INSTRUCTIONS TO AUTHORS FOR THE PREPARATION

advertisement

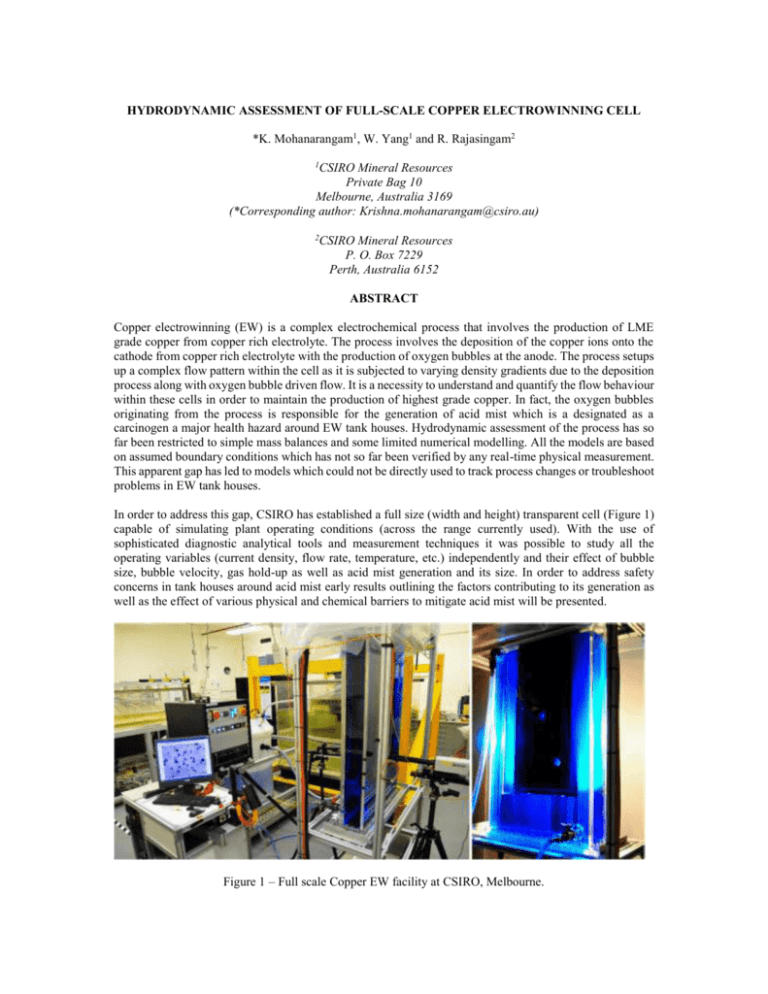

HYDRODYNAMIC ASSESSMENT OF FULL-SCALE COPPER ELECTROWINNING CELL *K. Mohanarangam1, W. Yang1 and R. Rajasingam2 1 CSIRO Mineral Resources Private Bag 10 Melbourne, Australia 3169 (*Corresponding author: Krishna.mohanarangam@csiro.au) 2 CSIRO Mineral Resources P. O. Box 7229 Perth, Australia 6152 ABSTRACT Copper electrowinning (EW) is a complex electrochemical process that involves the production of LME grade copper from copper rich electrolyte. The process involves the deposition of the copper ions onto the cathode from copper rich electrolyte with the production of oxygen bubbles at the anode. The process setups up a complex flow pattern within the cell as it is subjected to varying density gradients due to the deposition process along with oxygen bubble driven flow. It is a necessity to understand and quantify the flow behaviour within these cells in order to maintain the production of highest grade copper. In fact, the oxygen bubbles originating from the process is responsible for the generation of acid mist which is a designated as a carcinogen a major health hazard around EW tank houses. Hydrodynamic assessment of the process has so far been restricted to simple mass balances and some limited numerical modelling. All the models are based on assumed boundary conditions which has not so far been verified by any real-time physical measurement. This apparent gap has led to models which could not be directly used to track process changes or troubleshoot problems in EW tank houses. In order to address this gap, CSIRO has established a full size (width and height) transparent cell (Figure 1) capable of simulating plant operating conditions (across the range currently used). With the use of sophisticated diagnostic analytical tools and measurement techniques it was possible to study all the operating variables (current density, flow rate, temperature, etc.) independently and their effect of bubble size, bubble velocity, gas hold-up as well as acid mist generation and its size. In order to address safety concerns in tank houses around acid mist early results outlining the factors contributing to its generation as well as the effect of various physical and chemical barriers to mitigate acid mist will be presented. Figure 1 – Full scale Copper EW facility at CSIRO, Melbourne. Figure 2 - Sample images of bubbles (left) and acid mist droplets (right) measured in-situ KEYWORDS Electrowinning, Copper, Hydrodynamics, Bubbles, Mist, Physical measurement