The Project - University of Canterbury

advertisement

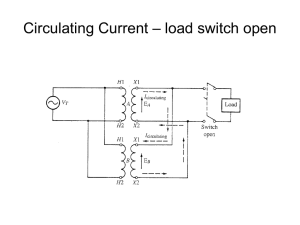

Dean of Postgraduate Research Vice-Chancellor’s Office Extension: Email: 7285 lucy.johnston@canterbury.ac.nz Summer Research Scholarship Scheme 2014-2015 Project Application Form Please complete and submit the application form as a WORD document and send to: summerscholarships@canterbury.ac.nz The Project Title of Project (max 30 words): Investigation of the break down of particles in a circulating gas flow. Project Leader(s): Robert Holt Host Department/Organization: Materials Department / Callaghan Innovation Other persons involved in this topic/activity: (List other significant members involved along with their affiliation to the research project.) Name Affiliation to project Dr Vlatko Materic Science Leader Brief outline of project Describe the proposed research project – maximum of 400 words (box will expand as you type). Note that this information will be published on the web in order to attract student applicants and therefore be mindful of any Intellectual Property issues Many industrial processes rely on chemical reactions between solids and gases. To maximise the reaction and transfer reagents many of these processes move solids in a gas stream, often in a circulating fluidised bed (CFB). Circulating particles are subject to many stresses that lead to attrition (breaking and wearing that reduce particle size). There are no standard methods to determine the key parameters that control the rate of attrition in a CFB, but the CO2 Capture (Ca-looping) team at Callaghan Innovation have proposed a method to solve this problem. The project proposed here will involve comparing the performance of particles in a transparent (cold flow) model with that observed in a high temperature circulating attrition tester. The correlation of gas and particle flow rates with the rates of different attrition mechanisms will provide insight into underlying limits for the solids in CFB systems. 1 The work will be in a small, experienced team and the student will have opportunities to learn much from practical chemical engineering to computer control of custom experimental facilities. This research started investigating the best way to capture CO2 from coal-burning power stations and has evolved to include a number of other very interesting applications. A successful student will enjoy practical experimental work and the challenge of producing hypotheses and testing them in a positive environment. If the project involves work away from the University campus (e.g., at fieldwork sites) please detail all locations. This work will be undertaken on site at Callaghan Innovation's Gracefield Campus, in Lower Hutt. If the student be required to work outside of normal university hours (8am-5pm) please provide details It is not expected that the student will have to work outside the hours of 8am – 5pm, Monday to Friday. Benefits student will gain from involvement in the project Describe the research experience and skills that the student will acquire through involvement in this research project – maximum of 100 words. The student will enjoy a great experience seeing some theories of fluidised particle flow in reality and then have the chance to push beyond established limits to discover more of the real world behaviour of fluidised particles. The student will be encouraged to contribute new ideas and then work out will experienced researchers how they could be tested. There will be opportunities to produce semi-empirical mathematical models, in Matlab, or using alternative programming tools to predict the attrition rates of circulating particles. Specific student requirements Please provide details of all requirements you have for the student to work on this project – for example, if specific courses/experience are necessary. The student must understand the basics of inorganic chemical reactions and understand the principles of fluid flow (e.g. the venturi effect). The student must be able organise themselves and listen carefully to instructions, especially those concerned with health and safety (temperatures up to 950°C will be reached within the apparatus). The student must have an enquiring mind and the confidence to present their own ideas. It would be very useful if the successful student is competent and confident at writing Matlab programs. 2