Supplementary Material ID L15-03393

advertisement

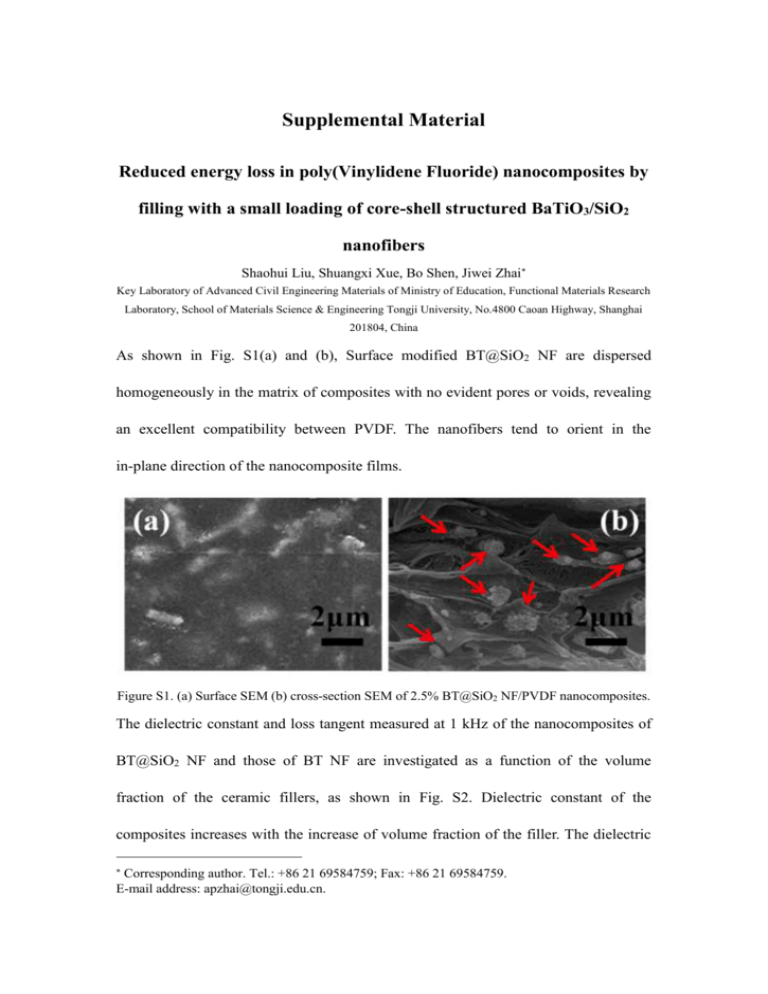

Supplemental Material Reduced energy loss in poly(Vinylidene Fluoride) nanocomposites by filling with a small loading of core-shell structured BaTiO3/SiO2 nanofibers Shaohui Liu, Shuangxi Xue, Bo Shen, Jiwei Zhai Key Laboratory of Advanced Civil Engineering Materials of Ministry of Education, Functional Materials Research Laboratory, School of Materials Science & Engineering Tongji University, No.4800 Caoan Highway, Shanghai 201804, China As shown in Fig. S1(a) and (b), Surface modified BT@SiO2 NF are dispersed homogeneously in the matrix of composites with no evident pores or voids, revealing an excellent compatibility between PVDF. The nanofibers tend to orient in the in-plane direction of the nanocomposite films. Figure S1. (a) Surface SEM (b) cross-section SEM of 2.5% BT@SiO2 NF/PVDF nanocomposites. The dielectric constant and loss tangent measured at 1 kHz of the nanocomposites of BT@SiO2 NF and those of BT NF are investigated as a function of the volume fraction of the ceramic fillers, as shown in Fig. S2. Dielectric constant of the composites increases with the increase of volume fraction of the filler. The dielectric Corresponding author. Tel.: +86 21 69584759; Fax: +86 21 69584759. E-mail address: apzhai@tongji.edu.cn. constant enhancement can be explained by the MWS interfacial polarization, which originates from the charge movement and accumulation at the interface between the fillers and PVDF matrix. The MWS interfacial polarization can enhance the dielectric constant of the nanocomposites. The dielectric constant of the nanocomposites of BT NF is higher than that of BT@SiO2 NF. This phenomenon can be attributed to the reduction of MWS interfacial polarization. As the MWS interfacial polarization is strongly depending on the dielectric differences between the filler and matrix, coating by SiO2 layers reduces the dielectric differences between the two phases and further results in the reduction of the dielectric constant of the nanocomposites. Meanwhile, the loss tangent of the nanocomposites still remains at a low value. Figure S2 Comparison of dielectric constant and dielectric loss of BT@SiO2 NF/PVDF nanocomposites and BT NF/PVDF nanocomposites with various concentrations of fillers measured at 1 kHz. The breakdown strength is the key parameter in determining the energy storage density of nanocomposites. As shown in Fig. S3, the breakdown strength of the nanocomposites of BT@SiO2 NF is higher than that of BT NF at the same volume fraction of fillers. The improvement of the breakdown strength has two reasons. On the one hand, as result of the large difference in dielectric constant between the two phases in the nanocomposites, space charges accumulate at the interface between the filler and matrix especially under high electric field. The accumulated charges would reduce the breakdown strength by distorting electric field. SiO2 layer on the surface of BT NF reduces the dielectric differences between the filler and the PVDF polymer matrix and further results in the reduction space charges accumulation in PVDF composites, leading to higher breakdown strength in the polymer nanocomposites. On the other hand, the SiO2 layer can enhance the insulation of BT NF and prevent the contact between fillers in polymer matrix to reduce the leakage current of nanocomposites. Comparison dielectric constants and breakdown strength of BT NF/PVDF nanocomposites and BT@SiO2 NF/PVDF composites, SiO2 shell layers forming on the surface of BT NF reduce the interfacial polarization and space charge polarization in these nanocomposites. Figure S3 Breakdown strength comparison for BT@SiO2 NF/PVDF nanocomposites and BT NF/PVDF nanocomposites loaded with various concentrations of fillers.