Leak Remediation Procedure Template

advertisement

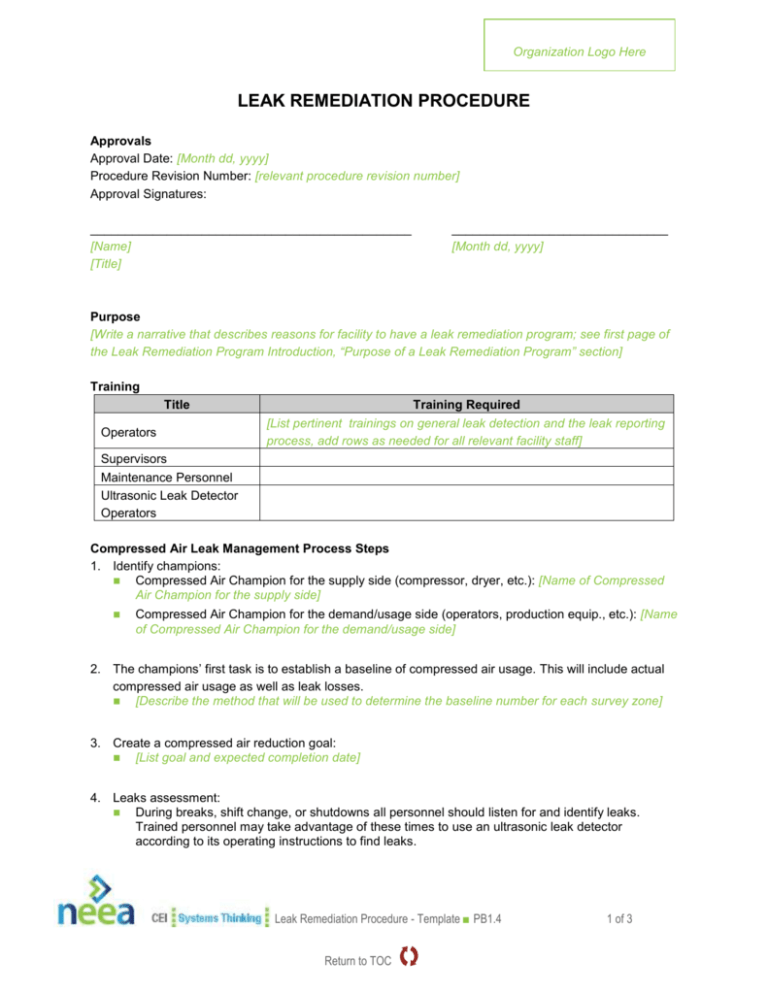

Organization Logo Here LEAK REMEDIATION PROCEDURE Approvals Approval Date: [Month dd, yyyy] Procedure Revision Number: [relevant procedure revision number] Approval Signatures: ______________________________________________ [Name] [Title] _______________________________ [Month dd, yyyy] Purpose [Write a narrative that describes reasons for facility to have a leak remediation program; see first page of the Leak Remediation Program Introduction, “Purpose of a Leak Remediation Program” section] Training Title Operators Training Required [List pertinent trainings on general leak detection and the leak reporting process, add rows as needed for all relevant facility staff] Supervisors Maintenance Personnel Ultrasonic Leak Detector Operators Compressed Air Leak Management Process Steps 1. Identify champions: Compressed Air Champion for the supply side (compressor, dryer, etc.): [Name of Compressed Air Champion for the supply side] Compressed Air Champion for the demand/usage side (operators, production equip., etc.): [Name of Compressed Air Champion for the demand/usage side] 2. The champions’ first task is to establish a baseline of compressed air usage. This will include actual compressed air usage as well as leak losses. [Describe the method that will be used to determine the baseline number for each survey zone] 3. Create a compressed air reduction goal: [List goal and expected completion date] 4. Leaks assessment: During breaks, shift change, or shutdowns all personnel should listen for and identify leaks. Trained personnel may take advantage of these times to use an ultrasonic leak detector according to its operating instructions to find leaks. Leak Remediation Procedure - Template ■ PB1.4 Return to TOC 1 of 3 Organization Logo Here Survey the facility and identify the leaks: Survey Zones: [State how the facility is divided into survey zones; for example: by building, area, or production line] Map Reference: [If applicable, list references to any color codes, survey zone maps] High compressed air usage areas and equipment: [List any high compressed air usage equipment and the survey zone it is in] Survey zone responsibilities: Survey Zone Name/Color [Add rows as necessary] Supply-side Responsibility Demand-Side Responsibility Surveys schedule: [List how often each survey zone will be inspected for leaks; for example: one each month, one each quarter, etc] Survey zones baselines: Survey Zone Name/Color [Add rows as necessary] Baseline Compressed Air Usage Track changes in line pressure for each survey zone during each scheduled inspection. Report results and any variation from baselines to those responsible for compressed air in each survey zone, listed above, after each inspection. Identify leaks by listening, or use an ultrasonic leak detector according to its operating instructions. Special areas of concern to be checked during all leak inspections: [List areas of special concern]. 5. Document leaks: During the inspection of the survey zone, note the leak information on the [type of tracking form that will be used]. Place a leak tag as close to the leak as possible. [Describe any additional procedures for the leak tag process; leak tags should not take the place of a master leak list or work orders] Submit leaks for repair by [name relevant facility procedure for this]. Report results and any variation from baselines to those responsible for compressed air in each survey zone, listed above, after each inspection. Develop an Estimated Cost for the Air Leaks 1. Calculate leak cost by [describe facility preferred method for determining costs]. 2. Prioritize the leak repairs: [List the criteria maintenance, production, and senior management have agreed on for when leaks are significant enough to justify being fixed; for example: cost/benefit ratio cutoff number, leak size, etc] Determine if repairs will require downtime. If so, evaluate the cost of the leak versus the cost of downtime. Be sure to consider whether the production has a planned downtime, excess capacity, stores of product, etc. which may reduce the cost of downtime. Leak Remediation Procedure - Template ■ PB1.4 Return to TOC 2 of 3 Organization Logo Here If downtime is needed, but cannot be obtained immediately, schedule leak repairs for planned downtime or routine maintenance times. Be sure to track accumulated leak costs to ensure all expenses of allowing leaks to continue are considered. Repairs and Reductions 1. Leak Repairs: Fix leak immediately (such as tightening a connection) or [name of facility procedure for submitting work orders or adding a leak to the master list] to schedule repair. If using ultrasonic detector, re-test leak with detector after repair to ensure leak is fixed. Once the leaks have been repaired, re-evaluate the compressor control system and make any adjustments needed. 2. Leak Reductions: While conducting inspections of each survey zone, note on the [name of leak tracking form] any processes which are currently using compressed air where the usage could be reduced, or where methods other than compressed air could be used instead. 3. Documenting and Reporting Repairs and Reductions: [Describe how the cost savings from each repair and reduction will be tracked and reported] will be reported to [the titles of who it will be reported to] every [frequency of reporting]. 4. After repairs, review compressor utilization and controls protocols to determine if supply can be trimmed back or better managed, given reduced demand. 5. Compile and track baseline to survey numbers for each [list relevant survey zone, department, and/or production line], and the entire facility. Publish trends by [method that will inform the whole facility; for example, an energy awareness bulletin board] after each survey. Procedure Review Frequency 1. [Describe frequency the procedure will be reviewed; for example: quarterly, annually, etc] 2. [Describe any unusual problems which may require the procedures to be reviewed or changed before the scheduled review; for example: a large quantity of leaks all of a sudden, a large quantity of a certain type of leak, etc] 3. [Names of those who must be included in the review of the procedure] 4. [Names of those who must approve changes to the procedure] 5. Update the approval date and revision number of this document. Leak Remediation Procedure - Template ■ PB1.4 Return to TOC 3 of 3