OSHA Hazard Communication Training Minutes

advertisement

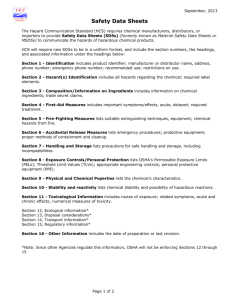

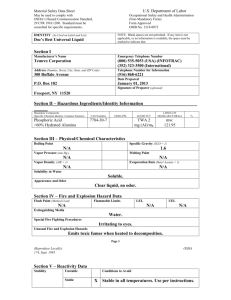

RRT III 2012 OSHA Hazard Communication Training State College, Pennsylvania Tuesday, September 11, 2012 1320 - 1420 COORDINATOR: Adam Hamrick (OSHA Region III) NOTES: Mr. Hamrick welcomed everyone. He is the Region III point of contact for OSHA HAZCOM. The FEMA Office of National Capital Region Coordination (NCRC) announced the release of two new Independent Study (IS) courses on emergency preparedness for Federal employees: 1. IS-450 (Target Audience is those folks outside the Washington D.C. area/National Capital Region (NCR)): http://training.fema.gov/emiweb/IS/IS450.asp 2. IS-450.NC (Target Audience is for federal employees within the NCR): http://training.fema.gov/emiweb/IS/IS450NC.asp Both courses introduce practical steps Federal employees can take to prepare for emergencies that could threaten their homes, workplaces, or communities. The NCR version includes information specific to the Washington, D.C. Area, including information on Metro, Office of Personnel Management (OPM) closure and dismissal procedures, and local alerting systems. Both courses take approximately one hour to complete. These courses are designed so any Federal department or agency can choose to adopt them as recommended or mandatory training, depending on agency needs. Some departments, like DHS, intend to implement these courses as required training for all employees. Other organizations may choose to recommend these courses to employees with certain emergency duties, like members of an Emergency Relocation Group or Occupant Emergency Team. These courses can be taken online, for free, at the public website for the FEMA Independent Study Program, available at http://www.training.fema.gov/is/. Employees who complete training through this website will receive a certificate of completion after successfully passing a final exam. In addition, these courses may be available to load into your agency's own internal learning management system. PRESENTATION: OSHA’s Final Rule to Modify the Hazard Communication Standard (Adam Hamrick, OSHA, Region 3) This presentation is provided in its entirety on the RRT Region III website at: http://www.rrt3.nrt.org. For additional information or if you have any other questions on this topic, please contact Adam Hamrick (hamrick.adam@dol.gov; 215-861-4930). OSHA Hazard Communication Training State College, Pennsylvania September 11, 2012 Page 2 of 4 In order to ensure chemical safety in the workplace, information about the identities and hazards of the chemicals must be available and understandable to workers. OSHA's Hazard Communication Standard (HCS) requires the development and dissemination of such information: Chemical manufacturers and importers are required to evaluate the hazards of the chemicals they produce or import, and prepare labels and safety data sheets to convey the hazard information to their downstream customers; All employers with hazardous chemicals in their workplaces must have labels and safety data sheets for their exposed workers, and train them to handle the chemicals appropriately. The OAHA HCS has been revised to better align the requirements with the United Nations’ Globally Harmonized System (GHS) for the classification and labeling of chemicals. The Final Rule was filed on March 20th at the Office of the Federal Register and available for viewing at http://www.osha.gov/dsg/hazcom/ghs-final-rule.html. The Federal Register published the final rule on March 26, 2012. The effective date of the final rule is 60 days after the date of publication. Notable changes within the Final Rule include: Hazard classification: Provides specific criteria for classification of health and physical hazards, as well as classification of mixtures. Labels: Chemical manufacturers and importers will be required to provide a label that includes a harmonized signal word, pictogram, and hazard statement for each hazard class and category. Precautionary statements must also be provided. Safety Data Sheets (SDSs): Replace Material Safety Data Sheets (MSDSs) and will now have a specified 16-section format. Information and training: Employers are required to train workers by December 1, 2013 on the new labels elements and safety data sheets format to facilitate recognition and understanding. In general, the HCS require chemical manufacturers, distributors or importers to provide SDSs to communicate the hazards of chemical products. As of June 1, 2015, the HCS will required new SDSs to be in a uniform format, and include the section numbers, heading, and associated information for the following: Section 1, Identification includes product identifier; manufacturer or distributor name, address, phone number; emergency phone number; recommended use; restrictions on use. Section 2, Hazard(s) identification includes all hazards regarding the chemical; required label elements. Section 3, Composition/information on ingredients includes information on chemical ingredients; trade secret claims. OSHA Hazard Communication Training State College, Pennsylvania September 11, 2012 Page 3 of 4 Section 4, First-aid measures includes important symptoms/effects, acute, delayed; required treatment. Section 5, Fire-fighting measures lists suitable extinguishing techniques, equipment; chemical hazards from fire. Section 6, Accidental release measures provides emergency procedures; protective equipment; proper methods of containment and cleanup. Section 7, Handling and storage includes precautions for safe handling and storage, including incompatibilities. Section 8, Exposure controls/personal protection lists OSHA's Permissible Exposure Limits (PELs); Threshold Limit Values (TLVs); appropriate engineering controls; personal protective equipment (PPE). Section 9, Physical and chemical properties lists the chemical's characteristics. Section 10, Stability and reactivity contains chemical stability and possibility of hazardous reactions. Section 11, Toxicological information includes routes of exposure; related symptoms, acute and chronic effects; numerical measures of toxicity. Section 12, Ecological information (non-mandatory) Section 13, Disposal considerations (non-mandatory) Section 14, Transport information (non-mandatory) Section 15, Regulatory information (non-mandatory) Section 16, Other information, includes the date of preparation or last revision. The dates of importance associated with the implementation of this Final Rule include (taken from http://www.osha.gov/dsg/hazcom/HCSFactsheet.html): Effective Completion Date Requirement(s) Who December 1, 2013 Train employees on the new label elements and SDS format. Employers June 1, 2015* December 1, 2015 Comply with all modified provisions of this final rule, except: Distributors may ship products labeled by manufacturers under the old system until December 1, 2015. Chemical manufacturers, importers, distributors and employers June 1, 2016 Update alternative workplace labeling and hazard communication program as necessary, and provide additional employee training for newly identified physical or health hazards. Employers Transition Period Comply with either 29 CFR 1910.1200 (this final standard), or the current standard, or both. All chemical manufacturers, importers, distributors and employers *This date coincides with the European Union implementation date for classification of mixtures. OSHA Hazard Communication Training State College, Pennsylvania September 11, 2012 Page 4 of 4 OSHA has developed Quick Cards (in both English and Spanish) to promote the new HCS. Quick Cards available online (http://www.osha.gov/dsg/hazcom/ghsquickcards.html) include: Safety Data Sheets – new standardized communication reporting identifying the hazards associated with hazardous chemical products; Standard Labeling Requirements for hazardous chemicals; and Standard Pictograms for labeling – to alert users of the chemical hazards to which they may be exposed. The Meeting Adjourned at 1420.