Amol Bhandarkar (Assistant Manager - Maintenance)

advertisement

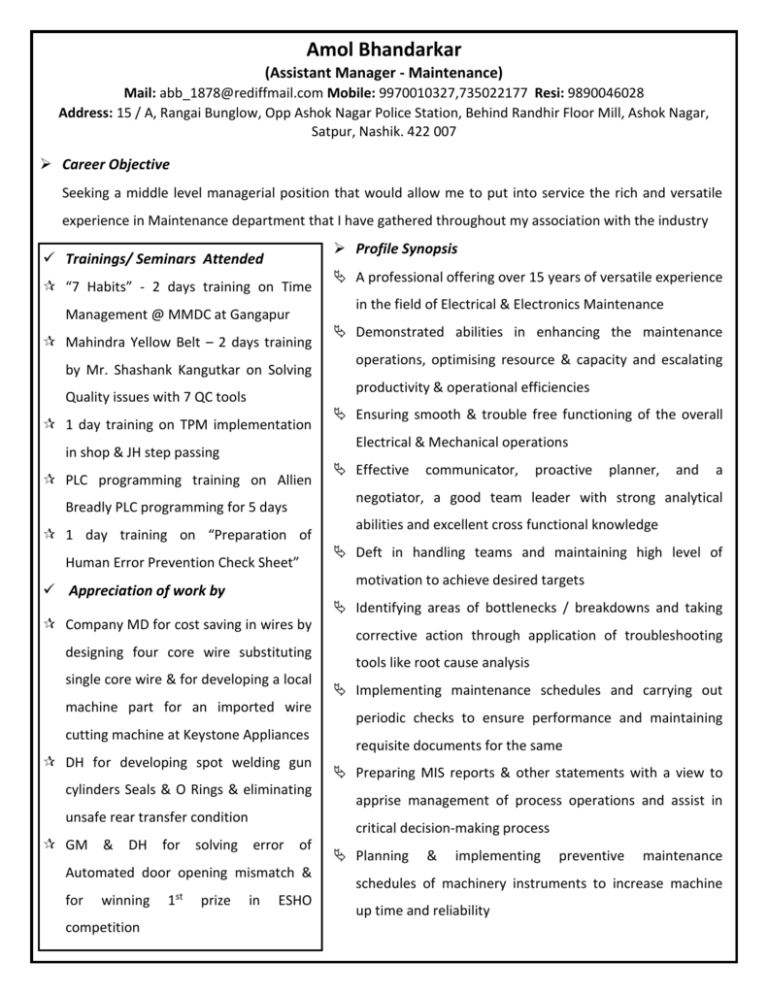

Amol Bhandarkar (Assistant Manager - Maintenance) Mail: abb_1878@rediffmail.com Mobile: 9970010327,735022177 Resi: 9890046028 Address: 15 / A, Rangai Bunglow, Opp Ashok Nagar Police Station, Behind Randhir Floor Mill, Ashok Nagar, Satpur, Nashik. 422 007 Career Objective Seeking a middle level managerial position that would allow me to put into service the rich and versatile experience in Maintenance department that I have gathered throughout my association with the industry Profile Synopsis Trainings/ Seminars Attended “7 Habits” - 2 days training on Time in the field of Electrical & Electronics Maintenance Management @ MMDC at Gangapur Mahindra Yellow Belt – 2 days training by Mr. Shashank Kangutkar on Solving 1 day training on TPM implementation PLC programming training on Allien 1 day training on “Preparation of Human Error Prevention Check Sheet” Company MD for cost saving in wires by designing four core wire substituting single core wire & for developing a local machine part for an imported wire cutting machine at Keystone Appliances DH for developing spot welding gun cylinders Seals & O Rings & eliminating unsafe rear transfer condition solving winning competition 1st prize communicator, proactive planner, and a abilities and excellent cross functional knowledge Deft in handling teams and maintaining high level of Identifying areas of bottlenecks / breakdowns and taking corrective action through application of troubleshooting tools like root cause analysis Implementing maintenance schedules and carrying out periodic checks to ensure performance and maintaining requisite documents for the same Preparing MIS reports & other statements with a view to apprise management of process operations and assist in critical decision-making process error of Automated door opening mismatch & for Effective motivation to achieve desired targets Appreciation of work by for Ensuring smooth & trouble free functioning of the overall negotiator, a good team leader with strong analytical Breadly PLC programming for 5 days DH operations, optimising resource & capacity and escalating Electrical & Mechanical operations in shop & JH step passing & Demonstrated abilities in enhancing the maintenance productivity & operational efficiencies Quality issues with 7 QC tools GM A professional offering over 15 years of versatile experience in ESHO Planning & implementing preventive maintenance schedules of machinery instruments to increase machine up time and reliability Last Assignment Mahindra & Mahindra Ltd, Nashik (November 2011 – June 2015) As Asst Manager - Maintenance Company Profile: Mahindra and Mahindra Ltd is an Indian multinational automobile manufacturing company. Mahindra manufactures vehicles in both personal and commercial segment. Responsibilities Shouldered: Accountable for Electrical and Electronics Maintenance of Bolero - Body Shop machines. Associated with a TS company with using various tools like Kaizen, TPM, Safety, Mahindra Quality System (MQS) and OHSES. Active involvement in installation and successful buy – off of the body shop equipments like Main Framing line fixtures of Bolero Pick Up, Line Electro pneumatic fixtures, Electric Hoists, I.T, Spot Guns, Pneumatic tools – Atlas Copco and Dynabrade Make, Dent Puller, etc. Proficiently overseeing automation of Electro – pneumatic fixtures, conveyers (Roller bed and COE – Vinar Systems). Deftly with the conventional and IT spot welding guns, Co2 welding. Managing the implementation of various projects related to energy conservation, productivity, quality & safety. Successful execution of PM, CBM and TBM plan and activities smoothly for all the equipments. Successfully making programming modifications in the fixtures and conveyers for saving the time through synchronizing sequences. Various Continual Improvement Projects for increase in productivity. Dexterous in handling Rockwell software like RS Logix 500 and RS View. Involved in Breakdown Analysis to find out root cause. Spearheading activities involving cost control methods, yearly budget and implementation of energy conservation projects. Spare Part Management and overseeing finalization of equipment spares with suppliers. TPM implementation for machines in the shop. Involved in implementation of SAP MM procedure. Initiative in reducing MTTR and increasing MTBF of equipments. To carry out Safety petrol round in shop & take counter measures on unsafe conditions. Ensuring implementation of safety procedure like “Lockout / Energy Control System Procedure”, “Inadequate lockout system”. Preparation of daily MIS for Maintenance department. Previous Assignments Keystone Appliances Pvt. Ltd. Nashik (April 2010 – November 2011) Asst DH Purchase Responsibilities Shouldered: Created daily production plan and monitored the production with respect to target to meet the monthly production schedule of analog panel meters. Preparing daily, monthly production plans and raw material consumption reports. Responsible for supervising, monitoring and ensuring smooth functioning of the analog panel meter assembly line. Overlooking the production activities for the organization ranging from generating material requirements to production of final product. Successful in implementation on Kaizen. Proficiently handling company ERP system. Overseeing routine purchase activities. Actively involved sourcing new vendors and suppliers in alignment with company requirements. Responsible for ensuring the timely delivery of materials. Maintaining liaison and ensuring smooth transaction of materials from Production department. Monitoring deviation between ordered and received quality ensuring supply compliances. Clearly conveying quality issues to the vendor and ensuring the same are resolved thereby ensuring the production of finest quality. Mahindra & Mahindra Ltd, Nashik (July 2007 - February 2009) Contract Officer Maintenance Responsibilities Shouldered: Accountable for electrical and Mechanical Maintenance of Logan - Body Shop machines. Involved in Breakdown Analysis to find out root cause. Insightful knowledge in maintenance of equipments in reducing downtime and enhancing operational effectiveness of equipment Scheduling and planning predictive, preventive & breakdown maintenance of equipment during operation cycle Sinic Electronics Pvt Ltd, Dhule (August 2004 - February 2006) Team Head – Servicing & Production Responsibilities Shouldered: Overseeing Electrical maintenance activities of the plant. Associated with ISO - 9002 and ISO – 14001 company. Looking after manufacturing of Banking Automation Products (Currency counting machine, Fake note detector) to provide service to banks under warranty and AMC period. Project Achievements Project 1: Elimination of rear door opening mismatch for longer at Mahindra and Mahindra Ltd Highlights: Rejection reduction up to 20%, Cost saved due to Buff paper saved for cutting up to 5% Project 2: Elimination of root cause of floor falling from tackle during transfer at Mahindra and Mahindra Ltd Highlights: Rejection cost saving by 2% Project 3: Energy saving of cooling ponds pump at Mahindra and Mahindra Ltd Highlights: Energy cost saving up to 10% Project 4: Energy saving by using simple single phase pump instead of three phase pump at Mahindra and Mahindra Ltd Highlights: Energy cost saving up to 15% Educational Credentials Course Diploma in Industrial Electronics Diploma in Instrumentation College Year of Passing Grade S.S.V.P.S Polytechnic, Dhule 1997 1st Class Gangamai Polytechnic, Dhule 1998 1st Class Value Add Courses C.C.C.O. (Certified certificate Course in Computer Operation) in 1995 SAP PM Module – OJT in 2014 Declaration: I hereby declare that all the above mentioned information is correct and true to the best of my knowledge. Signature: ________________________ Amol Bhandarkar Date: Location: