing with EPC projects of companies like ADCO (UAE), TAKREER (UAE), KOC (KUWAIT). Current Status I am staying in UAE on visit visa valid till Dec 24. I am looking for suitable job in the same field in UAE itself. Work Experience Languages Known English, Hindi & Malayalam (Read, Write and Speak) Tamil & Telugu (Speak) Availability Can join immediately Preferred location UAE Expected salary As per company norms Driving License Valid UAE D/L SEMINARS/TRAINING HUET (Helicopter Underwater Escape Training) Emergency Breathing System (EBS)-5095 Elementary First Aid Personal Survival Techniques Personal Safety & Social Responsibility (PSSR) Safety Regulations & Work Permit System in ADCO ADCO & TAKREER LOTO Training Job Originator training for ADCO Fire fighting procedures HSE Induction. H2S Awareness and Escape hood. Job Hazard Analysis INSTRUMENT ENGINEER 2013 – 2015 SK Engineering Ltd Abu Dhabi Oil Refining Company, (TAKREER) RUWAIS REFINERY EXPANSION Project. Designing the Concept P&ID, GA drawing, Electrical Wiring drawing and get Customer approval before starting production. Preparation of Instrument datasheets, I/O list, Cable schedule Carrying out FAT with presence of Customer/End-user before dispatch of the System. Monitoring the work on site as per Drawing, Supervision & Job Allocation. INSTRUMENT SUPERVISOR 2011 – 2012 SK Engineering Ltd COMPANY FOR ONSHORE OIL OPERATIONS (ADCO) BAB GAS COMPRESSION Projects CS#1, 2, 3, MIS AND MGCR. Responsible in commissioning, maintenance, troubleshooting repairs and replaces defective parts. Planning and Execution of Electrical Activities on Daily Basis, with Construction Team, Preparation & Co-ordination with Construction Team & Client for Inspection Activities, INSTRUMENT FOREMAN 2009 – 2010 (S.K. E & I (1) KUWAIT OIL COMPANY (KOC) H.O. KOREA) KOC Project in GC- 24 KUWAIT Installing of Transmitters, Valves, and Sensors & Installation of both DCS and PLC Panels. Conducting SAT (Site Acceptance Test). SIT (site integration test) Plant Operation Checking from the Control Room. Skills Engineering Management Hazardous Area Classification Engineering Survey I&C project engineering Supervision/Coordination Co-ordination with vendor Instrument cable laying Maintenance Management Oil and Gas Engineering Erection and Plant Operation Trouble-shooting and problem-solving Field start up, and operations. Punch list clearance Project Engineering 1 AREA OF EXPERTISE Supervision of Instrument Installation, conduit installation, inspection, calibration, Monthly progress review meeting, and hand over as built Understand the concept of IEC/ATEX, NEC/CSA and NEC 505 Erection and Commissioning Of Separators Experience in Bently Nevada System (Vibration Monitoring system) Planning and Execution of Electrical Activities on Daily Basis with Construction Team Experience in technical field Calibration of Most of the Instruments in the Lab such as: Testing of Well Head Control Panels Calibration & testing all types of Valves Calibration of all types of Transmitters Calibration of all types of Gauges. Thermocouple calibration Preparation of calibration certificates ITS Skills Operating systems : Windows XP, 7, 2008 Server Programs : Office Tools , AutoCAD Internet : Very good PC Networking : Very good Intergraph IN-Tools, intermediate MS PowerPoint, intermediate MS Project, intermediate Professional Qualification: Training and Qualifications Diploma in Instrumentation in 2008. Completed plus Two in 2005. Completed SSLC in 2003. Key Professional Skills: Experience in Trouble shooting of HART instruments using 375 Field Communicator & 475 Field Communicator. Knowledge to operate PLC, DCS, ESD & FGS of various engineering system. Familiar in Interpreting engineering Documents & Drawing like Instrument Hookup drawings, Instrument Data Sheets, Junction Box & Panel Interconnection & Termination Drawings, Loop Drawings, Instrument Index, Cable Schedule, Junction Box Schedule etc. Procurement of work permits & cancelling them once job is completed, coordinating with field operators well attending the job. Performing and witnessing the all type of instruments, Control valves, ESD, ON/OFF valves Fire &Gas, Analyzer instrument, Loop testing, Alarm point checking Functional test of all type of Fire and Gas instruments and calibration of instruments Coordinate between Contractor and Operator the work permits and lock-out/ tag out permits Allocate work and Toolbox meetings to ensure understanding of the task & implementation. SUMMARY OF JOB PROFILE: FAMILIAR WITH:-F&G System (Honeywell SMS, Tyco), VTMS (Bentley Nevada), MMS (Machine Monitoring System), VSDS (Variable Speed Driving System), CEMS (continuous emissions monitoring system) FAMILIAR WITH: DCS: - Honeywell, ABB-Taylor, Yokogawa. PLC: - Alan Bradly, Triconex, Triplex, ABB. ESD SYSTEM: - ABB, Emerson, Yokogawa F & G SYSTEM: - Honeywell, Tyco, SAFCO Electronic Transmitters:- Foxboro, Smart type Fisher, Rosemount, Semen, Vortex type, Endress+Hauser, Taylor, ABB-Kent, Honeywell, Yokogawa, GE Ultrasonic Flow meter On /OFF Valves: - Automax, Valtek, CCI Drag Valve, BIFFI, Neles-Jamesbury,ACCO, Rotork Control Valves: - Fisher, Flow serve ,Taylor, MIL Fisher SMART Valve Positioner, Masoneilan, Rotork Level Measuring Devices: - Nucluyanic Fisher, Masoneilan, Mother Well Servo Gauge, Magnetrol EZ Modulevel, DP Level Transmitter Analysers: - Yokogawa, Rose Mount, (O2, SOX, NOX, LPG) ABB-VISTA-2(Gas Chromatography), FIRE & Gas Instruments: - H2S, Deficiency Detector (O2), Smoke Detection, LPG, Toxic, Combustible, open-path detector, UV/IR detector, Smoke detector and Break glass unit, Equipment Handle: - Hart Communicator 475, Communicator (mov) Duck, and Fluke Calibrator. LEVEL SENSORS: -Ultrasonic, Magnetic Level Gauges, Radar type, GWR Level Transmitters Calibrators: - Thermocouple and RTD Simulators, Pressure Calibrators, AmetekTemperature Calibrator 2 Job Responsibilities & Experience To work in close co-ordination with the Section Head to plan, coordinate, Supervise and direct the work of Instrument Technician, all instruments related activities complying with all HSE&PTW requirement. Maintenance in various type field Instruments of electronics Transmitters, Control Valve, ON/OFF Valve and actuators. Maintenance of Gas compressors, Rotating equipment, utilities, Fire & Gas Detection, and ICS, DCS, ESD, PLC. Operation and maintenance of various equipment’s and air compressors, diesel generators, Fire water pumps, Nitrogen production unit, Calibration, Loop checking & Trouble shooting of Gas Detectors, Smoke detectors, Analyser Transmitters and repair and replace defective parts. Participate in technical discussions with customer for understanding their requirements. Thorough review of client specifications and ensure all requirements are identified for inclusion, exclusion or deviation Site modification as required at site condition, discuss & finalize with clients changes Carries out necessary tests and performance monitoring upon startup of all electronic and pneumatic instruments. Raising of Punch list, Clearing and getting Documents approval from Client side, Loop Checking and Functional Checking. Anti-surge Control system Loop Checking and Functional Checking. Instrument air control system Testing & Wiring of PLC, DCS, ESD, FGS Control Panels &marshalling cabinet. Ensure all works are completed to the standard specification before final inspection. Installing of Transmitters, Valves, and Sensors & Installation of both DCS and PLC Panels. Installation of field simulation for all electronic and pneumatic instruments and controls such as vibration (Bently Nevada), detectors (flame and gas), electronic and pneumatic transmitters (flow, pressure, level and temperature), electronic and pneumatic Controllers (level, pressure, temperature and flow), transducers, control valves, switches, solenoid valves, gauges, recorders, positioner, regulators, converter, and electronic and pneumatic indicators. Pre-commissioning and Commissioning of all types of flow, level, temperature, pressure transmitters and switches. (Both Hart and FF family) Reading P&ID, PID Loop Schematics and safety interlocks on, Compressors, Turbines and Pumps Sound knowledge and good experienced in the management Plant Instrument Maintenance. PERSONAL DETAILS Father’s Name Date of Birth Gender Marital Status Nationality : Sri. Rajan A.N : 07st April 1988 : Male : Married : Indian Passport No Issued Place Issued Date Expiry Date Visa status : : : : : G4705839 Trivandrum 26.10.2007 25-10-2017 on visit visa DECLARATION I hereby declare that the information furnished above is true to the best of my knowledge and belief. Thanks, (RENJITH RAJ A.R) Date: 10.10.2015 3