Low-frequency acoustic set

advertisement

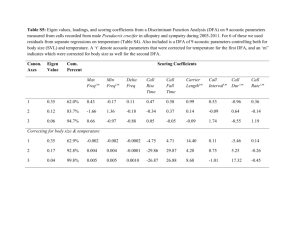

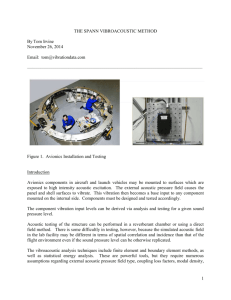

The low-frequency acoustic complex The low-frequency acoustic complex is intended for vibroacoustic wave action on the zone of perforation of oil land ore wells in order to increase their production rate, as well as the productive layer surrounding the area of perforation. The technology is based on the low-frequency (200 Hz to 1000 Hz) the impact on the oil layer with a special down hole acoustic transmitter (RF Patent № 2263203). The technology of low-frequency stimulation of the layer is used to increase the recoverability rate of viscous oil from the well. Increasing of the extraction of oil is a result of a violation of connections of pseudo-crystal structural framework of paraffin and other hydrocarbons from the walls of the pores under the influence of an intense acoustic field. With a significant weakening of the connection formation pressure gradient causes the oil flow in the pore space and the final destruction of the structural frame. After the acoustic stimulation in the formation and operation of wells in the input rate increases recoverability of oil and retains its value over the long term. Developed in the present apparatus, which implements the technology of low-frequency stimulation of the layer can be used in vertical and inclined oil wells 3,000 meters deep, with the temperature of the liquid to 100 Cº degrees Celsius, the internal diameter of the casing column in the area of the productive layer from 100 to 150 mm. The wave effect is achieved by using three processes. • Impact directly on the environment that plugs holes of perforation. Due to the oscillatory rocking rock particles are destroyed "plug". The most effective process for the joint use of sound effects and chemically active fluids in wells that are losing yield due to prolonged use. • Impact on the layer behind the casing column. A wide class of liquids reveals a property to change the viscosity under the influence of external load, revealing at the same viscoelastic properties. In such liquids, as a rule, the viscosity of the medium decreases with increasing applied voltage - medium "slides" along a solid surface. Increases the influence of watered well. • Layer can function as a waveguide, without giving effect to weaken the acoustic of the departure power beyond its borders, intensifying the effect specified in the preceding paragraph. Low-frequency radiators of two kinds are made (photographs in Fig. la and Fig.lb). Patents are number 2,263,203 from 05.11.2003, № 2286587 from 08.06.2005. Radiators are designed and manufactured at Mechanical engineering design office (KBM), Moscow. Low-frequency acoustic transducers Fig.1a.(resonant frequency of 700 Hz) 1 1 Fig.1b.(resonant frequency of 500 Hz) 1 Down hole radiator is delivered to the productive layer area under its own weight on a logging cable lengths up to 5 km. The principles of their operation are shown in Figure 2. From a well undergoing vibro-impact the column of compressor pipes is removed. Low-frequency acoustic complex consists of: • low-frequency acoustic transducer • Electric Generator • Geophysical cable-rope Acoustic radiator is lifted on a logging cable inside the casing colon via a cable car down to the perforation area. Acoustic energy radiated by the transmitter, located in the volume of fluid between the radiating surface of the emitter and reflector. Flat radiating plate and a flat reflecting surface of the screen are oriented perpendicular to the axis of the casing clones, and the gap between them and the nuts columns is minimal.The resounding volume of a liquid is created. At the photo of emitter, this volume is indicated by the numbers 1. One of the emitters it is below the radiating surface and the radiator shell, with a different design of the radiator it is between the radiator shell and casing column. Changing the distance between the emitter and reflector is achieved by optimization of the intensification of the acoustic field. Power is supplied to the radiator from the generator through a current collector geophysical car. Turbulenting liquid medium by sound frequency vibrations in the area of the perforation holes clean punching in a few hours. Simultaneously, low-frequency vibrations make it easier to move oil to the oil well through the pores of oil-bearing layer. 1 2 7 6 4 5 3 Fig.2. 380V 50Hz 1. An electric generator powered by Three-phase 380V 50 Hz 2. Geophysical vehicle with a lift 3. Acoustic transducer 4. Logging cable 5. Pay zone 6. External master generator 7. Equipmentcontrol The first two instances were tested twice in the fields of Tat RITEK Oil in the Republic of Tatarstan in 2005 - 2006, in the fields of Tatneft in 2009. The results obtained in all works very positive and significant. The processing zone punching well number 2576 for 48 hours in the wellboreoil column rose to a height of 75 ÷100 m compared with that before treatment was well. In October-December of 2006 the equipment was used to influence the perforation zone of production wells 2567,3609, as well as the injection well 2504, operating in the same region (Nurlat), as well in 2576. All wells perforated zone is located at a depth of about 1100-1200m, but the structure of the layer varies. Injection well- not functioning, due to the complete no admission water. A characteristic feature is that immediately after the vibroacousticeffect, all wells sharply increased the impact or acceleration. Deaf injection well for each of the two treatments lasting about 3 days of each said acceleration in terms of daily consumption (24) value of 144 m3. The subsequent behavior of well production is not known, because customer with these results are not briefed. The results of the work conducted in 2006 and 2009 are summarized in Tables 1 and 2. Table 1 well number Debit of oil after processing Action time №2567 Debit of oil before processing 5,2m3/day. 11,5m3/day . two days №3609 Injection well 2,9m3/day . 0m3/day . 5,8 m3/day . 144 m3/day . three days about 3 days Table 2 Date Well number Debit of oil after processing №26280 Debit of oil before processing 0,7 tons / day 29.06.2009 30.06.2009 Thickness of processed horizons №17673 6 tons / day 9 tons / day 4m 8h. 16 tons / day two horizons of 3m 12h. 1,9 tons / day Action time 4,5h. (Jalil) 01.07.2009 23081 11,78 tons / day (Alekseevskaya Square) Documentation on the low-frequency acoustic complex was prepared to carry out its certifications. Developers equipment can take orders for its manufacturing production for a period four to five months, taking into account changes in customers' request. They take on the responsibility for teaching personnel of service companies, as well as repair in the field of its use. Note Experimental work on the new technology in TATRITEK-OIL was carried out on the field at a depth of 1000 meters reservoir, oil viscosity in the range from 100 to 160 centipoises at asphalten content to 7.2%. For comparison: Western Siberia (Surgut region) in the main part of the stock values of oil viscosity is within 0.5 - 5 cps. in Alaska bed, folded sandstone at a depth of 1,000 meters with a constant (0,01-0,14 um2), contains the oil density960 kg/m3 and a viscosity of 20 100 cps. Results of studies have shown that the presented technology can increase the level of production of viscous oil from wells to near its original value and reduce the water content of oil by 30% Contact number: 8-903-779-0811 Nicolay Lvov Appendix 1. Technical parameters of the complex Table № 3.Low-frequency acoustic transducer number №la. 1 2 Designed acoustic transducer with a fundamental operating frequency Note: If low-power can work in a range of Hz 3 4 Maximum power consumption from the supply of electric generator Maximum value of the external pressure of 5 6 7 8 9 Range of operating temperatures of the liquid to The length of the zone simultaneously acting on the perforation Weight of radiator Length of the radiator without a reflector of is designed to operate in wells with an inner diameter of 700 Hz 400Hz ─1500 Hz 2кW 40 МPа (Maximum operating depth — 4 km) 130°С 2m 90 кg 2,7 m 100 mm ─ 150 mm Table № 4. Powerful electric generator 1 Frequency range of generator 2 3 4 Maximum power supplied to a resistive load of Regulation of output - gradual The magnitude of the load impedance 5 6 The magnitude of the reactance load The load is the acoustic radiator is powered via the logging cable lengths up to 7 The generator — three-phase AC 50Hz 8 Weight of the generator does not exceed 9 Volume of the generator is less than 10 Time of continuous operation is not limited * Electrical energy generator is converted into acoustic energy radiator 400 Hz ─ 1500 Hz 2 кW 20dB 150 Оhms ─ 600 Оhms 0,2─0,7 uF 5 кm 380V or 220V 20 kg 0.1 m³ Powerfull electric generator Appendix 2. Work on oil wells in republic Tatarstan