full public report

advertisement

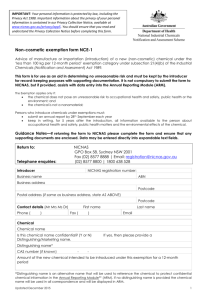

File No STD/1071 June 2004 NATIONAL INDUSTRIAL CHEMICALS NOTIFICATION AND ASSESSMENT SCHEME (NICNAS) FULL PUBLIC REPORT Component of Caltex RPM Grease SRI 2 This Assessment has been compiled in accordance with the provisions of the Industrial Chemicals (Notification and Assessment) Act 1989 (Cwlth) (the Act) and Regulations. This legislation is an Act of the Commonwealth of Australia. The National Industrial Chemicals Notification and Assessment Scheme (NICNAS) is administered by the Department of Health and Ageing, and conducts the risk assessment for public health and occupational health and safety. The assessment of environmental risk is conducted by the Department of the Environment and Heritage. For the purposes of subsection 78(1) of the Act, this Full Public Report may be inspected at: Library National Occupational Health and Safety Commission 25 Constitution Avenue CANBERRA ACT 2600 AUSTRALIA To arrange an appointment contact the Librarian on TEL + 61 2 6279 1161 or + 61 2 6279 1163. This Full Public Report is available for viewing and downloading from the NICNAS website or available on request, free of charge, by contacting NICNAS. For requests and enquiries please contact the NICNAS Administration Coordinator at: Street Address: 334 - 336 Illawarra Road MARRICKVILLE NSW 2204, AUSTRALIA. Postal Address: GPO Box 58, SYDNEY NSW 2001, AUSTRALIA. TEL: + 61 2 8577 8800 FAX + 61 2 8577 8888. Website: www.nicnas.gov.au Director Chemicals Notification and Assessment TABLE OF CONTENTS FULL PUBLIC REPORT ....................................................................................................................................... 4 1. APPLICANT AND NOTIFICATION DETAILS ...................................................................................... 4 2. IDENTITY OF CHEMICAL ...................................................................................................................... 4 3. COMPOSITION ......................................................................................................................................... 5 4. INTRODUCTION AND USE INFORMATION ....................................................................................... 5 5. PROCESS AND RELEASE INFORMATION .......................................................................................... 5 6. PHYSICAL AND CHEMICAL PROPERTIES ......................................................................................... 7 7. TOXICOLOGICAL INVESTIGATIONS .................................................................................................. 8 8. ENVIRONMENT ..................................................................................................................................... 11 9. RISK ASSESSMENT ............................................................................................................................... 13 10. CONCLUSIONS – ASSESSMENT LEVEL OF CONCERN FOR THE ENVIRONMENT AND HUMANS ......................................................................................................................................................... 14 11. MATERIAL SAFETY DATA SHEET ................................................................................................ 14 12. RECOMMENDATIONS ...................................................................................................................... 14 13. BIBLIOGRAPHY................................................................................................................................. 15 File No: STD/1071 June 2004 NATIONAL INDUSTRIAL CHEMICALS NOTIFICATION AND ASSESSMENT SCHEME (NICNAS) FULL PUBLIC REPORT Component of Caltex RPM Grease SRI 2 This Assessment has been compiled in accordance with the provisions of the Industrial Chemicals (Notification and Assessment) Act 1989 (Cwlth) (the Act) and Regulations. This legislation is an Act of the Commonwealth of Australia. The National Industrial Chemicals Notification and Assessment Scheme (NICNAS) is administered by the Department of Health and Ageing, and conducts the risk assessment for public health and occupational health and safety. The assessment of environmental risk is conducted by the Department of the Environment and Heritage. For the purposes of subsection 78(1) of the Act, this Full Public Report may be inspected at: Library National Occupational Health and Safety Commission 25 Constitution Avenue CANBERRA ACT 2600 AUSTRALIA To arrange an appointment contact the Librarian on TEL + 61 2 6279 1161 or + 61 2 6279 1163. This Full Public Report is available for viewing and downloading from the NICNAS website or available on request, free of charge, by contacting NICNAS. For requests and enquiries please contact the NICNAS Administration Coordinator at: Street Address: Postal Address: TEL: FAX Website: 334 - 336 Illawarra Road MARRICKVILLE NSW 2204, AUSTRALIA. GPO Box 58, SYDNEY NSW 2001, AUSTRALIA. + 61 2 8577 8800 + 61 2 8577 8888 www.nicnas.gov.au Director Chemicals Notification and Assessment June 2004 NICNAS FULL PUBLIC REPORT Component of Caltex RPM Grease SRI 2 1. APPLICANT AND NOTIFICATION DETAILS APPLICANT(S) Caltex Australia Petroleum Pty Ltd (ABN 17 000 032 128) Level 12, MLC Centre 19 – 29 Martin Pl SYDNEY NSW 2000 Australasian Lubricants Manufacturing Company (ACN 088 894 857) Tanker St LYTTON QLD 4178 NOTIFICATION CATEGORY Standard: Chemical other than polymer (more than 1 tonne per year). EXEMPT INFORMATION (SECTION 75 OF THE ACT) Data items and details claimed exempt from publication: chemical name, CAS No., molecular and structural formulae, molecular weight, spectral data, purity, additives, manufacture and import volumes and identity of manufacturing sites. VARIATION OF DATA REQUIREMENTS (SECTION 24 OF THE ACT) No variation to the schedule of data requirements is claimed. Variation to the schedule of data requirements is claimed as follows: vapour pressure, water solubility, hydrolysis as a function of pH, partition coefficient, adsorption/desorption, dissociation constant, particle size, flash point, flammability limits, autoignition temperature, acute oral toxicity, acute dermal toxicity, acute inhalation toxicity, skin irritation, eye irritation, skin sensitisation, repeated dose toxicity, induction of point mutations, induction of germ cell damage, chromosomal damage, fish acute toxicity, Daphnia acute toxicity, alga growth inhibition test, ready biodegradation. PREVIOUS NOTIFICATION IN AUSTRALIA BY APPLICANT(S) None. NOTIFICATION IN OTHER COUNTRIES None. 2. IDENTITY OF CHEMICAL MARKETING NAME(S) The notified chemical is a component of Caltex RPM Grease SRI 2. MOLECULAR WEIGHT < 1000 METHODS OF DETECTION AND DETERMINATION ANALYTICAL METHOD Remarks Atomic and IR spectroscopy An infrared (IR) spectrum was provided. FULL PUBLIC REPORT: STD/1071 Page 4 of 16 June 2004 3. NICNAS COMPOSITION DEGREE OF PURITY High. HAZARDOUS IMPURITIES/RESIDUAL MONOMERS None. NON HAZARDOUS IMPURITIES/RESIDUAL MONOMERS (>1% by weight) None. ADDITIVES/ADJUVANTS The grease product of which the notified chemical is a component contains: Distillates, petroleum, hydrotreated heavy paraffinic (CAS No. 64742-54-7) Polyurea thickener Additives 4. > 80% < 10% < 10% INTRODUCTION AND USE INFORMATION MODE OF INTRODUCTION OF NOTIFIED CHEMICAL (100%) OVER NEXT 5 YEARS The notified chemical will be imported as a component (at 1% (w/w)) of a grease product in 181 kg metal, open head drums lined with a polyethylene liner. MAXIMUM INTRODUCTION VOLUME OF NOTIFIED CHEMICAL (100%) OVER NEXT 5 YEARS Year Tonnes 1 < 10 2 < 10 3 < 10 4 < 10 5 < 10 USE Grease component used for lubricating anti-friction ball, needle and roller bearings operating at high speeds and high temperatures or where salt water may penetrate the bearings. 5. PROCESS AND RELEASE INFORMATION 5.1. Distribution, Transport and Storage PORT OF ENTRY Unknown. IDENTITY OF MANUFACTURER/RECIPIENTS Notifier. TRANSPORTATION AND PACKAGING The notified chemical will be transported as a component of grease in 181 kg metal drums to 3 repackaging sites in Perth, W.A., Newport, Victoria and Lytton, Queensland. It will be repackaged into 181 kg drums, 20 kg pails, 2.5 kg tins and 450 gram plastic cartridges for transport to retailers. 5.2. Operation Description For repackaging the drum is opened and a drum pump inserted into the grease. The pump consists of a rubber lid that holds the grease down while it is being pumped through a hose. The grease is drawn out of the drum into a packaging machine. The packaging machine is fully automated and will fill the various sized containers. FULL PUBLIC REPORT: STD/1071 Page 5 of 16 June 2004 5.3. NICNAS Occupational exposure Number and Category of Workers Category of Worker Transport and storage Repackaging Equipment cleaning Laboratory staff End users Number 10 – 20 1 – 5 per site 1 – 5 per site 1 – 2 per site > 1000 Exposure Duration 1 – 2 hours 0.5 – 1 hour 0.5 – 1 hour 0.25 hour 1 – 8 hours Exposure Frequency 50 days/year 200 days/year 50 days/year 200 days/year 200 days/year Exposure Details The hoses are dedicated to each product. The metal fittings attached to the hoses are cleaned with solvent before use, and the solvent goes to incineration. The drum pump and follower plate are wiped clean with rags after each use. The rags are taken by a recycling company that cleans the rags with solvent and the solvent is incinerated. The repackaging equipment is cleaned using cleaning rods, then the next product is pushed through the equipment. Waste from this process is collected and used for the lubrication of non-critical equipment. Dermal or ocular exposure to grease residues or greasecontaining solvent may occur but is controlled by the use of coveralls, safety boots and gloves. Laboratory staff will take samples of the grease at the time of delivery and may be dermally exposed. Such exposure will be limited to a few minutes per batch. End users (auto mechanics, electric motor refurbishers and agricultural mechanics) will load grease guns and apply grease to bearings. Exposure may occur during loading and use of the grease guns. Workers will wear overalls, cotton hat and safety boots when handling the grease. Handling parts which may have been in contact with grease is likely to be the route of maximum exposure. In all cases exposure will be to formulated grease containing 1% (w/w) notified chemical. 5.4. Release RELEASE OF CHEMICAL AT SITE Environmental release is unlikely during importation, storage and transportation, with spillage during a transport accident the most likely reason for environmental release. Individual container capacity (181 kg), container specifications (lined steel drums) and emergency procedures would limit the extent of release. Significant release of the notified chemical during repackaging is unlikely due to the minimal amount of handling required, environmental controls, wastewater and solid waste management practices and spill response procedures. Spilled grease will be collected and reused. A fraction of the grease containing the notified chemical may come into contact with worker clothing. After washing of clothing, the notified chemical may subsequently be collected in wastewaters for either on-site treatment at a wastewater treatment plant (WWTP) or sent to sewer for disposal. RELEASE OF CHEMICAL FROM USE The proposed use of the grease containing the notified chemical is unlikely to result in releases to the environment, with the most likely release occurring due to accidental spillage of individual containers. Equipment regreasing activities using a pneumatic grease gun may result in a proportion of the aged grease being collected and discarded to landfill. A fraction of the grease containing the notified chemical may come into contact with worker clothing. After washing of clothing, the notified chemical may subsequently be collected in wastewaters and sent to sewer for disposal. 5.5. Disposal Drum liners will be removed and any grease residues attached to liners will be disposed of by incineration (< 10 kg of notified chemical/year). The presence of liners should prevent drums being contaminated with the grease. Emptied drums will be sent to commercial drum recyclers for steam cleaning prior to reuse. Rags used to wipe down drum pumps, etc, will be recycled, cleaned in solvent, with the solvent waste incinerated (< 10 kg/year). Solvents used to clean equipment at the repackaging facility will be collected and incinerated (< 10 kg/year). Unwanted grease products, spilled material and residues in emptied consumer products are likely to be sent to landfill for disposal (< 100 kg/year). Greased machinery may eventually be recycled as metal scrap or sent to landfill for disposal. Wash FULL PUBLIC REPORT: STD/1071 Page 6 of 16 June 2004 NICNAS water from soiled clothing that potentially contain a small quantity of the notified chemical (eg. < 10 kg/year) may be sent to on-site WWTP and/or sewer for disposal. 5.6. Public exposure Consumer exposure to the grease containing the notified chemical can be high when car or truck owners add grease to their wheel bearings or do their own repair work. Exposure to the notified chemical is limited by its low concentration in the grease. 6. PHYSICAL AND CHEMICAL PROPERTIES No actual test results were provided and the following were estimated using the EPIWIN (EPI) computer program: vapour pressure, water solubility, partition coefficient and adsorption/desorption. Appearance at 20oC and 101.3 kPa Grease containing the notified chemical has typical green appearance. Melting Point/Freezing Point 62oC Density 1030 kg/m3 at 25oC Vapour Pressure METHOD 2.84 x 10-19 kPa at 25C Estimated using the modified Grain Method. Water Solubility METHOD 8.35 x 10-12 to 6.2124 x 10-10 g/L at 25oC Estimated using the WATERNT (v1.01) and WSKOW (v1.41) computer programs. Hydrolysis as a Function of pH REMARKS Not likely to hydrolyse in the environmentally relevant pH range pH 4-9 since there are no hydrolysable groups. log Pow = 11.88 at 20oC Partition Coefficient (n-octanol/water) METHOD Estimated using the KOWWIN v1.67 computer program. Will strongly partition to octanol phase. log Koc = 3.509 x 107 Adsorption/Desorption METHOD Estimated using the PCKOCWIN (v1.66) computer program. Expected to strongly sorb to soils and sediments. Test not conducted. Dissociation Constant REMARKS Contains a carboxylic acid functionality that will dissociate at low pH. Flash Point Not determined. Flammability Limits Not flammable. Autoignition Temperature 460oC (analogue chemical) METHOD DIN 51794 Explosive Properties Reactivity REMARKS Not explosive. Expected to be stable under normal environmental conditions. May react with strong oxidising agents. FULL PUBLIC REPORT: STD/1071 Page 7 of 16 June 2004 7. NICNAS TOXICOLOGICAL INVESTIGATIONS Toxicity data are not available for the notified chemical. However, there are adequate data available for the close analogues designated here as analogues A, B and C. Data for acute dermal toxicity and chromosomal damage are not available for the analogues, however, if the notified chemical is to be imported at concentrations above 1%, data covering these endpoints may need to be supplied (see section 12.1 Secondary notification). Endpoint and Result Rat, acute oral LD50 > 25 mL/kg bw (analogue A); LD50 > 10 g/kg bw (analogue C) Rabbit, skin irritation (analogue A) Rabbit, eye irritation (analogue A) Contact allergy in humans(analogue B) Rat, feeding study, 13 weeks (analogue B) Rat, feeding study, 3 months (analogue C) Genotoxicity - bacterial reverse mutation (analogues B and C) Genotoxicity – in vitro chromosomal aberrations (analogue B) Genotoxicity – in vivo mouse micronucleus test (analogue B) Developmental and reproductive effects (analogues B and C) Carcinogenicity (analogue C) 7.1. Assessment Conclusion low toxicity slightly irritating slightly irritating evidence of sensitisation NOAEL = 2.5% in the diet NOEL = 2500 mg/kg/day bw non mutagenic non genotoxic non genotoxic negative negative Acute toxicity – oral Analogue A in doses of 12.5, 20.0 and 25.0 mL/kg was administered to groups of 10 mice. In the 20.0 mL/kg group one mouse died within 24 hours; in the 25.0 mL/kg group two mice died between days 4 and 7 preceded by a loss of body weight (in common with other test animals). It was concluded that the LD50 value for Analogue A was greater than 25.0 mL/kg. Therefore the test substance can be considered to be of low acute toxicity via the oral route (CIR, 1988). Analogue C was administered to albino rats at doses of 0.05 to 10.0 g/kg at 25% in corn oil. The LD50 was greater than 10.0 g/kg (CIR, 1982). 7.2. Irritation – skin A 0.5 mL sample of analogue A was applied to the skin of 4 New Zealand White rabbits under occlusive patch for 24 hours. Two of the rabbits had very slight erythema at 24 hours and 1 rabbit had well-defined erythema. The remaining rabbit had no reactions. The test substance was judged to be mildly irritating to the skin (CIR, 1988). Undiluted analogue A (5.0 g) was applied to 6 New Zealand White rabbits under composite dressings for 24 hours. No reactions were noted up to 72 hours after patch removal and the test substance was judged to be nonirritant (CIR, 1988). Products containing 5.6% analogue A were evaluated as single insult under occlusive patch in 2 studies of 20 and 19 panellists and found not to be irritating (CIR, 1988). Analogue C (0.5 g) applied under occlusive patch for 4 hours or 24 hours to 6 albino rabbits was not irritating (CIR, 1982). 7.3. Irritation - eye Mild irritation of the conjunctiva lasting no longer than 24 hours was observed up to 7 days after 0.1 mL of analogue A instilled into one eye of 3 New Zealand White rabbits (CIR, 1988). A further study of 6 New Zealand White rabbits involved checking corneal opacity at 24, 48 and 72 hours visualised by fluorescein dye after instillation of 0.10 g of analogue A into the conjunctival sac of one eye. No irritation was detected (CIR, 1988). FULL PUBLIC REPORT: STD/1071 Page 8 of 16 June 2004 NICNAS Analogue C applied to eyes of 6 albino rabbits was not irritating up to day 3 after instillation (CIR, 1982). 7.6. Skin sensitisation Two cases of contact allergy to analogue B in cosmetics have been reported (Brandle et al., 1983; Sai, 1983). 7.7. Repeat dose toxicity F344/N rats or B6C3F1 mice (10/sex) were fed analogue B continuously in the diet for 13 weeks at 0, 0.62, 1.25, 2.5, 5.0 or 10% (NTP, 1992). For the rats there was no effect on body weight or survival. Haematological effects in male rats not thought to be biologically significant included a slight decrease in MCHC at day 21 at the high dose, a statistically significant decrease in MCV at the high dose, a decrease in MCH in the 5% and 10% groups and an increase in platelets in the 1.25%, 5% and 10% groups. In females there was a statistically significant decrease in reticulocyte counts at day 5 in groups receiving 0.62% or 10%. For clinical chemistry parameters at treatment and dose-related increase in serum alkaline phosphatase was observed in male and females at days 5, 21 and termination. Total bile acids were increased in males receiving the higher dietary levels at days 5 and 21 but not at termination. Other minor changes were recorded but were isolated. Absolute liver weights and liver to body weight ratio were increased in high dose male rats. Heart to body weight ratios were increased in males receiving 0.62%, 5% and 10% but absolute weights were not. The organ changes had no histopathological correlates. Screening for reproductive toxicity involved checking sperm motility and morphology and vaginal cytology. A slight decrease in epididymal weight that occurred in the middle and high dose groups but was not dose-related. There were no other reproductive effects. There was no effect of treatment on survival of the mice and high dose male exhibited lower body weight from week 3 to the end of the study. Liver weights were higher in animals receiving 5% or 10% test substance and kidney weights were elevated in females at these doses. There were no histopathological correlates. Analogue B had no effect on any male (testes weight, epididymal sperm motility, density or testicular spermatid head count) or female (estrual cycle length or time spent in each phase of the cycle) reproductive parameter. Analogue C was fed to groups of male and female outbred Wistar/Af/Han/Mol (Han 67) rats (20/sex) at levels of 0, 5, 10 and 20% in a semisynthetic diet for 3 months (Søndergaard et al., 1980). Decreased weight gain occurred in high dose males and stone formation (due to high magnesium diet) was observed in the low urinary tract of 8 males and 7 females of the high dose group. Reduced liver weights were seen in males of the 10% and 20% groups and an increase in iron was found in the livers of the 20% group. The no effect level was estimated as 2500 mg/kg/day bw based on the liver effects. 7.8. Genotoxicity - bacteria Analogue C was not mutagenic in Salmonella typhimurium TA 1535, TA 1537 or TA 1538 or in Saccharomyces cerevisiae D4 with or without metabolic activation by liver and lung preparations from rats, mice and monkeys (Litton Bionetics, 1976). Analogue B was negative in a Salmonella mutagenicity test conducted by the US National Toxicology Program (NTP, 1992). Strains TA 100, TA 1535, TA 97 or TA 98 were tested with a preincubation protocol in the presence or absence of metabolic activation (S9) at 100 – 10000 g/plate. 7.9. Genotoxicity – in vitro Analogue B was negative in vitro in tests for chromosomal aberrations and sister chromatid exchange in Chinese Hamster ovary cells conducted by the US National Toxicology Program (NTP, 1992) at concentrations up to 5000 g/mL. 7.10. Genotoxicity – in vivo FULL PUBLIC REPORT: STD/1071 Page 9 of 16 June 2004 NICNAS Analogue B was negative in vivo in a mouse micronucleus test conducted by the US National Toxicology Program (NTP, 1992). Peripheral blood erythrocytes were sampled from B6C3F1 mice+ at the termination of the 13-week repeated dose study described above. 7.11. Developmental toxicity A vehicle used in coated pharmaceutical tablets, containing 5.5% analogue C was assayed for teratogenicity in rabbits. Fourteen females received the test substance orally at 2.5 mg/kg 70 hours post coitus and 13 females were given the same dose 192 hours post coitus. The absence of teratogenesis was indicated by 11% anomalies in the offspring of 16 untreated mothers as against 11% and 12% anomalies in the treated groups (dosed at 70 and 192 hours hours post coitus, respectively) (CIR, 1982). 7.12. Chronic toxicity/carcinogenicity Pellets of analogue C implanted in the bladders of 41 mice for 30 weeks produced a 5% incidence of bladder tumours, similar to the 4% incidence in 67 mice implanted with smooth glass beads (CIR, 1982). FULL PUBLIC REPORT: STD/1071 Page 10 of 16 June 2004 8. ENVIRONMENT 8.1. Environmental fate NICNAS 8.1.1. Biodegradable. Ready biodegradability Test not conducted. Estimated using the BIOWIN (v4.01) computer program. Estimates of biodegradability using EPI suite model indicate that biodegradation will be rapid. 8.1.2. Bioaccumulation Tests not conducted. Based on the high log P ow of 11.88 and very low water solubility, the notified chemical is unlikely to bioaccumulate. 8.2. Ecotoxicological investigations 8.2.1. Acute toxicity to fish TEST SUBSTANCE FM Grease EP NLGI (contains 5% notified chemical). METHOD USEPA (1993) Methods for measuring the acute toxicity of effluents and receiving waters to freshwater and marine organisms (EPA/600/490/027F) Rainbow trout (Onchorhynchus mykiss) 96 hours None 38 - 49 mg CaCO3/L Dissolved oxygen (DO), pH, and conductivity measured before, during and after tests, as well as alkalinity and hardness. Test temp. 12.4 - 13C, pH 7.4 - 8.0, DO 6.7 - 8.7 mg/L – acceptable. WAF loading rate was 1000 mg/L. WAF was obtained by smearing grease (3.5 g) onto the inside of a WAF jar containing 3.5 L of spring water, and stirred at 21C for 24 hours in a sealed container. 1 hour after stirring, 3 L of the 100% WAF solution was pipetted from inside the jar (first 20-30 mL rejected) to a 4 L jar for use in the tests. Photoperiod: 16 hours light:8 hours dark. 23 day old trout. Species Exposure Period Auxiliary Solvent Water Hardness Analytical Monitoring Remarks – Method RESULTS Concentration mg/L Nominal 0 1000 mg/L WAF LC50 NOEC (or LOEC) Remarks – Results CONCLUSION TEST FACILITY Number of Fish 10 10 % Survival 96 h 100 80 > 1000 mg/L WAF at 96 hours 1000 mg/L WAF at 96 hours. The treatment result was not significantly less than that for the control (P > 0.05). The test material is not toxic to rainbow trout up to the limit of its water solubility. Pacific EcoRisk, California, USA (2000b). 8.2.2. Acute toxicity to aquatic invertebrates TEST SUBSTANCE FM Grease EP NLGI (contains 5% notified chemical). METHOD USEPA (1993) Methods for measuring the acute toxicity of effluents and receiving waters to freshwater and marine organisms (EPA/600/490/027F) Daphnia magna Species FULL PUBLIC REPORT: STD/1071 Page 11 of 16 June 2004 Exposure Period Auxiliary Solvent Water Hardness Analytical Monitoring Remarks - Method NICNAS 48 hours None 42-94 mg CaCO3/L (100 mg/L WAF test). 35-49 mg CaCO3/L (1000 mg/L WAF test). Dissolved oxygen (DO), pH, and conductivity measured before, during and after tests, as well as alkalinity and hardness. Test temp. ~ 19-21.5C, pH 7.1 - 8.1, DO 6.5 - 8.7 mg/L – acceptable. WAF loading rates were 100 and 1000 mg/L. WAF was obtained by smearing grease (0.35 and 3.5 g) onto the insides of WAF jars containing 3.5 L of spring water, and stirred at 21C for 24 hours in a sealed container. 1 hour after stirring, 3 L of the 100% WAF solution was pipetted from inside the jar (first 20 - 30 mL rejected) to a 4 L jar for use in the tests. It is not stated whether the test solutions were clear or cloudy (caused by globules of grease). Photoperiod: 16 hours light: 8 hours dark. Neonates < 24 h old. RESULTS Concentration mg/L Nominal 0 100 mg/L WAF 1000 mg/L WAF Number of D. magna 10 10 10 % Survival 48 h 100 80 30* * Significantly different from control (P<0.05%; ToxCalc v5.0). LC50 NOEC CONCLUSION TEST FACILITY >100 - <1000 mg/L WAF at 48 hours 100 mg/L WAF at 48 hours The test material shows some toxicity to Daphnia magna below the limit of water solubility; however, a physical effect may also be possible. Pacific EcoRisk, California, USA (2000a, b). 8.2.3. Algal growth inhibition test Test not conducted. No significant toxicity to algae or plants is expected (expected EC50 > 1000 mg/L). Components of the notified chemical are essential for plant growth, and the notified chemical has a plant origin with no phytotoxicity. 8.2.4. Inhibition of microbial activity Test not conducted. FULL PUBLIC REPORT: STD/1071 Page 12 of 16 June 2004 NICNAS 9. RISK ASSESSMENT 9.1. Environment 9.1.1. Environment – exposure assessment The grease containing the notified chemical will be imported into Australia for repackaging at one facility prior to widespread and diffuse use throughout Australia. Environmental release of the grease is expected to be limited during repackaging and use in mechanical applications. Most waste grease containing the notified chemical is likely to be sent to landfill for disposal where the notified chemical is not expected to migrate and will degrade over time to simpler compounds of the constituent elements. Landfilled wastes are not likely to pose an unacceptable risk to the environment. Wastes generated during repackaging are collected and incinerated. A very small quantity of the notified chemical (eg. < 10 kg grease/year) may enter the sewerage system from clothing wash waters. An average solution concentration of approximately 10 -9 mg/L is anticipated, assuming a national wastewater volume of 3900 ML/day and no sewerage system attenuation. Releases to sewer are likely to attenuate within the sewerage system, with most partitioning to solids and retained as biosolids. 9.1.2. Environment – effects assessment Aquatic toxicity data indicate that the WAF from grease containing 5% of the test material shows some toxicity to Daphnia magna below its limit of water solubility; however, a physical effect may also be possible. The notified chemical has a very low water solubility, low affinity for octanol (log Kow estimated as 11.88) and is unlikely to bioaccumulate. 9.1.3. Environment – risk characterisation On the basis of the reported use pattern and expected waste management practices, the notified chemical is not considered to pose an unacceptable risk to the environment. 9.2. 9.2.1. Human health Occupational health and safety – exposure assessment Workers involved in testing and repackaging imported grease can be expected to be dermally and, to a lesser extent, ocularly exposed on an intermittent basis. The grease can remain on the skin for an extended period of time given its viscous nature. However, exposure to the notified chemical in these circumstances is low as it comprises 1% (w/w) of the imported grease. End users can be exposed to grease readily while handling machine parts but again, the exposure level is low. 9.2.2. Public health – exposure assessment The public can be exposed to the grease when performing repairs or maintenance on vehicles but the exposure to the notified chemical is limited by its low concentration in the grease. 9.2.3. Human health - effects assessment Data on analogues suggests the notified chemical is of low toxicity via the oral route, is a slight skin and eye irritant, exhibits limited evidence of skin sensitisation and is neither genotoxic, reprotoxic nor carcinogenic. Repeated dose studies with analogue B and analogue C did not indicate significant organ toxicity. 9.2.4. Occupational health and safety – risk characterisation The low concentration of notified chemical in the imported grease coupled with a predicted benign toxicity profile suggests there is minimal risk of adverse health effects to workers handling the grease. 9.2.5. Public health – risk characterisation The risk to the public of adverse health effects from using the imported grease for vehicle repairs and maintenance is expected to be low given the low and intermittent exposure and low concentration of the notified chemical in the grease. FULL PUBLIC REPORT: STD/1071 Page 13 of 16 June 2004 10. NICNAS CONCLUSIONS – ASSESSMENT LEVEL OF CONCERN FOR THE ENVIRONMENT AND HUMANS 10.1. Hazard classification Based on the available data the notified chemical is not classified as hazardous under the NOHSC Approved Criteria for Classifying Hazardous Substances or using the Globally Harmonised System for the Classification and Labelling of Chemicals (GHS) (United Nations, 2003). 10.2. Environmental risk assessment The chemical is not considered to pose a risk to the environment based on its reported use pattern. 10.3. Human health risk assessment 10.3.1. Occupational health and safety There is Low Concern to occupational health and safety under the conditions of the occupational settings described. 10.3.2. Public health There is Negligible Concern to public health when used as indicated. 11. MATERIAL SAFETY DATA SHEET 11.1. Material Safety Data Sheet The MSDS for the imported product containing the chemical provided by the notifier was in accordance with the NOHSC National Code of Practice for the Preparation of Material Safety Data Sheets (NOHSC, 2003). It is published here as a matter of public record. The accuracy of the information on the MSDS remains the responsibility of the applicant. 11.2. Label The label for the imported product containing the chemical provided by the notifier w in accordance with the NOHSC National Code of Practice for the Labelling of Workplace Substances (NOHSC, 1994). The accuracy of the information on the label remains the responsibility of the applicant. 12. RECOMMENDATIONS CONTROL MEASURES Occupational Health and Safety A copy of the MSDS should be easily accessible to employees. If products and mixtures containing the notified chemical are classified as hazardous to health in accordance with the NOHSC Approved Criteria for Classifying Hazardous Substances, workplace practices and control procedures consistent with provisions of State and Territory hazardous substances legislation must be in operation. Environment Disposal The notified chemical should be disposed of by incineration or to landfill in accordance with State/territory waste management regulations. Emergency procedures FULL PUBLIC REPORT: STD/1071 Page 14 of 16 June 2004 NICNAS Spills/release of the notified chemical should be handled by isolating the spill area, scooping or wiping spilled material into a labelled container. Scrub spill area with detergent and water. Minimise entry of spilled material into sewers and drainage systems. Prevent entry by unauthorised persons to spill area. Prevent run-off to groundwater or stormwater. 12.1. Secondary notification The Director of Chemicals Notification and Assessment must be notified in writing within 28 days by the notifier, other importer or manufacturer: (1) Under Section 64(1) of the Act; if uses are proposed which will result in a much higher release to the aquatic compartment, a full suite of aquatic toxicity data for sensitive aquatic organisms representative of receiving environments (eg. waterfleas, algae) using appropriately sensitive test endpoints may be required as part of a secondary notification. the concentration of the notified chemical in the imported product is likely to exceed 1% (v/v) or (2) Under Section 64(2) of the Act: if any of the circumstances listed in the subsection arise. The Director will then decide whether secondary notification is required. No additional secondary notification conditions are stipulated. 13. BIBLIOGRAPHY Brandle I, Boujnah-Khouadja A and Foussereau J (1983) Allergy to Castor Oil. Contact Dermatitis, 9: 424 – 5. CIR (1982) Final Report of the Safety Assessment of Lithium Stearate, Aluminium Distearate, Aluminium Tristearate, Ammonium Stearate, Calcium Stearate, Magnesium Stearate, Potassium Stearate, Sodium Stearate and Zinc Stearate. J. Am. Coll. Toxicol., 1: 143 – 177. CIR (1988) Final Report of the Safety Assessment of Glyceryl Ricinoleate. J. Am. Coll. Toxicol., 7: 721 – 739. Litton Bionetics (1976) Mutagenic Evaluation of Compound FDA 75-33 0057-04-0 Magnesium Stearate. LBI Project No. 2468. Litton Bionetics, Maryland, USA (unpublished report submitted by notifier). NOHSC (1994) National Code of Practice for the Labelling of Workplace Substances [NOHSC:2012(1994)]. National Occupational Health and Safety Commission, Canberra, Australian Government Publishing Service. NOHSC (2003) National Code of Practice for the Preparation of Material Safety Data Sheets, 2 nd edn [NOHSC:2011(2003)]. National Occupational Health and Safety Commission, Canberra, Australian Government Publishing Service. NTP (1992) NTP Technical Report on the Toxicity Studies of Castor Oil in F344/N Rats and B6C3F1 Mice (Dosed Feed Studies). Report No. NIH/PUB-92-3131. NTP-TOX-12. National Toxicology Program, NC, USA. Pacific EcoRisk (2000a) Aquatic Toxicity of the “Water Accommodated Fraction” Produced from a Grease Product (FM Grease EP NLGI 2) to Daphnia magna: Loading Rate = 100 mg/L. Pacific EcoRisk, Martinez, California, USA (unpublished report submitted by notifier). Pacific EcoRisk (2000b) Revised Report: Aquatic Toxicity Screening of the “Water Accommodated Fraction” Produced from a Grease Product (FM Grease EP NLGI 2). Pacific EcoRisk, Martinez, California, USA (unpublished report submitted by notifier). Sai, S (1983) Lipstick Dermatitis Caused by Castor Oil. Contact Dermatitis, 9: 75. FULL PUBLIC REPORT: STD/1071 Page 15 of 16 June 2004 NICNAS Søndergaard D, Meyer O and Würtzen G (1980) Magnesium Stearate Given Perorally to Rats. A Short Term Study. Toxicology, 17: 51 – 55. United Nations (2003) Globally Harmonised System of Classification and Labelling of Chemicals (GHS). United Nations Economic Commission for Europe (UN/ECE), New York and Geneva. FULL PUBLIC REPORT: STD/1071 Page 16 of 16