Text - Elanders Dental

Material data sheet for Biomain I-Bridge and Abradere in Titanium

1.

Description of the product

Biomain’s products in titanium dioxide are especially developed for dental restorations. Biomain Zirkonia is biocompatible and is composed by commercially pure titanium grade 2.

2.

Instructions for use

Design parameters, Abradere

For copings we recommend a wall thickness of at least 0.4 mm and for bridges at least 0.5 mm. The connectors should have a cross section of at least 6 mm 2 .

Design parameters, I-Bridge

We recommend minimum 3 mm height and 2 mm width for the connectors. We allow 15 mm extension.

Veneering by ceramic

Use only veneering materials and processes suitable for the coefficient of thermal expansion of Biomain

Zirkonium (α=9,7 x 10 -6 m/m°C, at 0-540°C). Always follow the instructions of the ceramic manufacturer!

Surface Preparation

After mechanical preparation of the surface, the product should be blasted with Al

2

O

3

at 3-4 bar pressure and be steam-cleaned.

3.

Dangerous properties

Fire hazard

Chips and dust of titanium is flammable.

Personal protection equipment

Use eye protection and wash hands and face after working with the product.

4.

First aid

Inhalation:

Skin contact:

Eye contact:

Consumption:

The affected person should be brought to fresh air in case of symptoms.

Rinse with warm water and soap.

Rinse with water for at least 15 minutes. Contact a doctor in case of irritation.

Drink plenty of water

Information for doctor or medical personnel administering first aid

No specific antidote. Give help. Treatment according to diagnose depending on the patients reactions.

5.

Toxicological information

Inhalation:

Skin contact:

Eye contact:

Allergy:

No known irritating effect

Could have an irritating effect in case of prolonged contact.

Could have an irritating effect.

The product could be allergy-inducing in case of prolonged contact.

Measures in case of spillage

Use mechanic collection. The material should be disposed according to local regulation. Rests should be mixed with five parts sand and be stored separate from flammable materials.

Operation

Avoid dust formation. Avoid temperatures over 30°C and direct sunlight. Good ventilation of the workplace is recommended. Protective gloves are recommended, no special requirements for the material.

6.

Fire-fighting measures

Suitable extinguishing media

Special fire extinguisher for metal fires (class D according to EN 3 or equivalent), do not use water. Dry sand or salt could also be used.

Extingguishing media that cannot be used for safety reasons

Water

Carbon dioxide

ABC-powder

Foam

Special hazards measures in the event of fire

Burning titanium reacts with water and frees hydrogen.

Special protective measures in the event of fire

Avoid sources of ignition (as open flames, heat, static discharge). Do not smoke.

Additional advice

Avoid dust cloud formation.

7.

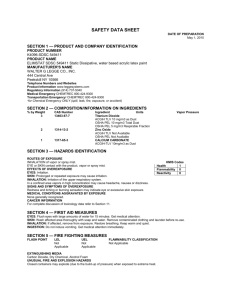

Technical data

Mechanical and thermal properties at 20°C after veneering with ceramic

Tensile strength, min

Yield strength

Young’s modulus (E-modulus)

Hardness, Vickers

Thermal expansion, α (0 – 540°C)

345 MPa

275-450 MPa

105 GPa

145 Hv

9,7 x 10 -6 m/m°C

The data is based on our present process parameters and are subject to changes without notice. They are provided as an indication and not as a guarantee of suitability for any specific application.